Prestress combined beam, continuous prestress combined beam structure and producing connection method

A composite beam and prestressing technology, which is applied in the direction of load-bearing elongated structural members, structural elements, building structures, etc., can solve problems such as rough appearance, low rigidity ratio, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Reference will now be made in detail to specific embodiments of the invention, examples of which are shown in the accompanying drawings, like parts being given like reference numerals throughout.

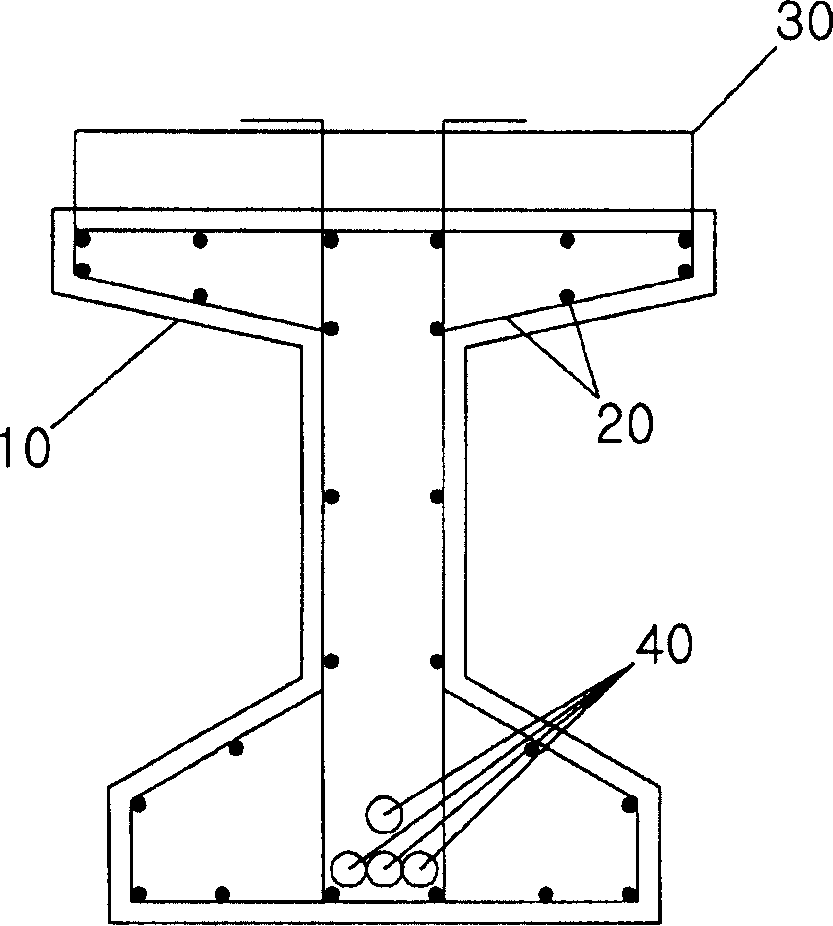

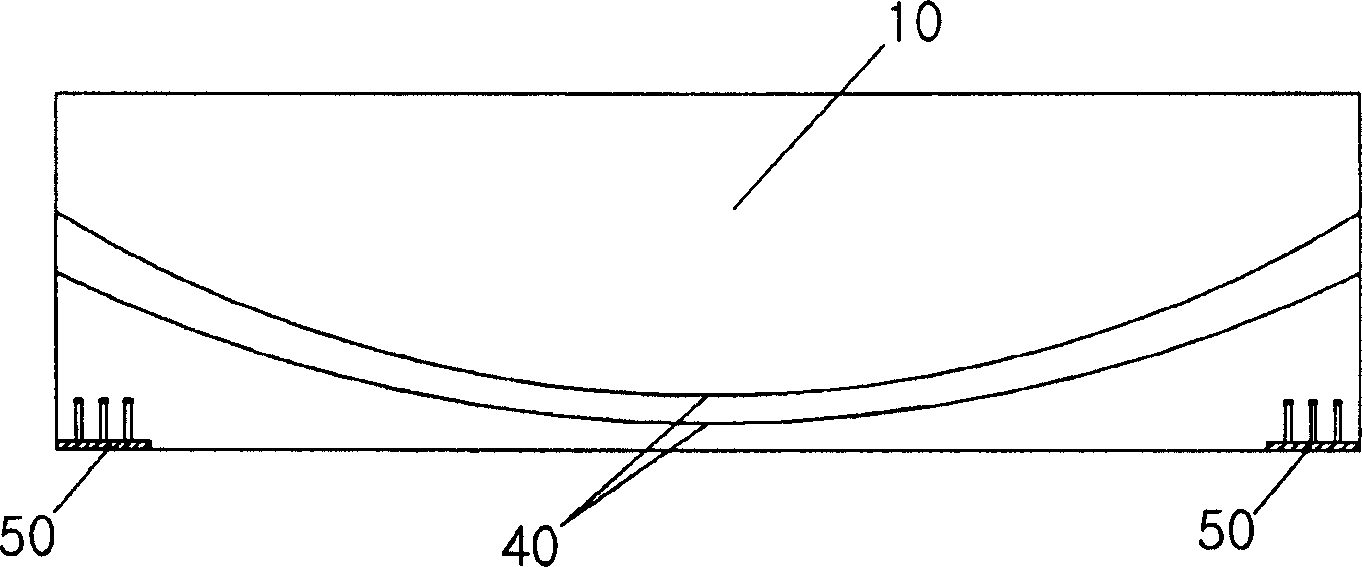

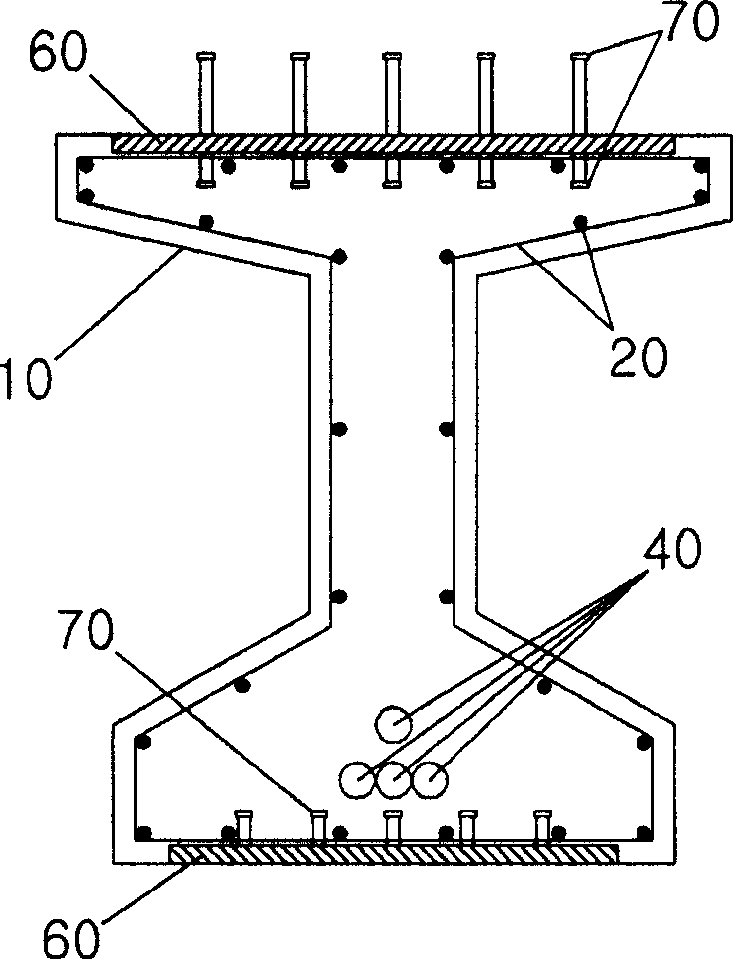

[0020] Figures 2A to 7 is a view of a prestressed composite beam including steel plates. Figure 2A with 2B is a front sectional view of a composite beam with steel plates according to the present invention. Figures 3A to 3C Respectively, the moment diagram and the side cross-sectional diagram of the composite beam with steel plates according to the invention in the case of a simply supported bridge. Figures 4A to 4D Respectively, the moment diagram and the side cross-sectional diagram of the composite girder with steel plates according to the invention in the case of the outer span of a continuous girder bridge. Figures 5A to 5D Respectively, the moment diagram and the side cross-sectional diagram of the composite girder with steel plates according to the invention in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com