One-step forming process of inner automobile door decorating board with soft stuffing

A technology of filling material and molding method, which is applied in the field of one-time molding of automobile door interior panels, can solve the problems of complicated operation and long labor time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

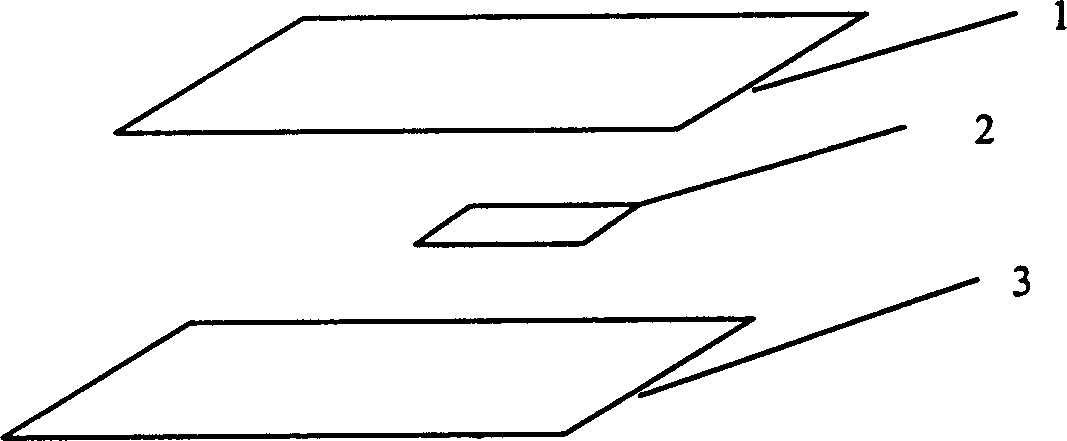

[0016] The drawings illustrate a preferred embodiment of the molding process according to the present invention.

[0017] See first figure 1 The door trim panel of the present invention is composed of three layers, including a substrate (wood powder board) 3, a surface decoration material 1 and a soft filling material 2 between the two, and only the armrest pad is added The soft filling material 2.

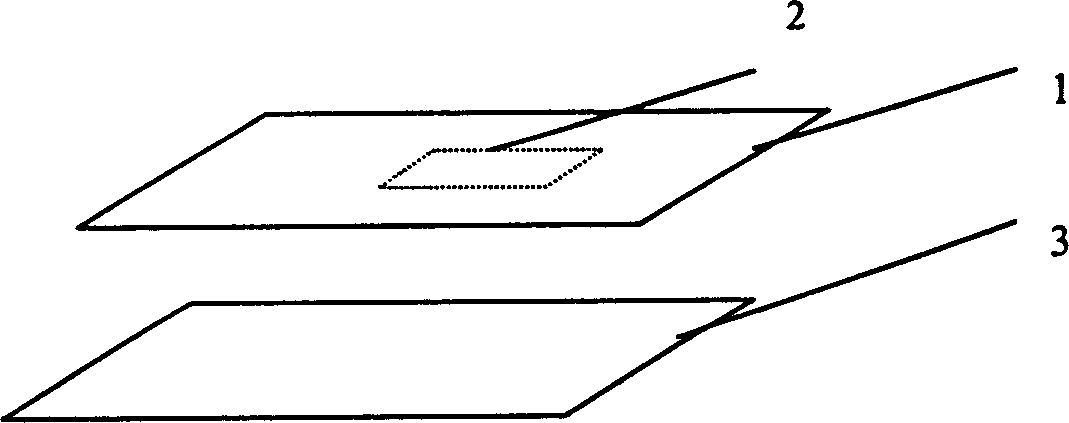

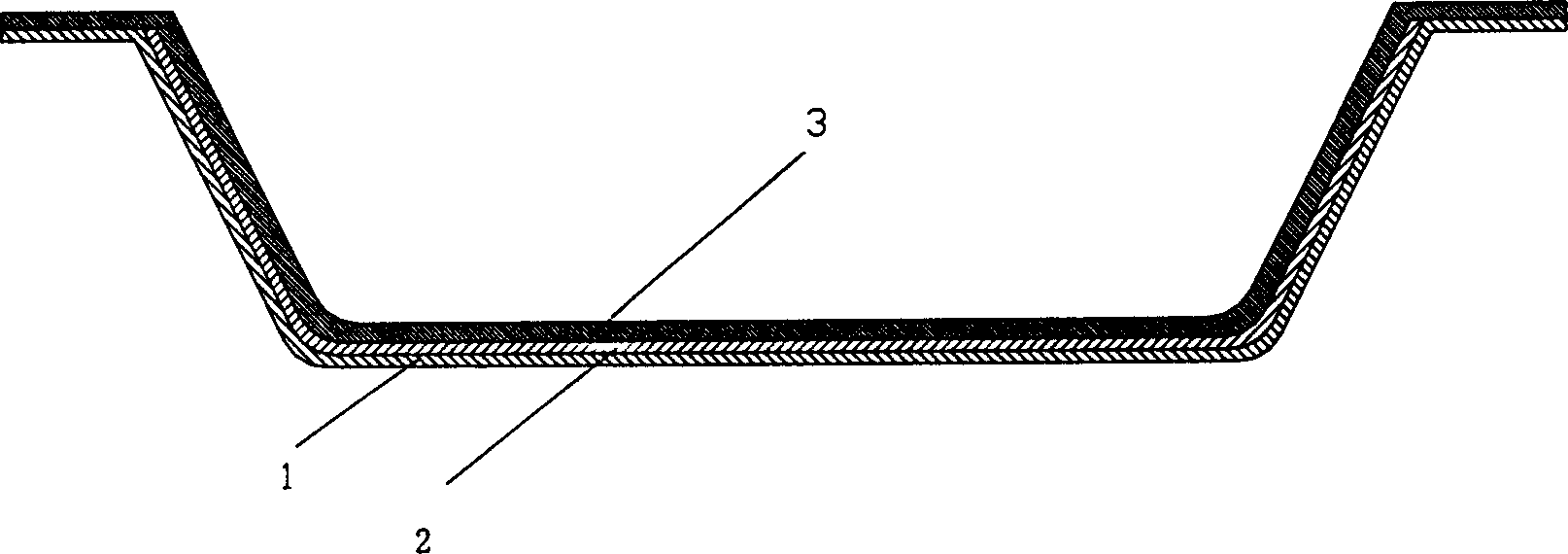

[0018] The method of the present invention includes the following steps: In the first step, the soft filling material 2 is pasted on the preset position on the back of the surface decoration material 1 (such as figure 2 Schematic), that is, select a soft filling material 2 with a certain thickness and good resilience, then stretch and unfold it, and bond it to the back of the surface decoration material 1; the second step is to position the surface decoration material 1. Put the surface decoration material 1 with the unbonded soft filling material 2 upwards into the upper mold of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com