Oil Controller for two-stroke engine

A technology for engines and internal combustion engines, applied to combustion engines, internal combustion piston engines, and controlling the pressure of lubricants, etc., which can solve problems such as the complexity of the control system, the increase in the number of components, and the placement of throttle valve position sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

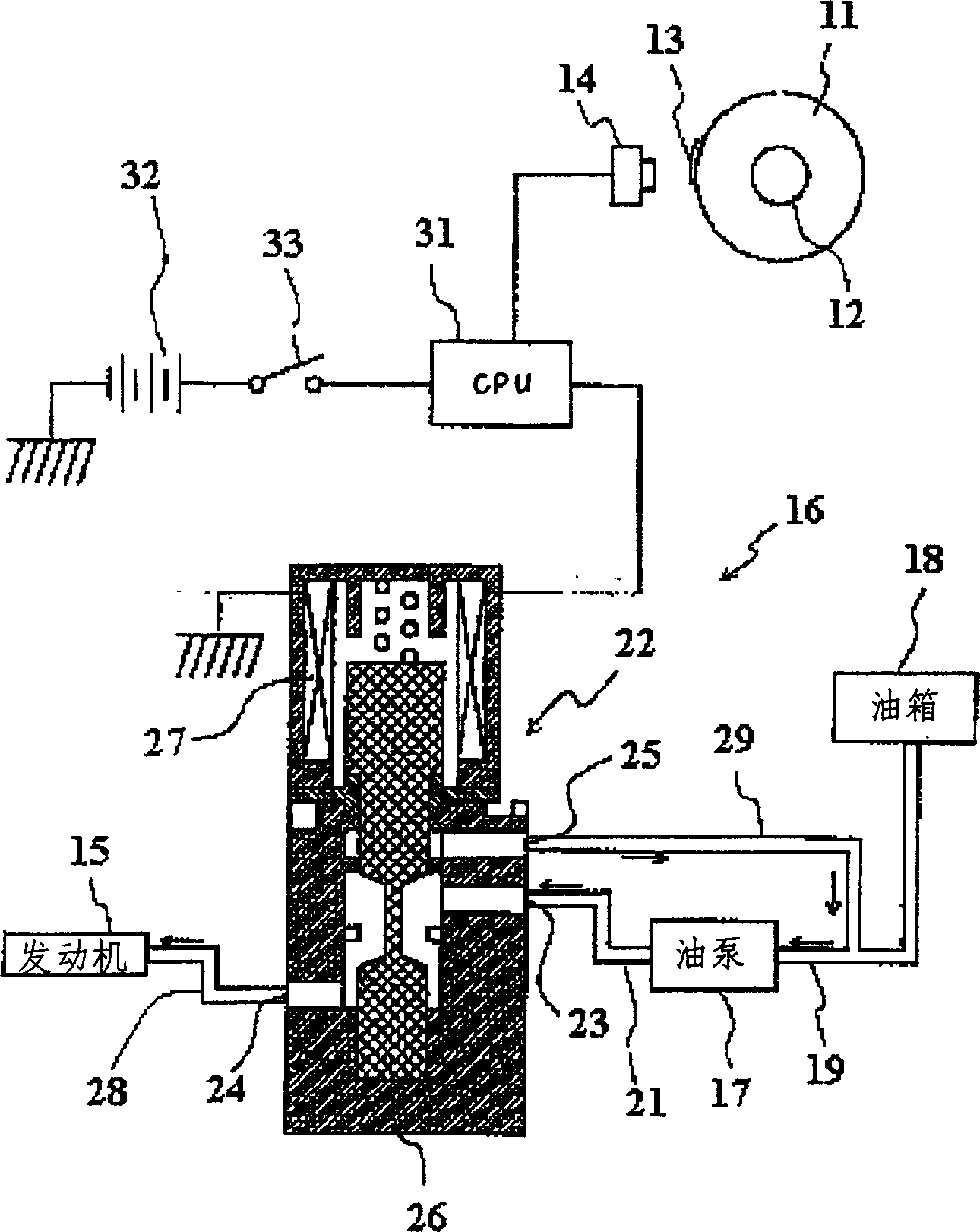

[0016] Before describing the invention with reference to the accompanying drawings, the contents of the above-mentioned co-pending application are hereby incorporated by reference as there is shown in more detail the basic type of engine with which the invention can be utilized and a basic Spark time control apparatus and method. However, it is also believed that from the following description, those skilled in the art will not only understand how to practice the present invention with the basic structure and method shown in this application, but also understand how to use the engine lubrication system to be described hereinafter. practice the invention.

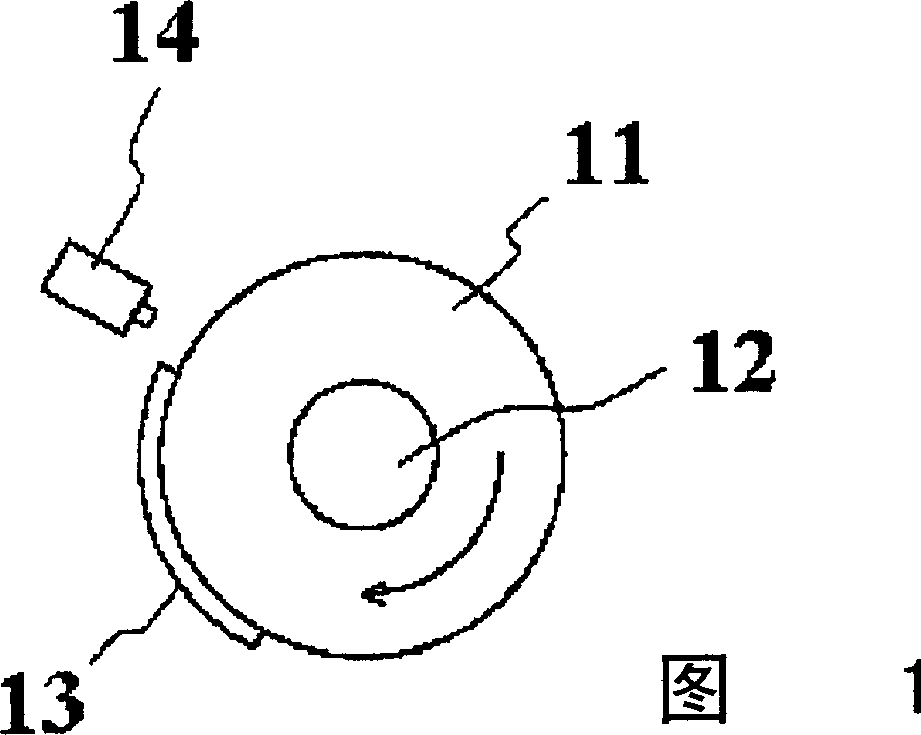

[0017] Referring next in detail to the drawings, and first to Figure 1, there is shown an engine timing sensor, for example, associated with an engine driven shaft member of any desired type of associated internal combustion engine. In particular, a flywheel 11 is fixed for rotation with the engine shaft, in particular the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap