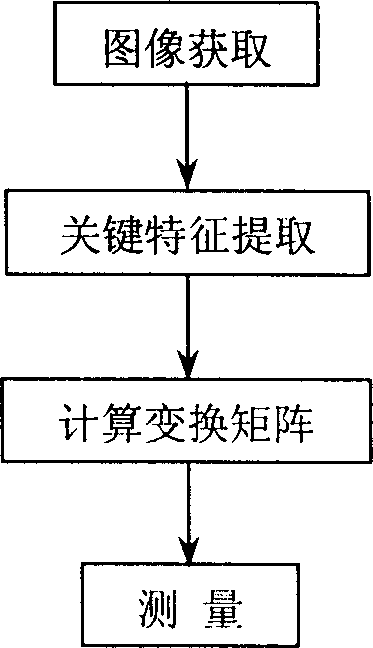

Single sight plane measuring method based on parallel lines

A technology of plane measurement and parallel lines, applied in measurement devices, photogrammetry/video measurement, surveying and navigation, etc., can solve the problems of difficult selection of control points, impossible to measure images, and difficult to put into practical application, etc. To achieve the effect of good robustness, high measurement accuracy, and avoidance of inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

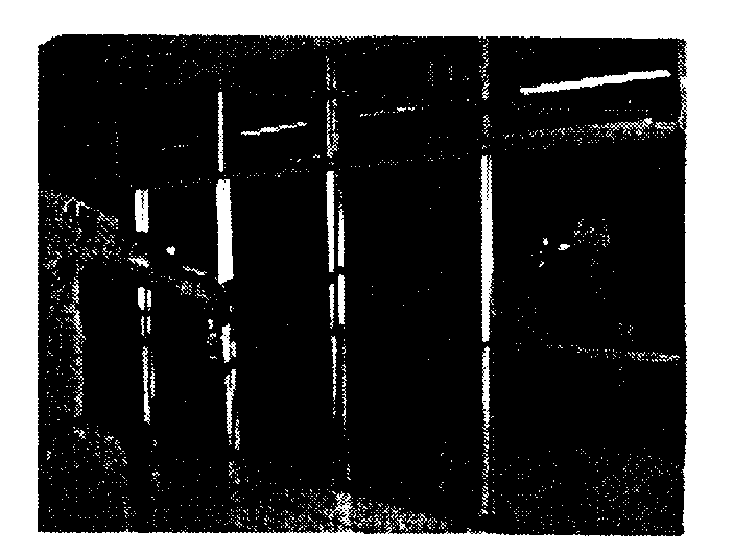

[0021] Such as figure 2 Shown is an image of a tested scene. According to the method described in the present invention, two groups of mutually perpendicular parallel lines are extracted in the image as shown in the green lines, and the transformation matrix is calculated by using its blanking points and the side length of one of the frames is selected as the reference distance, in the image Select two points with the mouse, and the distance between the two points in the scene can be calculated directly from the image by using the transformation matrix and the reference distance. For example: D 1 ,D 2 The real lengths of the two are respectively 362.96cm and 429.05cm, the measured values obtained by the method of the present invention are respectively 365.82cm and 433.36cm, and the relative errors of the measurement are respectively 0.79% and 1.0%, which can reach the measurement accuracy requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com