Threaded crown for timepiece

A crown and timepiece technology, which is applied to the mechanical device for time indication, the mechanical device for adjusting the time indication device, and the mechanically driven clock, etc., can solve the problems of unfavorable aesthetic appearance and unsuitability of the casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

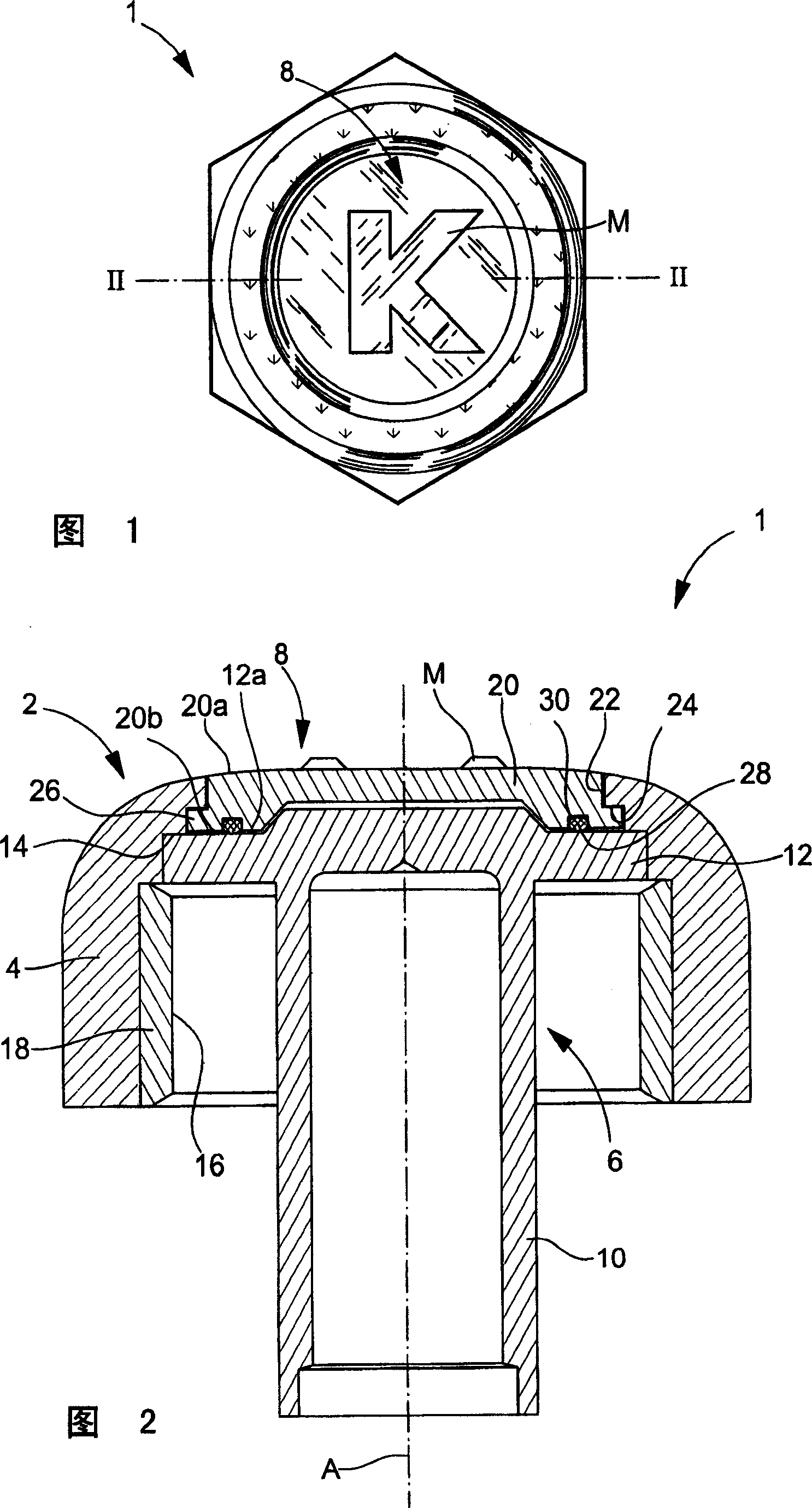

[0012] Figures 1 and 2 show a screw-on crown, generally indicated by the reference number 1, for screwing onto a threaded pipe (not shown) which is driven into a In the central part of the watch case (not shown).

[0013] The crown 1 comprises a first part comprising a head 2 extending from a lateral skirt 4 surrounding a central part 6 fastened to the head. The head 2 includes an end face or front surface 8 on which a design such as a logo or trademark M is implemented by printing or engraving or in any suitable manner. The central part 6 is intended to be connected to the movement of the timepiece by means of a mainspring or time setting lever in a conventional manner. In the illustrated embodiment, the central part 6 is added to and fastened to the head 2 . The central part 6 comprises a tube 10 fitted with a disc 12 at one end thereof. The central part 6 is generally fastened into a first shoulder 14 provided in the head 2 by eg welding, gluing, crimping or any suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com