Drum convex lug fixing structure

A technology for fixing structures and lugs, applied to percussion instruments, instruments, musical instruments, etc., can solve problems such as hindering the replacement of the drum head 2, and difficult bolts for the operator, and achieve the effect of preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below by way of example with reference to the accompanying drawings.

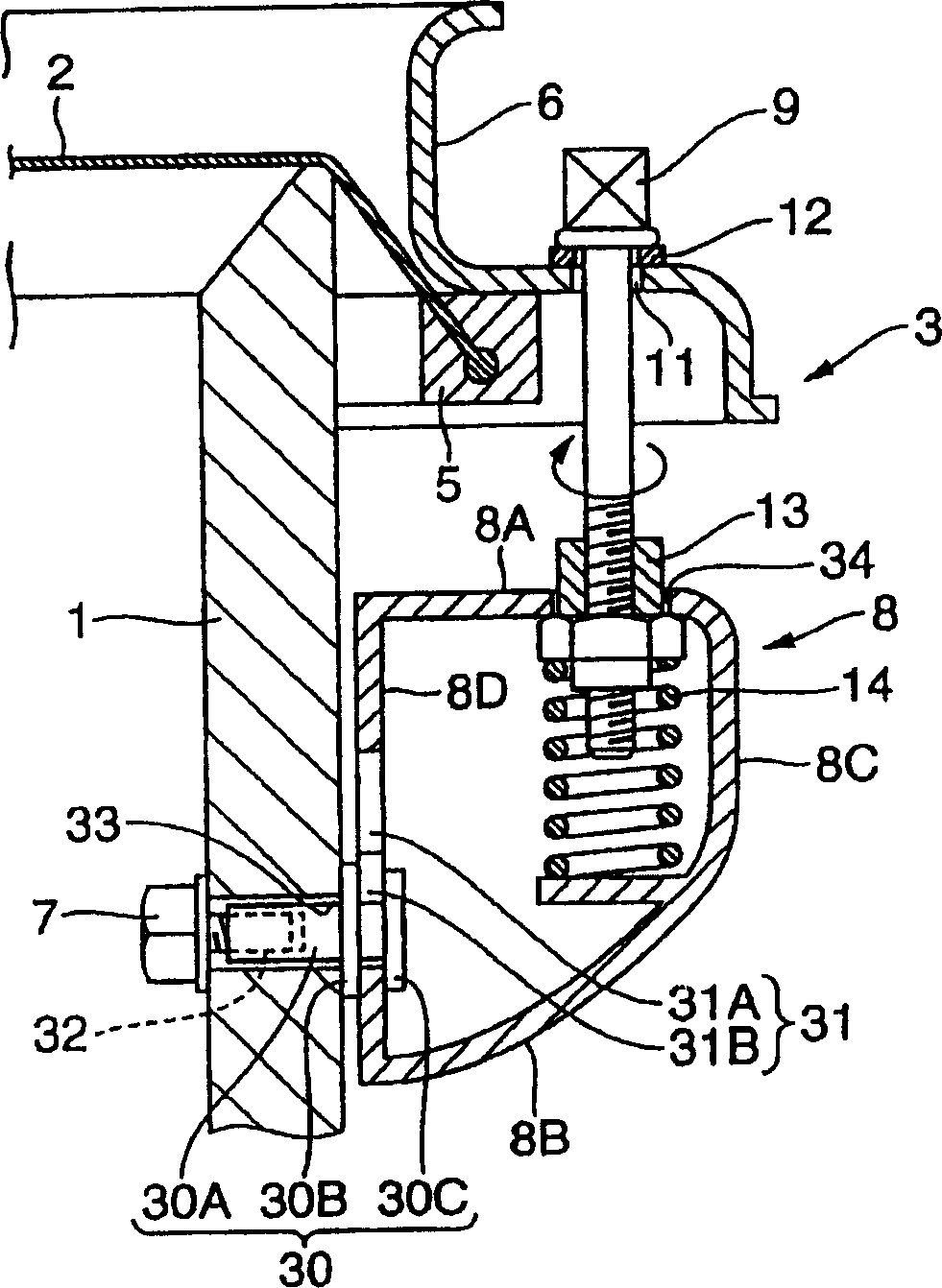

