Method of manufacturing an aluminum design tab end for a beverage can

A manufacturing method and pattern technology, applied in the field of end manufacturing, can solve problems such as unfavorable productivity or cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

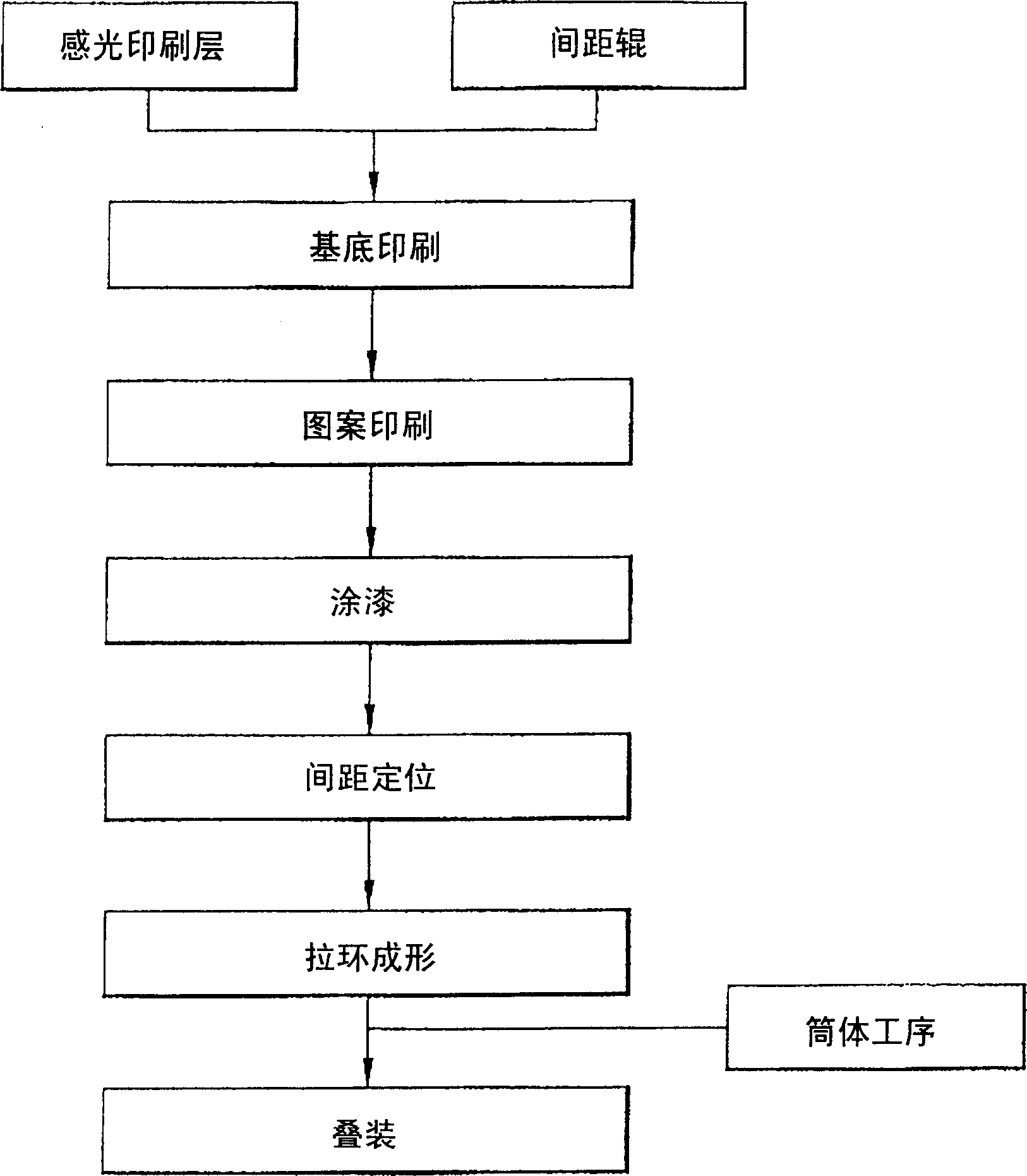

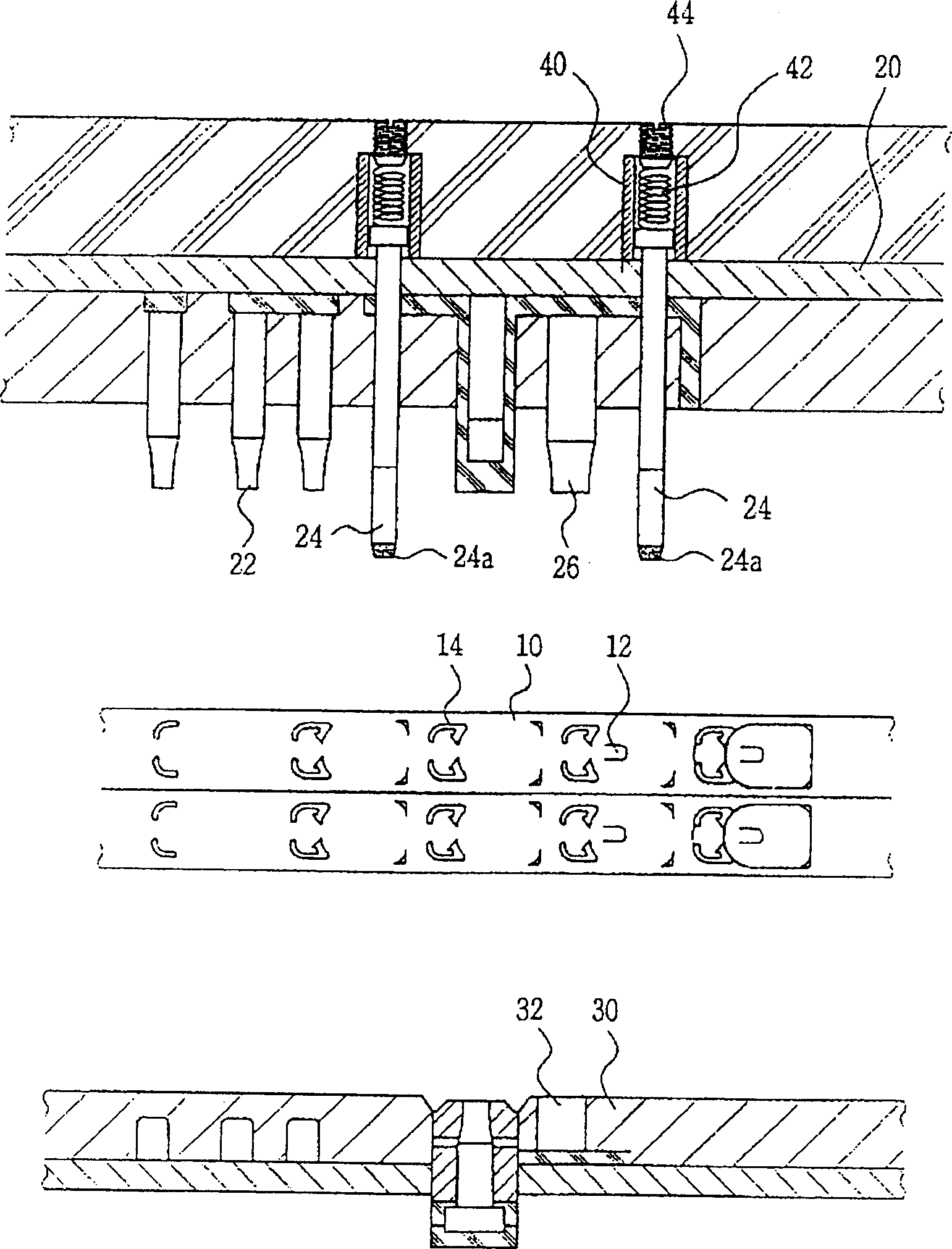

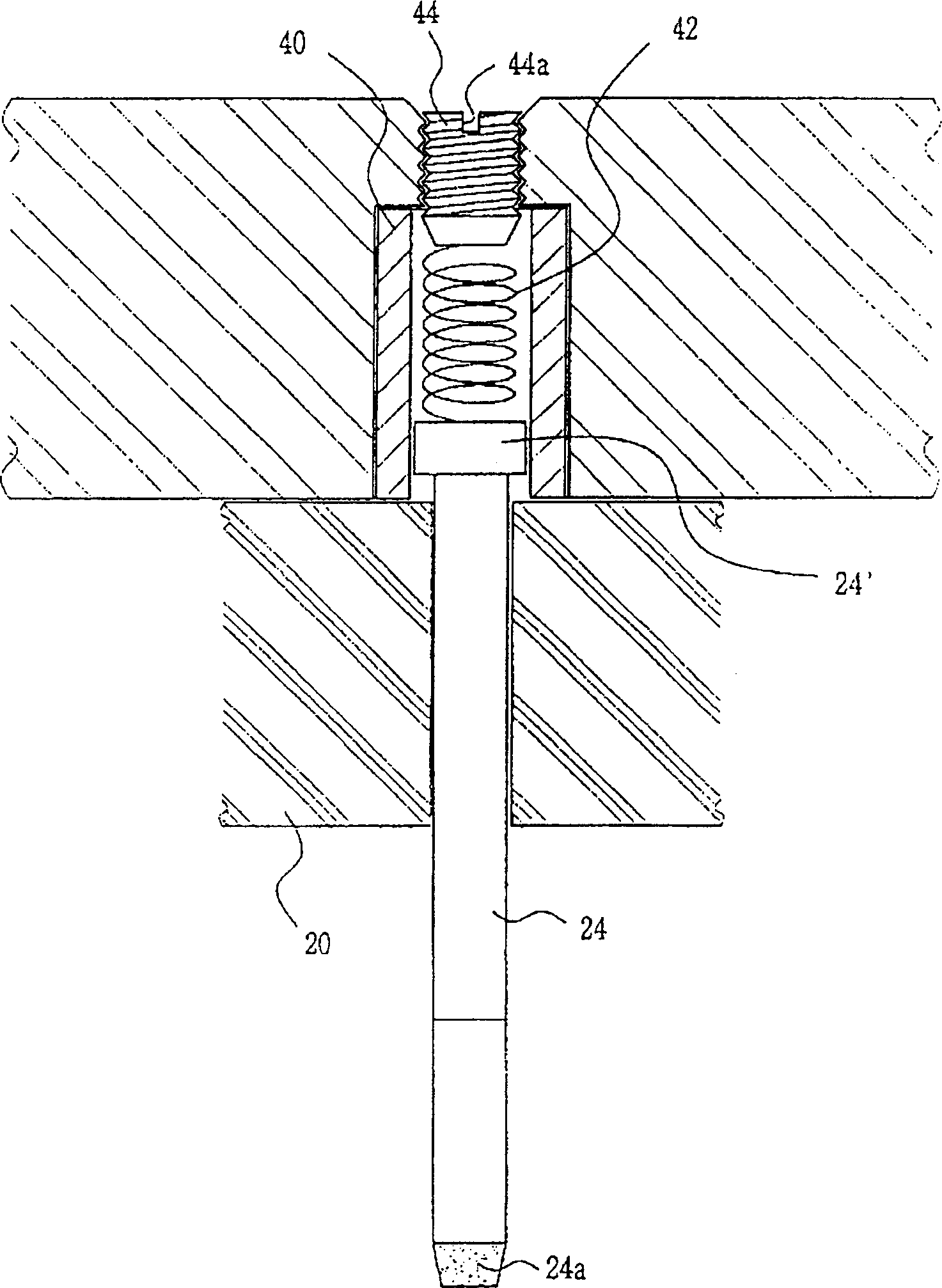

[0015] Below, refer to the attached figure 1 The method of manufacturing the end portion of the tab-attached pattern of the beverage can according to the preferred embodiment of the present invention will be described in detail.

[0016] In order to improve productivity and save costs in the process of printing characters or company logos, mascots and other patterns on the surface of the closed pull ring, in a preferred embodiment of the present invention, use the spacing Positioning device, the position of the background color and pattern of the tab printed on the surface of the coil is accurately positioned at the required position of the tab to be formed later, and the tab printing process is completed, and the tab after the pattern printing is completed The coils are painted at the same pitch as the printing process. Then, by performing the tab forming process with the same pitch, the base printing process of the tab, the pattern process of the tab, and the painting proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com