Resin sheet having hair-like bodies, and molded article of resin sheet having hair-like bodies

A resin sheet and trichome technology, applied in the field of resin sheet and its molded products, can solve the problems of lack of light transmission, complicated manufacturing process, increased hole processing or embossing processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

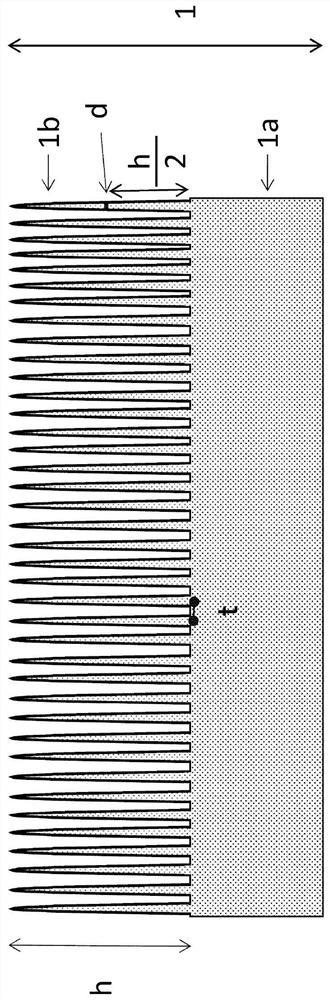

[0027] The resin sheet according to the first embodiment of the present invention is a resin sheet having trichomes regularly arranged on at least one side of the base layer, having no structural boundary between the base layer and the trichomes and forming a continuous phase, wherein , the average height of the trichomes is 30 μm or more and 500 μm or less, the total light transmittance of the above-mentioned resin sheet measured according to JIS K 7136-1 is 0.1% or more and 20% or less, and the concealment rate measured according to JIS K 5600 4-1 It is 70% or more and 98% or less.

[0028]

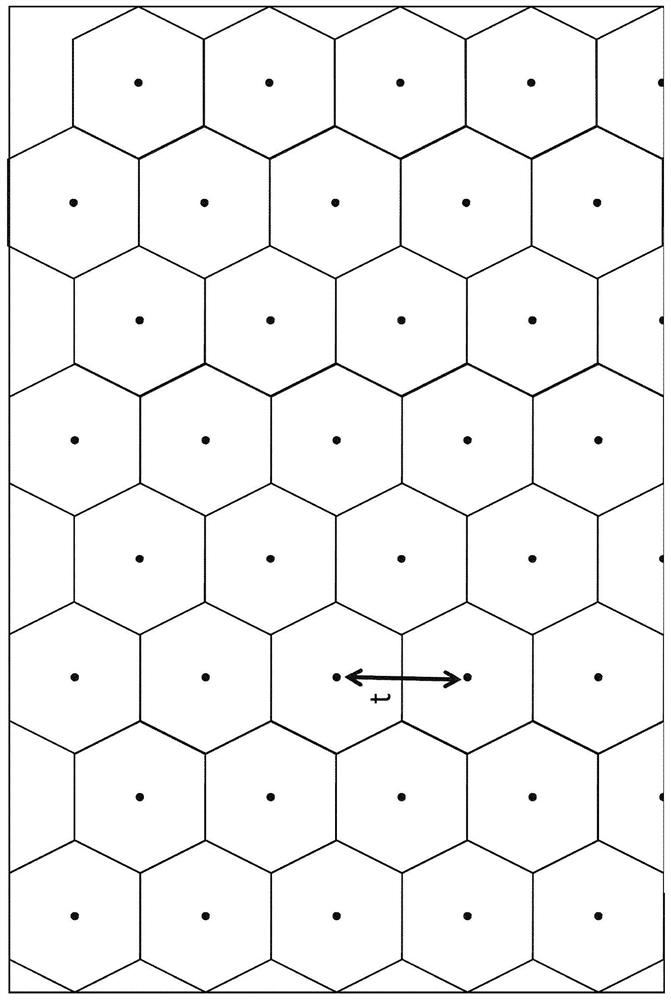

[0029] The basal layer (1a) is the layer that becomes the base of the trichome, figure 1 In the shown reference numeral 1, it means the part other than the surface trichome 1b. The thickness of the basal layer refers to the thickness from the root of the trichome to the surface on the opposite side of the basal layer. The average thickness of the base layer is preferably 15 μm-1000 ...

