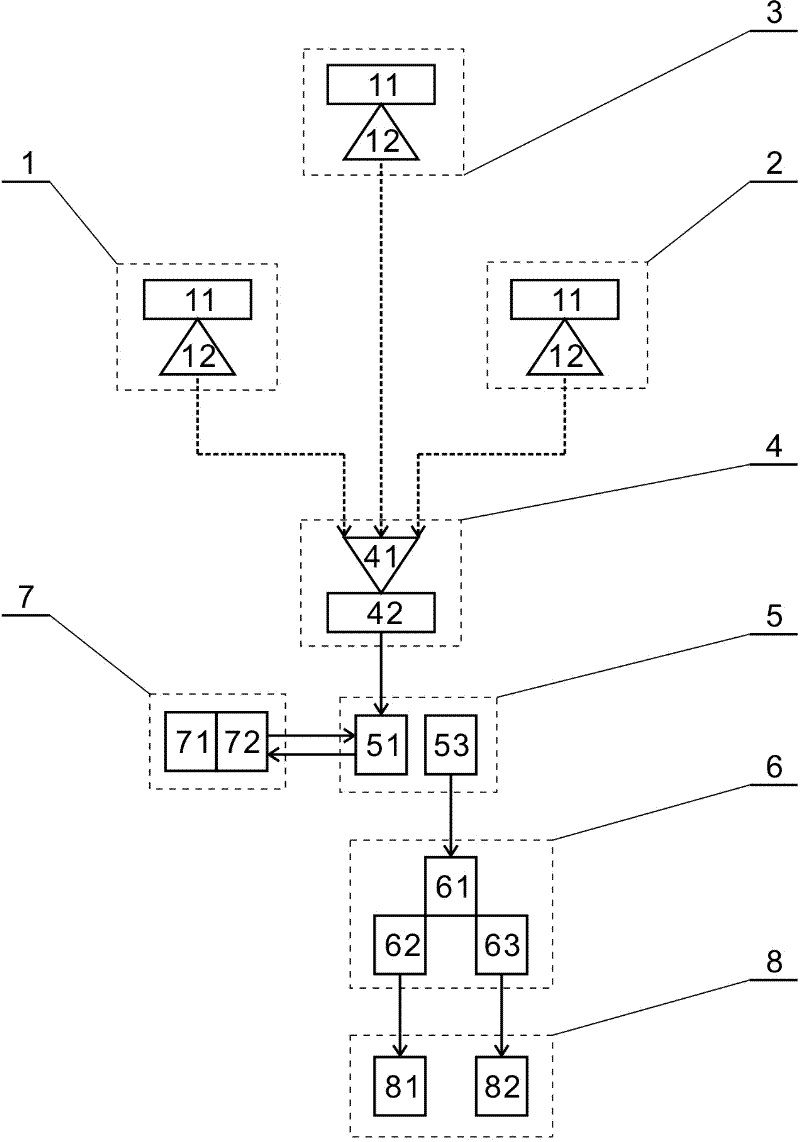

Patents

Literature

34results about How to "Appropriate correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

