Method for preparing glass stick

A technology for glass rods and glass ingots, which is applied in the field of preparing glass rods, and can solve problems such as poor economy and moisture removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

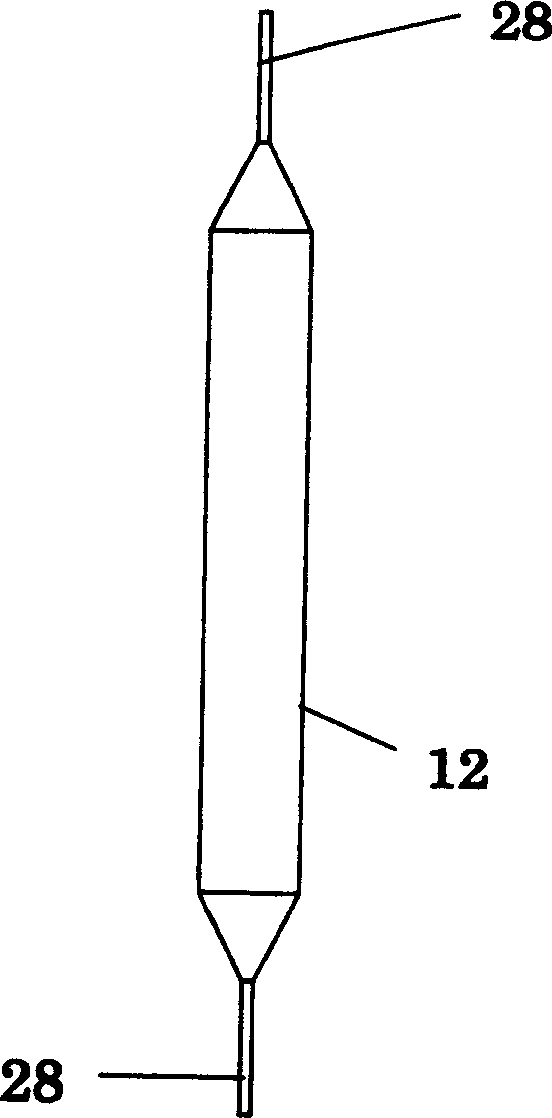

[0041] Using an external cylindrical grinder, the fused silica glass substrate was ground into a cylinder having an outer diameter of 130 mm by using a grinding stone of fixed grain size #200, thereby providing a cylindrical glass substrate 12 .

