Stop valve combination with integrated valve core for air conditioner

A shut-off valve, integrated technology, applied in the field of the shut-off valve group of the integrated valve core air conditioner, can solve the problem of insufficient air tightness, etc., and achieve the effect of long service life and strong sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

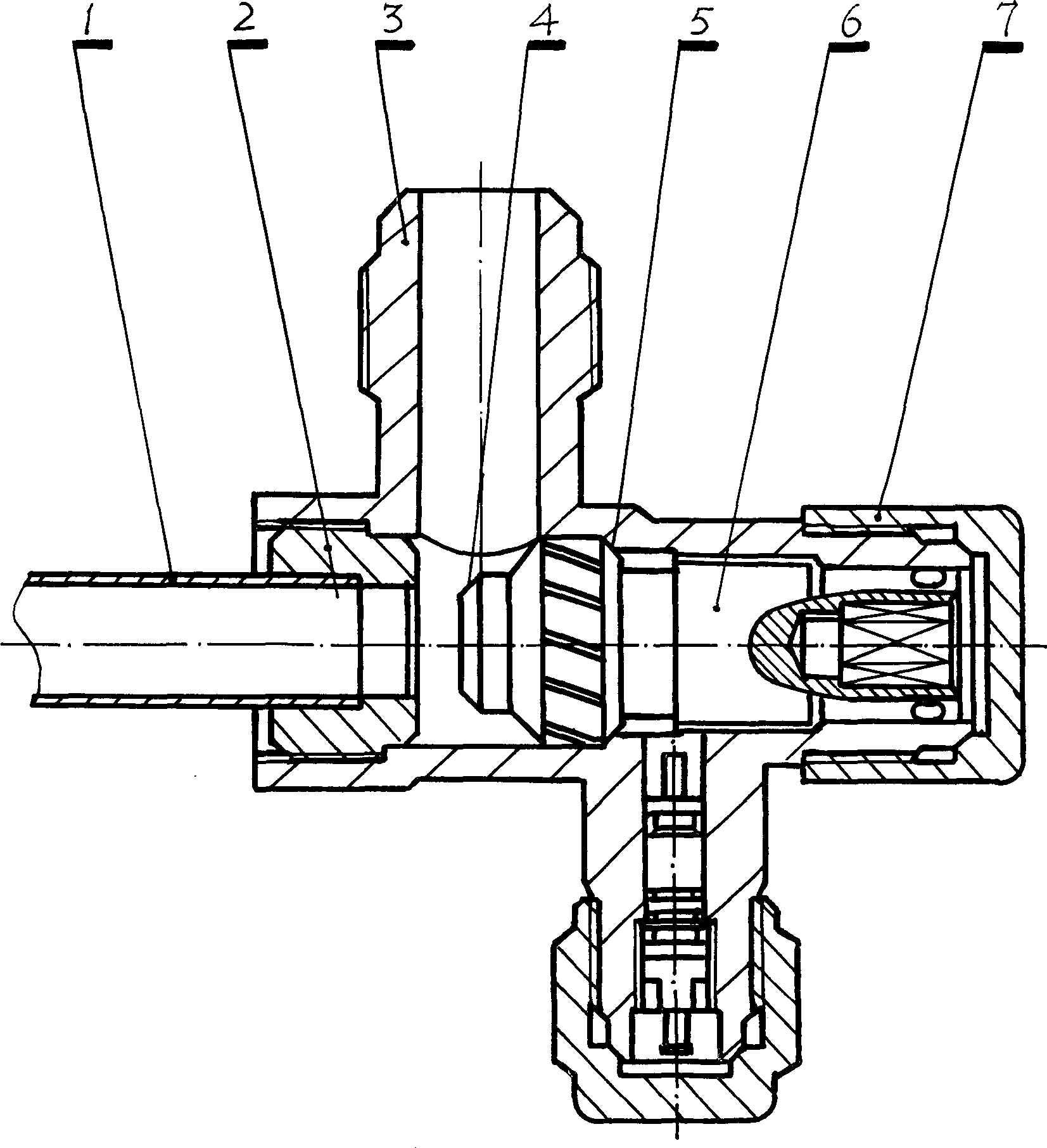

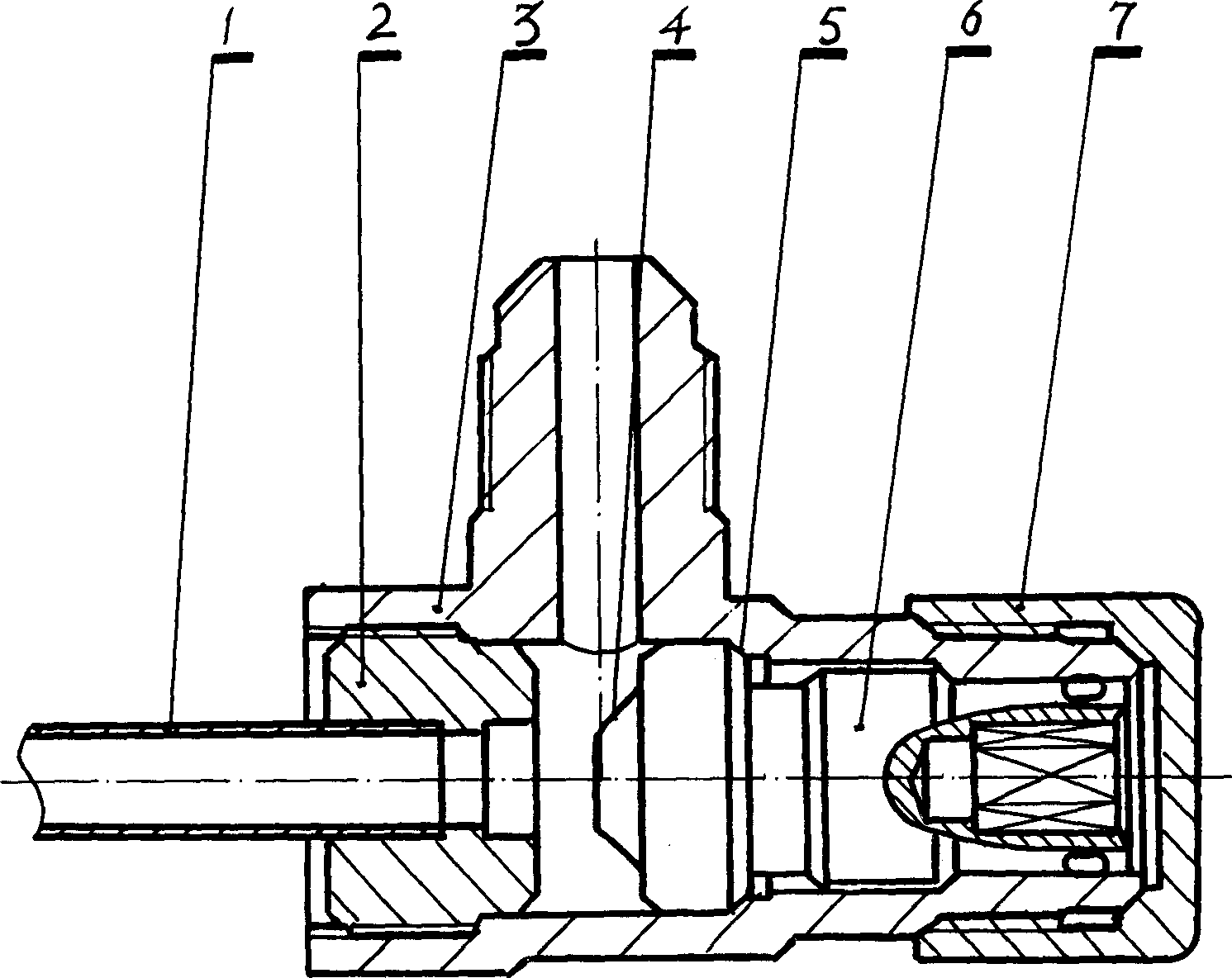

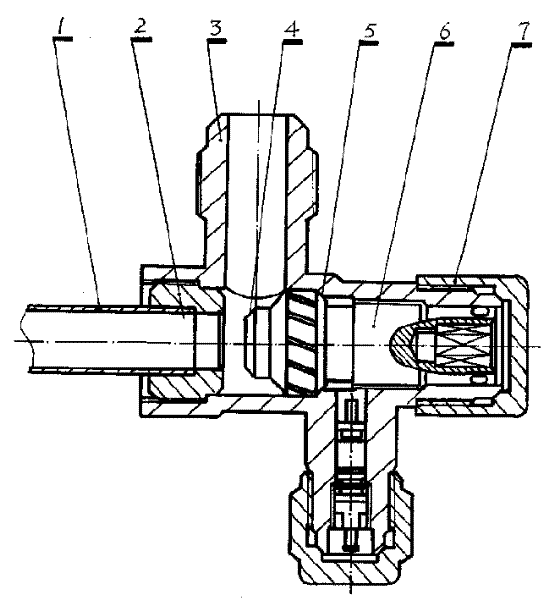

[0009] as attached figure 1 and 2 As shown, the one-piece spool air conditioner cut-off valve group consists of a low-pressure cut-off valve and a high-pressure cut-off valve. The low-pressure stop valve and the high-pressure stop valve include a valve body 3 and a valve core 6 and a valve sleeve seat 2 installed therein, a sealing cap 7 installed outside the valve body 3, and a connecting pipe 1 fixed on the valve sleeve seat 2. The valve core 6 has a front sealing surface 4 and a rear sealing surface 5, and the inner cavity of the valve body 3 has a structure corresponding to the rear sealing surface 5. The spool 6 is integrated. The valve sleeve seat 2 adopts the method of post-loading to install.

[0010] The valve body 3 of the low-pressure stop valve has four inner cavities, wherein the left and right two inner cavities are coaxial, which is the same as the prior art; and the upper and lower inner cavities are different axes, which is different from the prior art. th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com