Weft contact part and weft detecting method

A detection method and a weft thread technology, which is applied in textiles, textiles, papermaking, looms, etc., can solve problems such as cloth strip-shaped weft thread detection that is not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

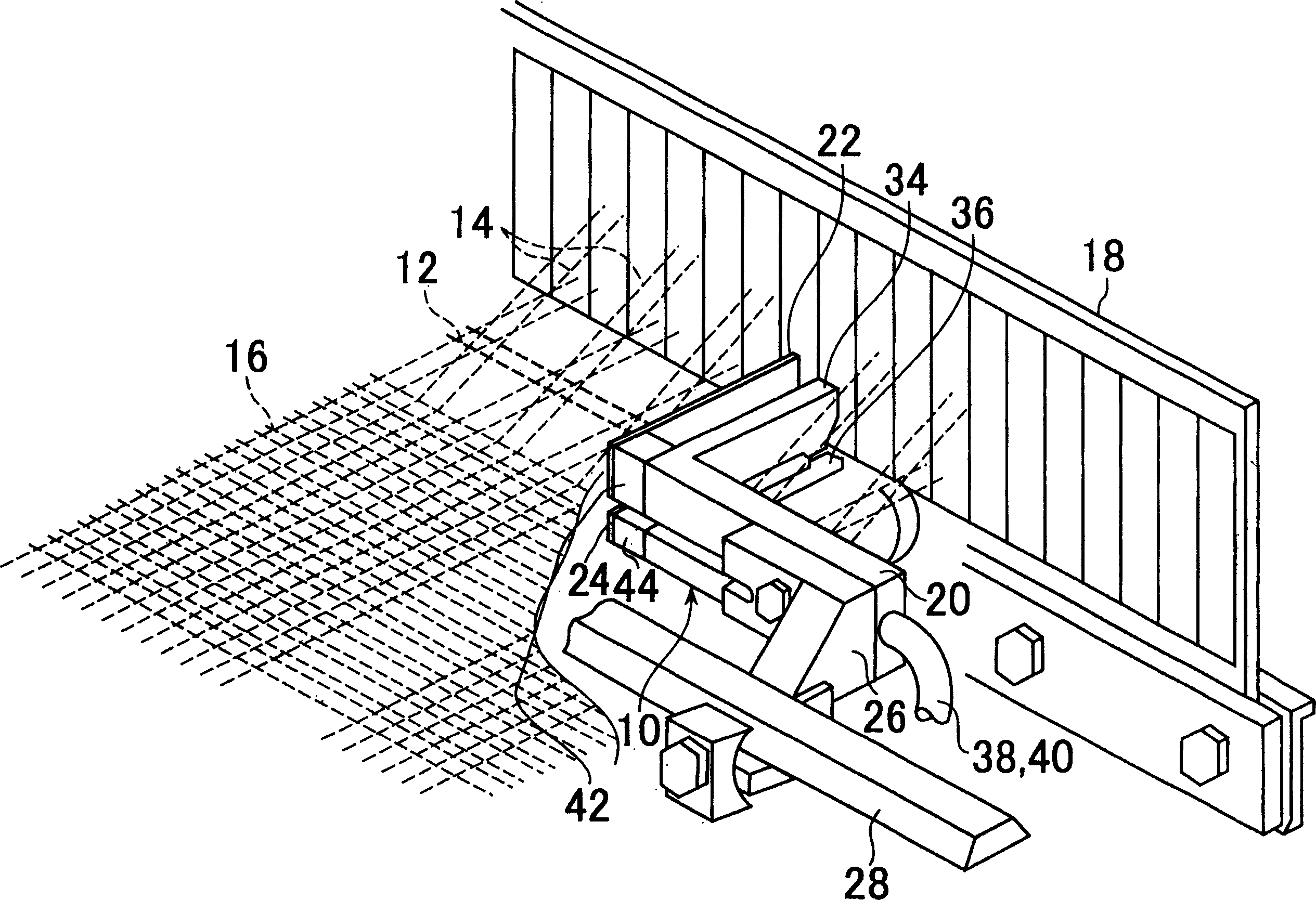

[0043] refer to figure 1 , the weft thread contact 10 is used on a water-jet loom that uses strip-shaped flat threads as weft threads 12 and warp threads 14, and is used to weave strip-shaped (ribbon-shaped) base fabrics, that is, weaving cloth 16. . It can also be used on looms that use flat yarns only as weft yarns 12.

