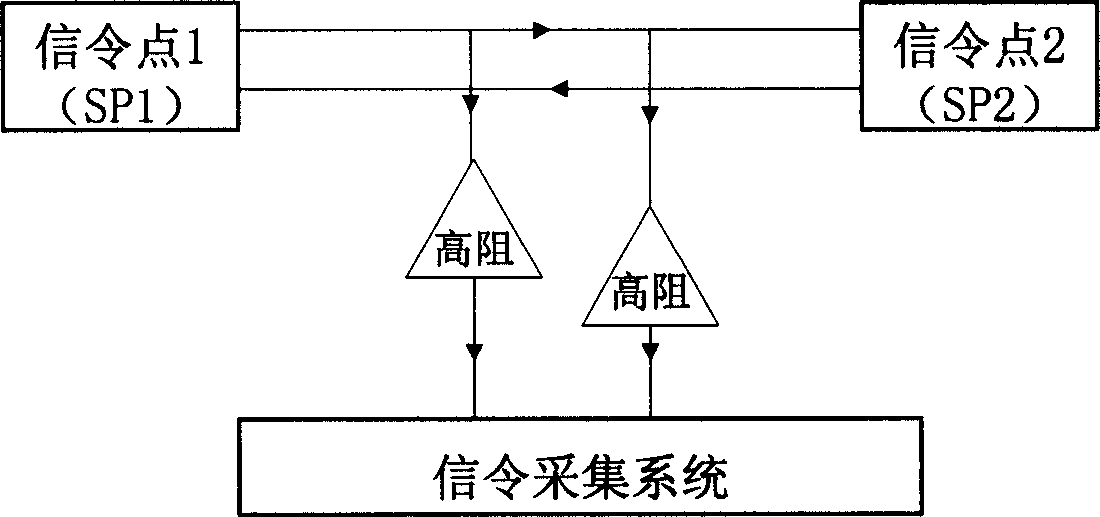

High impedance isolation device in signalling monitoring system

A monitoring system and high-resistance isolation technology, applied in transmission systems, selection devices, line transmission monitoring/testing, etc., can solve problems such as inability to transmit far, large signal loss, and easy oscillation, so as to extend transmission distance and improve high performance. resistance performance, reducing the effect of current shunt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

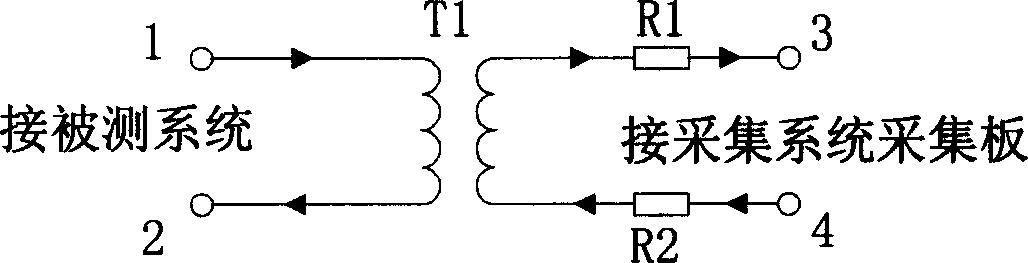

[0012] figure 1 and figure 2 It has already been explained in the background art.

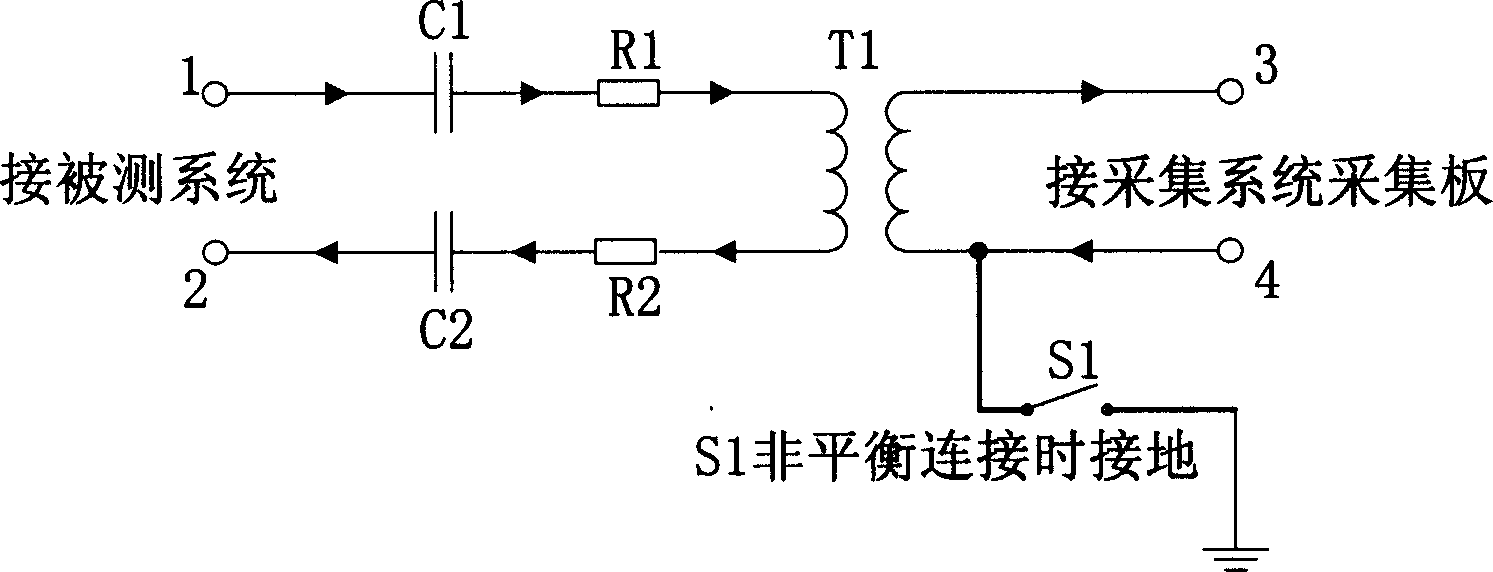

[0013] image 3 It is a schematic structural diagram of the high-resistance isolation device proposed by the present invention. like image 3 As shown, the high-impedance isolation device proposed by the present invention includes a coupling coil T1, two resistors R1 and R2 with the same resistance value; and two capacitors C1 and C2 with the same capacitance value; one end of the capacitor C1 is connected to the measured system, the other end is sequentially connected in series with the resistor R1, the positive and negative poles of the original terminal of the coupling coil T1, the resistor R2, and the capacitor C2, and then connected to the system under test; the positive and negative poles of the coupled output terminal of the coupling coil T1 are con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance value | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com