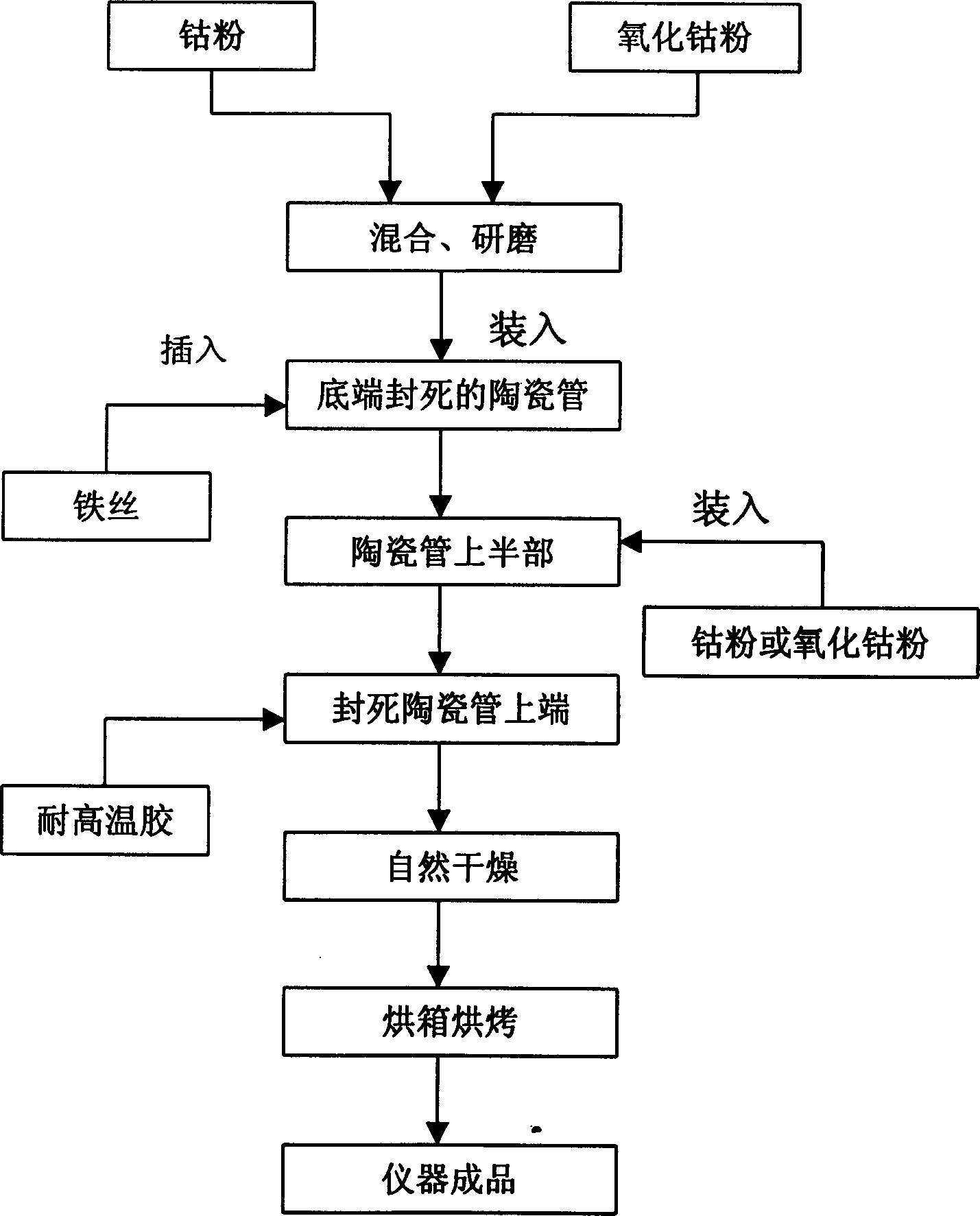

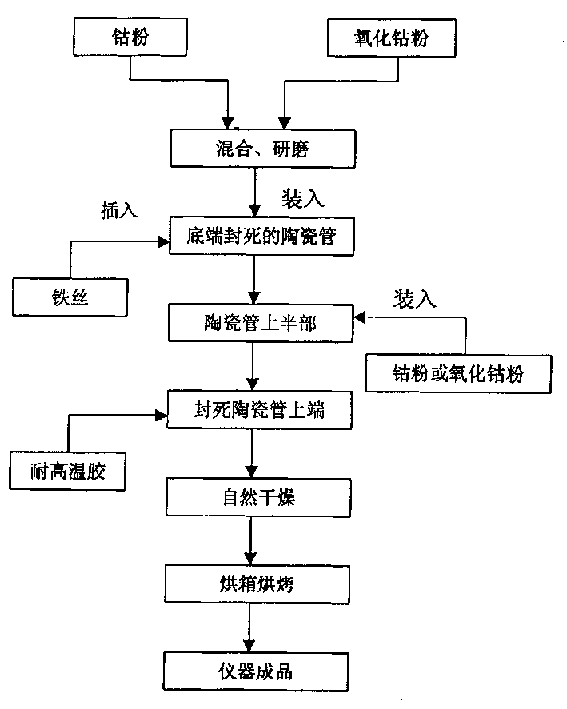

Making process of oxygen-measuring copper solution sensor

A technology of oxygen sensor and manufacturing method, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., and can solve the problems of copper backlog, copper not meeting oxygen content requirements, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0024] The process steps described in Example 2 and Example 1 are exactly the same, except for the following differences: take 30 grams of cobalt powder with a purity of 99.99%, and 3 grams of cobalt oxide powder with a purity of 99%, and put them in a jade vessel Mix and grind for 40 minutes, pour the ground mixed powder into the cobalt oxide tube, and keep compacting, the mixed powder accounts for 40% of the volume of the cobalt oxide tube; pour the cobalt powder into the upper half of the cobalt oxide tube, after compacting, Cobalt powder accounts for 60% of the volume of the cobalt oxide tube.

specific Embodiment approach 3

[0025] The process steps described in the present embodiment 3 are exactly the same as those in the embodiment 1, but there are the following differences: take 40 grams of cobalt powder with a purity of 99%, and 34 grams of cobalt oxide powder with a purity of 99%, and put them into a ceramic vessel Mix in medium and grind for 30 minutes. Pour the ground mixed powder into the cobalt oxide tube and keep compacting. The mixed powder accounts for 89% of the volume of the cobalt oxide tube. Pour the aluminum oxide powder into the upper half of the cobalt oxide tube. Finally, alumina powder accounts for 11% of the volume of the cobalt oxide tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com