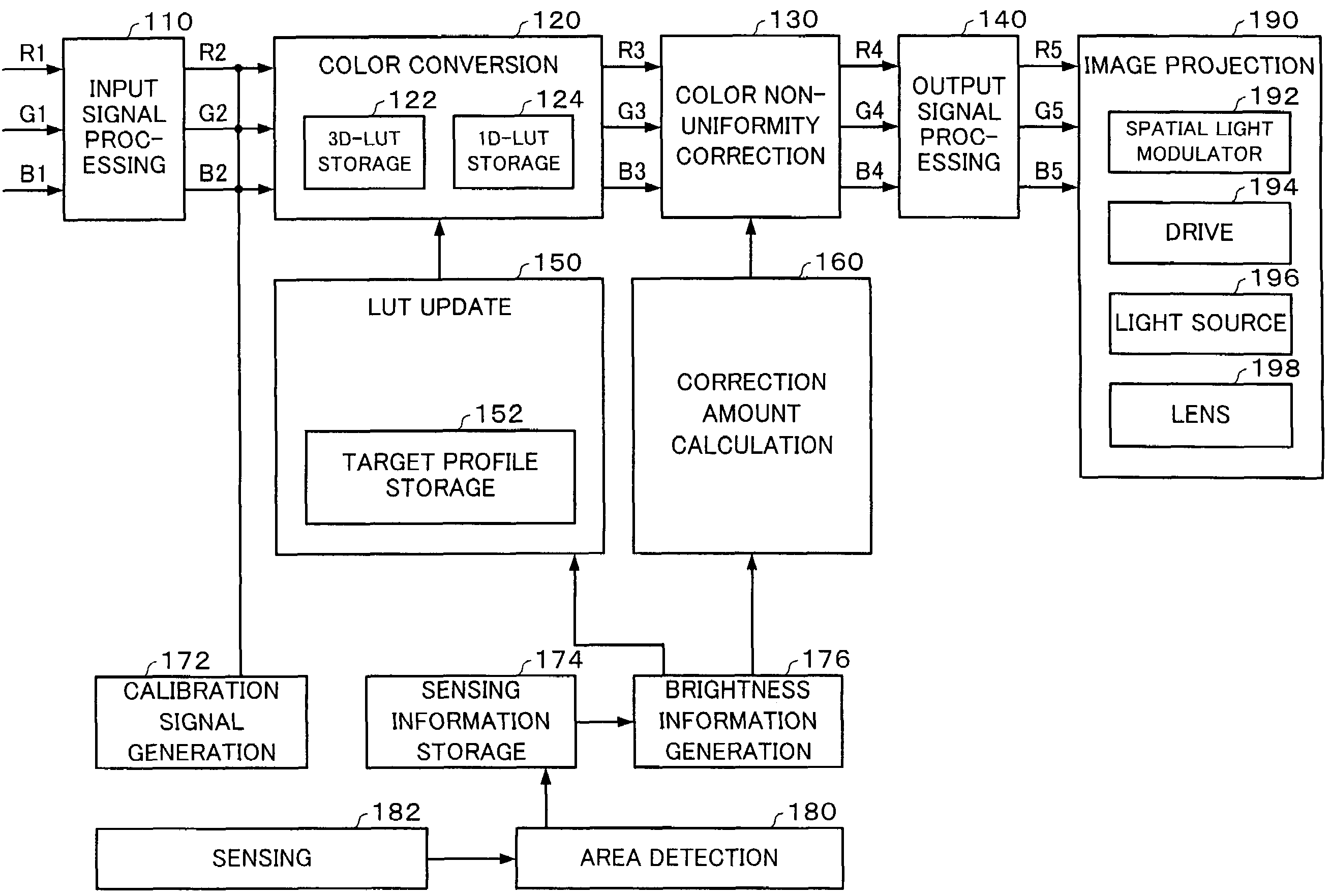

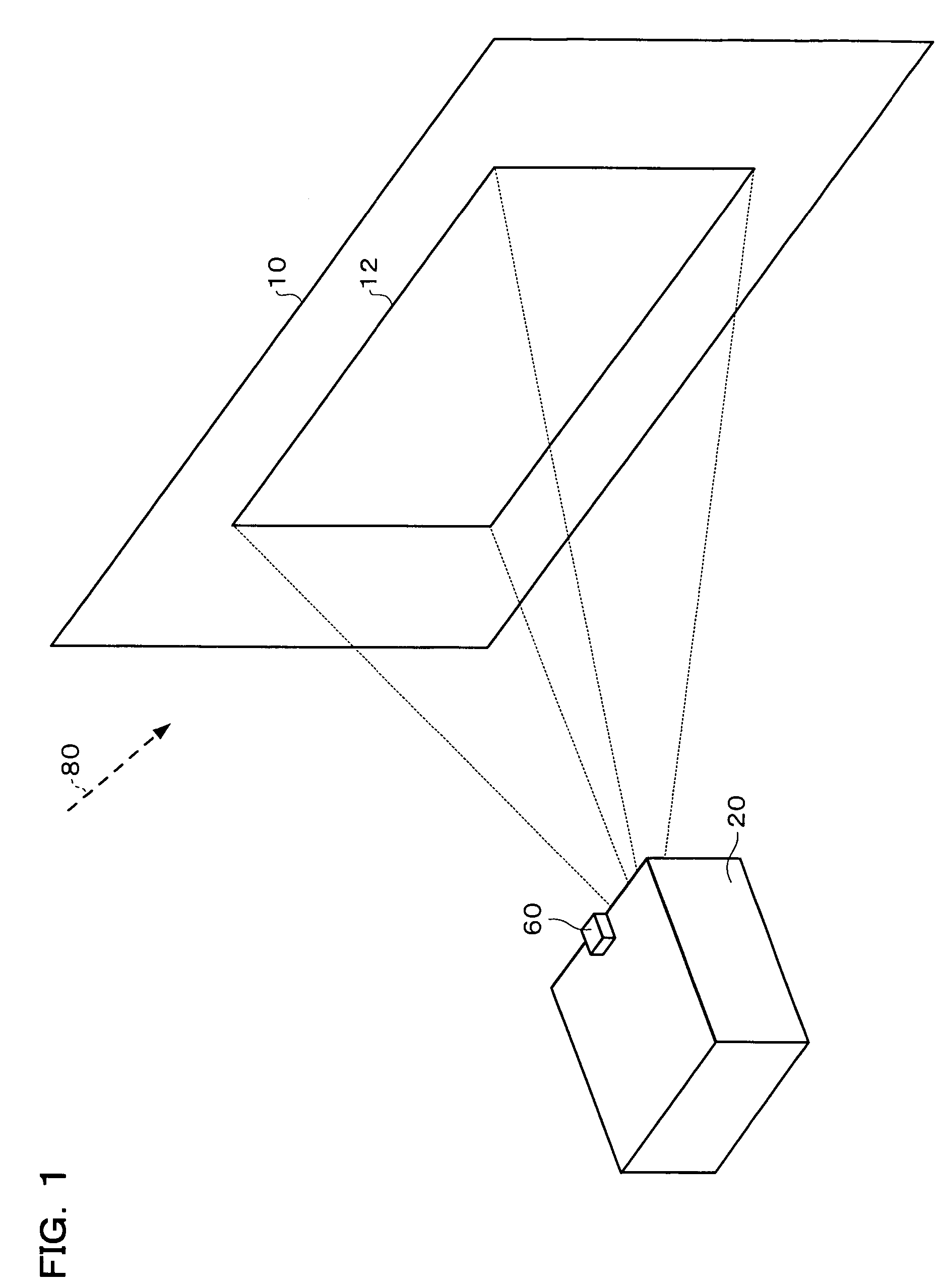

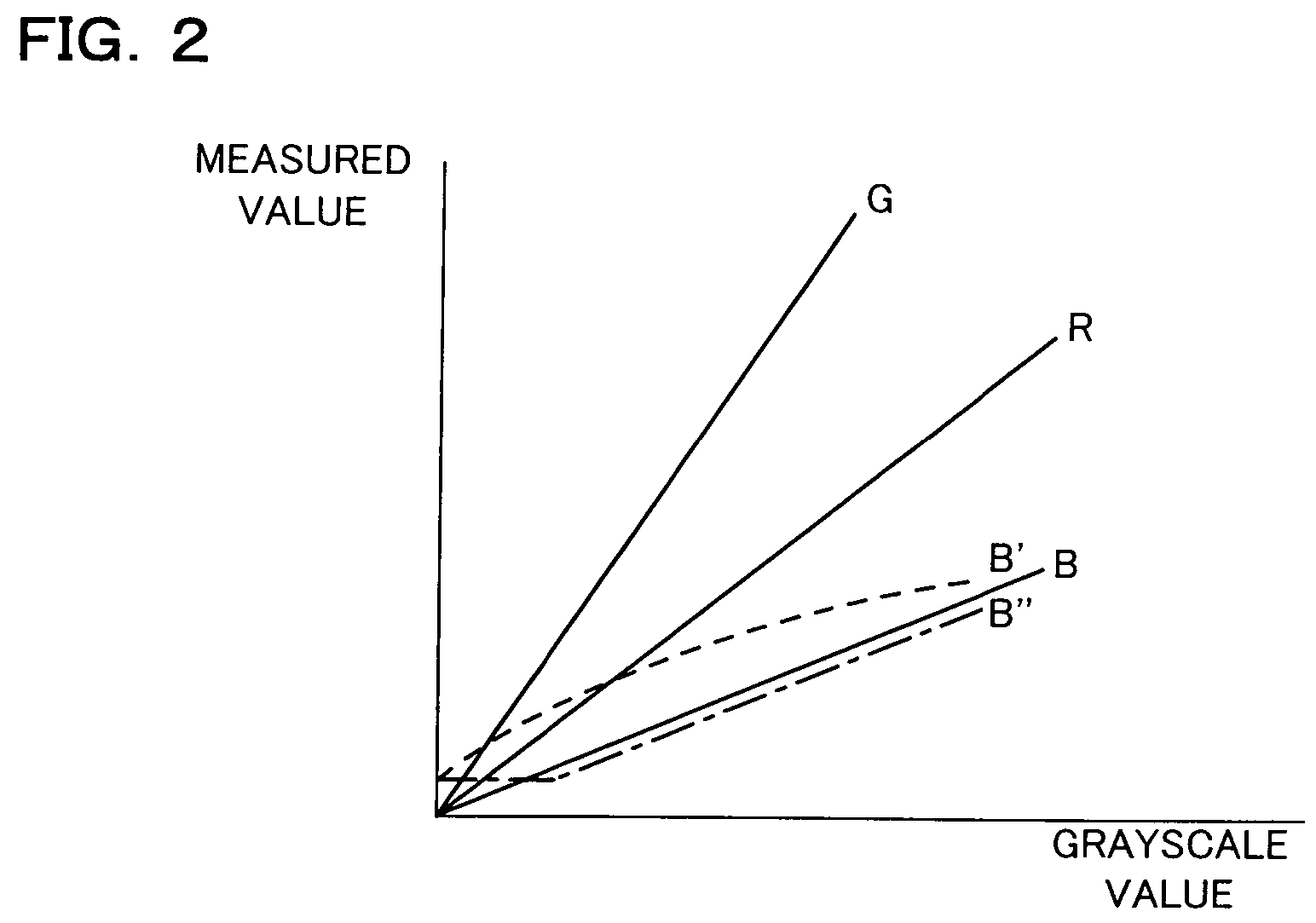

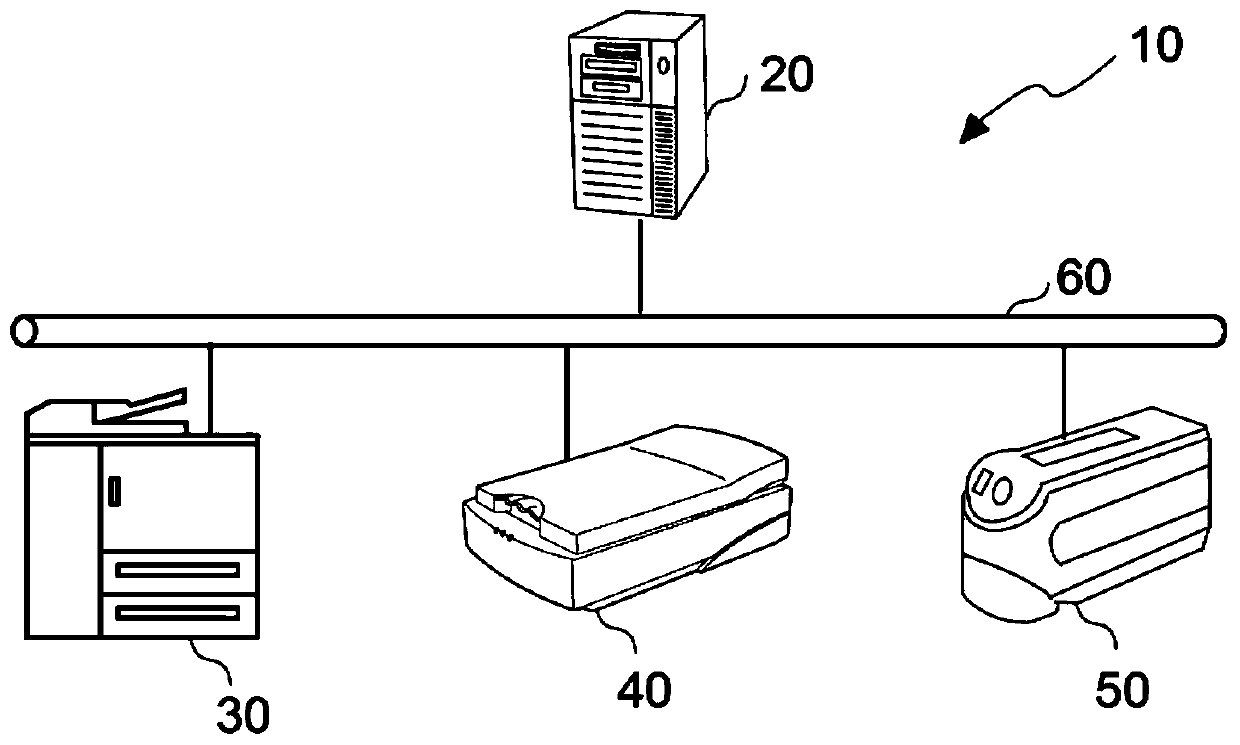

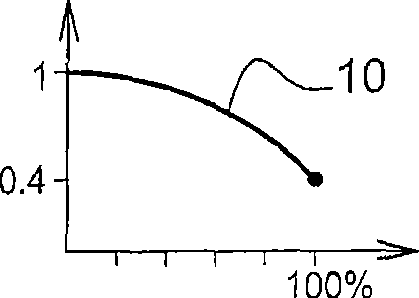

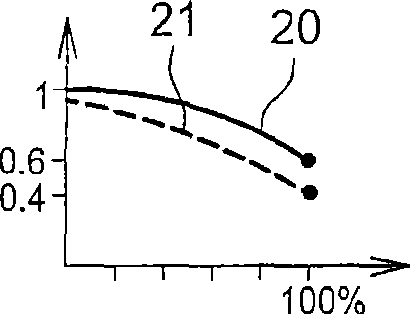

Image processing system, projector, program, information storage medium, and image processing method

ActiveUS7170535B2Deteriorate with timeAppropriate correctionSuture equipmentsColor signal processing circuitsRegion detectionInput/output

In order to provide an image processing system that can correct color non-uniformity due to deterioration with time in a more appropriate manner, a projector is provided with an image projection section which displays a calibration image; a sensing section which senses the displayed calibration image; an area detection section which detects an image display area based on sensing information, and also divides the image display area into a plurality of target areas; a brightness information generation section which generates brightness information which indicates an average brightness index value within each of the target areas that have been divided by the area detection section, based on the sensing information; a correction amount calculation section which calculates a correction amount for input-output characteristic data from each of the target areas, based on the brightness information; and a color non-uniformity correction section which corrects color non-uniformity of the image, based on input-output characteristic data that has been corrected based on the correction amount.

