Assembling structure of washing machine display part

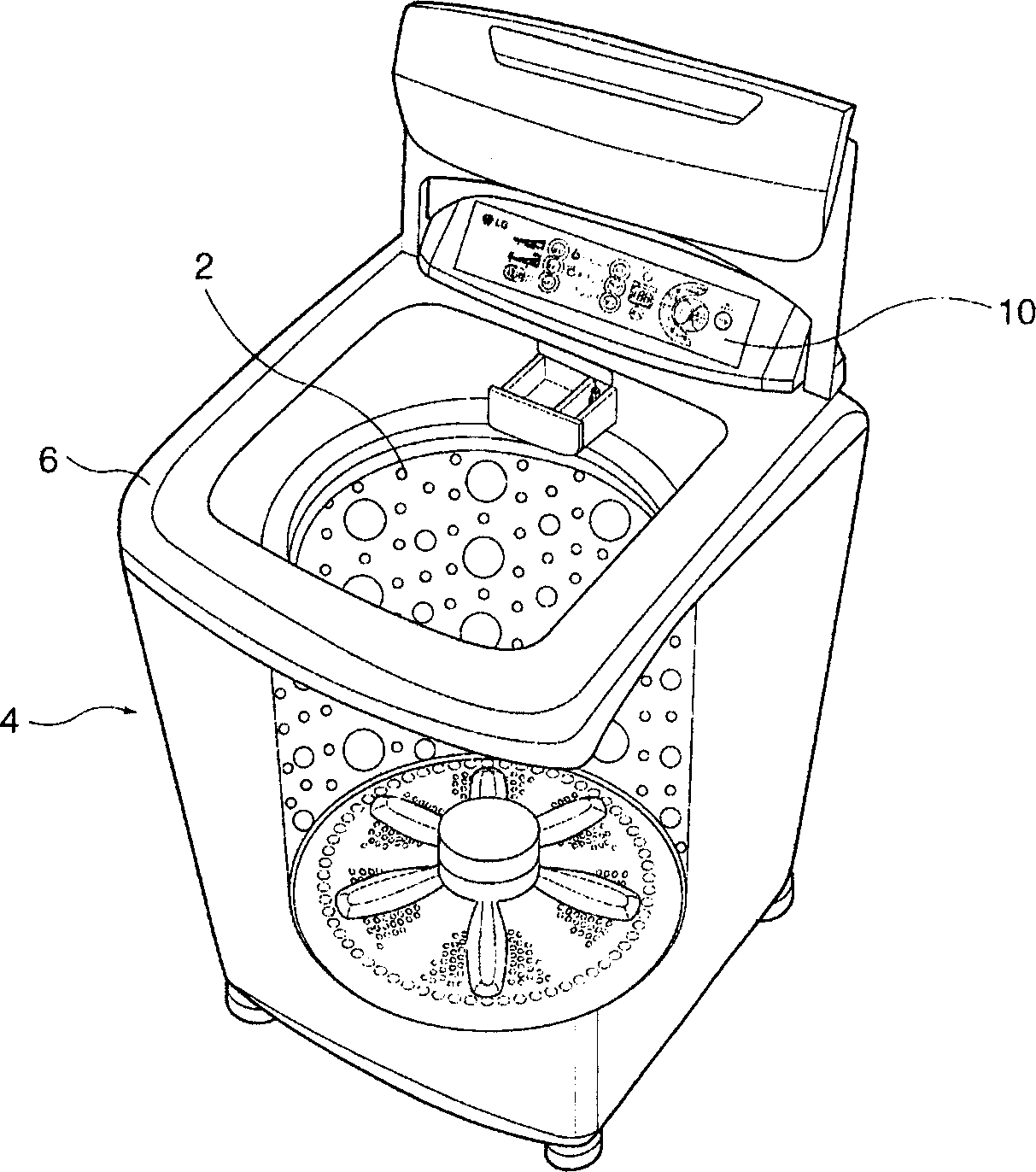

A technology for assembling a structure and a display part, which is applied in the field of washing machines, can solve problems such as the bad influence of product quality and poor performance, and the control panel 22 cannot operate normally, and achieves the effect of reducing assembly processes and improving work performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will be described in detail in conjunction with the accompanying drawings and embodiments.

