Water area rescue protective clothing fabric and protective clothing

A technology for water rescue and protective clothing, which is applied in the field of protective clothing fabrics, can solve the problems of water repellency and waterproof performance, friction resistance and puncture force that cannot meet the requirements of water area protective clothing, and achieve low raw material costs, strong sealing performance, and high product performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

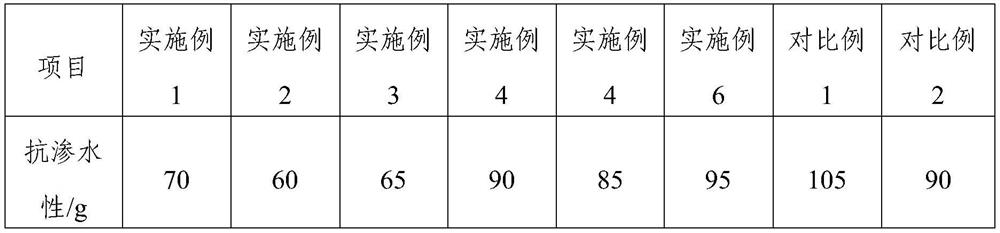

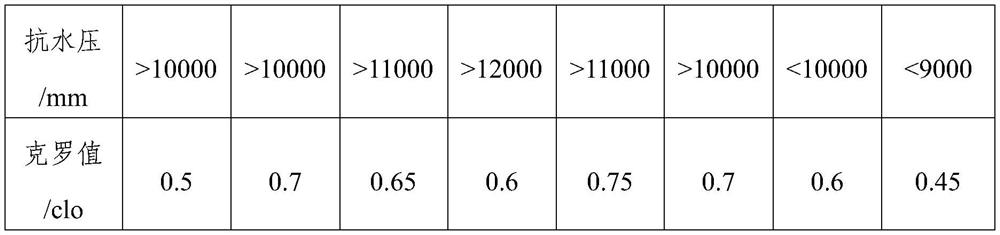

Embodiment 1

[0018] The waterproof fabric layer is nylon fiber and graphene fiber textile, wherein the nylon fibers and graphene fibers are the core structure, the graphene fibers are core layers, and the nylon fibers cover the graphene fibers to form a cortex; the base fabric layer includes up and down two The layer structure is woven from different yarns, and the upper structure is interleaved by the yarn and the lower structure weft yarn, forming a connection point, woveting the fabric into an integral, the upper structure of the yarn comprising components and weight percentage: Polyester 30%, aramid 10%, acrylic 15%, cotton fibers, 15% glass viscose fibers, yarns of the lower layer structure include ingredients and weight percentage: aramid 50%, nylon 2%, chloron 8%, asbestos fiber 15%, silk fiber 5%; the insulation layer is processed by a aramid fiber and color cotton fibers by mixed spinning and woven fabric, wherein the color cotton fiber content is 30% by weight, and the rest is aramid...

Embodiment 2

[0020] The waterproof fabric layer is nylon fiber and graphene fiber textile, wherein the nylon fibers and graphene fibers are the core structure, the graphene fibers are core layers, and the nylon fibers cover the graphene fibers to form a cortex; the base fabric layer includes up and down two The layer structure is woven from different yarns, and the upper structure is interleaved by the yarn and the lower structure weft yarn, forming a connection point, woveting the fabric into an integral, the upper structure of the yarn comprising components and weight percentage: 40% polyester, 25% aramid, 20%, cotton fibers, 20% of the glass viscose fibers, the lower structure of the yarn containing the ingredients and weight percentage: aramid 60%, nylon 8%, p 10%, asbestos fiber 25%, silk fiber 15%; the insulation layer is processed by the aramid fiber and color cotton fibers by mixed spinning and woven fabric, wherein the color cotton fiber content is 80 wt%, and the rest is aramid fiber...

Embodiment 3

[0022] The waterproof fabric layer is nylon fiber and graphene fiber textile, wherein the nylon fibers and graphene fibers are the core structure, the graphene fibers are core layers, and the nylon fibers cover the graphene fibers to form a cortex; the base fabric layer includes up and down two The layer structure is woven from different yarns, and the upper structure is interleaved by the yarn and the lower structure weft yarn, forming a connection point, woveting the fabric into an integral, the upper structure of the yarn comprising components and weight percentage: Polyester 30%, aramid 25%, 20% acrylic, cotton fiber 10%, glass viscose fiber, yarn containing the ingredients and weight percentage: aramid 50%, nylon 8%, pecton 10%, cotton fiber 25%, silk fiber 15%; insulation layer by aramid fibers and lane cotton fibers by mixed spinning and woven fabric, the color cotton fiber content is 80% by weight, and the rest is aramid fiber A layer of 0.3 mm titanium alloy material laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Crow value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com