Slot shaping appts.

A forming device and annular groove technology, applied in the direction of groove needles, metal processing equipment, manufacturing tools, etc., can solve the problem of unstable extrusion force of the metal tube 90, poor engagement, and friction between the metal tube 90 and the pressing roller 82 Problems such as resistance cannot be completely eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

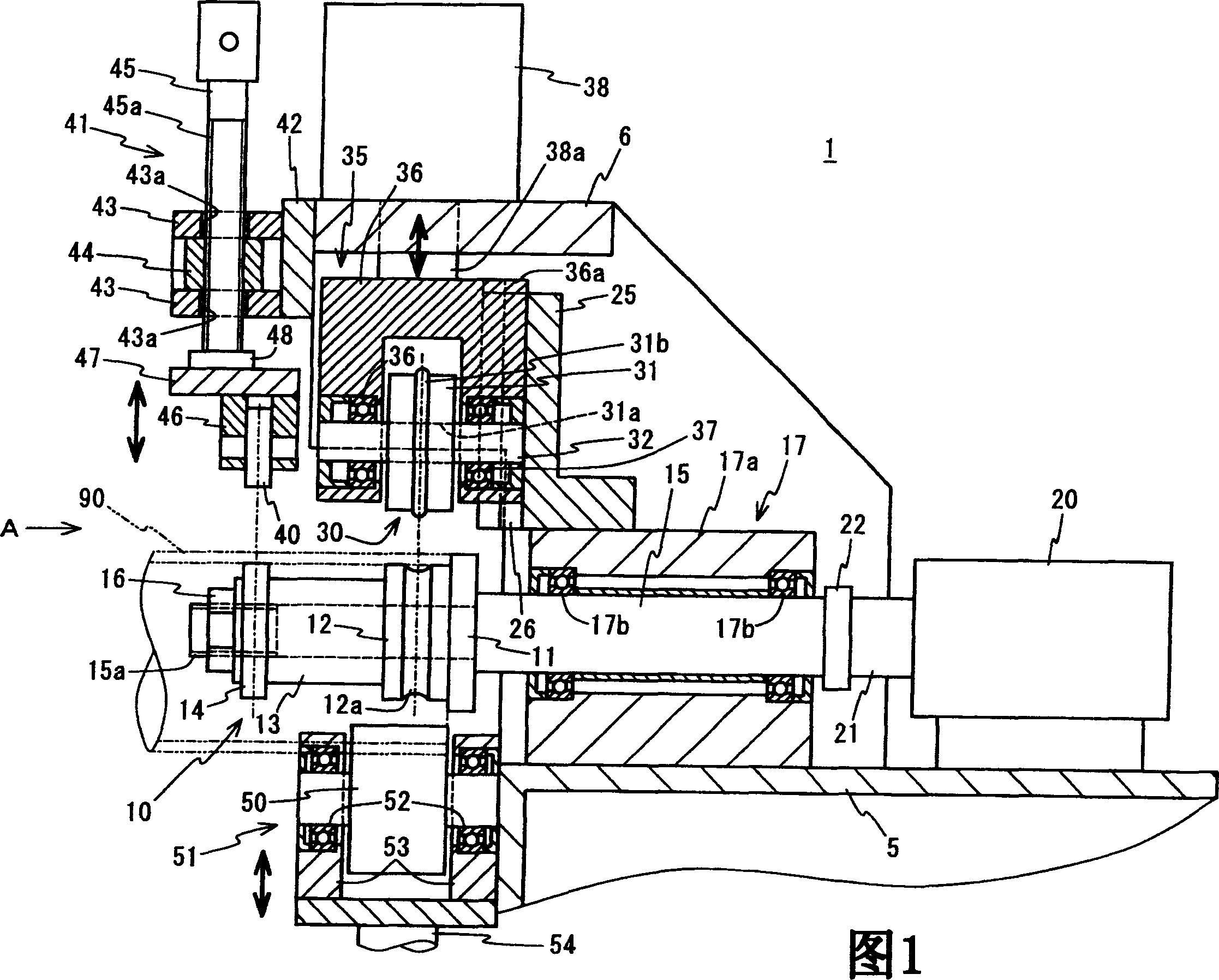

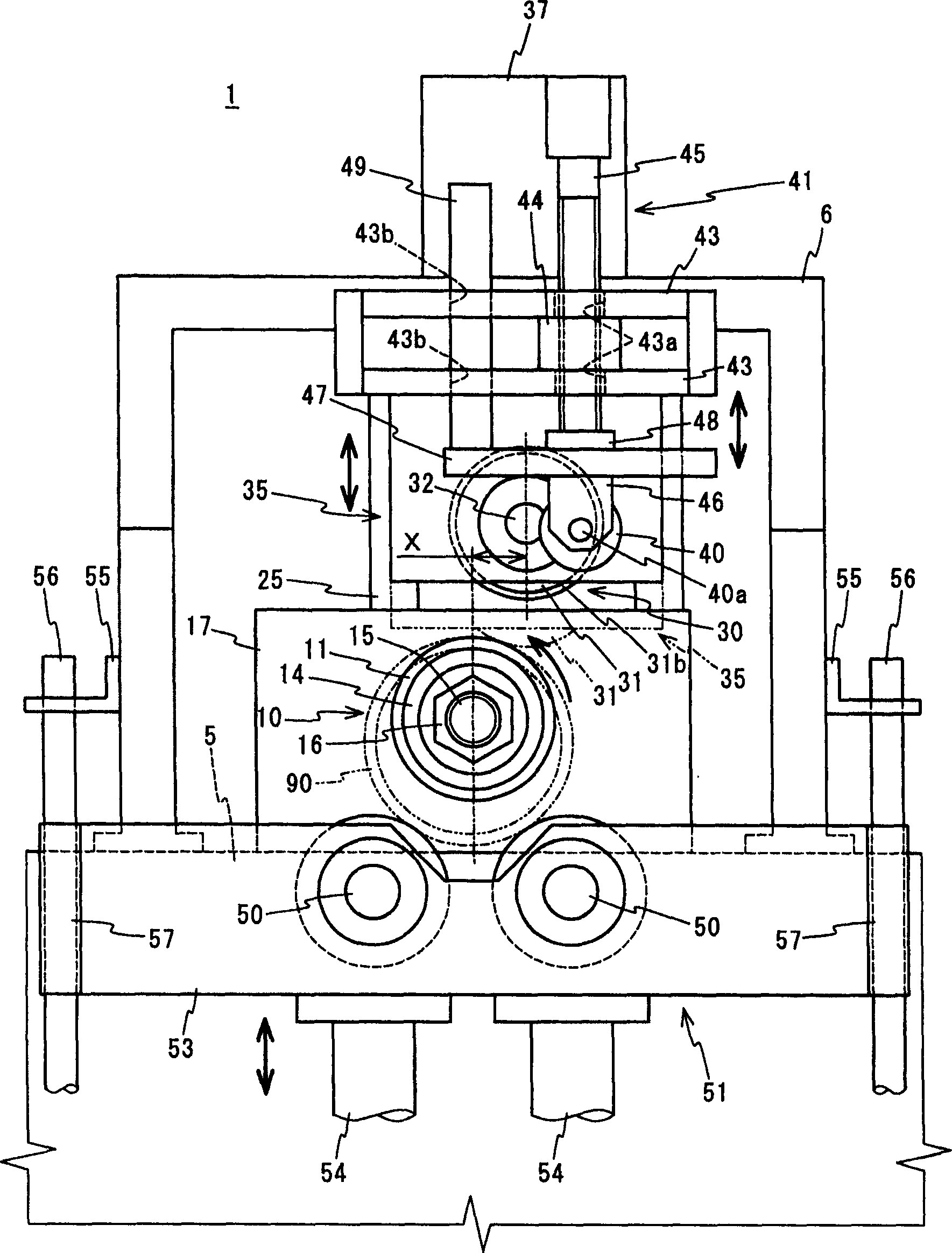

