Pattern production system, exposure system, and exposure method

A manufacturing system and exposure device technology, which is applied in the direction of photolithography exposure device, radiation-sensitive mask exposure method, printed circuit manufacturing, etc., can solve the problem that the developer or etching solution is slowly degraded, cannot be ignored, and cannot inhibit the finished product Deviation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

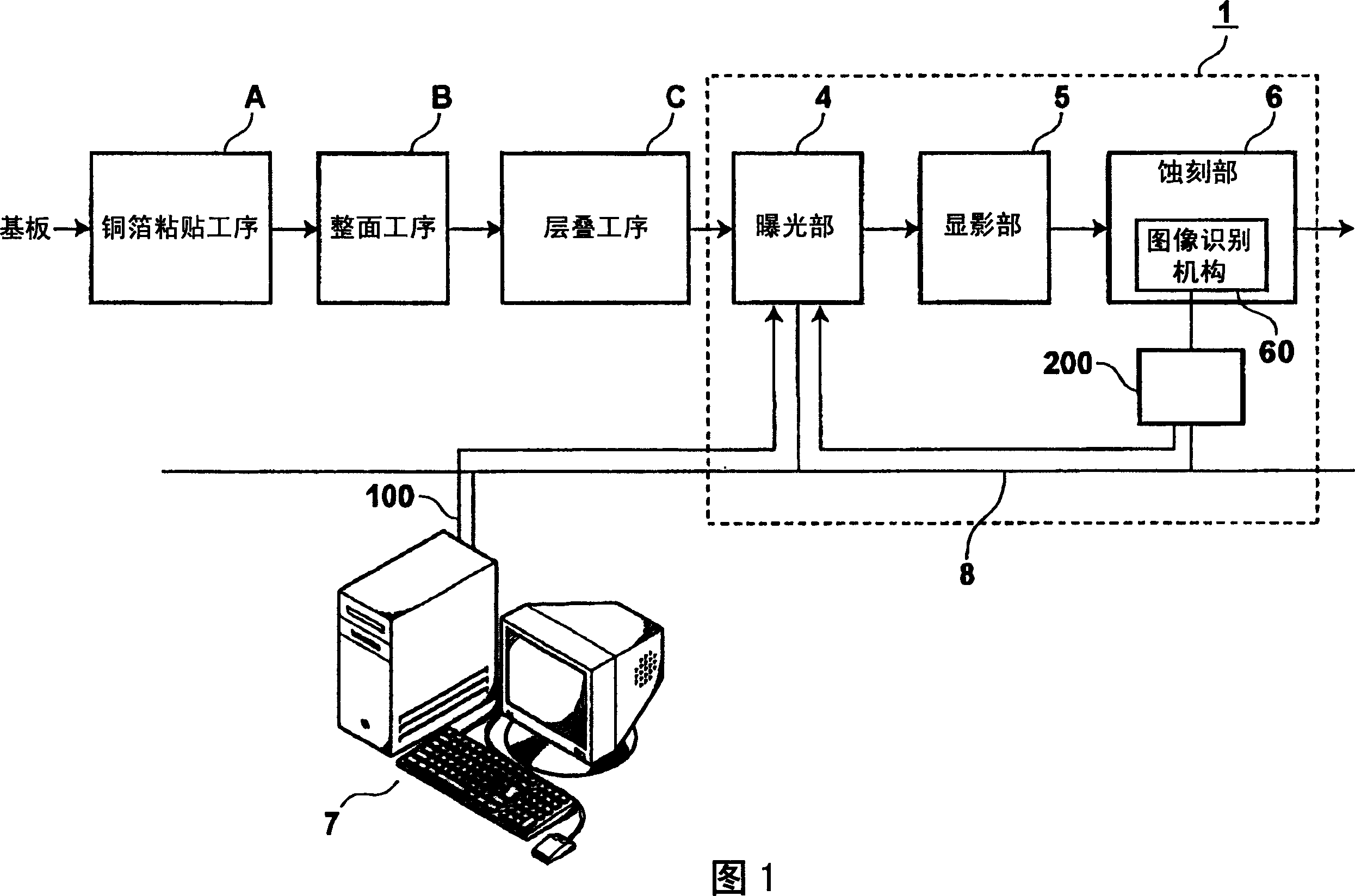

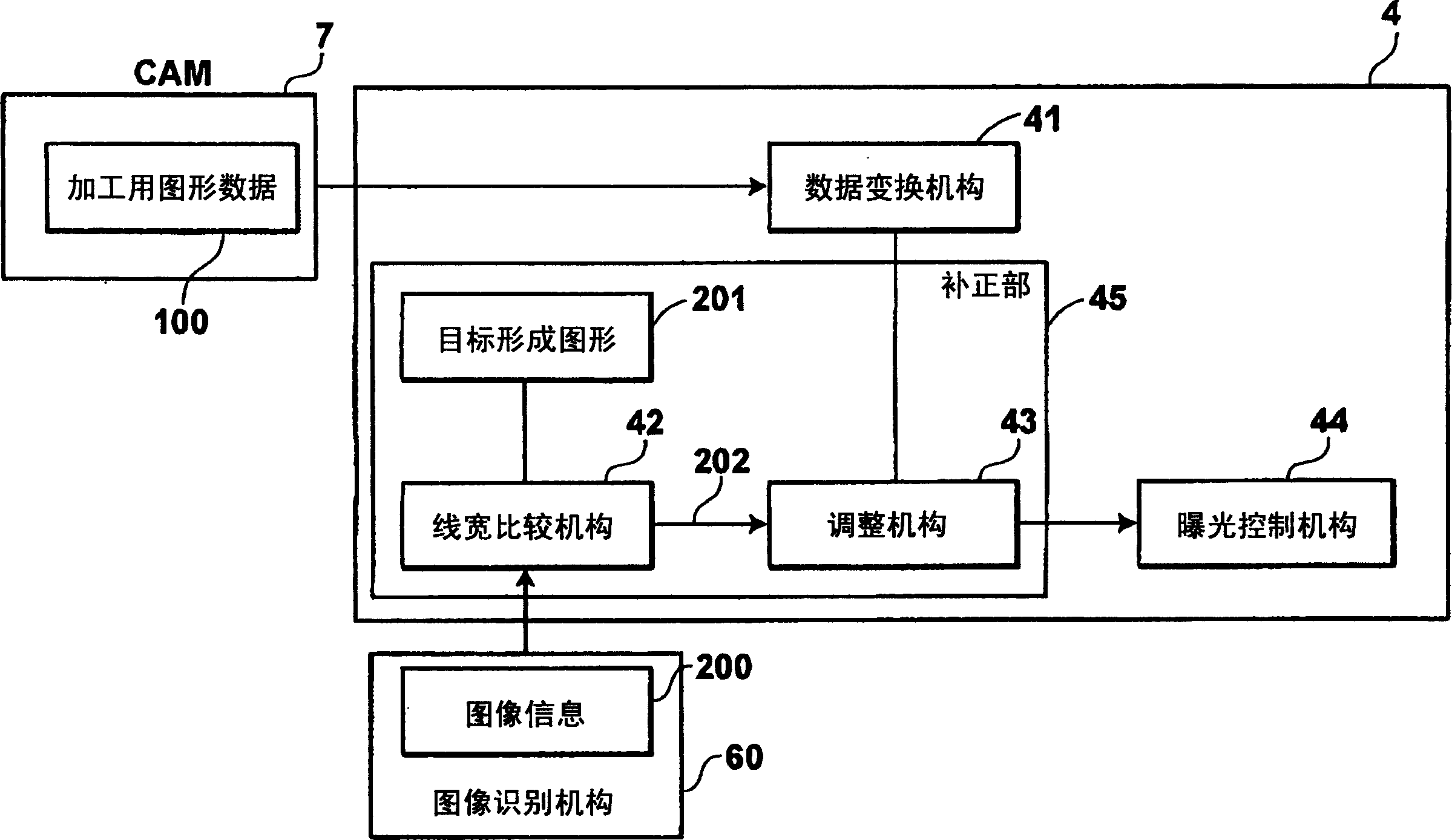

