Full automatic washing machine

A technology for fully automatic washing machines and washing machines, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve problems such as excessive noise and unstable operation of clutch parts, and achieve the effect of stable switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

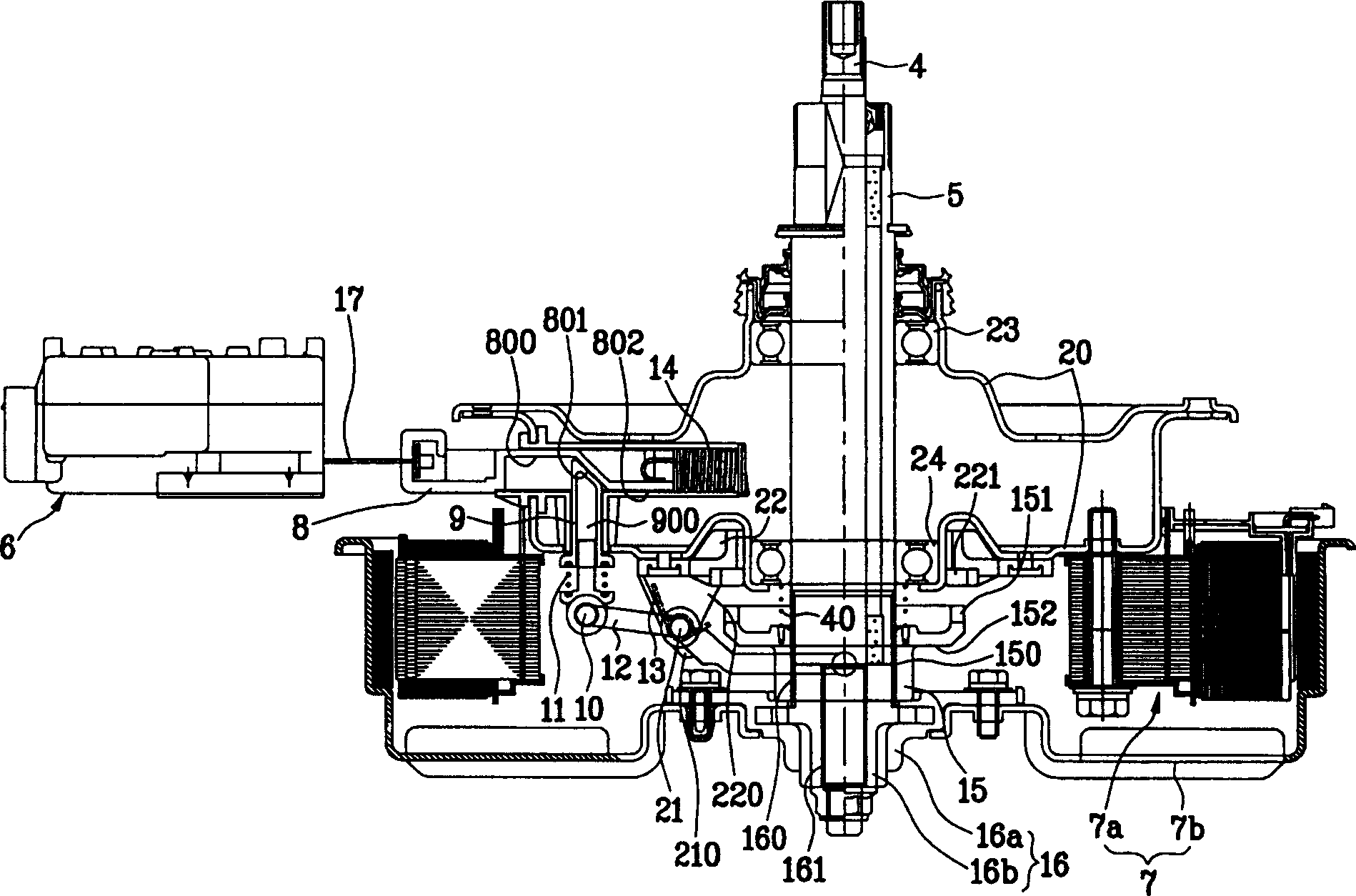

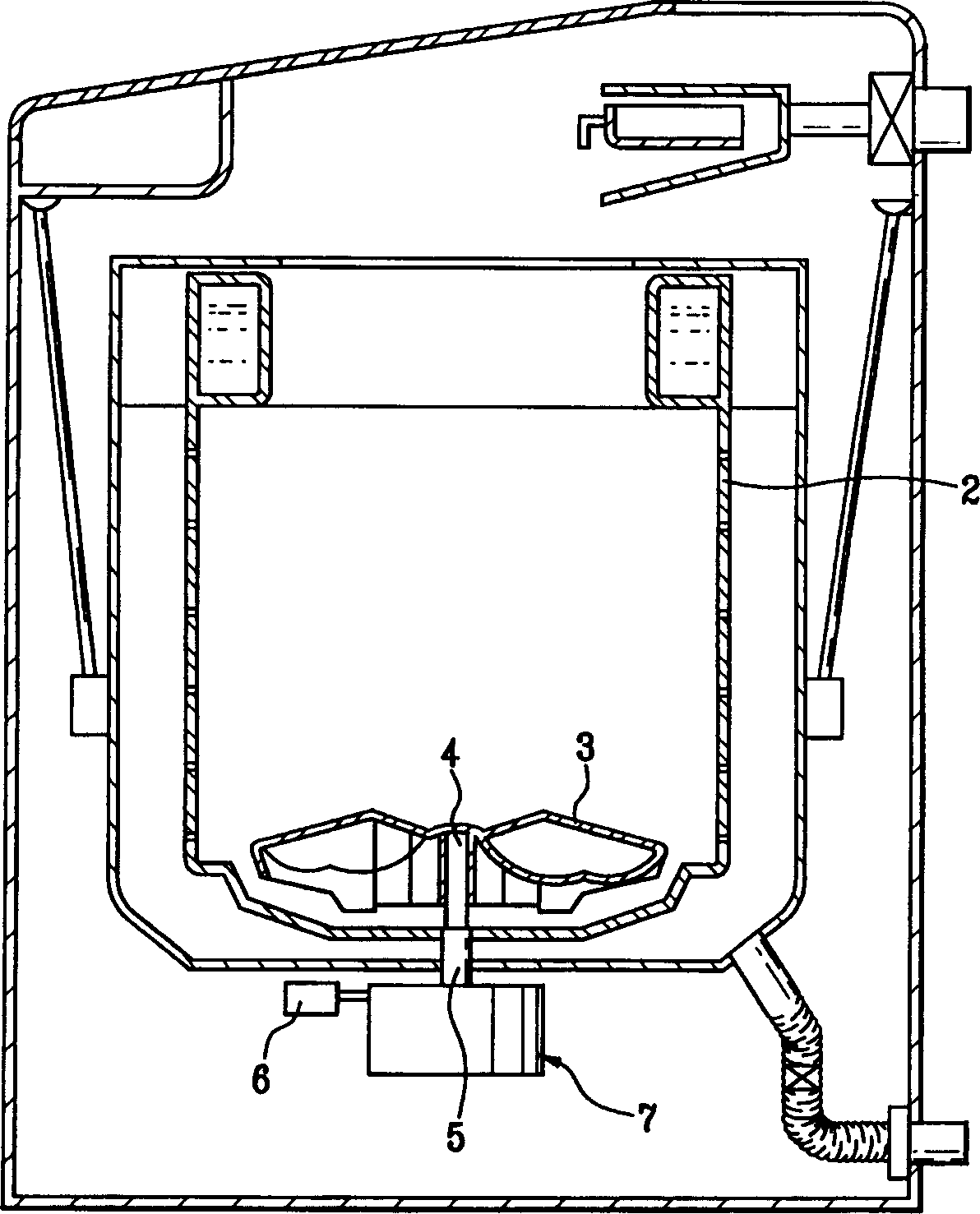

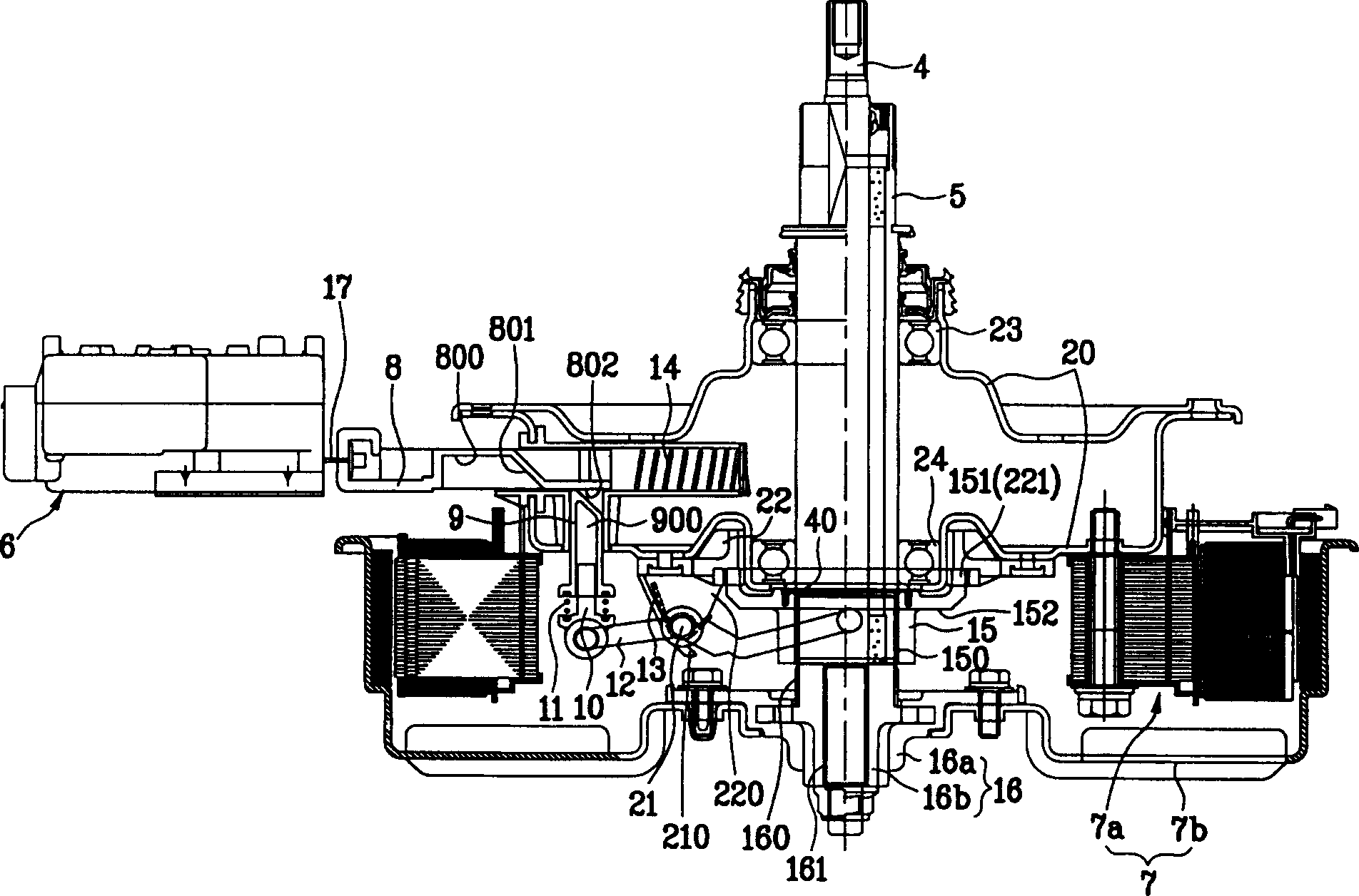

[0042] Refer to the attached Figure 1 to Figure 4c , an embodiment of the present invention will be described in detail.

[0043] figure 1 is a longitudinal sectional view showing the main part of the clutch part of the present invention, figure 2 It is an explanatory diagram showing the overall outline of the fully automatic washing machine of the present invention. As shown in the figure, the fully automatic washing machine of the present invention includes the following structures: dehydration tank 2, agitator 3, dehydration shaft 5, washing shaft 4, motor 7 and clutch components. The above-mentioned dehydration tank 2 is rotatably arranged inside the main body outer cylinder 1 of the washing machine; the above-mentioned agitator 3 is arranged inside the above-mentioned dehydration tank 2, and can rotate independently relative to the above-mentioned dehydration tank 2; The water tank 2 transmits rotational power, and the above-mentioned dehydration tank 2 can be suppor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap