Method and appts. for defining position of edge surface of piled, e.g. boardlike objects

An edge and object technology, applied in the direction of optical devices, measuring devices, transportation and packaging, etc., can solve the problems of no precise positioning, changes in the distance between each board and the print head, and poor printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

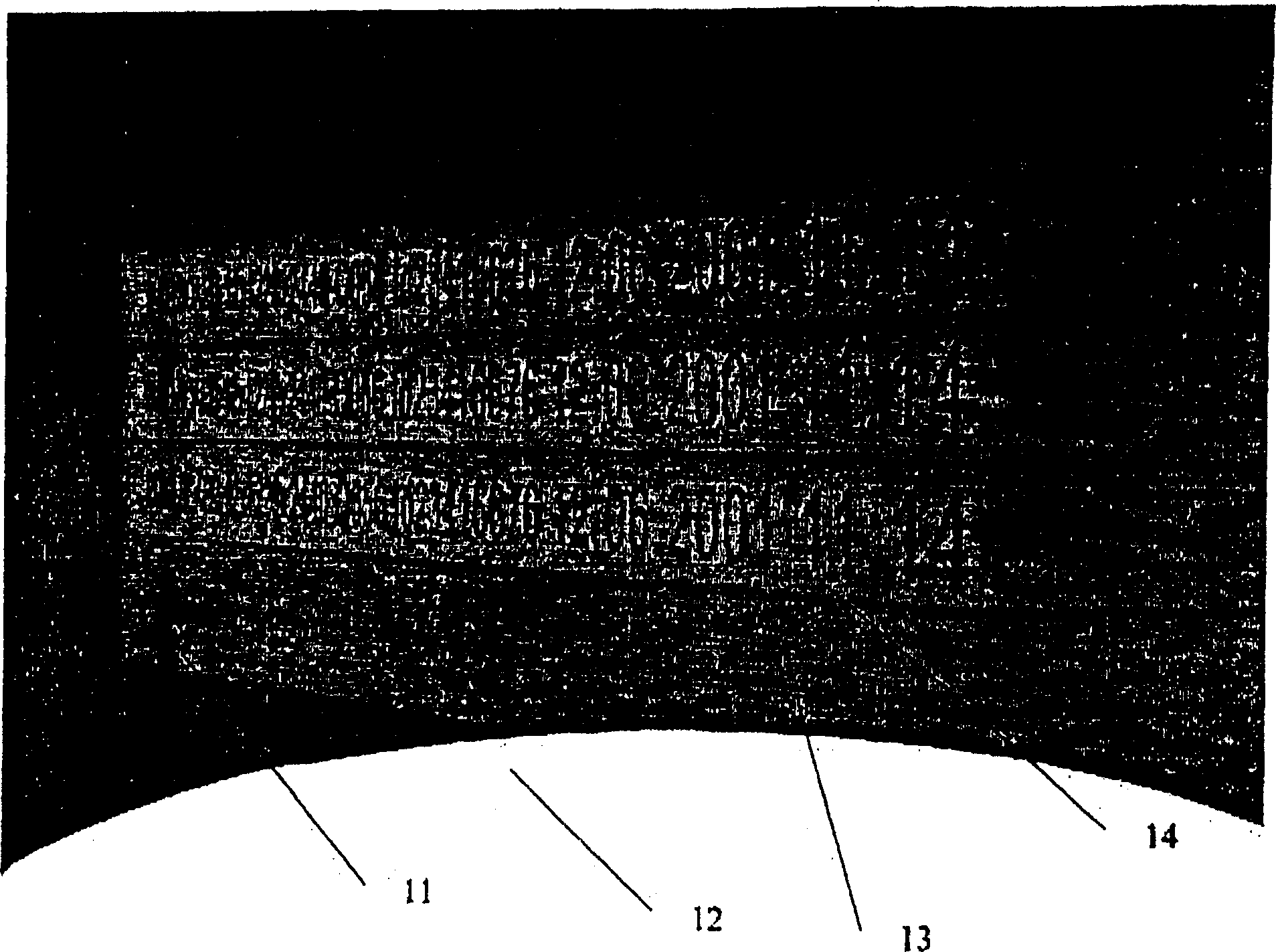

[0010] attached figure 1 The panels 11 are shown stacked on top of each other to form a stack 12 . Printed on the edge 13 of each board 11 is a marking 14 including information such as board type, size, manufacturer, date of manufacture and other similar data. The panel stack 12 may comprise further panels placed one above the other, their height typically being up to eg 1 metre. Furthermore, the stack may include, for example, protective panels above and below it.

