Copper receptacle assembly with sectional pins and elastic groove

A technology of elastic grooves and special-shaped needles, which is applied in the direction of contact parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

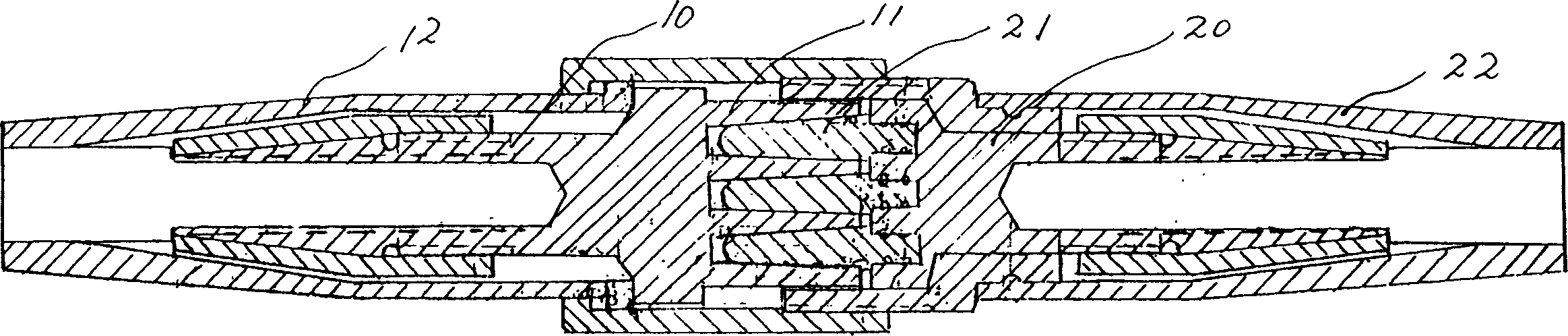

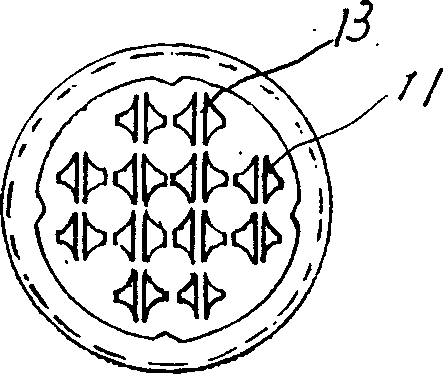

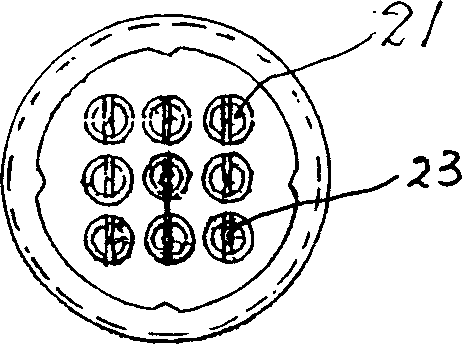

[0008] In the figure, a special-shaped pin-type copper connector assembly provided with an elastic groove is mainly composed of a connector 10 and a plug-in 20. The upper end of the connector 10 is provided with a cross-conical needle body 11, and a cross-taper needle body 11 is provided with a There is an elastic groove 13, the two adjacent ends of the cross-conical needle body form a quarter of a conical groove, the lower end is screwed with a cap 12, and the upper end of the insert 20 is provided with a conical groove formed with the connector 10 and The number of matching conical needle bodies 21 is provided with an elastic groove 23 , and a cap 22 is screwed to the lower end of the conical needle body 21 . Among them, the elastic groove can make the two better match under the action of deformation when they are plugged in. When in use, the two can be plugged together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com