Device suitable for dust removal of ore tank

A mine tank and dust hood technology, applied in the field of dust control in production workshops, can solve the problems of increasing system energy consumption, affecting dust removal effect, increasing system failure rate, etc., so as to reduce dust removal energy consumption, improve dust removal effect, and reduce dust removal air volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

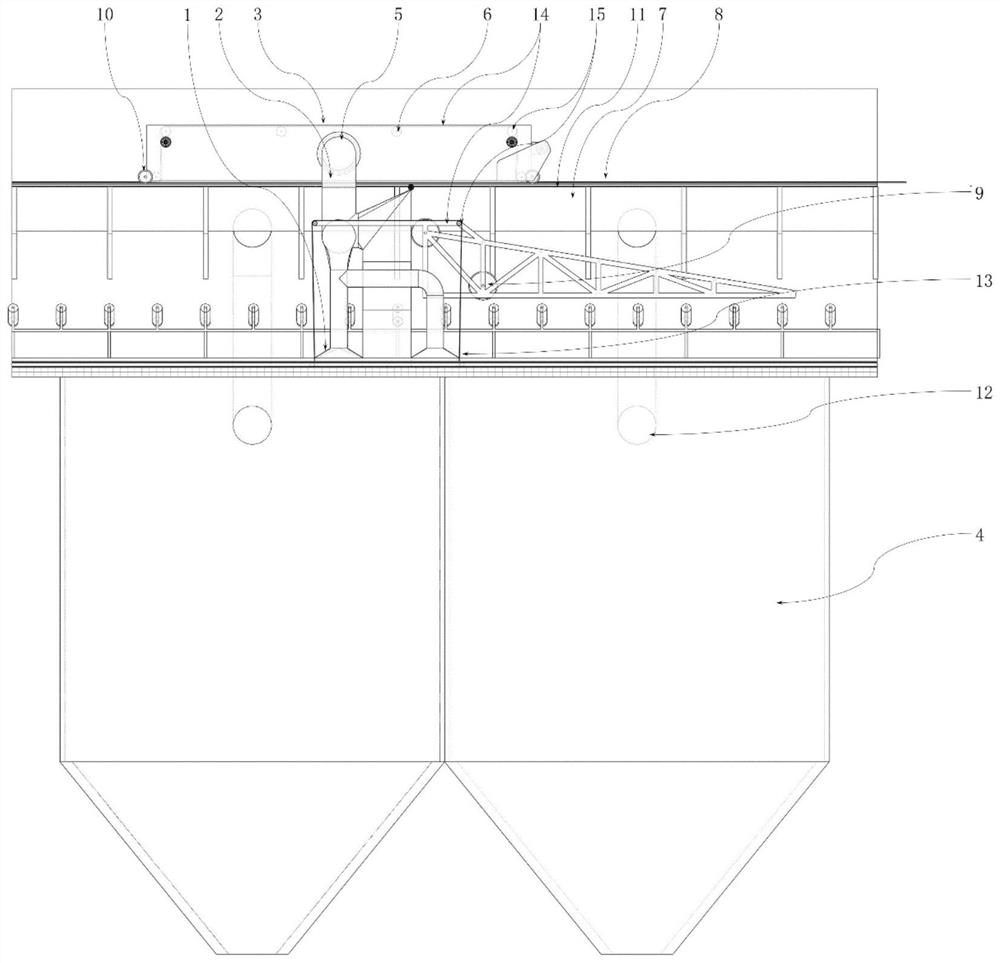

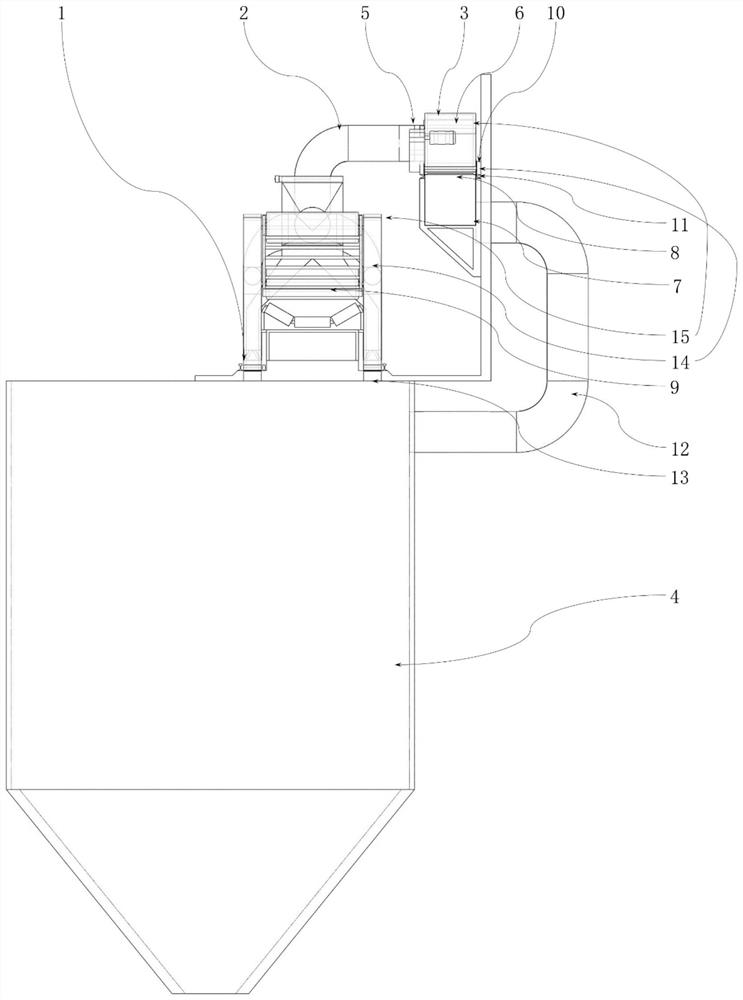

Embodiment 1

[0027] like figure 1 The above-mentioned device suitable for dust removal in mine tanks includes a dust collection hood 1, a pneumatic conveying pipeline 2, a tape-sealed synchronous transfer system 3 and dust removal equipment. The dust collection hood 1 and the pneumatic conveying pipeline 2 are fixed on the unloading vehicle and move synchronously with it. The dust collection hood is placed above the place where the material and the belt are separated and enters the silo 4. One end of the pneumatic conveying pipeline 2 is connected to the dust collection hood. 1, and the other end is connected to the gas delivery port 5 of the tape-sealed synchronous transfer system 3. The tape-sealed synchronous transfer system 3 includes the gas delivery port 5, the mobile bellows 