Liquid crystal display equipment having digitalized device and its manufacturing method

A technology of equipment and sensors, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems such as inability to set digitizers, decline in equipment quality and output, PCB and TCP are vulnerable to damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings.

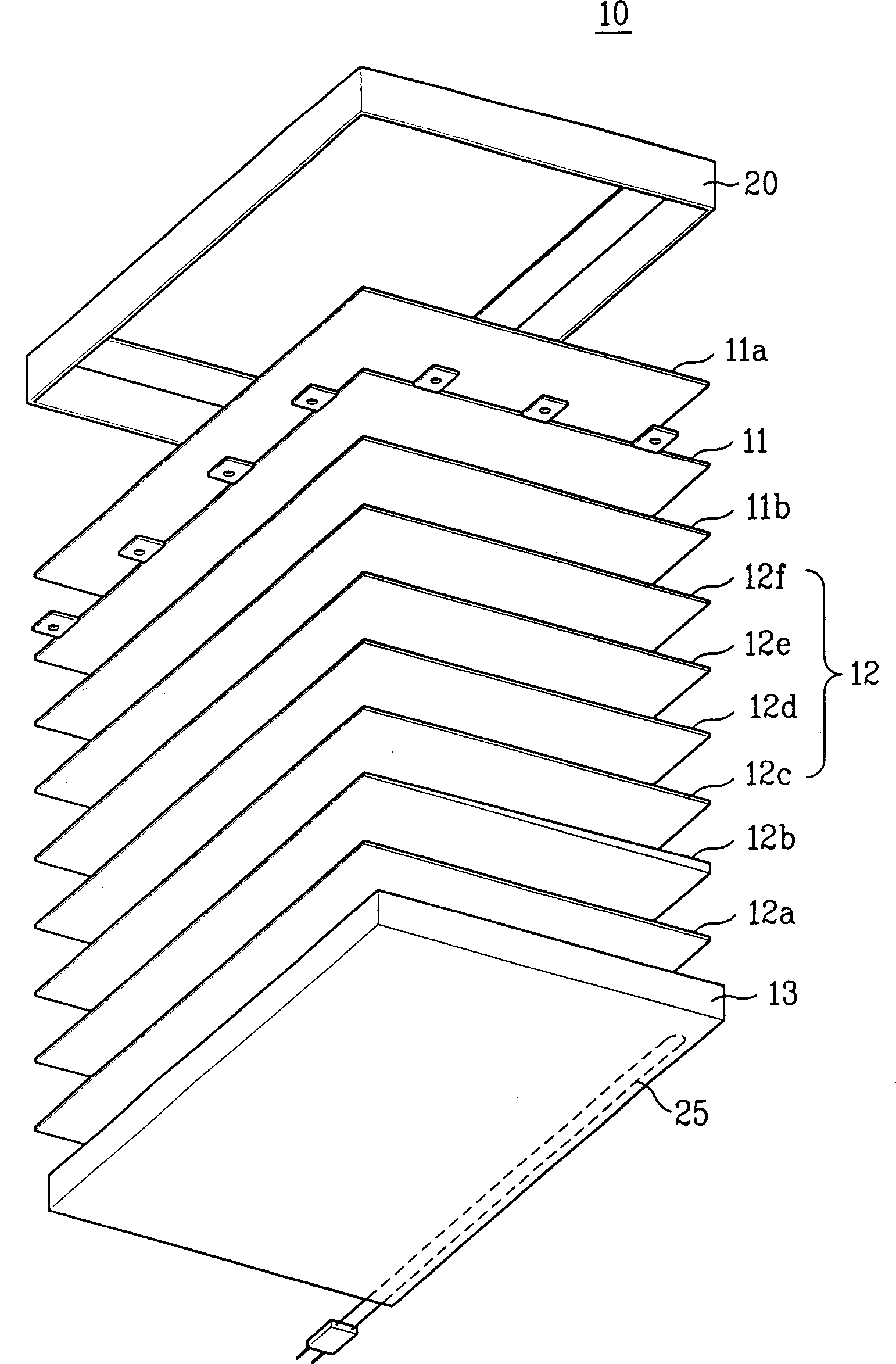

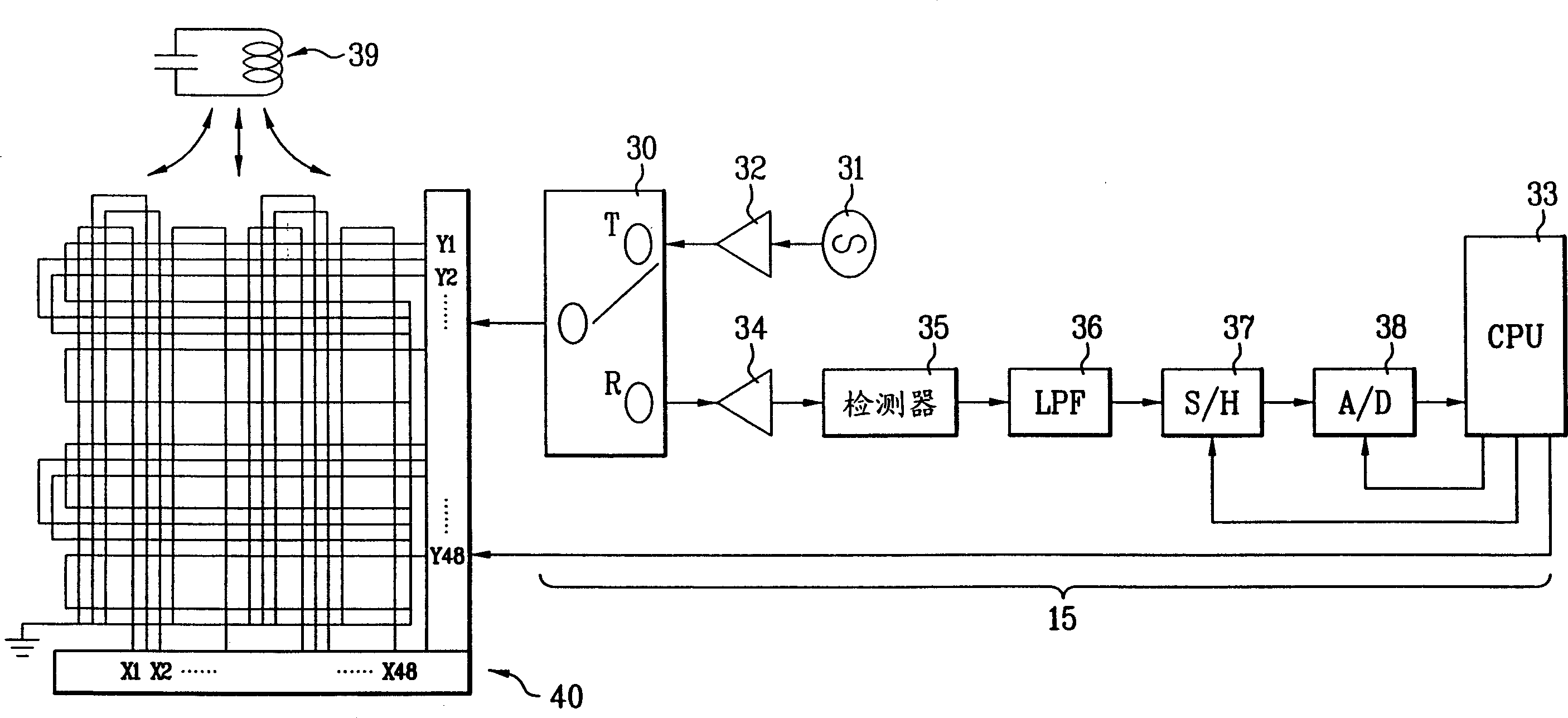

[0040] An LCD device with a digitizer and a method of manufacturing the same according to the present invention will be described below with reference to the accompanying drawings. The LCD device according to the present invention includes a main frame, a lamp, a light frame, and a digitizer, wherein one end of the digitizer is inserted into an opening of the light frame to detect coordinates of a contact point.

