Full-automatic lotus seed core-drilling machine

A fully automatic lotus seed technology, applied in food science, application, fruit pitting device, etc., can solve the problems of not being able to meet mass production, slow processing speed, small lotus seed particles, etc., achieve good market prospects, low manufacturing cost, and easy to use Convenient and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

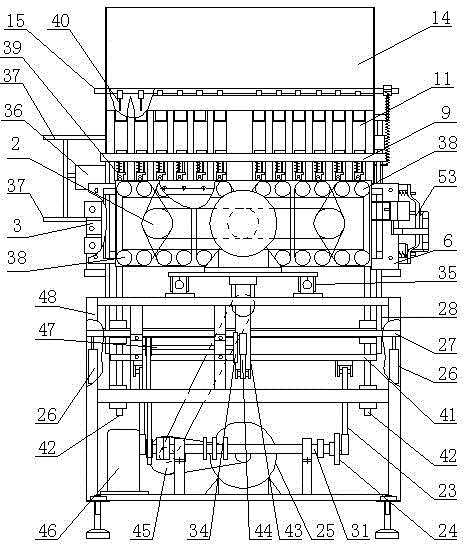

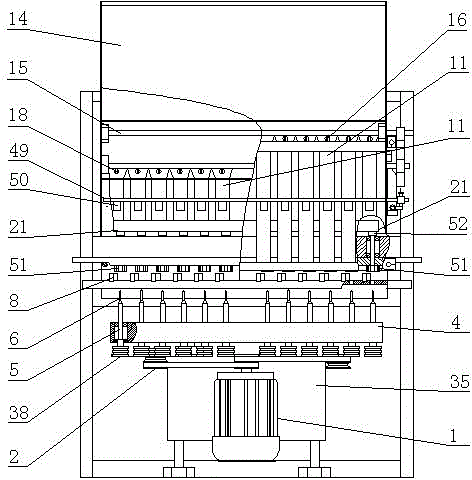

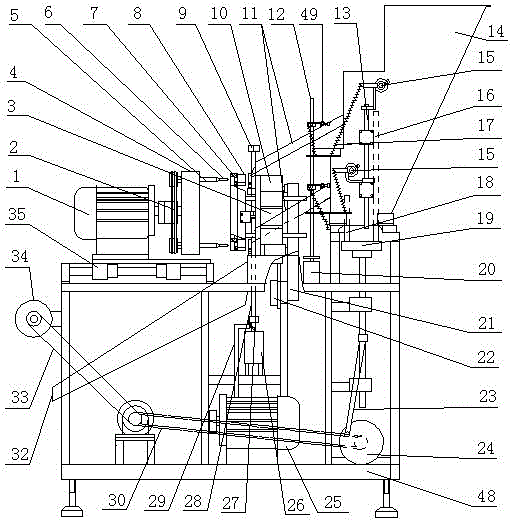

[0026] by attached figure 1 As shown in Fig. 4, a kind of full-automatic lotus seed core drilling machine comprises: a sliding fixed plate 35 is set on the frame 48, a core-drilling motor 1 is fixed on the fixed plate 35, and the core-drilling motor 1 is connected with several main drive wheels 2, and the main drive Wheel 2 connects a plurality of drill bit drive wheels 38, each drill bit drive wheel 38 connects a drill rod 5, and a plurality of drill rods 5 are installed on the multi-axis seat 4 in multiple rows up and down, and drill bits 6 are installed at the end of the drill rod 5; On the frame 48, the positioning seat 10 is fixed, and the both sides of the positioning seat 10 are fixedly installed with the positioning cylinder 3, and the two positioning cylinders 3 are connected to the fixed plate 7, and the fixed plate 7 is divided into upper and lower rows to set a plurality of positioning blocks 8, and the front of the positioning seat 10 is pressed A plurality of pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com