Placode treating method and treater

A substrate processing method and substrate technology are applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., and can solve the problems of reducing pure water, increasing consumption of carbon dioxide gas, increasing consumption of pure water, etc. To achieve the effect of reducing consumption and usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

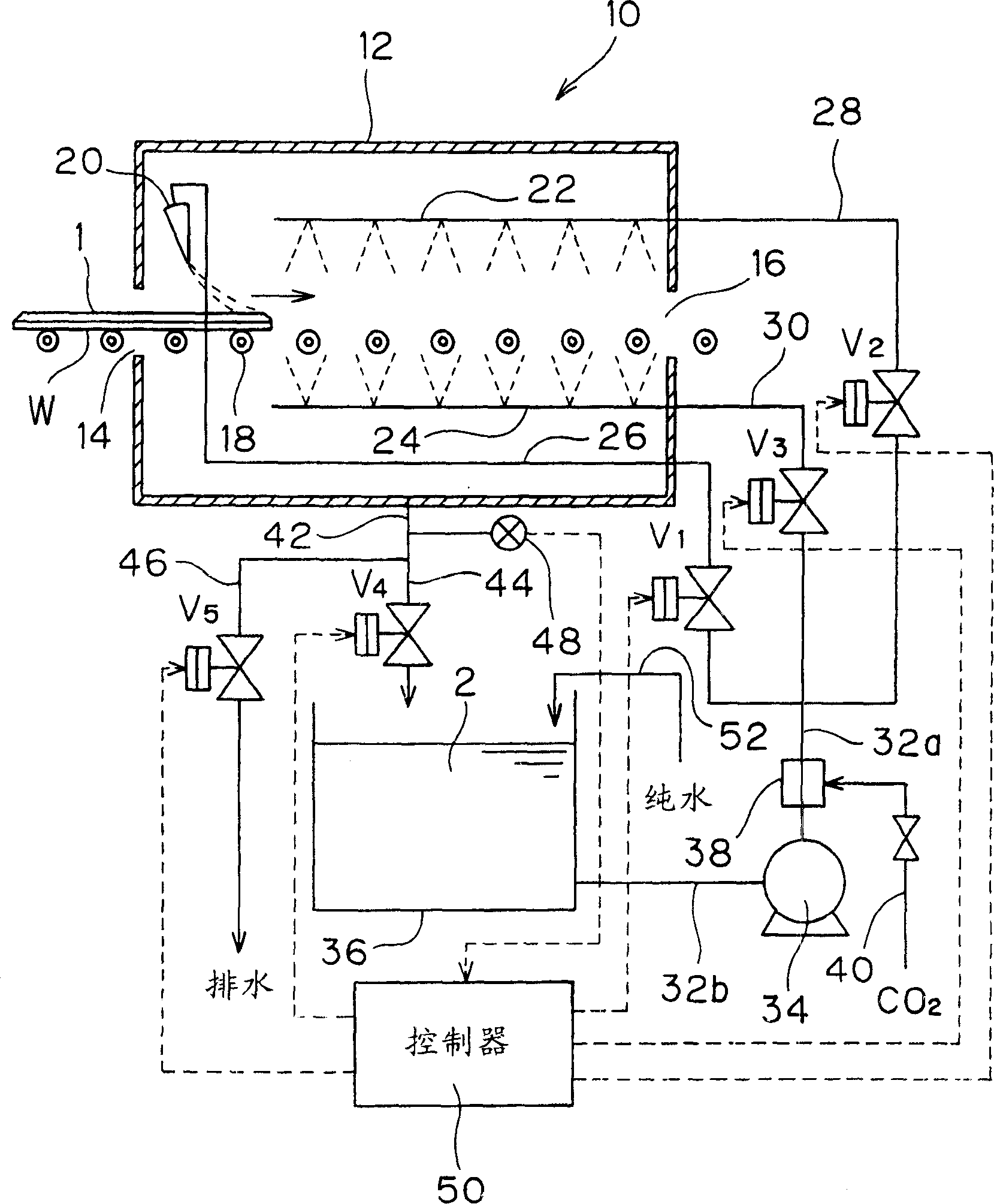

[0028] Below, refer to figure 1 with figure 2 The best embodiment of the present invention will be described.

[0029] figure 1 It shows an example of an embodiment of the present invention, and is a schematic front sectional view showing a schematic configuration of a substrate processing apparatus. In this figure, only the water washing treatment part is shown. A detachment processing unit is provided adjacent to the water rinsing treatment unit 10 on the preceding stage side of the water rinsing treatment unit 10 , but since the detachment treatment unit has been described above, its description is omitted here.

[0030] The water washing treatment unit 10 is equipped with a processing chamber 12 having an inlet-side opening 14 and an outlet-side opening 16. Inside the processing chamber 12, a roller conveyer that supports the substrate W in a horizontal posture or a slightly inclined posture and conveys it horizontally is arranged. Machine 18. The substrate W in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com