Shoe midsole

A technology for midsole and walking shoes, applied in the direction of sole, footwear, application, etc., can solve the problems of unusable, unsatisfactory, and unable to provide flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

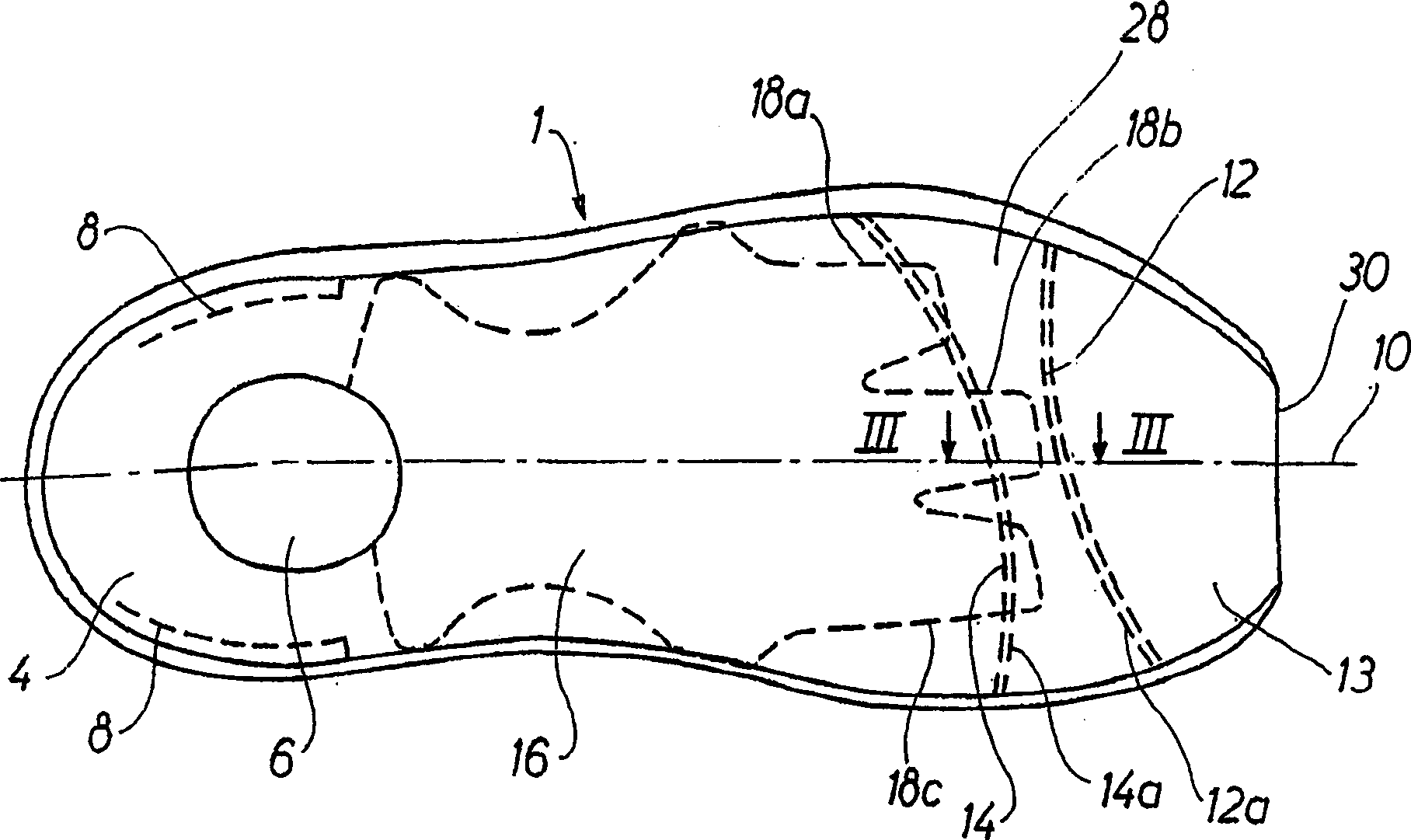

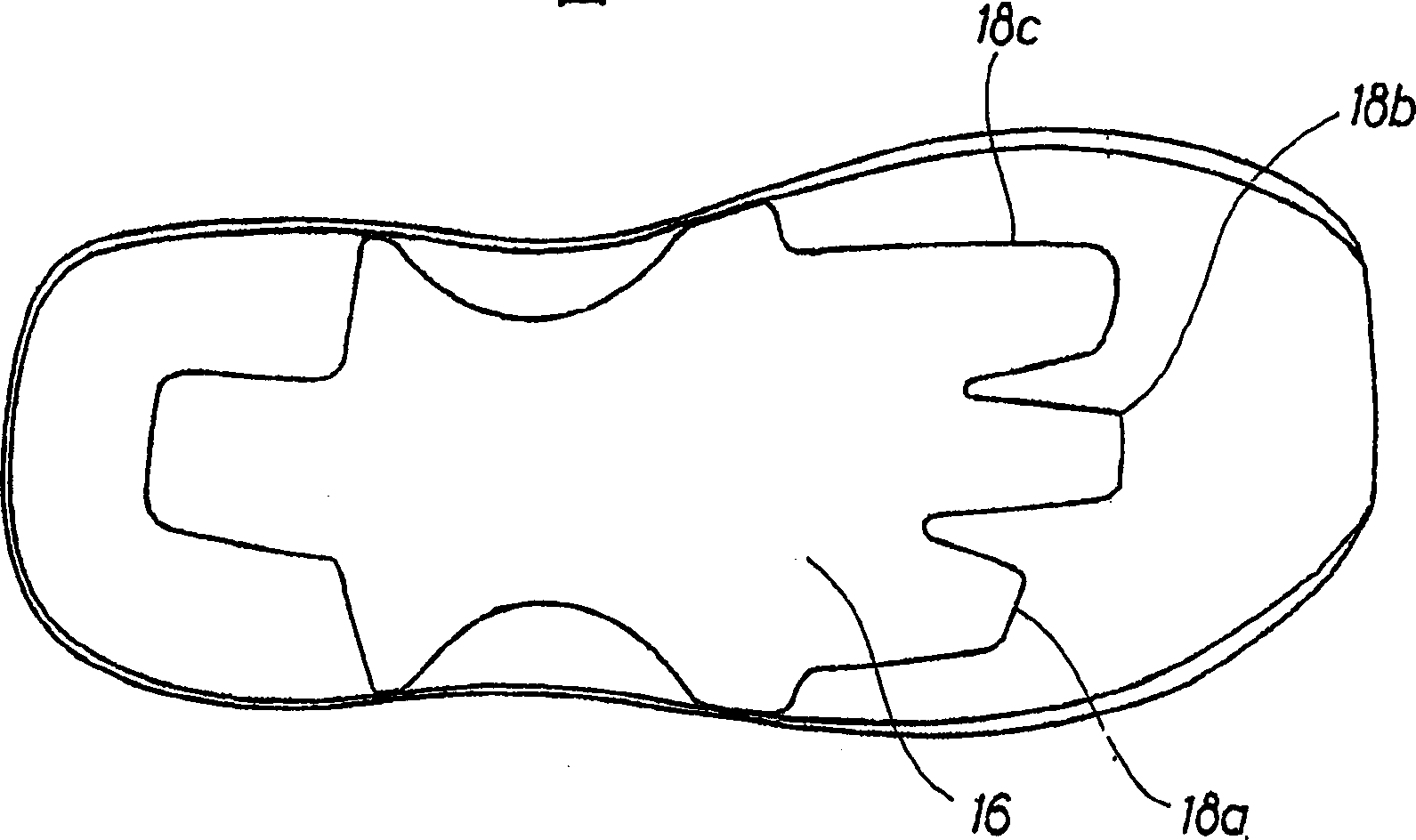

[0023] figure 1 The shown midsole, denoted by the reference number 1 , provides an exceptionally comfortable walking experience and is suitable for example for the manufacture of walking shoes. In its heel area 4, the sole is provided with a shock absorber 6 and behind or near this heel area at least one spacer 8 which completely or partially conforms to the U-shape and