Owner:SEIKO EPSON CORP

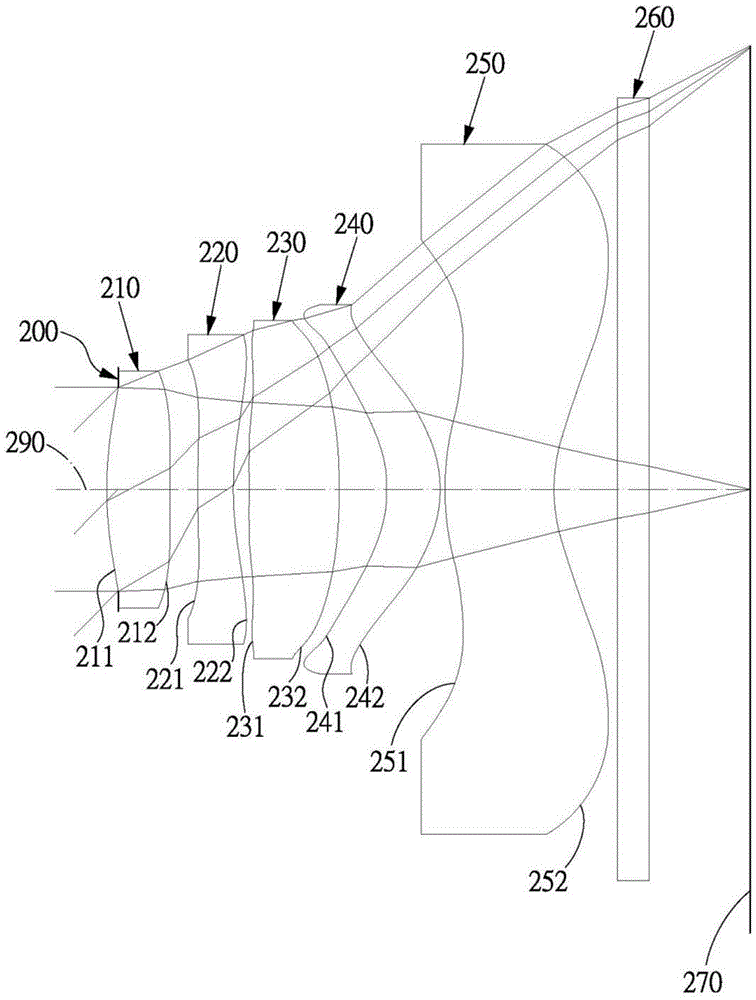

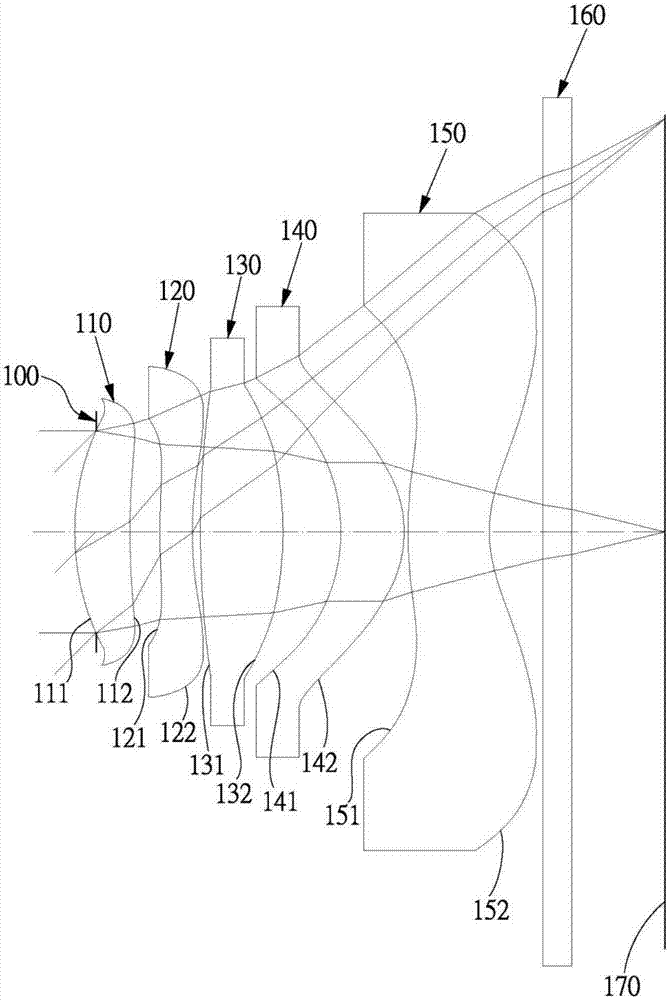

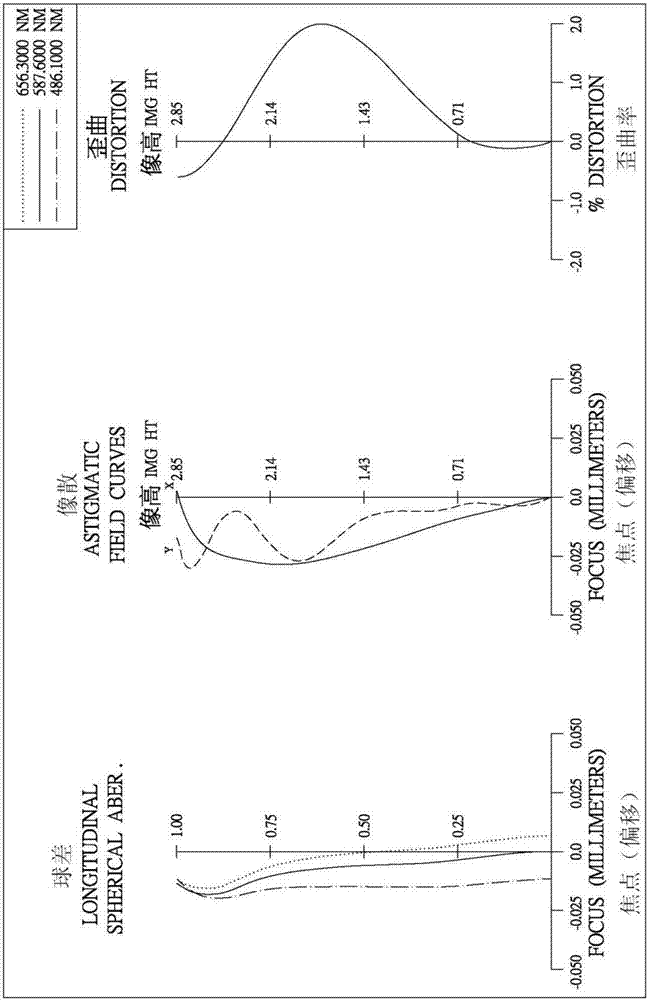

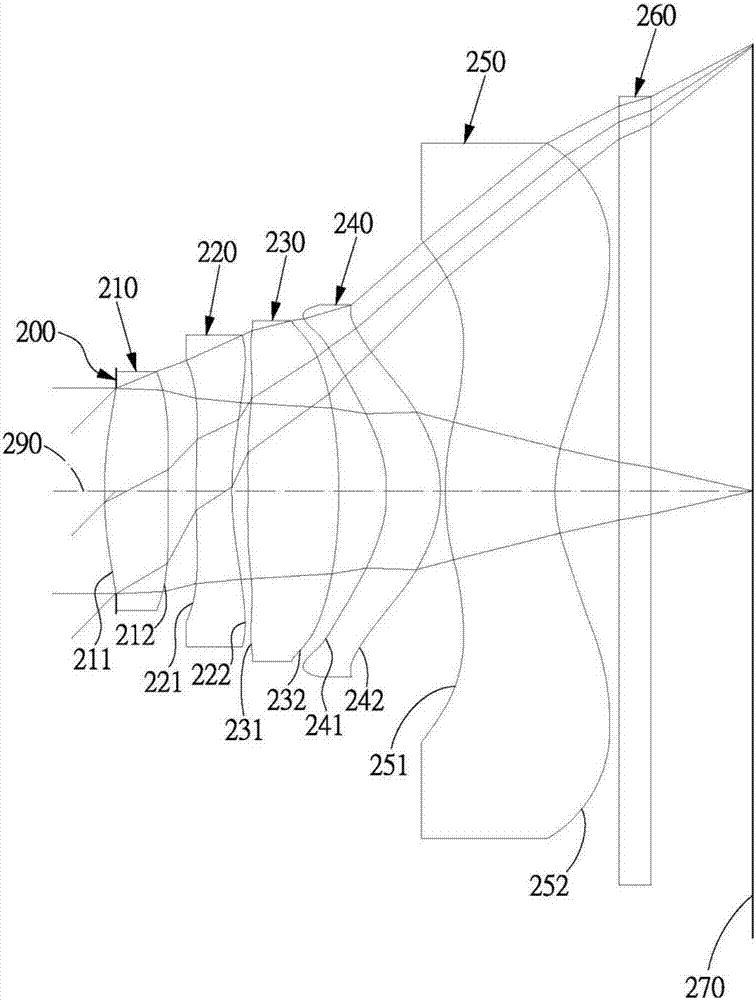

Imaging lens group

ActiveCN104914558AIncrease the imaging angleModerate burden of refractionOptical elementsCamera lensImaging lens

The invention discloses an imaging lens group, which comprises an aperture and an optical group, wherein the optical group comprises a first lens with positive refractive power, a second lens with negative refractive power, a third lens with positive refractive power, a fourth lens with positive refractive power and a fifth lens with negative refractive power sequentially from an object side to an image side; and the aperture is arranged between the image side surface of the first lens and a photographed object. The imaging lens group has the advantages of large view angle, high pixel, high resolution ability, short lens length, low material cost and low assembly tolerance sensitivity.