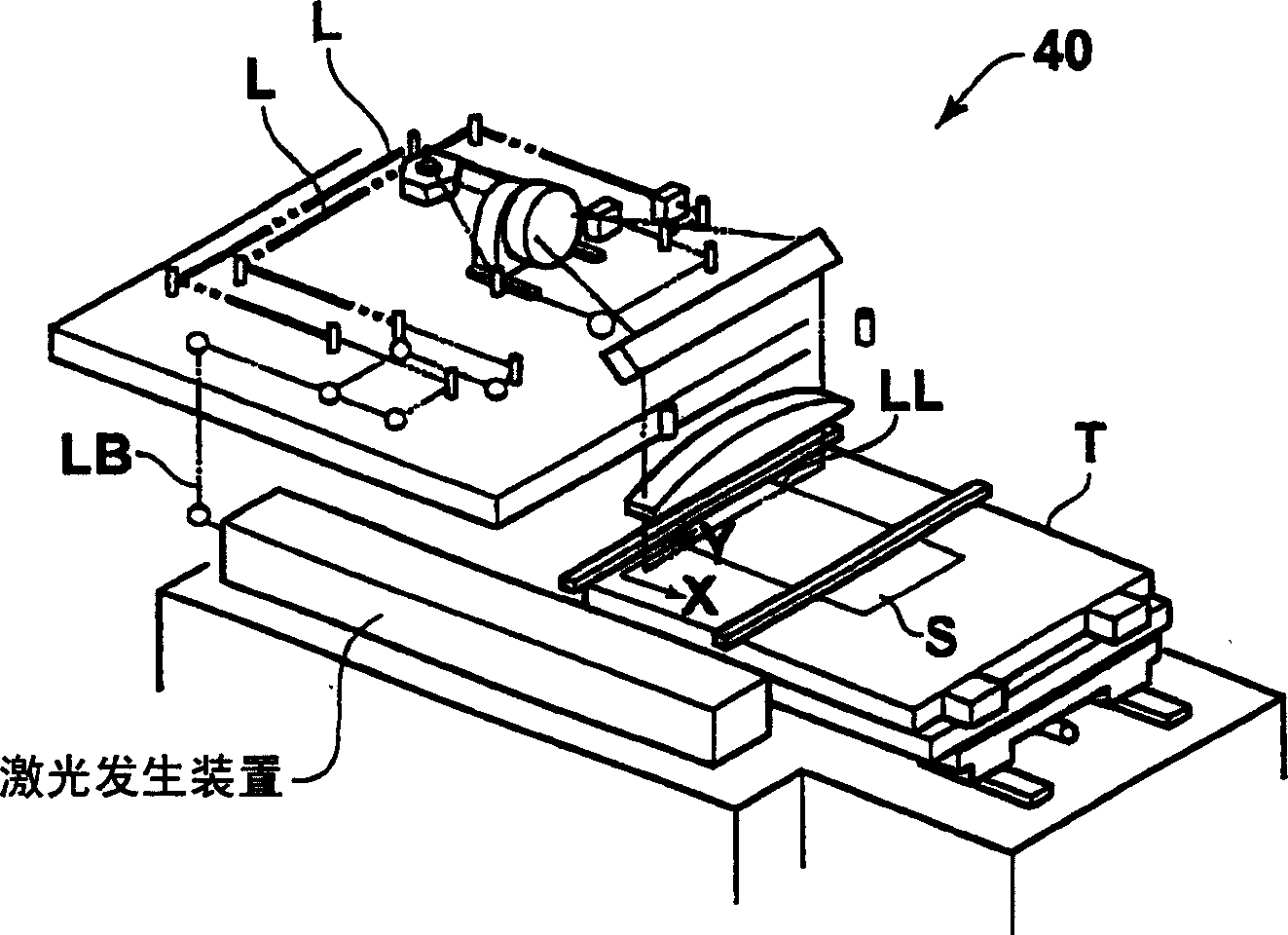

[0116] Hereinafter, a first embodiment of the pattern creation system of the present invention will be described with reference to the drawings.

[0117] FIG. 1 is a diagram showing a first embodiment of a pattern manufacturing system, and a case where a circuit pattern as an example of a formed pattern is manufactured by the pattern manufacturing system 1 will be described. When forming a circuit pattern on a substrate, first, in the copper foil pasting process A, copper foil as a circuit forming material is pasted on the substrate, and in the surface preparation process B, the surface of the pasted copper foil is mechanically polished or chemically polished. The upper surface is subjected to surface treatment, and in the lamination step C, a resist (resist material) is laminated on the entire surface of the copper foil upper surface. Secondly, by the pattern manufacturing system 1 of the present invention, the resist coated on the substrate is exposed, and the exposed resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com