Fastener of zipper

A zipper button and zipper technology, applied in the field of zipper button, can solve the problems such as the decline of production efficiency of zipper button 101

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the zipper buckle on the zipper according to the present invention will be described in detail below with reference to the accompanying drawings.

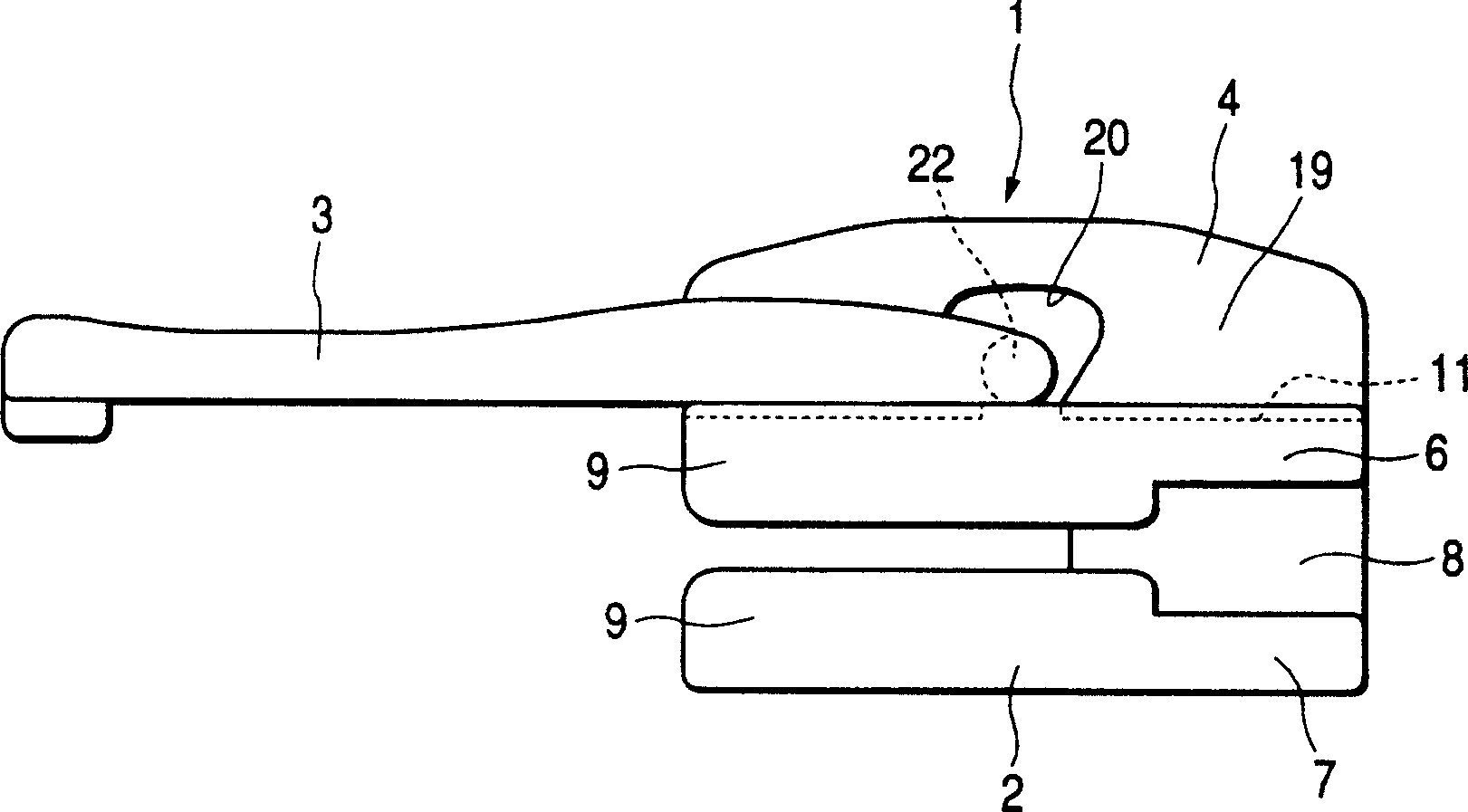

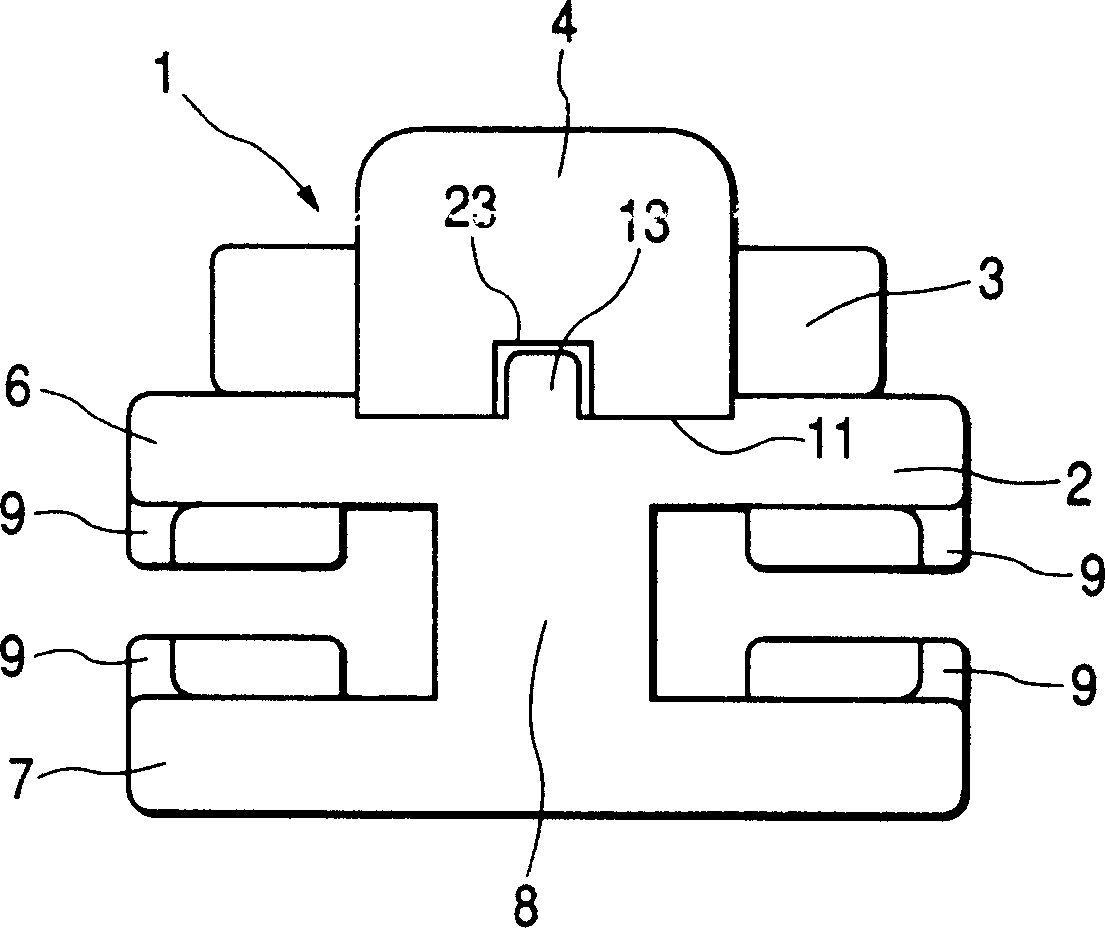

