Production device and production method for organic EL dispaly

A technology for manufacturing devices and displays, which is applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, lighting devices, etc., and can solve problems such as difficult to reliably form scribing lines, inability to obtain separation surfaces, and difficulty in supporting glass substrates 2, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, an organic EL display manufacturing apparatus according to the present invention will be described with reference to the accompanying drawings.

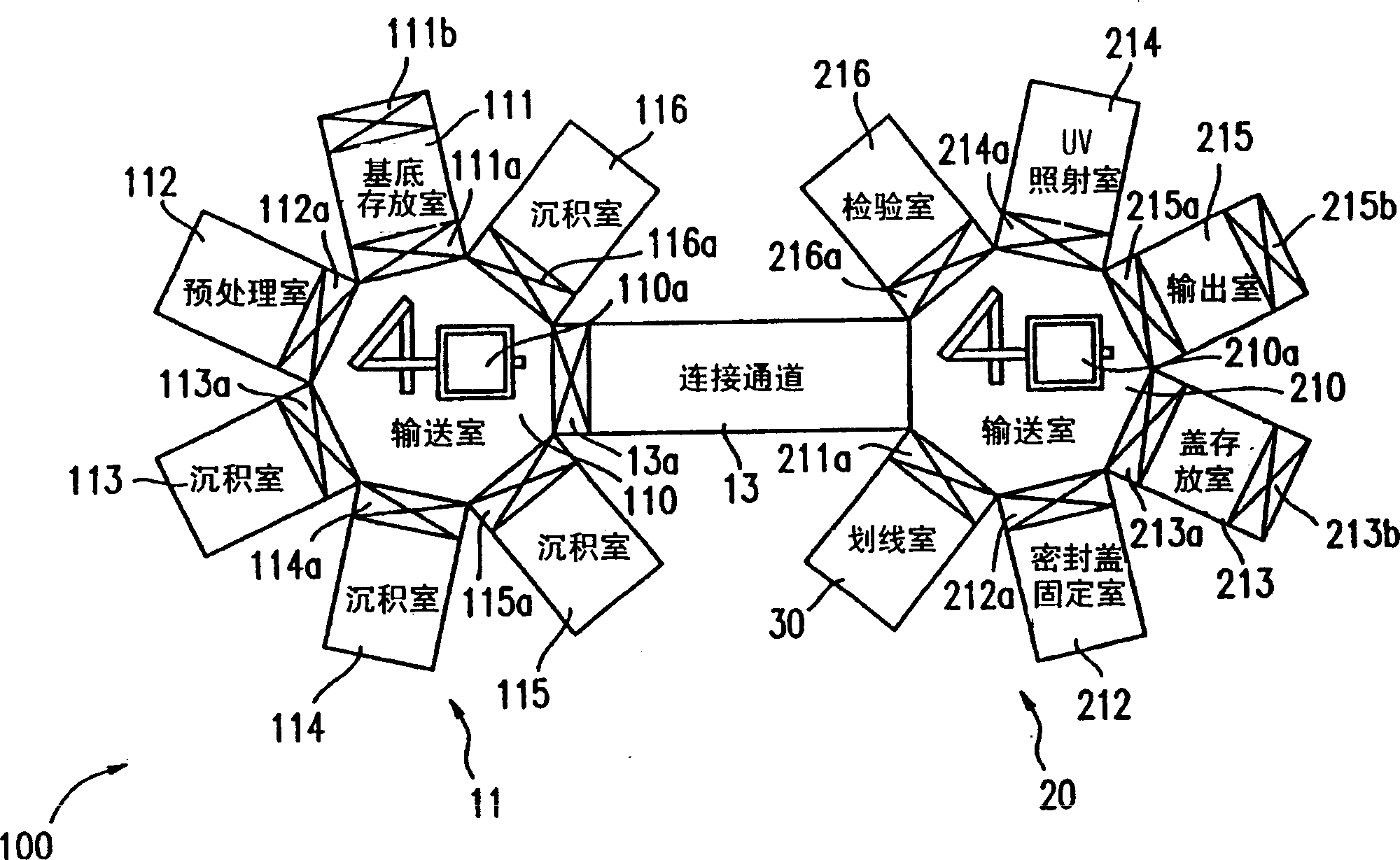

[0036] figure 1 A general structure of an organic EL display manufacturing apparatus 100 according to the present invention is shown. Manufactured organic EL displays with Figure 6 The structure shown is the same.