[0044] The weft thread 12 is ejected from the weft injection nozzle without the icon at the same time as the pressure water for weft insertion, and is inserted in the opening of the warp 14 with the thickness direction as the up and down direction, Weft thread is driven into the place just woven by reed 18 to weave as weaving cloth 16.

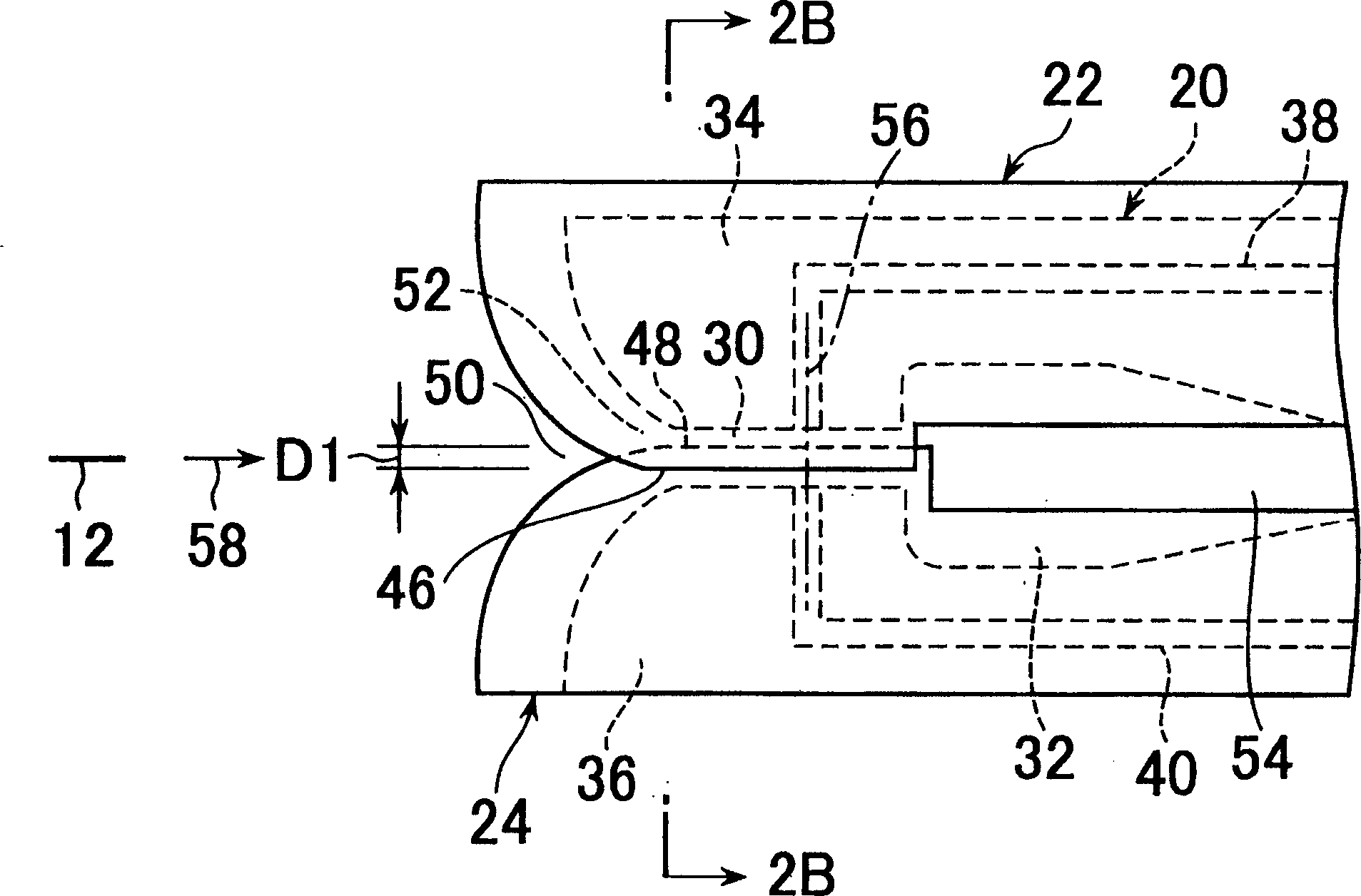