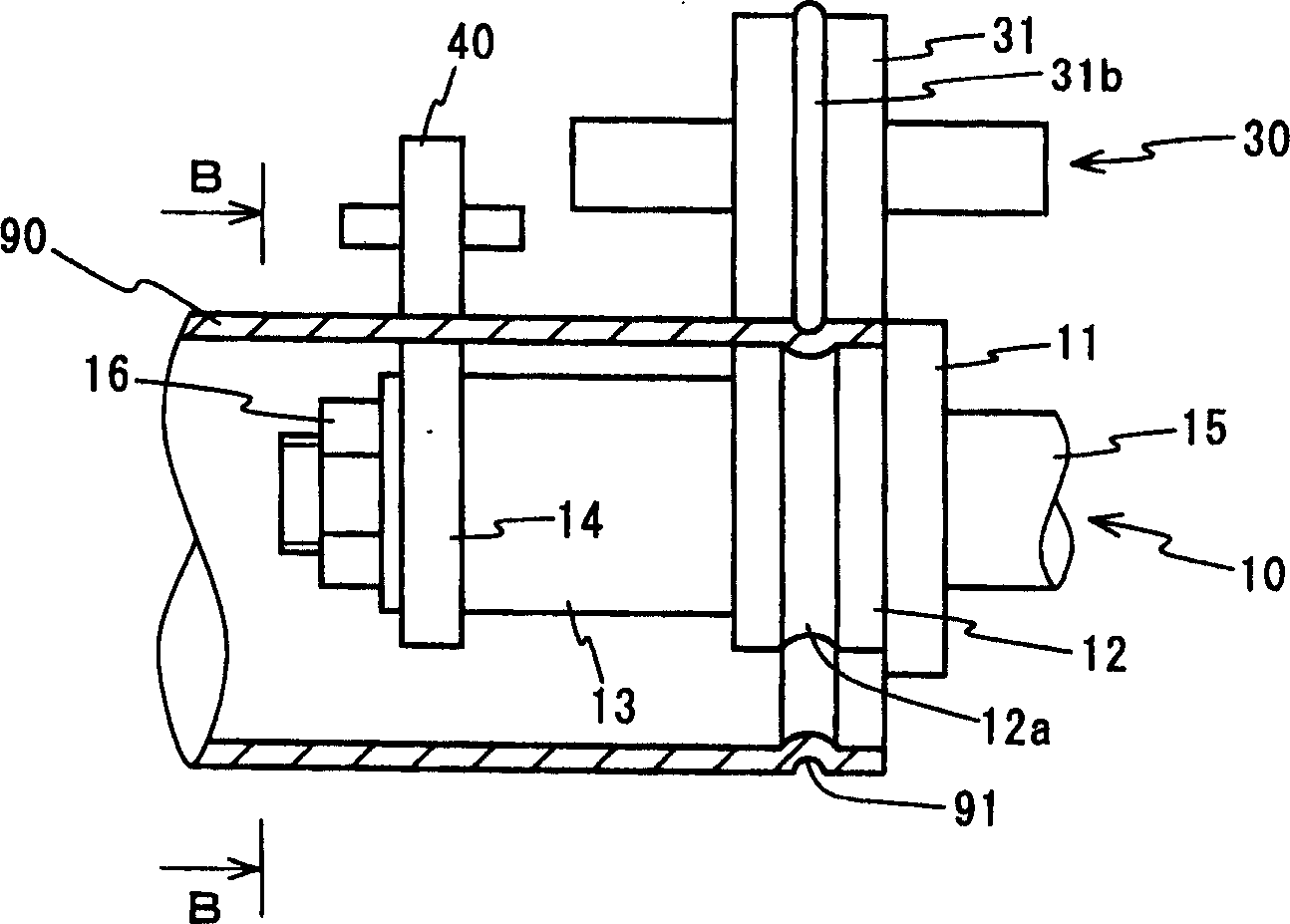

[0046] The specific embodiment of the present invention is described as follows according to the accompanying drawings. Fig. 1 is a cross-sectional view showing a schematic configuration of a groove forming device according to an embodiment of the present invention, figure 2 It is the front view of the direction A indicated by the arrow in Fig. 1. image 3 It is an explanatory diagram showing the state of support and abutment between the backup roller, the pressing roller, the anti-swing roller and the metal pipe according to the present embodiment, Figure 4 for image 3 The cross-sectional view of B-B direction indicated by the middle arrow. In addition, in this example, it is intended to form the annular groove 91 on the aforementioned metal pipe 90 .

[0047] Figure 1 to Figure 4 As shown, the groove forming device 1 of this example has: a support roll 10 that supports the inner peripheral surface of the metal pipe 90 inserted therein, a bearing portion 17 that suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com