no. 2 approach

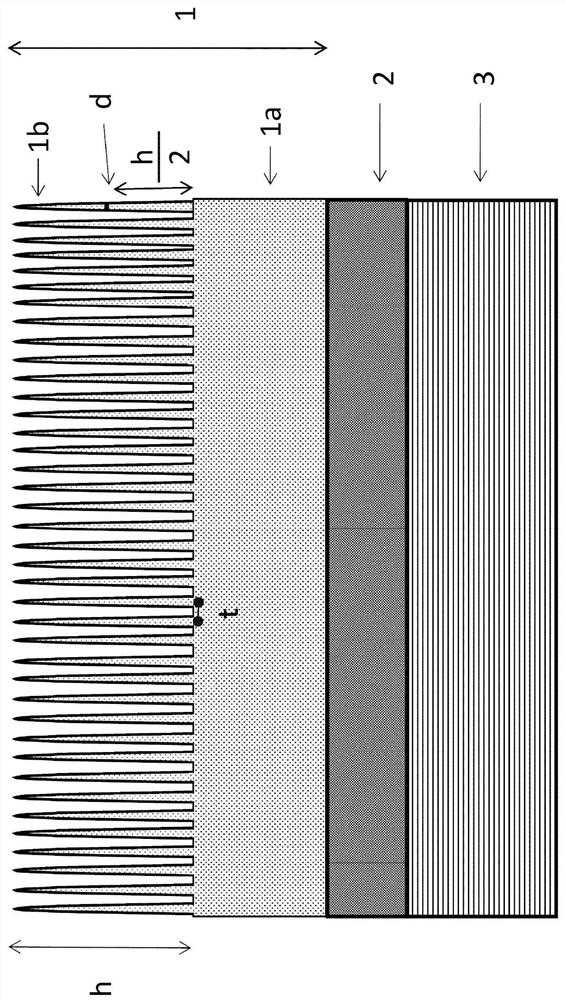

[0073] As an example of the resin sheet related to the second embodiment of the present invention, such as image 3 Shown is a resin sheet in which a sealant resin layer ( 2 ) is formed between a base layer ( 1 a ) and a base material layer ( 3 ). That is, the layer configuration of the resin sheet according to the second embodiment is, from top to bottom, wool and base layer (1), sealant resin layer (2), and base material layer (3). Here, the trichomes are the same as those described in the first embodiment, so description thereof will be omitted. However, the thickness of the trichomes and the base layer expressed as the sum of the average height of the trichomes and the average thickness of the base layer is preferably 115 to 900 μm. By setting it to 115 μm or more, good touch can be ensured, and by making it 900 μm or less, production cost can be reduced.

[0074]

[0075] The base layer is preferably a thermoplastic resin such as styrene-based resin, olefin-based resi...

no. 3 approach

[0092] The resin sheet related to the third embodiment of the present invention is such as Figure 4 As shown, the sealant resin layer ( 2 ) shown in the second embodiment is not used, but the hairs and the base layer ( 1 ) are directly laminated on the base material layer ( 3 ). That is, the layer constitution of the resin sheet according to the third embodiment is hair-like body and base layer (1) / base layer (3) from top to bottom, and has layer composition. Here, the trichomes and the base layer are the same as those in the first embodiment and the second embodiment, and therefore description thereof will be omitted. On the other hand, it is preferable that the base material layer (3) in this embodiment has sufficient adhesiveness with a base layer.

[0093] Moreover, in the resin sheet which concerns on 3rd Embodiment, it is preferable to use the thermoplastic resin excellent in the adhesiveness with a base layer as a base material layer. For example, when the base laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com