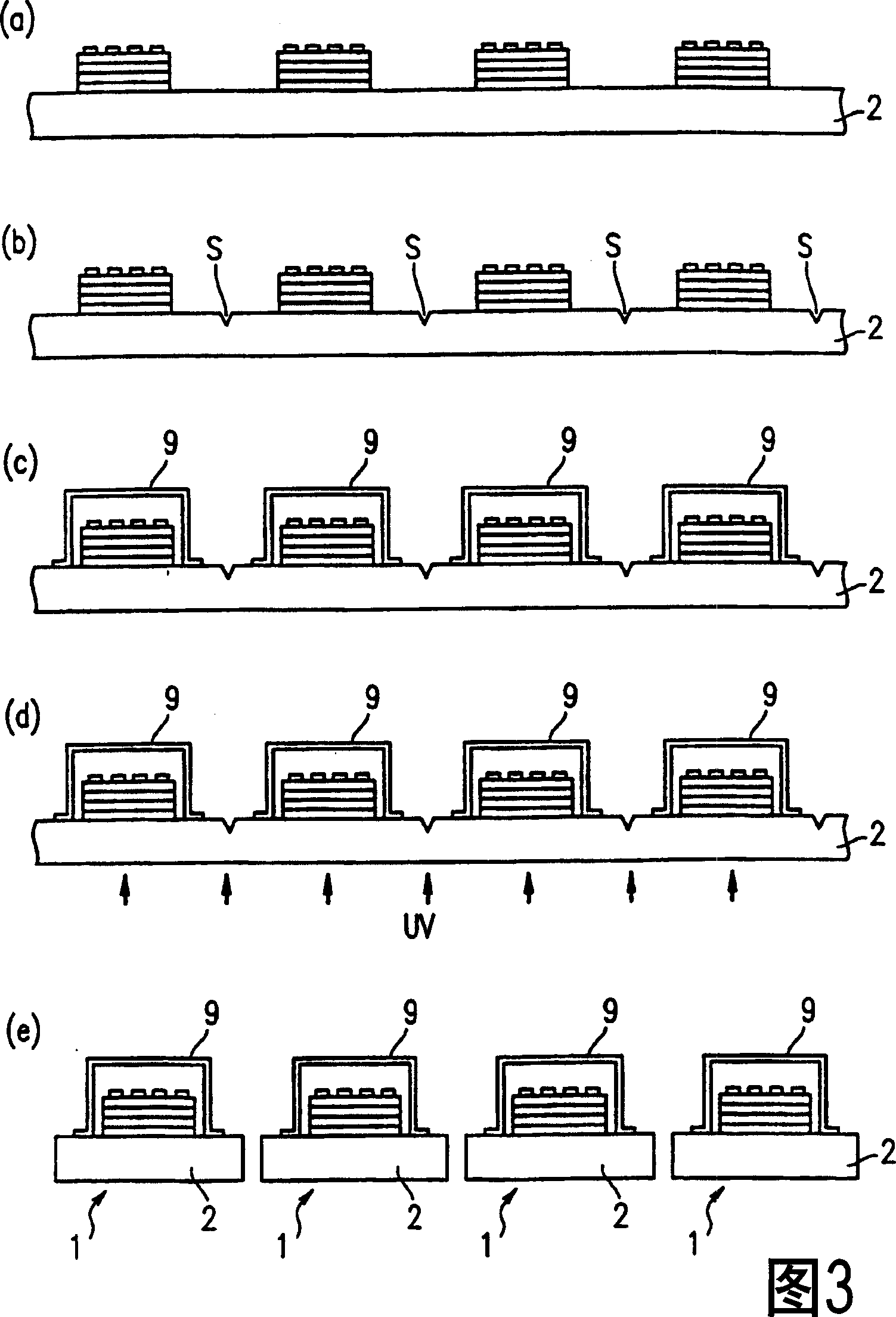

[0037] The organic EL display manufacturing apparatus 100 has: a thin film forming chamber 11 in which a thin film forming step is performed to form several layers on a glass substrate (brittle substrate) 2, such as an organic light emitting layer 5 and the like; and a sealed chamber 20 in which After the layered structure is formed on the glass substrate 2 , a sealing cover 9 is provided on the glass substrate 2 . The thin film forming chamber 11 and the sealing chamber 20 are connected to each other by a connecting passage 13 .

[0038] The film forming chamber 11 has a conveyance chamber 110, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com