Owner:GLORY SCI

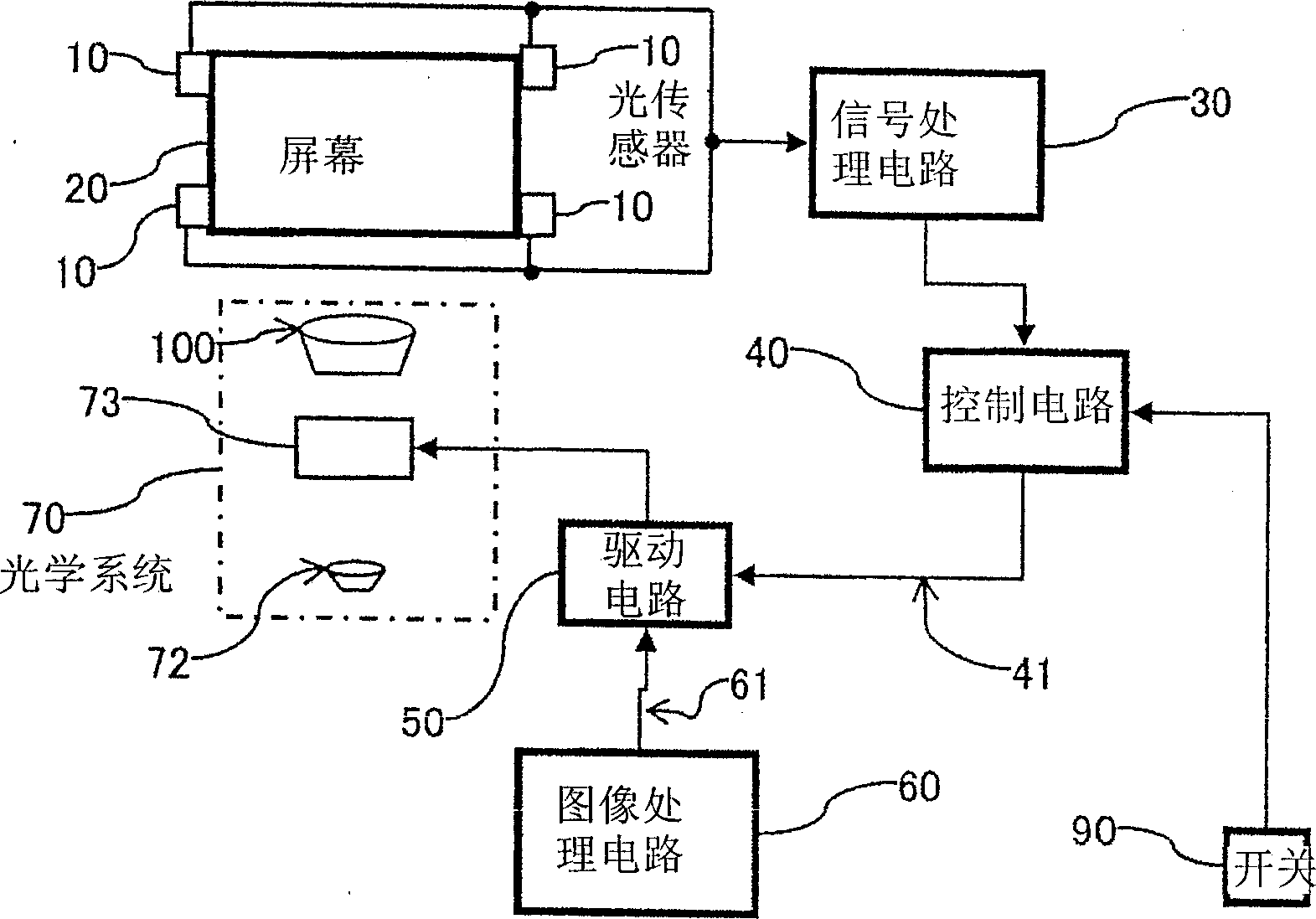

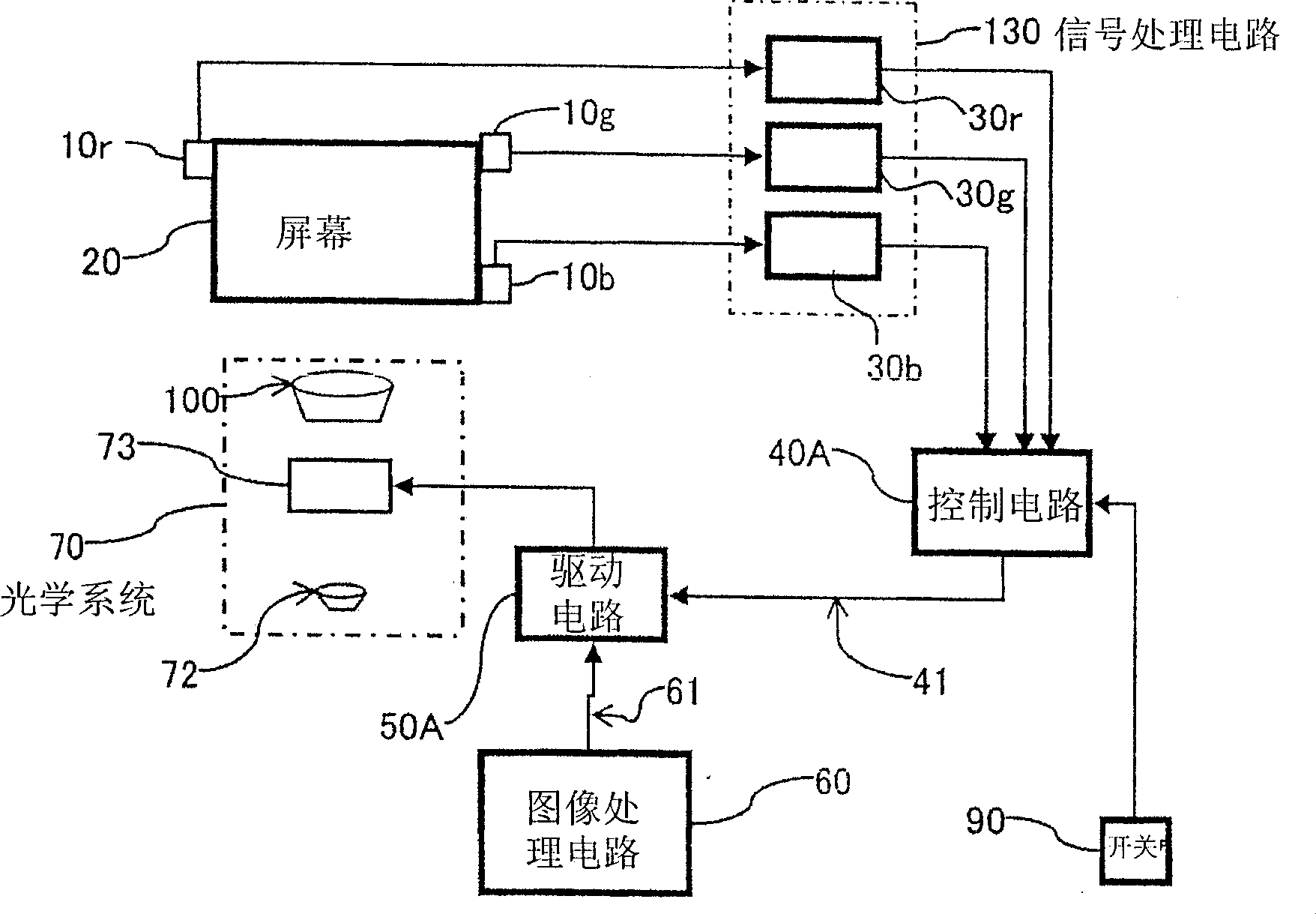

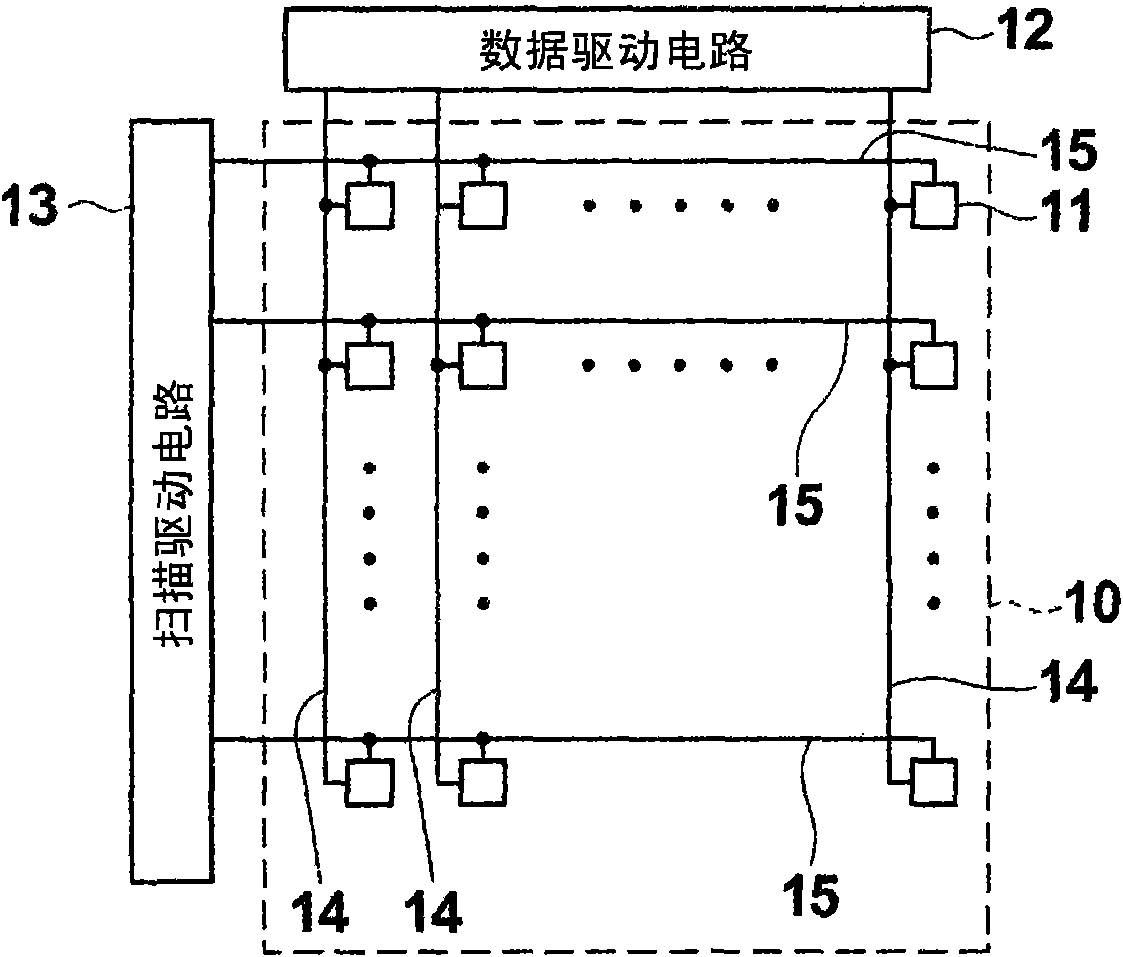

Image display device

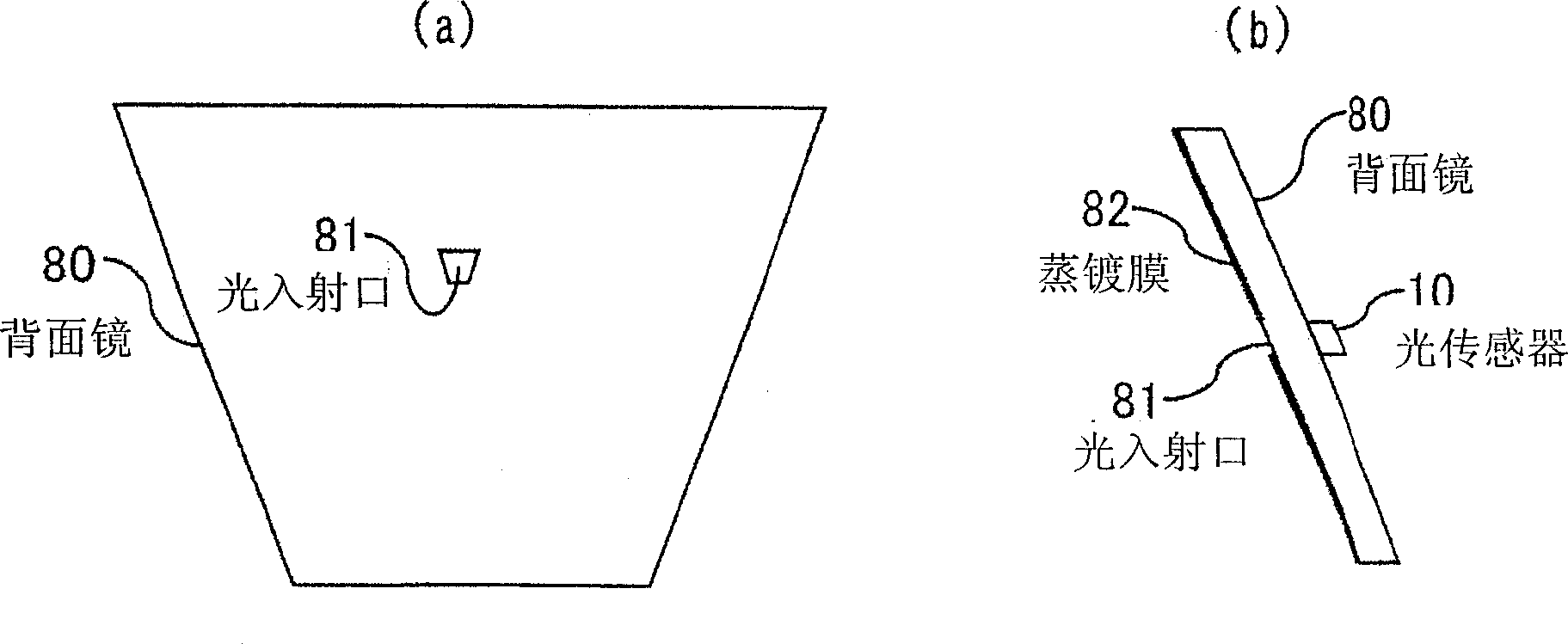

InactiveCN1848227AAppropriate correctionStatic indicating devicesLiquid-crystal displayDisplay device

The present invention provides an image display device capable of adjusting fluctuations in reference voltages of counter electrodes caused by aging changes in liquid crystal display elements without hindering display of input signals. In the present invention, an image display device that irradiates light from a light source onto a liquid crystal display element, forms an optical image corresponding to an image signal, and enlarges and projects it is provided with a reflector that reflects light irradiated onto the liquid crystal display element. mirror, a light sensor provided on the reflection mirror to detect light intensity, a drive circuit to drive the liquid crystal display element, and a control circuit to control the drive circuit based on the light intensity detected by the light sensor.