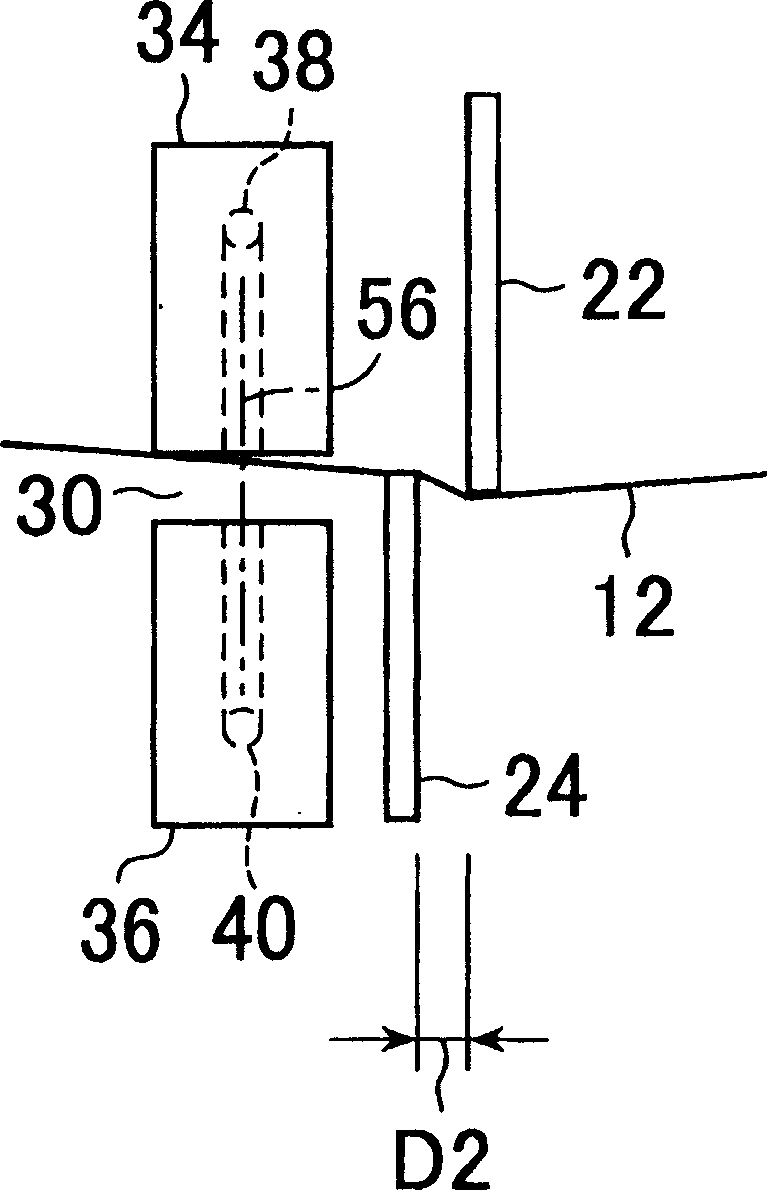

[0045] The weft thread contact 10 comprises: a contact body 20 formed in an L-shape when the boundary of the base and the front end is bent and viewed from a plane; The front end portion is a pair of guide members 22 and 24 used as a guide device for the weft yarn 12 . In more detail, the touch element main body 20, comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com