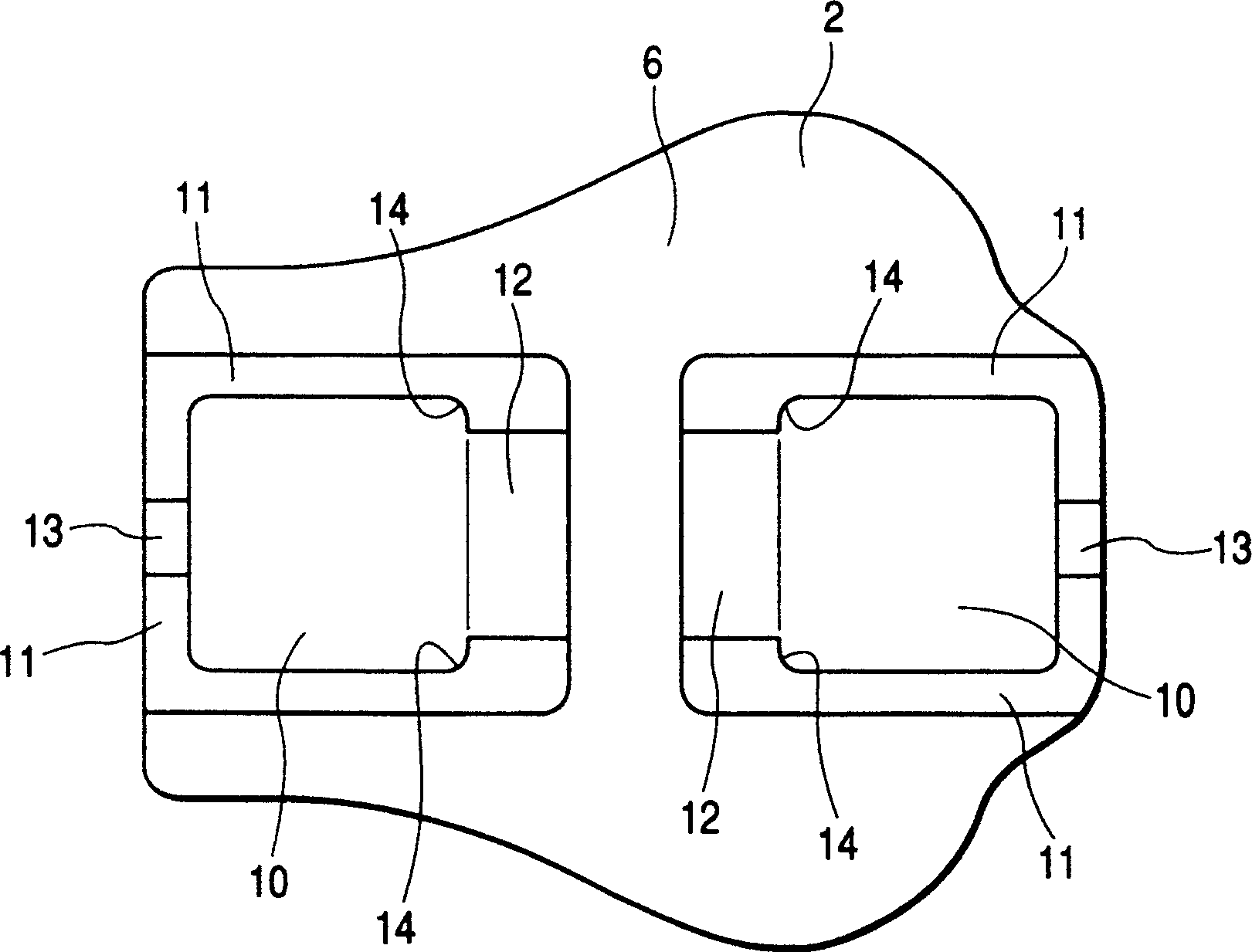

[0032] The zipper buckle on the zipper of the present invention is made up of three parts, as Figures 1 to 6 As shown, it includes a zipper body 2, a handle 3, and a cover 4 for connecting the handle. Wherein, at least the zipper body 2 and the cover 4 connected to the handle are injection molded by thermoplastic resin such as polybutylene terephthalate, polyamide, polyacetal resin or polypropylene. The handle 3 is installed on the formed zipper body 2 through a pivot support mechanism, the cover 4 is arranged thereon and welded with the upper surface of the zipper body 2, thus a zipper body 1 is produced.

[0033] The zipper body 2 of the zipper buckle 1 is connected to the upper blade 6 and the lower blade 7 through a guide column 8, and each edge of the upper blade 6 and the lower blade 7 has a flange 9 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com