Owner:HITACHI LTD

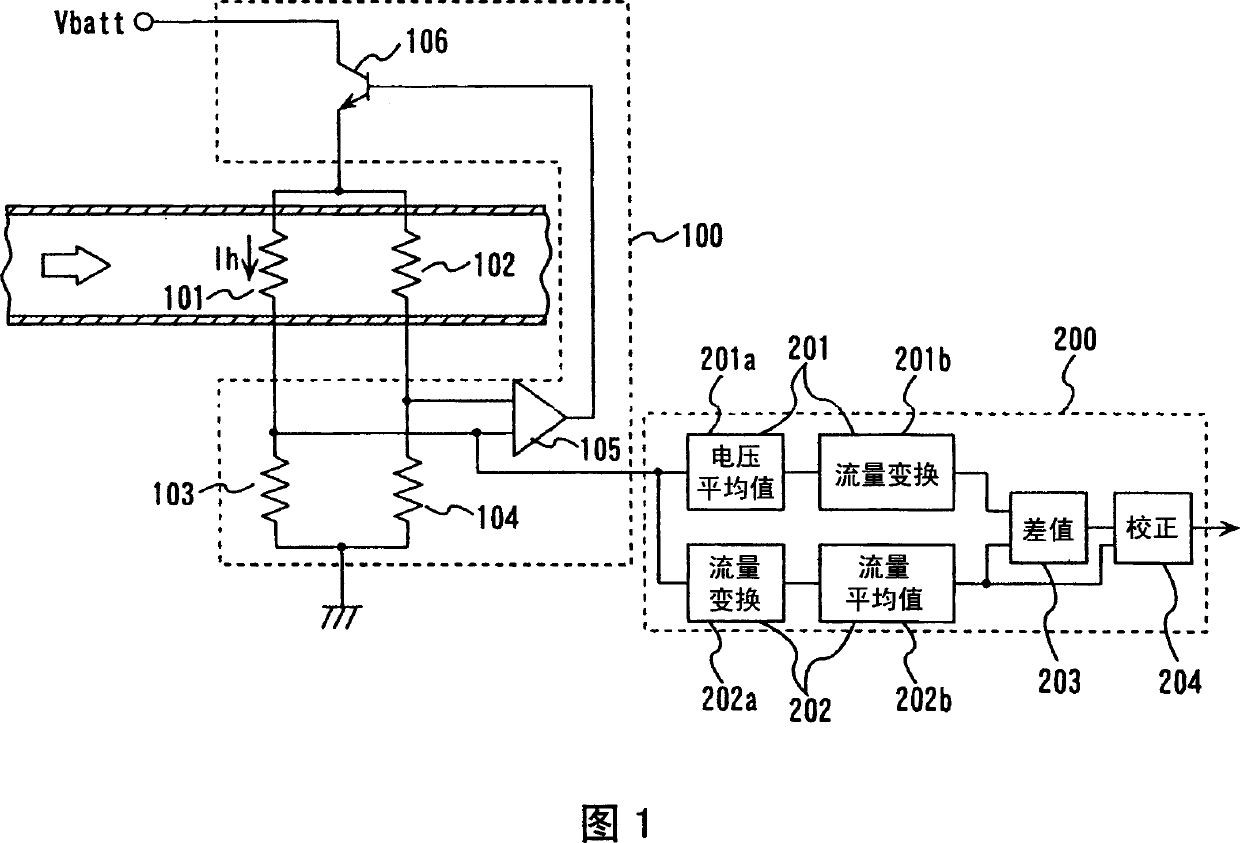

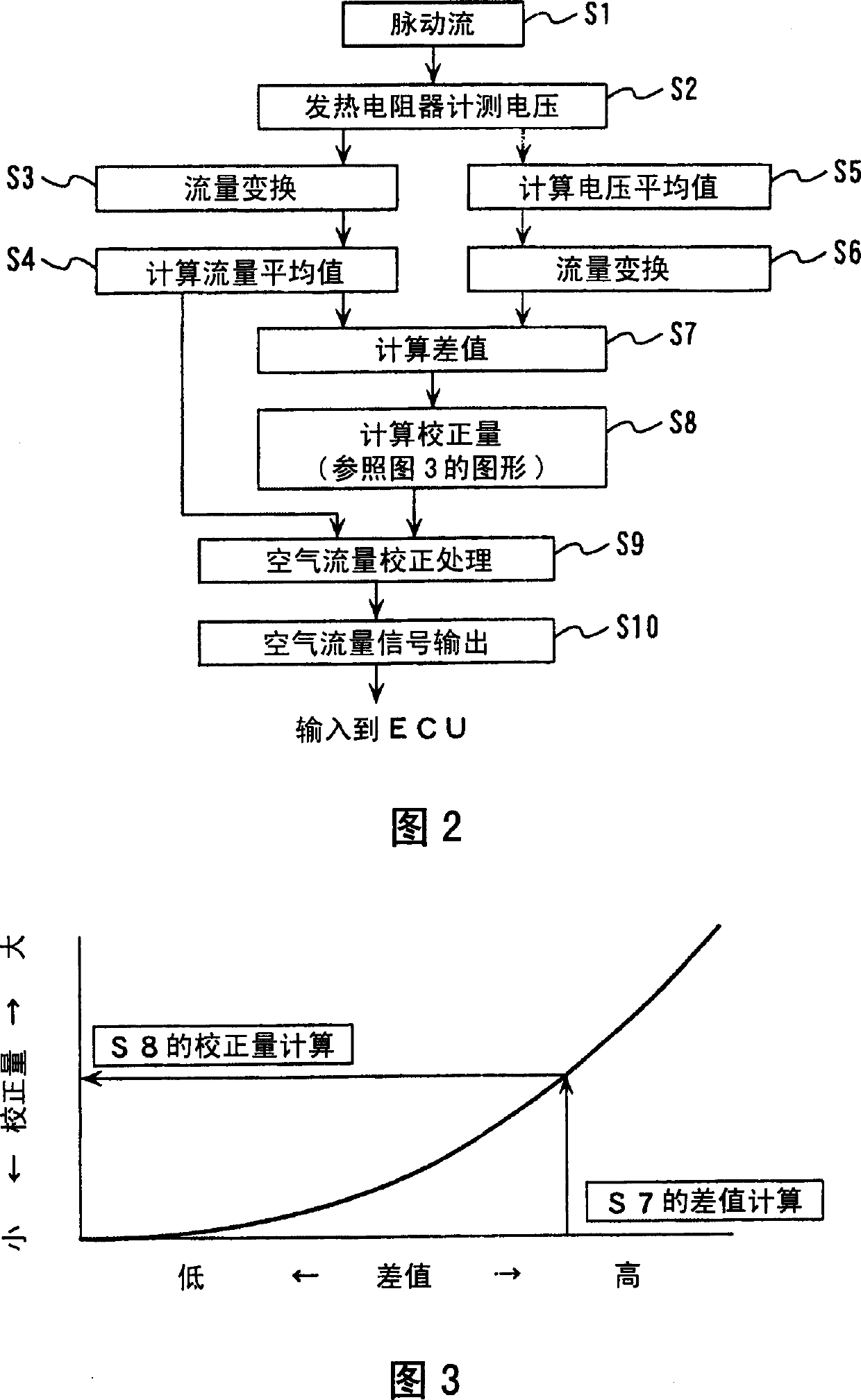

Heating resistor type air flow rate measuring device and method of correcting measurement error

InactiveCN1828231AAppropriate correctionElectrical controlVolume/mass flow by thermal effectsElectrical resistance and conductanceEngineering

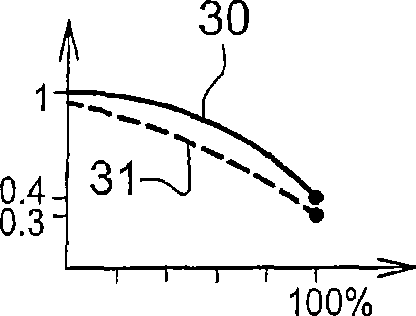

This invention relates to a measurement error attributable to intake air pulsation of a heating resistor type air flow rate measuring device is corrected. A measurement error correction method not dependent on an intake system of a vehicle is provided. An output from a sensing circuit (100) is sampled at prescribed time intervals. Output values thus sampled are successively converted to flow rate values. A first flow rate value is determined by averaging the flow rate values thus obtained in a prescribed amount of time. Separately, the output from the sensing circuit (100) is averaged for a prescribed amount of time. The average output value thus obtained is converted to a second flow rate value. A correction value for correcting a measurement error is determined based on a difference between the first and second flow rate values.