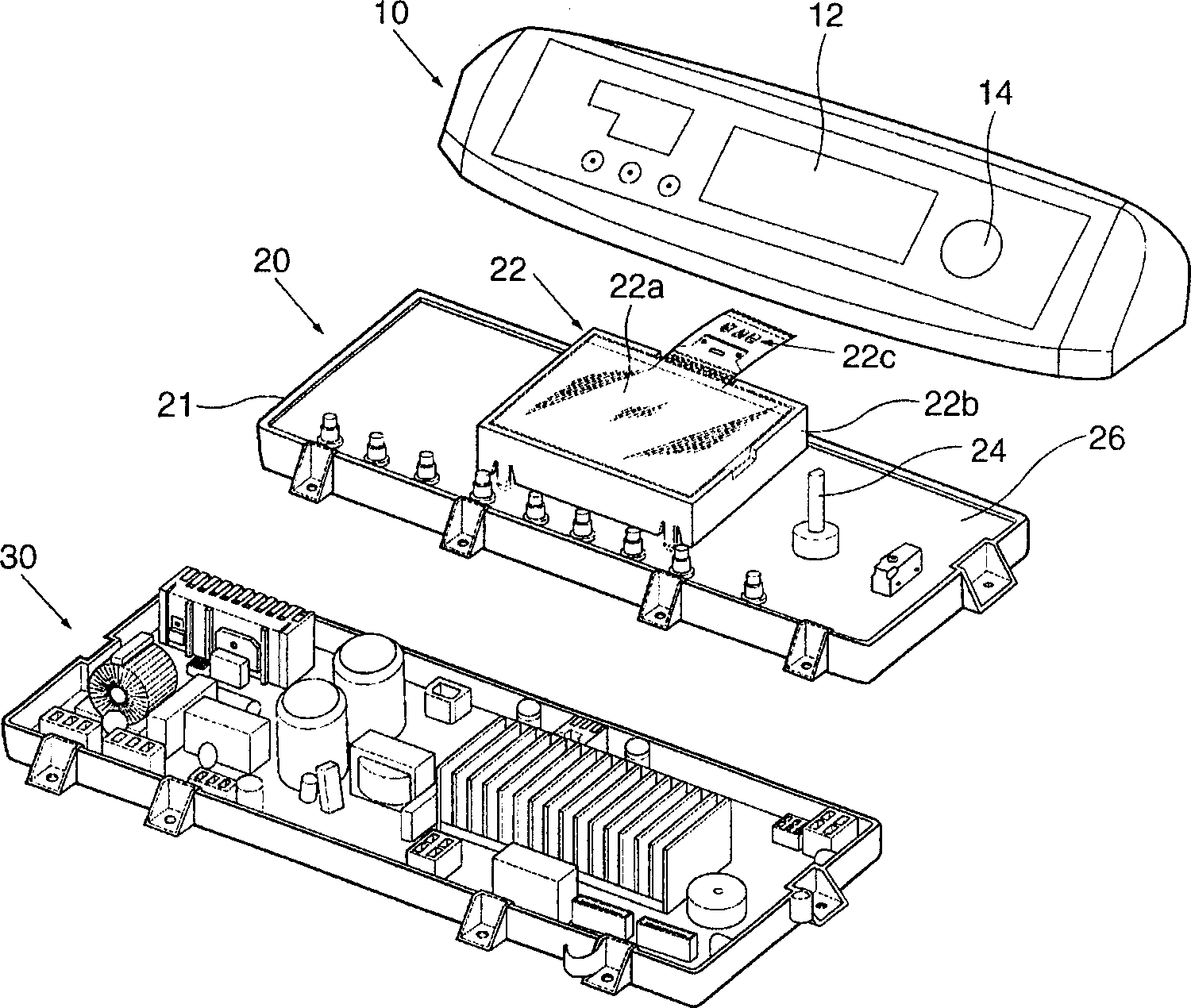

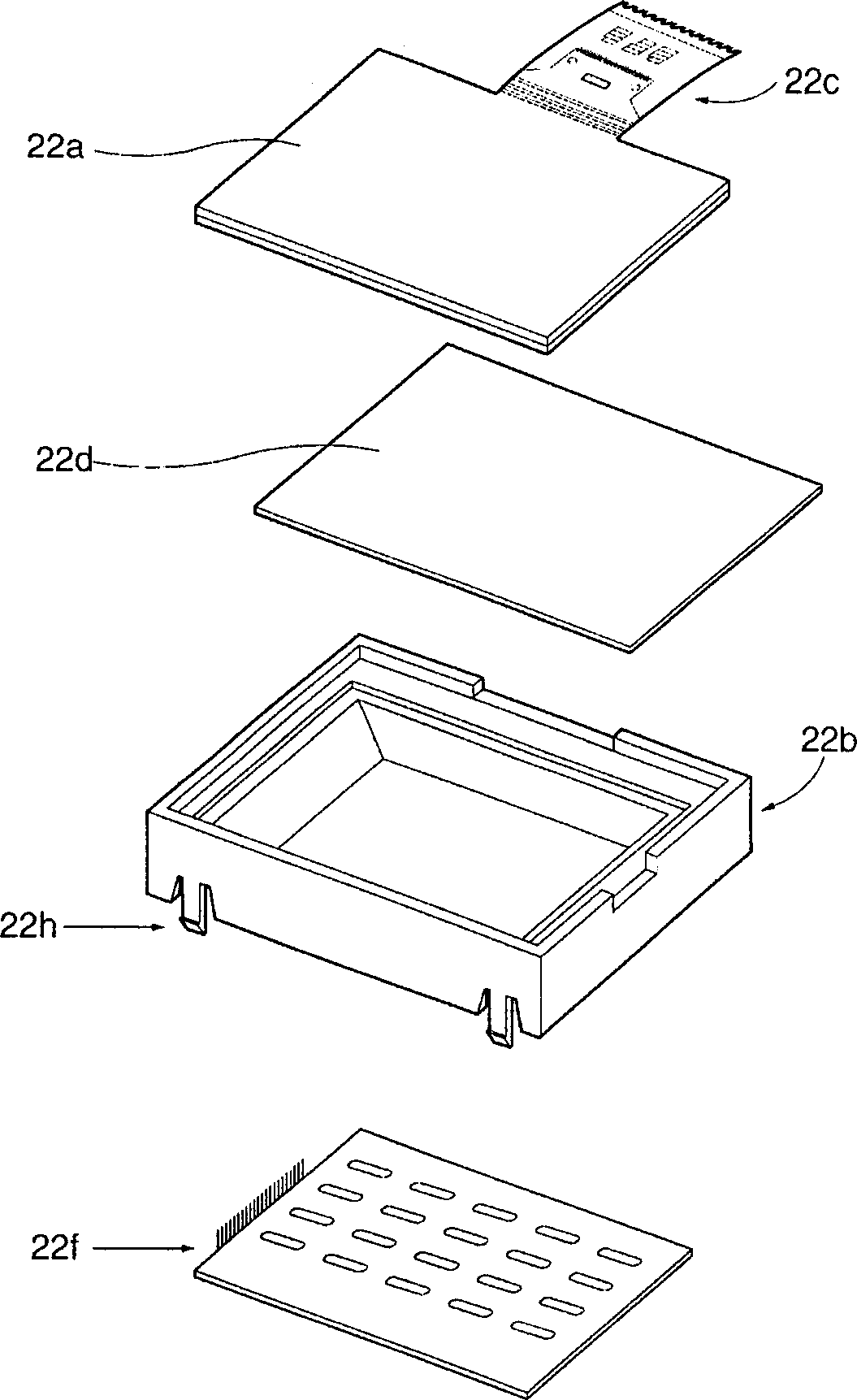

[0029] The washing machine control panel of the present invention is made of the following structures. The assembly structure of the washing machine control panel includes the circuit board PCB26 of the control panel, the folding circuit board 22c, and the liquid crystal display panel LCD22a. Insert the cover 36 of the folded circuit board 22c. The cover 36 is molded together with the display case 30 so that the folded circuit board 22c is inserted into the cover 36 from top to bottom and connected to the circuit board PCB26 of the control panel. On the lower end surface 31 of the display part housing 30, a pair of mounting insert pins 33 are provided, and a combination hole 43 corresponding to the insert pin 33 is formed on the light-emitting diode circuit board LED42, and the insert pin 33 is firmly fixed by heat sealing. is inserted into the combination hole 43....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com