6, the ventilation slot 7, the ventilation slot opening 8, the rubber Belt 14, rollers 15, and mobile bellows 6 are similar to an inverted U shape, and are movably installed on the upper surface of ventilation s...

Embodiment 2

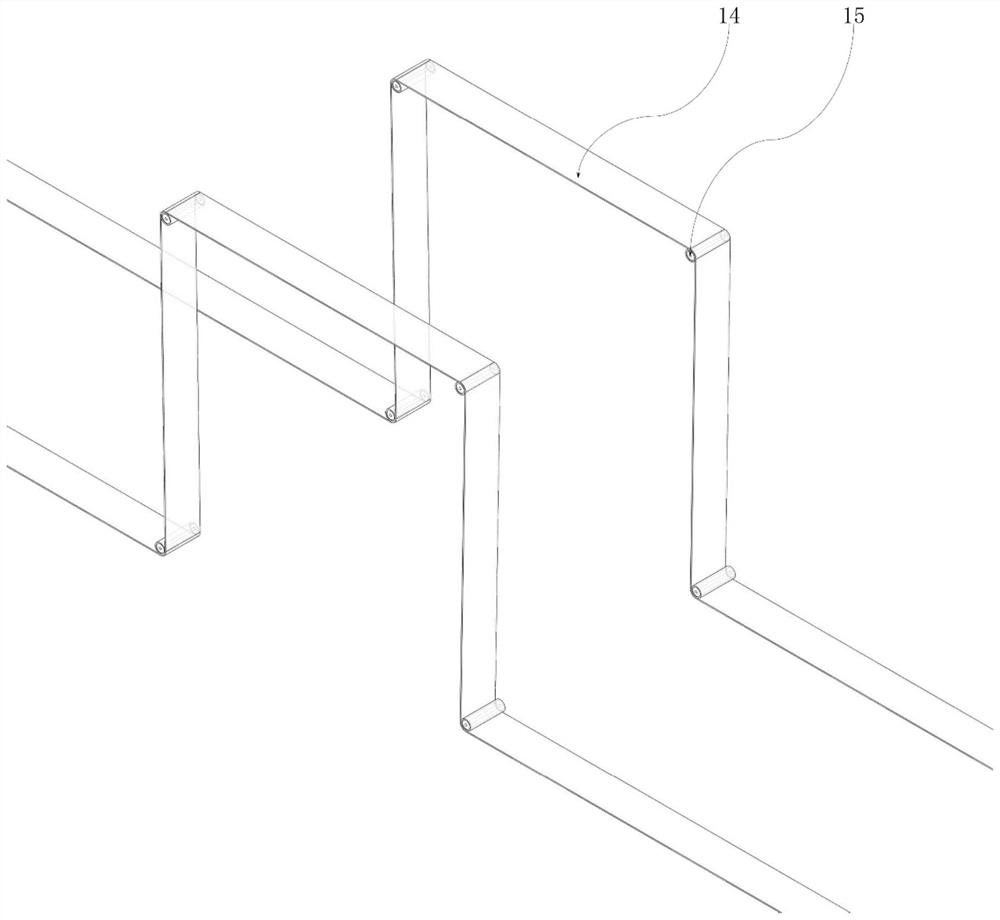

[0030] Compared with Embodiment 1, as an improvement, there are multiple dust suction hoods, which are respectively arranged on the upper part where the material breaks away from the belt and enters the bin 4 and on the mine troughs on both sides of the point where the material falls into the mine chute. There is a pressure sealing device 13, the pressure sealing device includes a rubber belt 14, a roller 15, at least four groups of rollers 15 are arranged at the front and rear ends of the dust collection hood 1 and at the upper turning point, and the rollers 15 at the front and rear ends of the dust collection hood 1 are located The upper part of the rubber belt 14 exerts downward pressure on the rubber belt 14. The roller 15 at the turning point on the upper part of the dust collector 1 is located at the lower part of the rubber belt 14, and is used to change the direction of movement of the rubber belt 14. When the discharge place changes At this time, the dust collection co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com