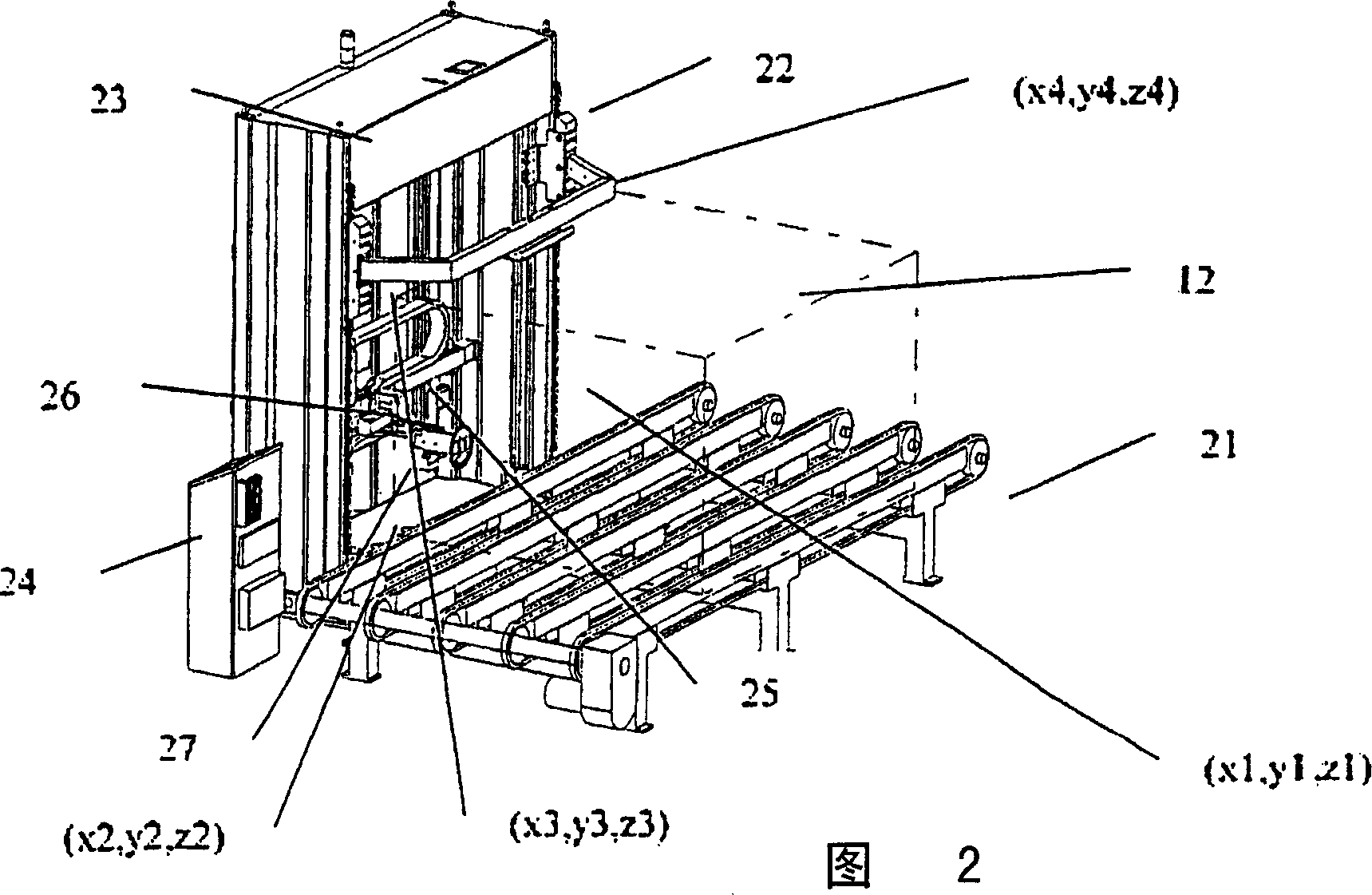

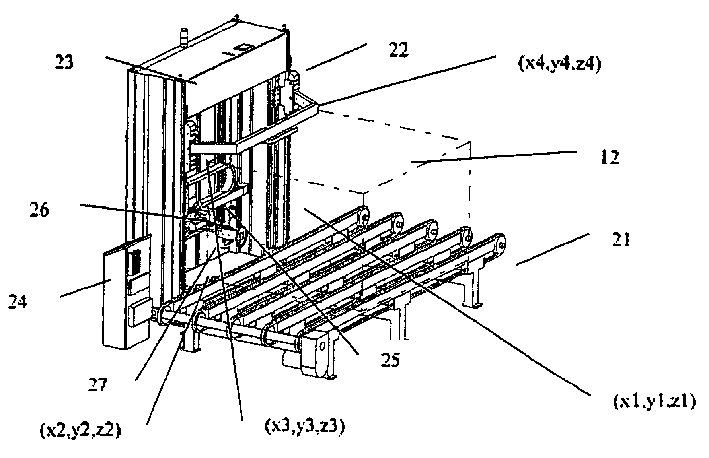

[0011] For example, the plate stack 12 is sent to the measuring and marking station 22 by the chain conveyor 21, wherein as figure 1 Markings are made on the edge of each board as shown. The measuring and marking station comprises a frame part 23, a printing unit 24 for controlling printing, and a system, such as a PLC system (not shown in the figure), for controlling the movable parts of the measuring and marking station. In the frame 23, a guide bar 25 that allows movement in its three main axes x, y, and z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com