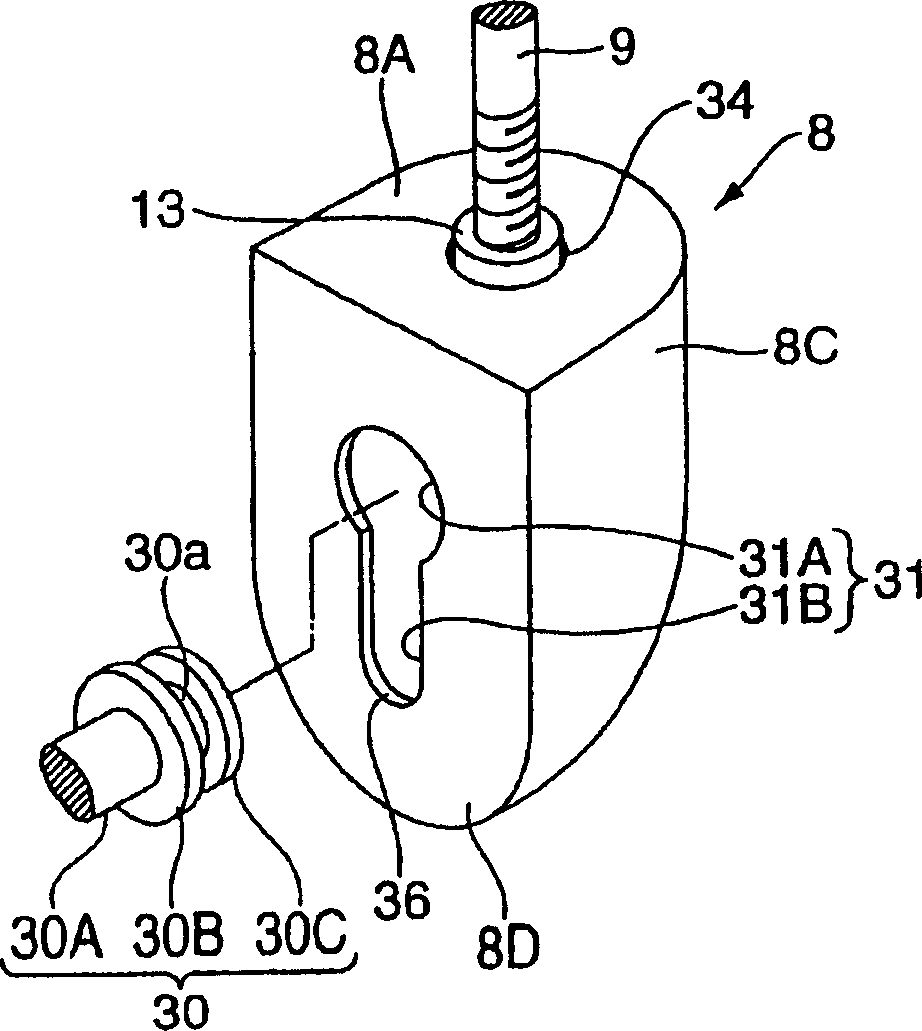

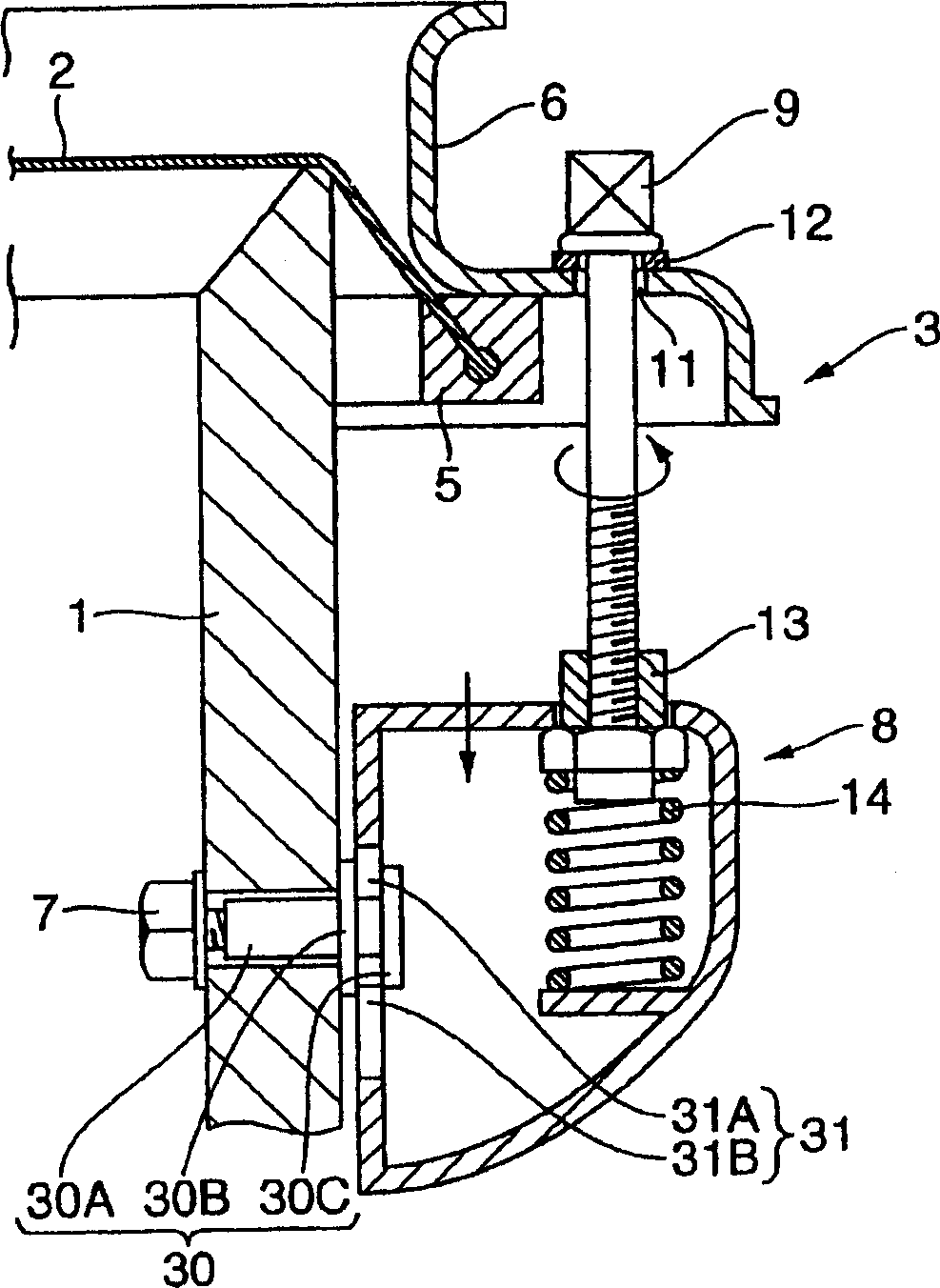

[0039] figure 1 is a sectional view of the lug fixing structure of the drum according to the first embodiment of the present invention. figure 2 yes figure 1 A perspective view of the main part of the lug fixing structure in . image 3 is a cross-sectional view of the lug fixing structure, where the bolt is in a loose state; Figure 4 is a cross-sectional view of the lug fixing structure, where the lug has been removed from the outer surface of the hollow cylinder; Figure 5 is a cross-sectional view of the lug fixing structure, where the lug has been turned over. exist Figure 1 to Figure 5 9 and 10, the same reference numerals are used for parts equivalent to those in FIGS. 9 and 10; therefore, their descriptions are omitted for brevity.

[0040]The lug fixing structure of the first embodiment is to detachably install the lug 8 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com