acts as a heel side support for the wearer. . The spacers are only shown by dashed lines. The shock absorber is preferably pneumatic and is preferably made of shock-absorbing sole material.

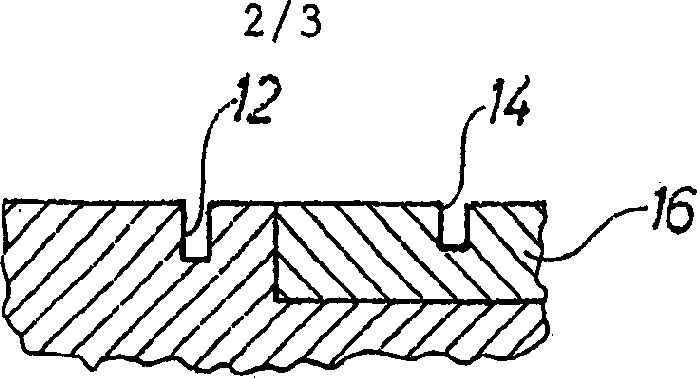

[0024] The midsole is flexible around two slightly curved lines of flex 12, 14 which are oblique with respect to the longitudinal axis 10 of the sole, the lines of flex 12, 14 not intersecting each other and their cavities facing away from each other . Each bend line 12, 14 may have a different radius of curvature; the radius of curvature is generally shortest at the center of the bend line and longest towards the ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com