Owner:HITACHI LTD

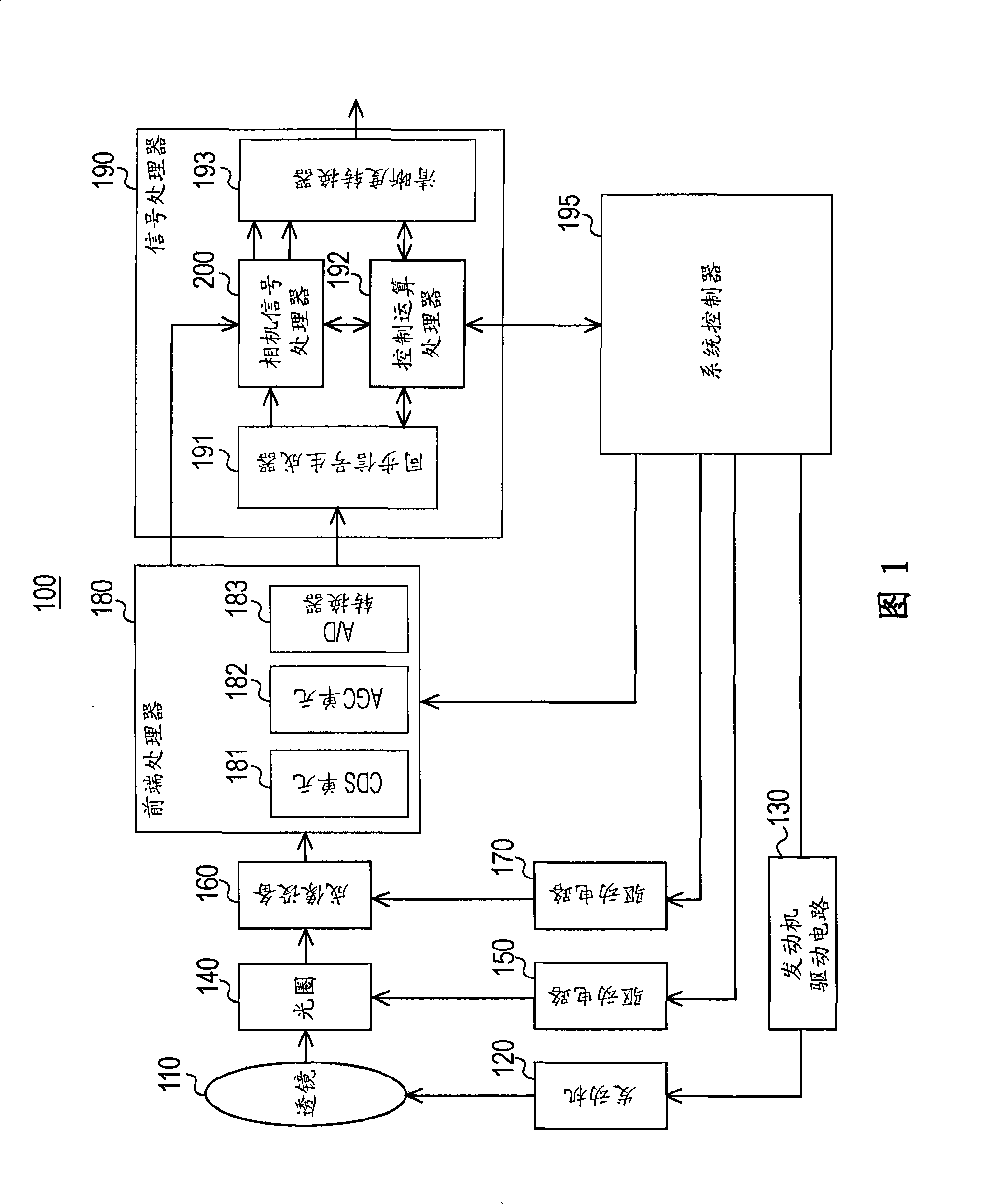

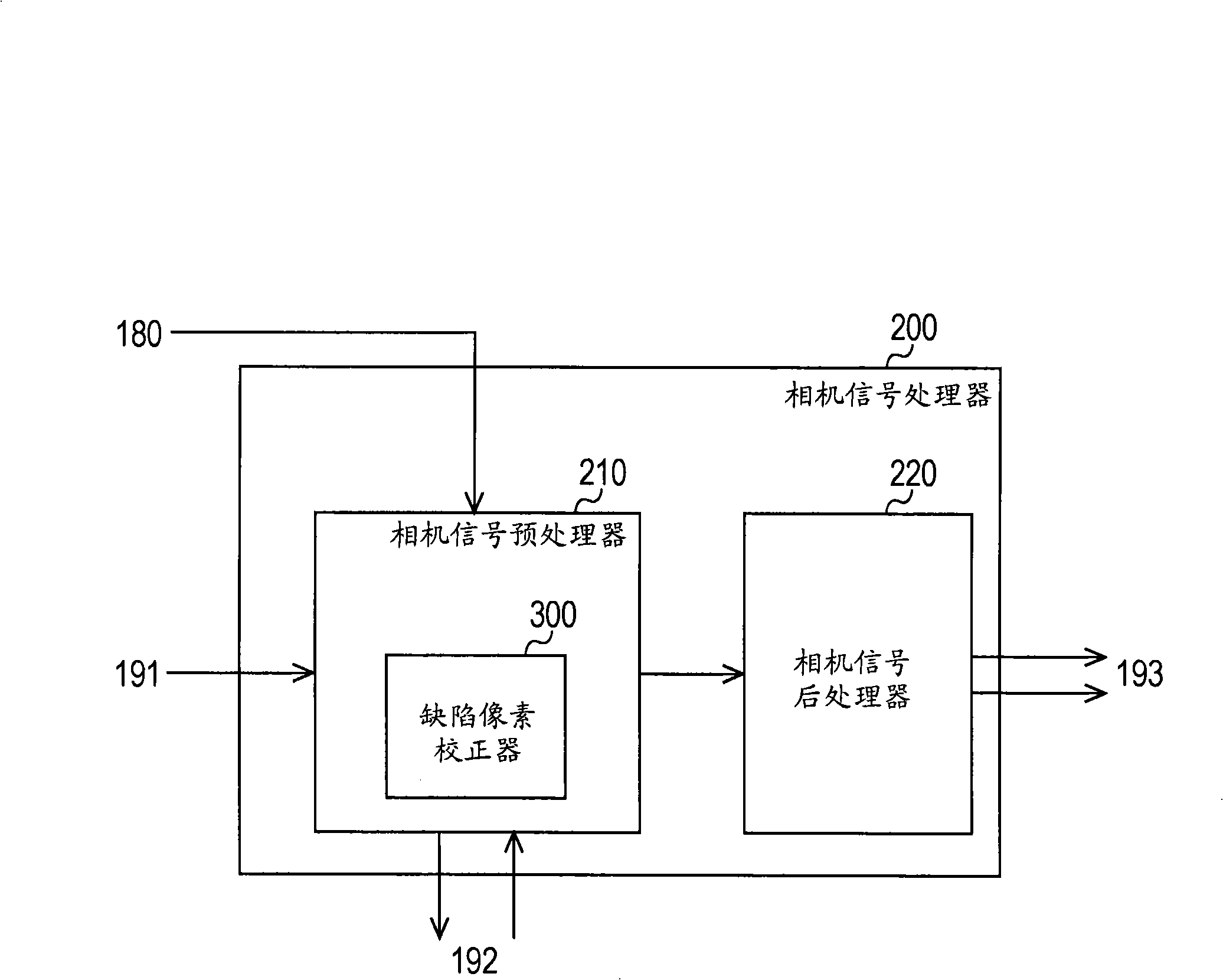

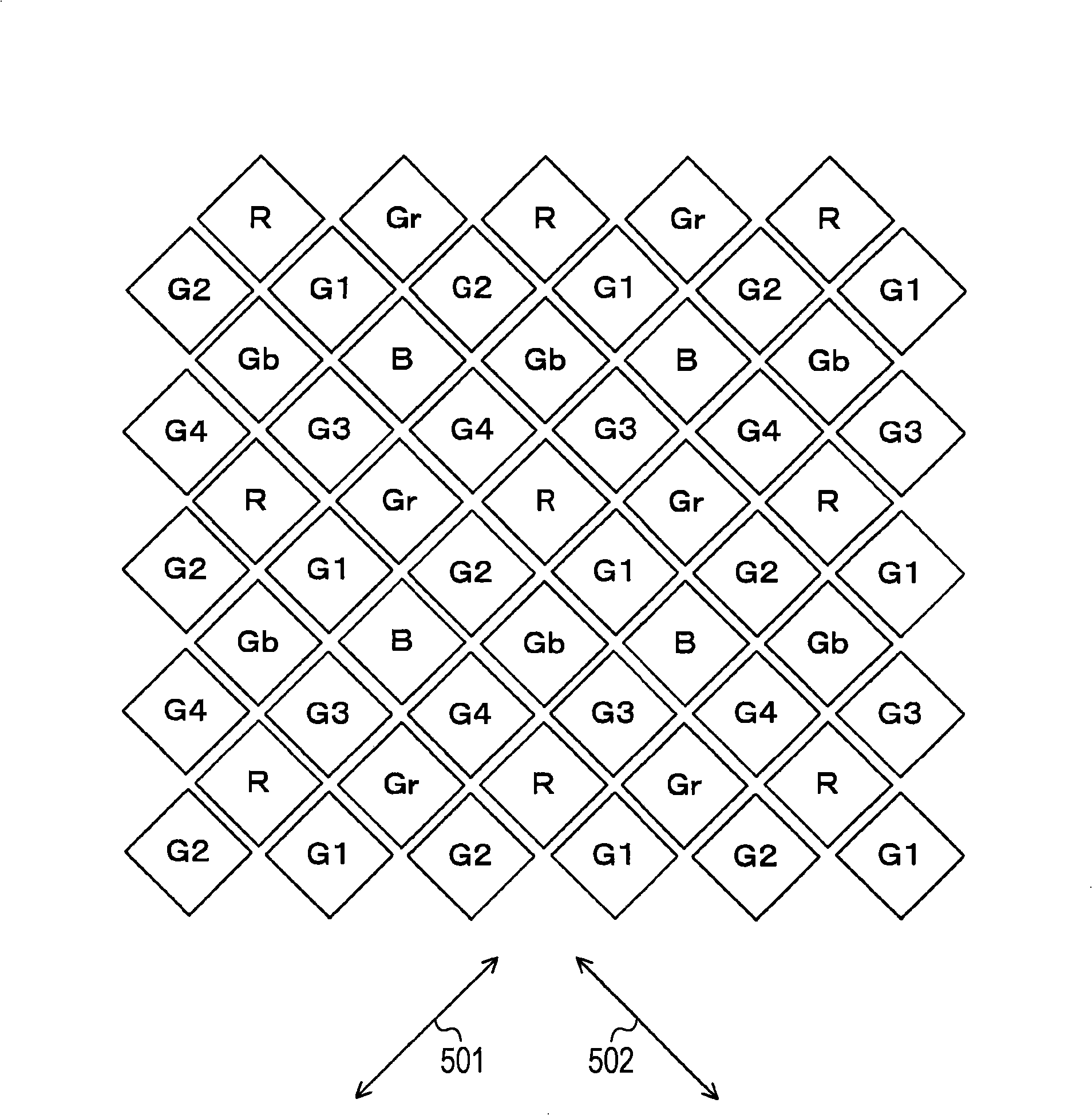

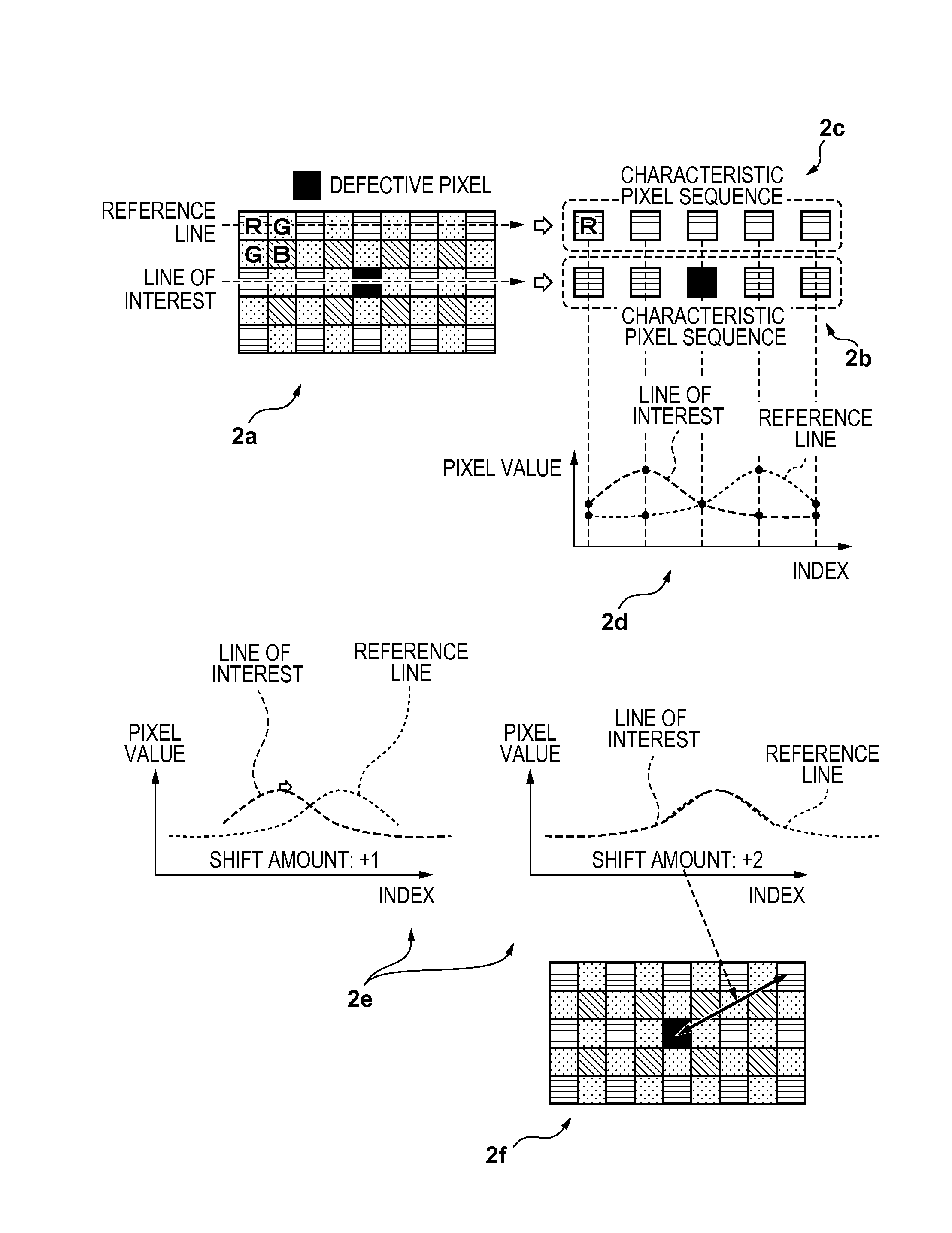

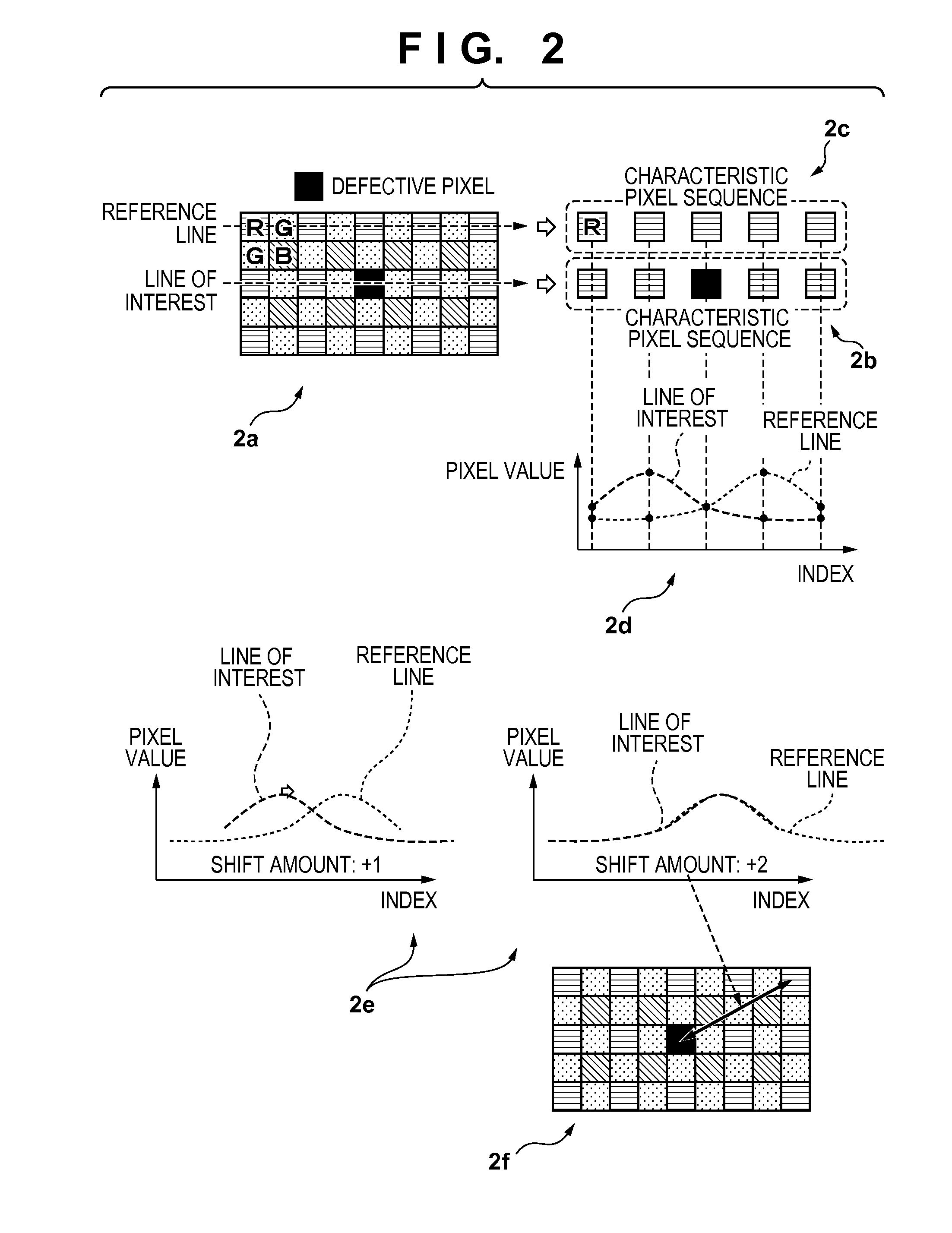

Image forming apparatus, flaw pixel correction apparatus, processing method program of the device

InactiveCN101304484AAppropriate correctionImage enhancementTelevision system detailsComputer visionComputer science

An imaging apparatus includes a defective pixel storing unit to store positional information of a defective pixel among pixels in an imaging device and pixel defect information indicating whether a defective pixel group including defective pixels includes the defective pixel related to the positional information; an image input unit to input an image; a defective pixel determining unit to determine whether each pixel in the input image is a defective pixel; a pixel sharing defect determining unit to determine whether the defective pixel is included in the defective pixel group; a pixel type determining unit to determine the type of each pixel in the input image; an interpolated pixel selecting unit to select surrounding pixels of the defective pixel; an interpolation value calculating unit to calculate an interpolation value of the defective pixel; ; and an interpolation value substituting unit to substitute the value of the defective pixel with the interpolation value.