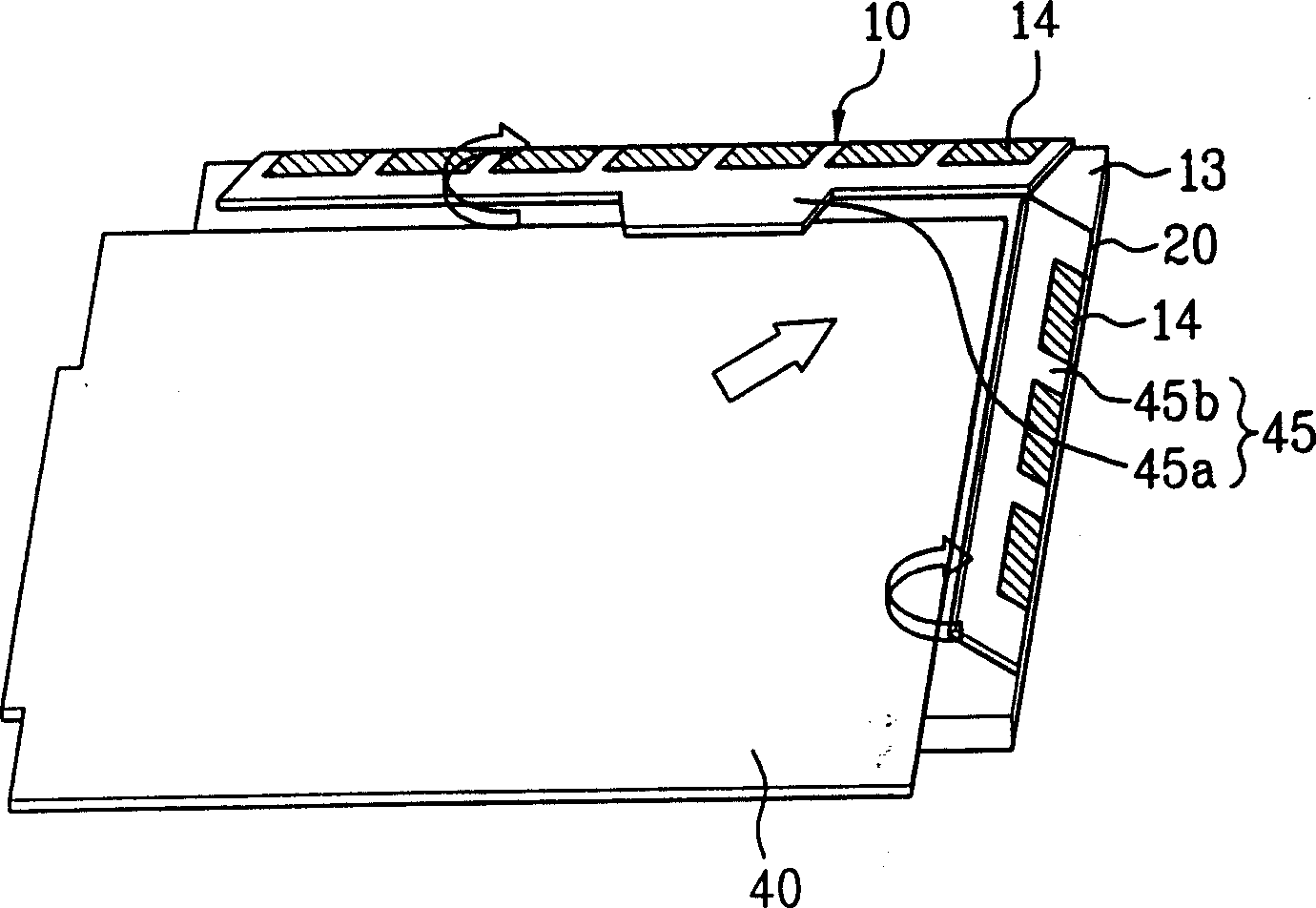

[0041] Figure 4 is a sectional view showing a portion adjacent to a lamp frame 26 of an LCD device having a digitizer 40 according to the present invention. Wherein, the part where the lamp 25 is installed on the main bracket 13 is called the incident part, and the opposite side is called the opposite side incident part.

[0042] Such as Figure 4 As shown, the lamp 25 is arranged on one side of the main bracket 13 along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com