Mining transportation management system and method thereof

A technology of mine transportation and management system, applied in the direction of underground transportation, transportation and packaging, surface mining, etc., can solve the problem of insufficient ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

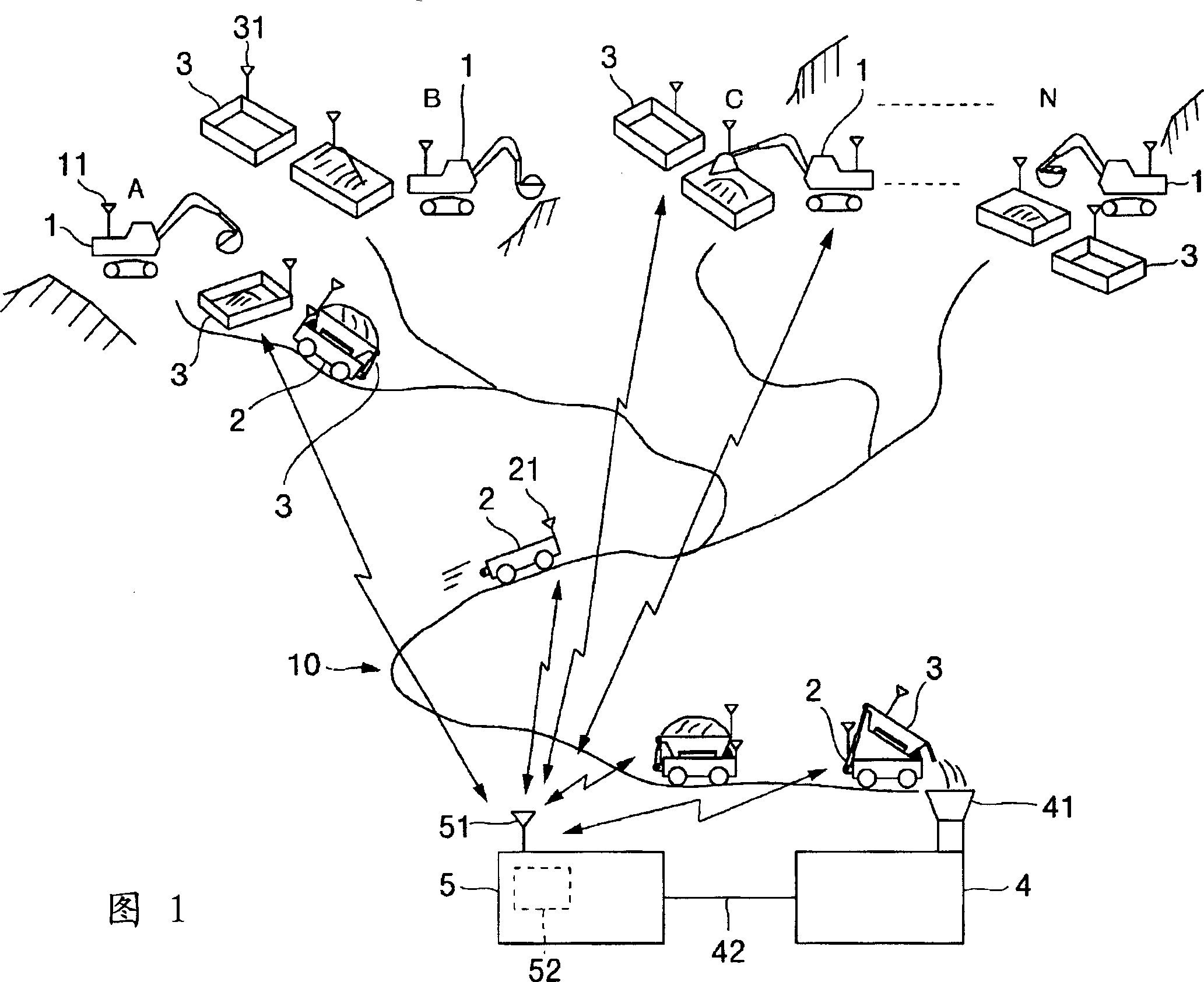

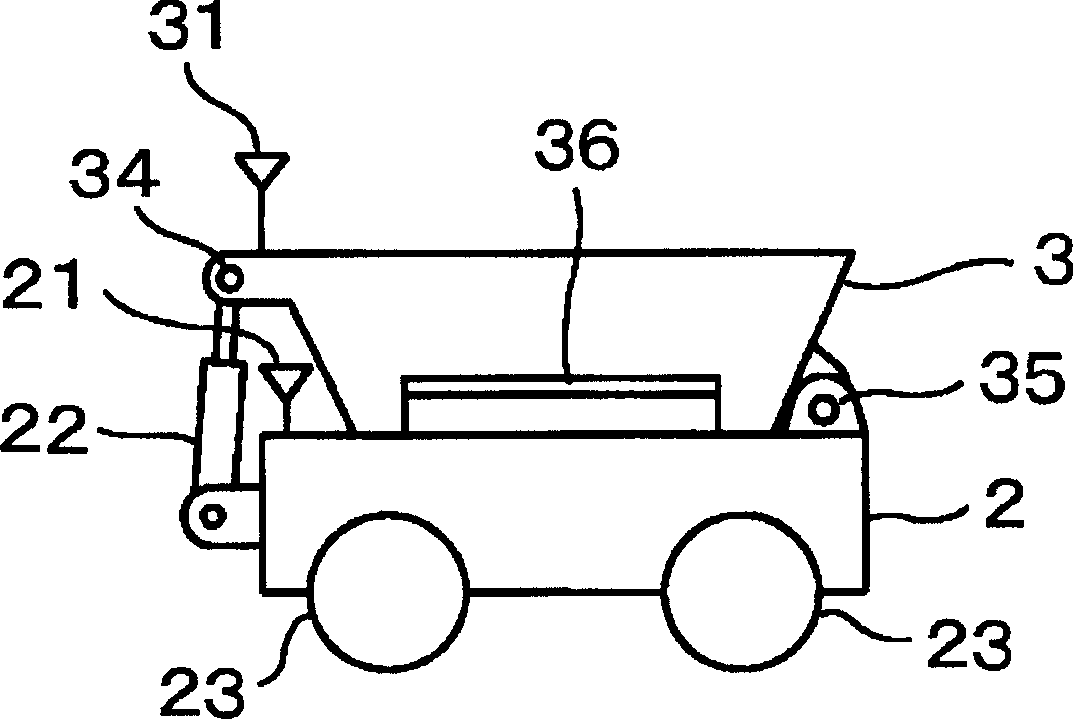

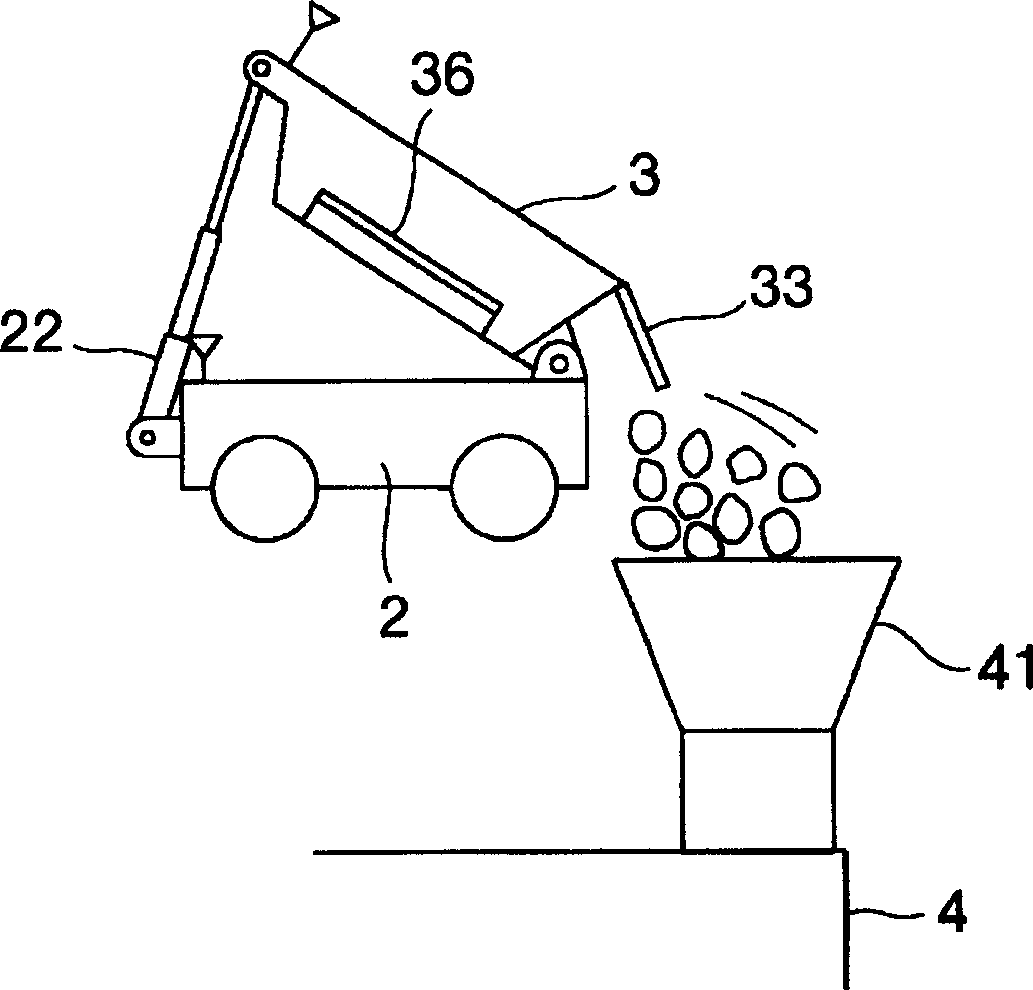

[0016] Hereinafter, preferred embodiments of the mine transportation management system according to the present invention will be described in detail with reference to the drawings. FIG. 1 is an explanatory diagram of the configuration of a mine transportation management system 10 . In FIG. 1 , a plurality of hydraulic forklifts 1 as an example of excavation and loading machines excavate ore at a mine site, and load ore as an example of a to-be-loaded object into a chute 3 . In the necessary excavation sites A, B, C...N, a plurality of material troughs 3 are arranged respectively. A plurality of self-propelled vehicles 2 travel in the mine respectively, some of them are loaded with the hopper 3 full of excavated ore, and some of them are loaded with an empty hopper 3, and drive to the specified site. The self-propelled vehicle 2 pours the ore into the hopper 41 of the processing facility 4 for crushing ore and distributing into specified components. The processing facility 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com