Clamp and element connection device

A technology of clips and mounting components, which is applied in the direction of connecting components, thin plate connections, mechanical equipment, etc., can solve the problems of complex structure of sleeves and pins, increased cost, weak fixing force of mounting components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

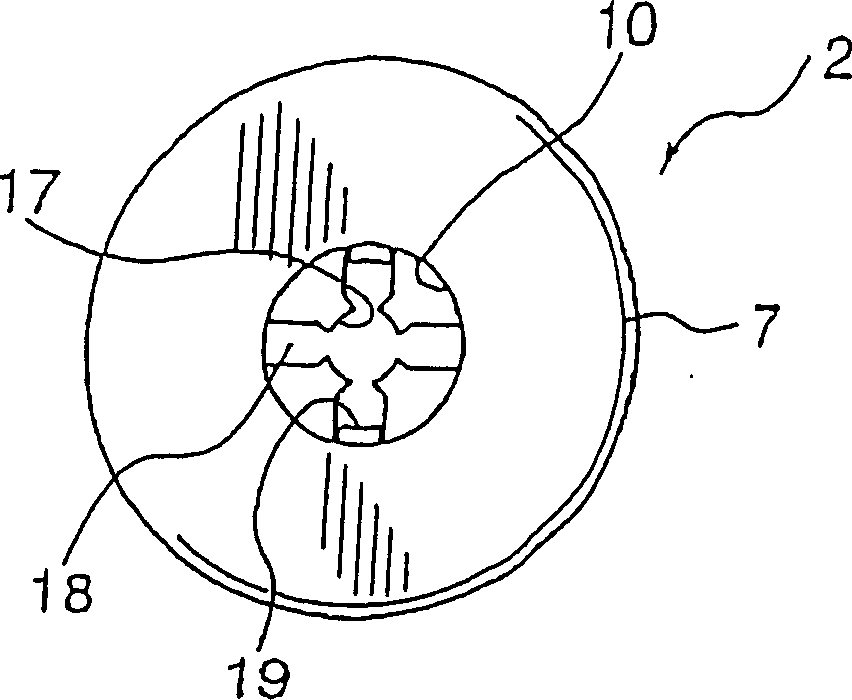

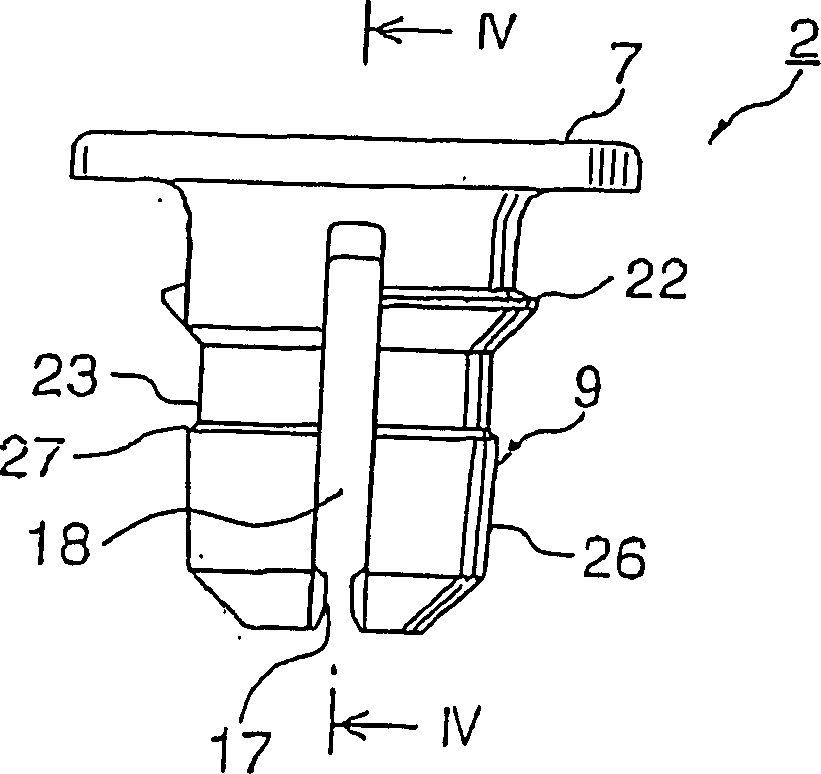

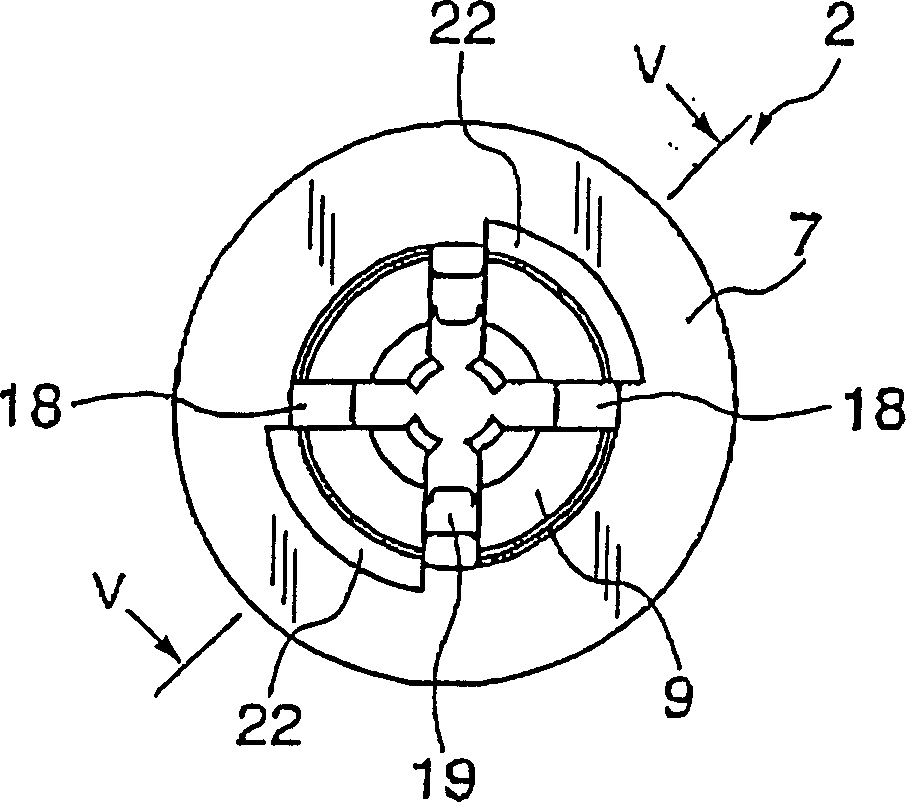

[0019] Embodiments of the present invention will be described below with reference to the drawings. Figure 1 to Figure 9 A clip 1 of an embodiment of the present invention is shown. Clip 1 by Figure 1 to Figure 5 Plastic sleeves shown 2 and Figure 6 and Figure 7 The shown plastic pin 3 consists of two parts. Such as Figure 8 As shown, the clip 1 made of the sleeve 2 and the pin 3 can make the pin 3 be connected to the sleeve 2 at a slightly inserted pre-installation position, and can be installed on the mounting member 5 such as a panel in a pre-installed connection state. When the clip 1 completely presses the pin 3 into the sleeve 2 from the pre-installed position, it moves as follows: Figure 9 Formal fixed position shown. In the connected state of the fixed position, the clip 1 can be used to connect the mounting member 5 such as the panel to the mounted member 6 such as the vehicle body.

[0020] refer to Figure 1 to Figure 5 Details of the sleeve 2 will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com