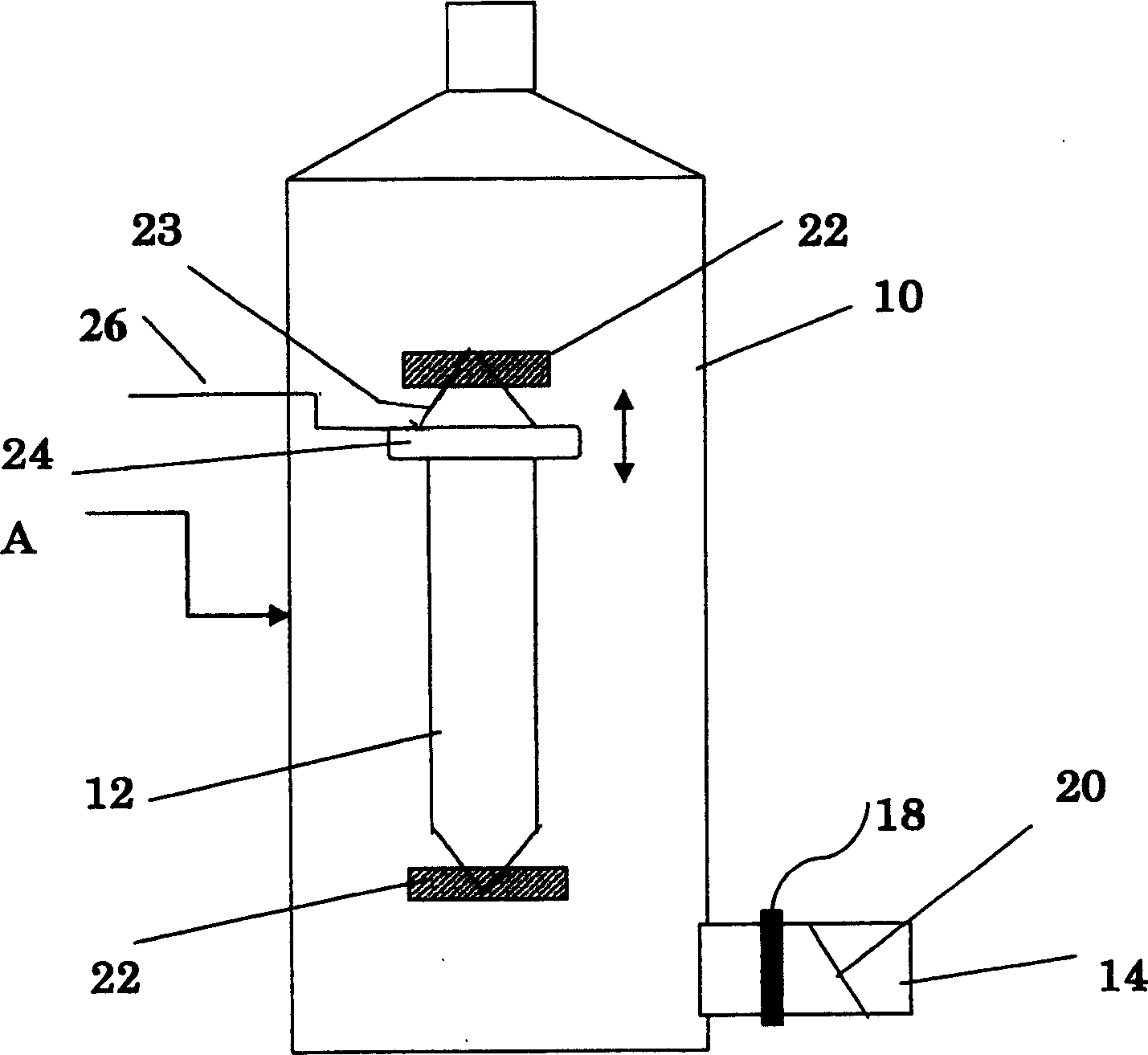

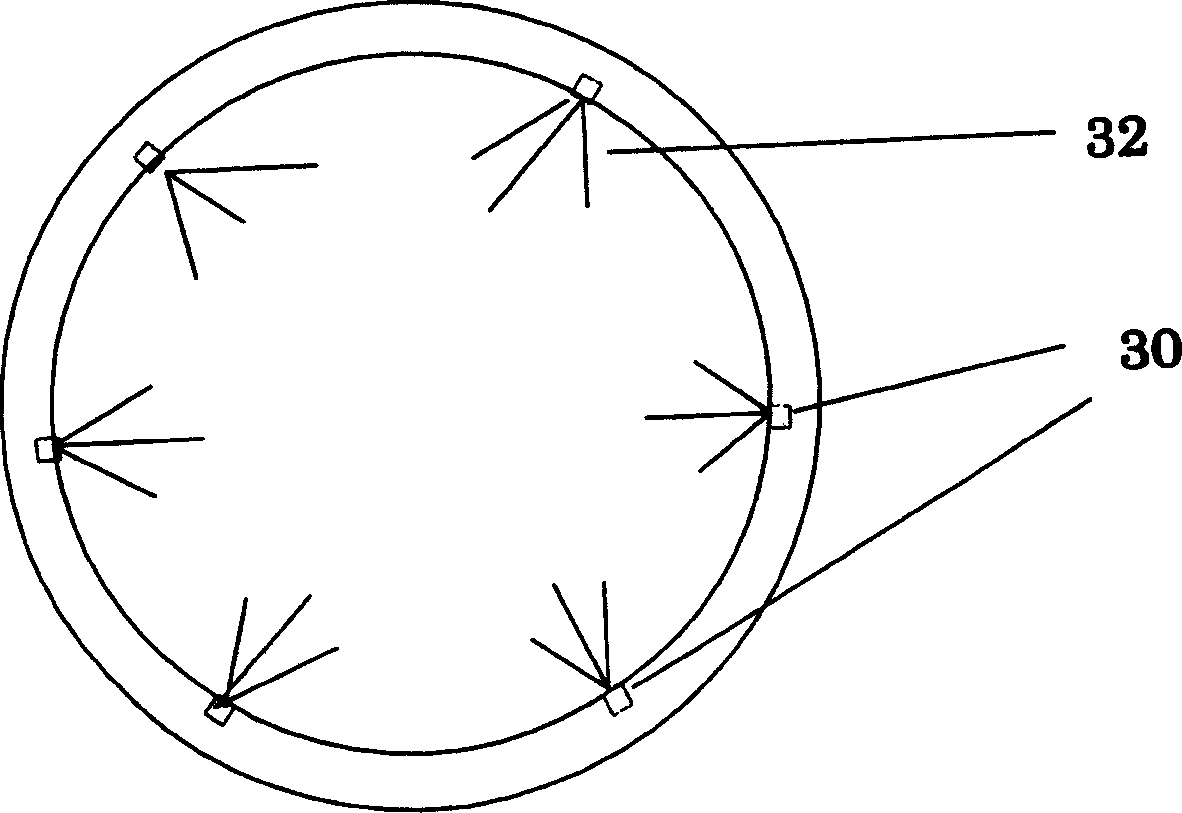

[0042] Next, the glass substrate 12 is placed on figure 1 Cleaning equipment A of the type shown. The cleaning apparatus A has 8 nozzles 26 aimed at the glass substrate, and the distance between them is set at 100 mm. The steam nozzle unit 26 was reciprocated 10 times at a moving speed of 2500 mm / min, and steam of 0.4 MPa was sprayed from the nozzle unit to the glass substrate 12 to clean the surface thereof. The consumption of steam is 42kg / hour.

[0043] Then, clean air was supplied to the cleaning device A from the air inlet 14 for 2 minutes. The supply of clean air is controlled by the control valve 20 , the air is passed into the apparatus A through the filter 18 , and after drying the surface of the glass substrate 12 , is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com