Owner:SONY CORP

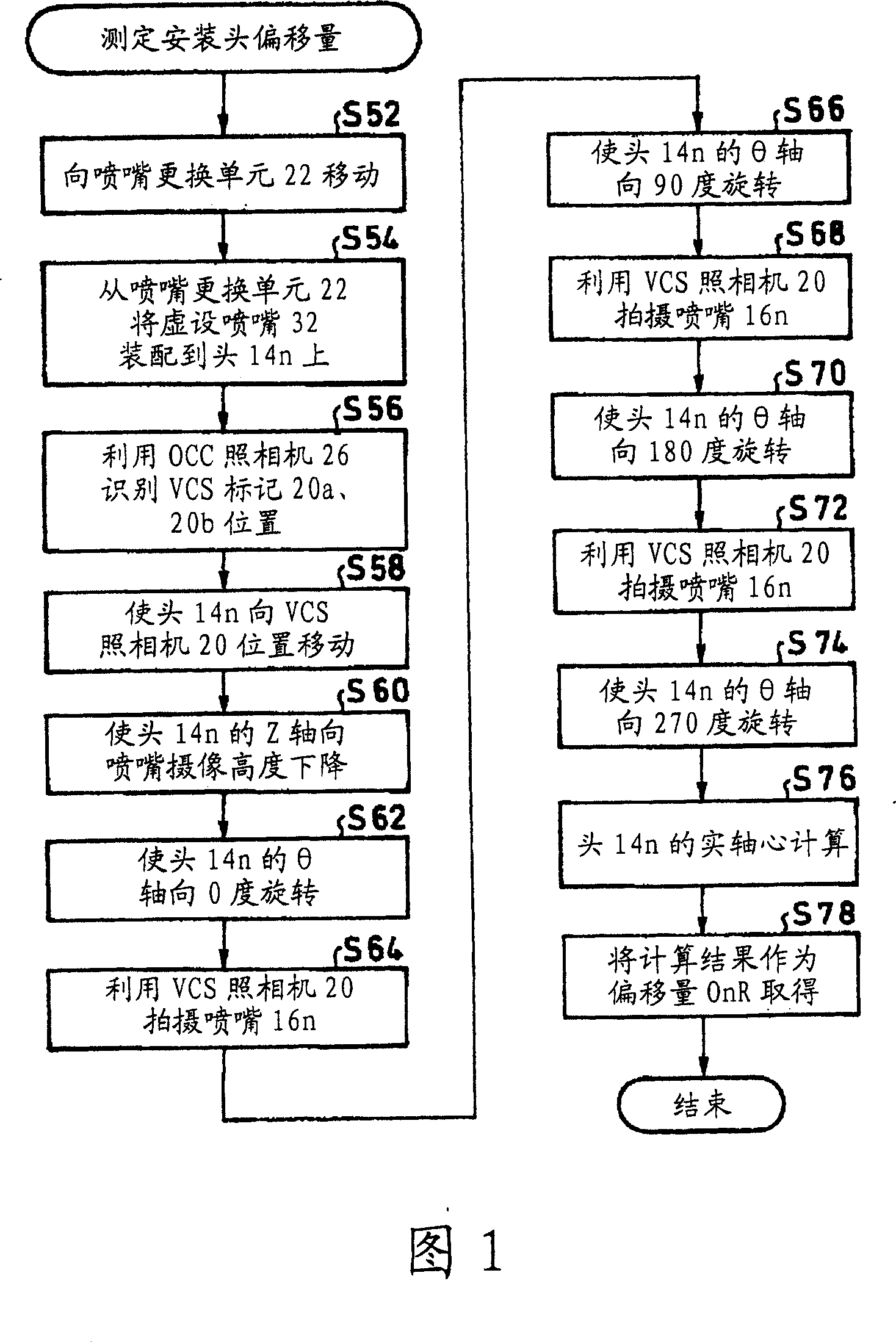

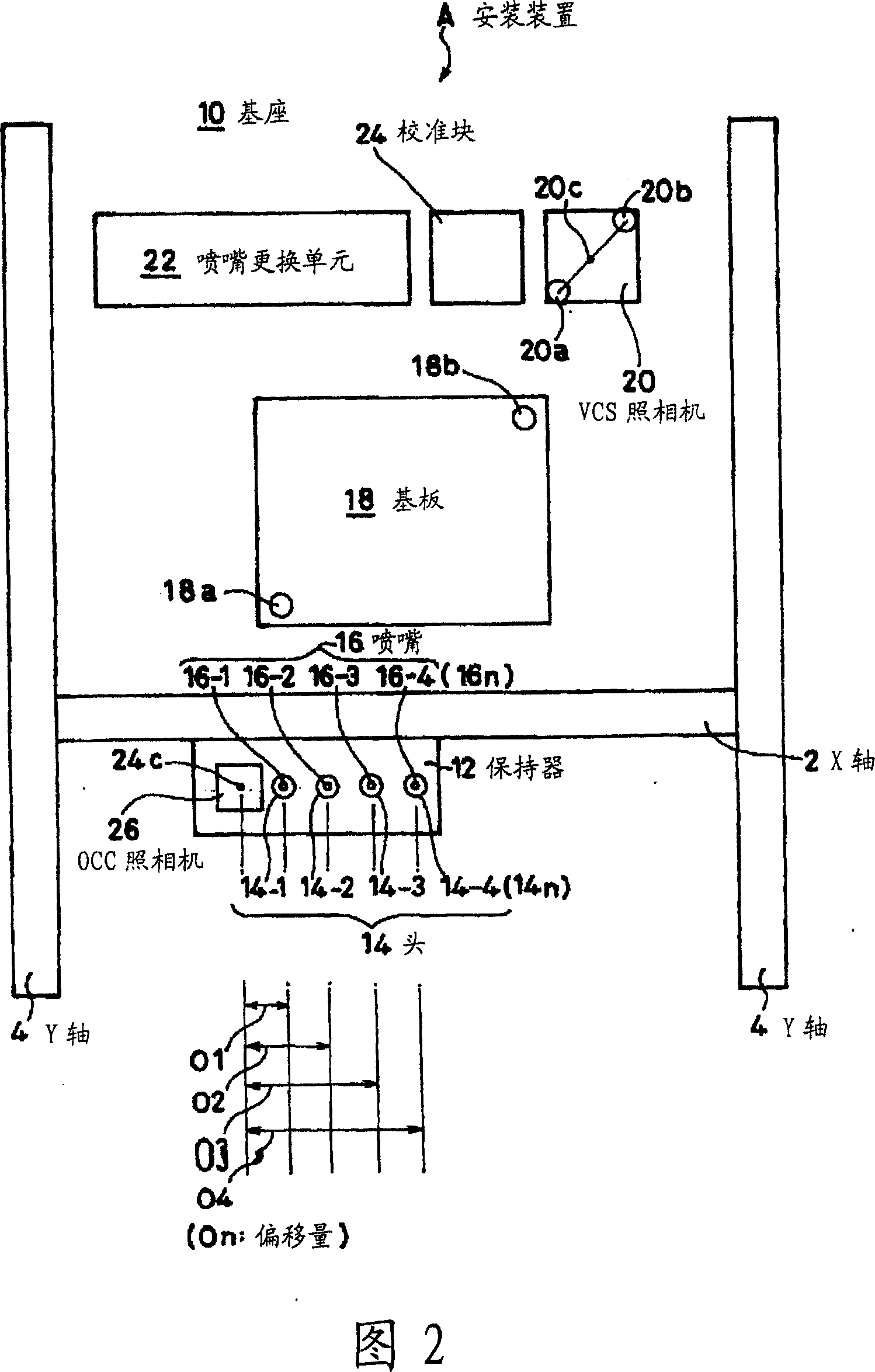

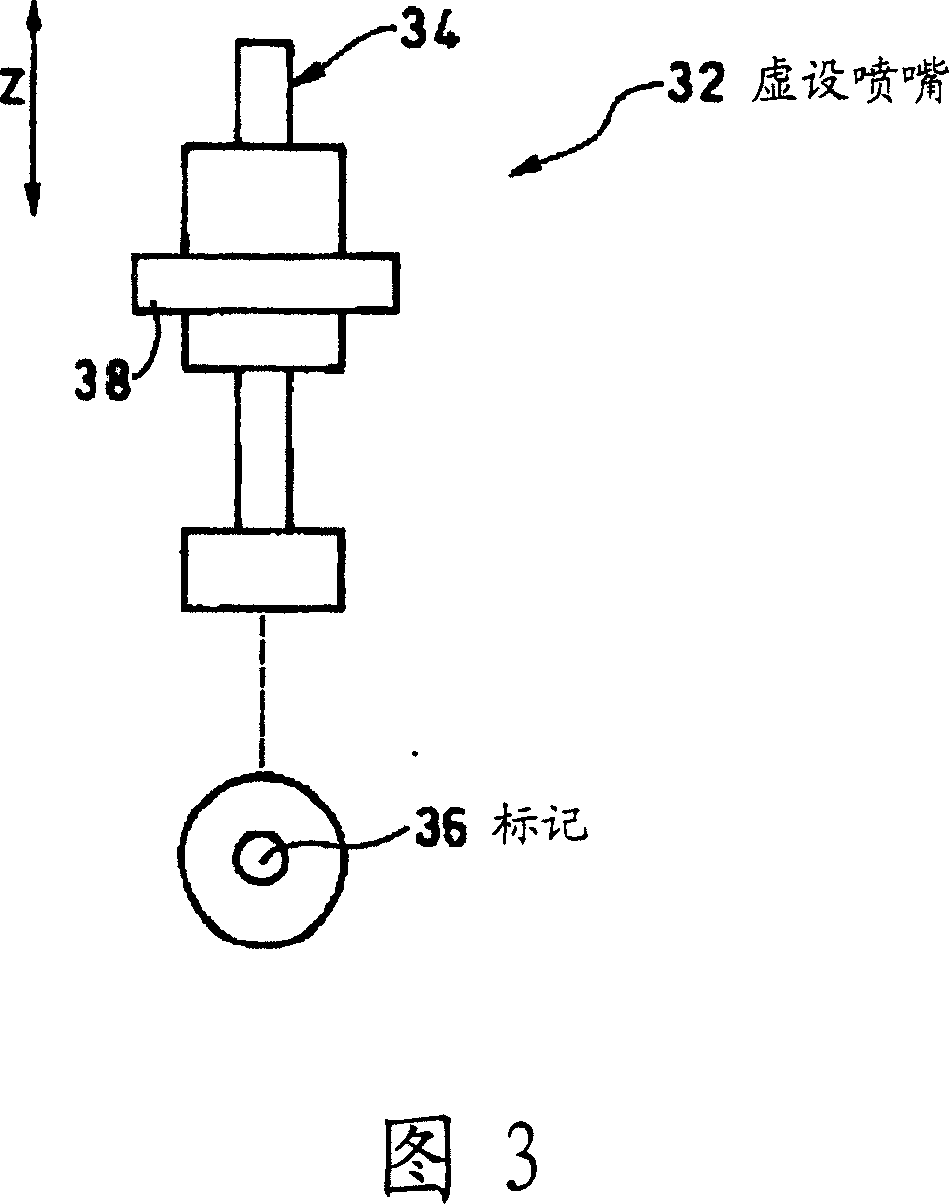

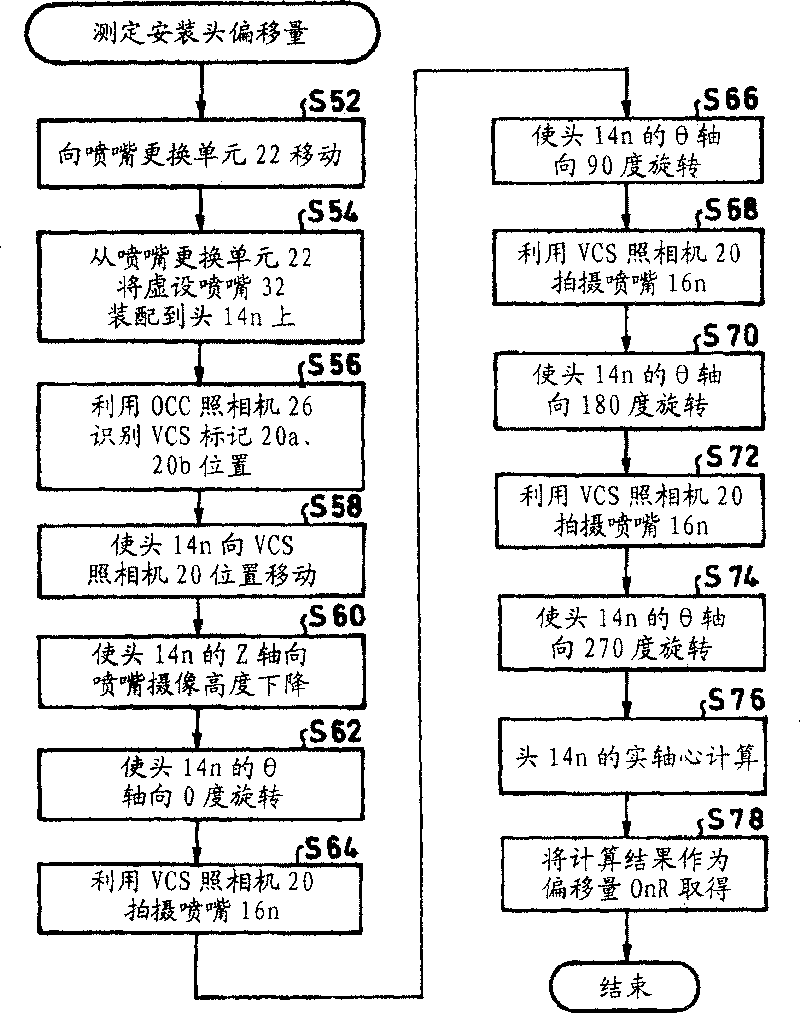

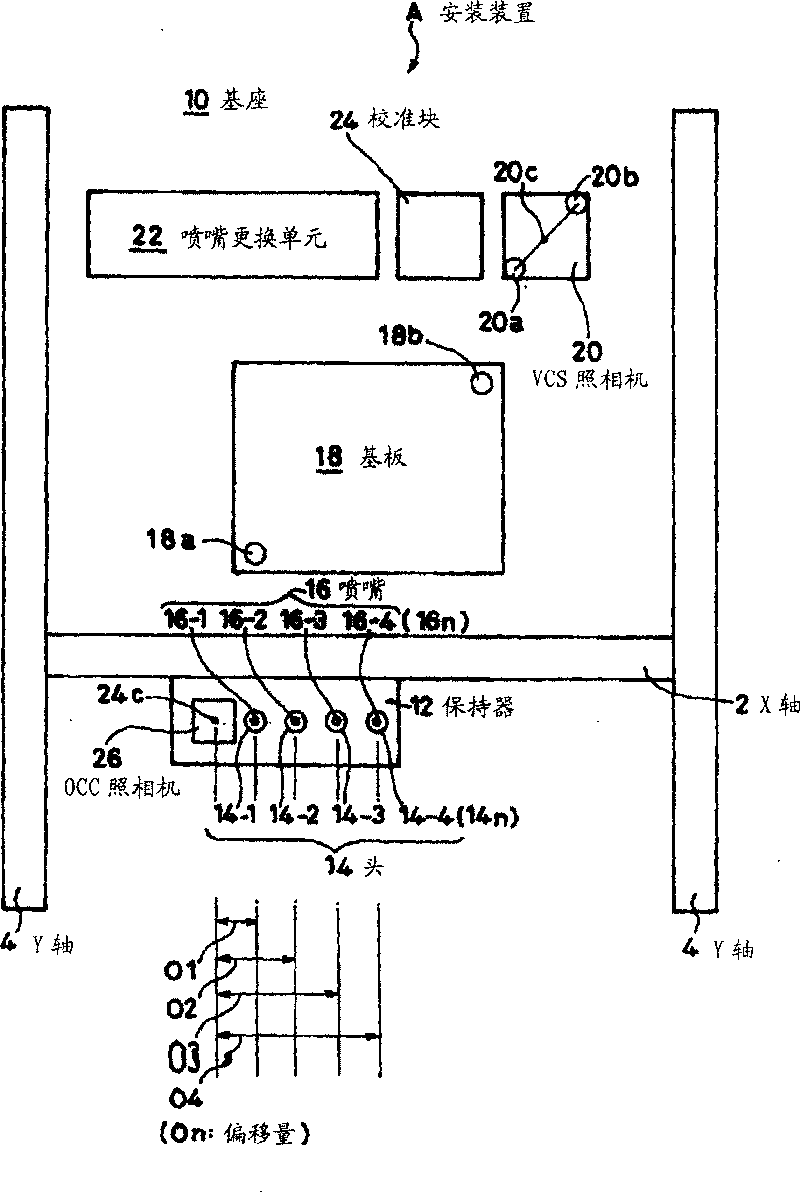

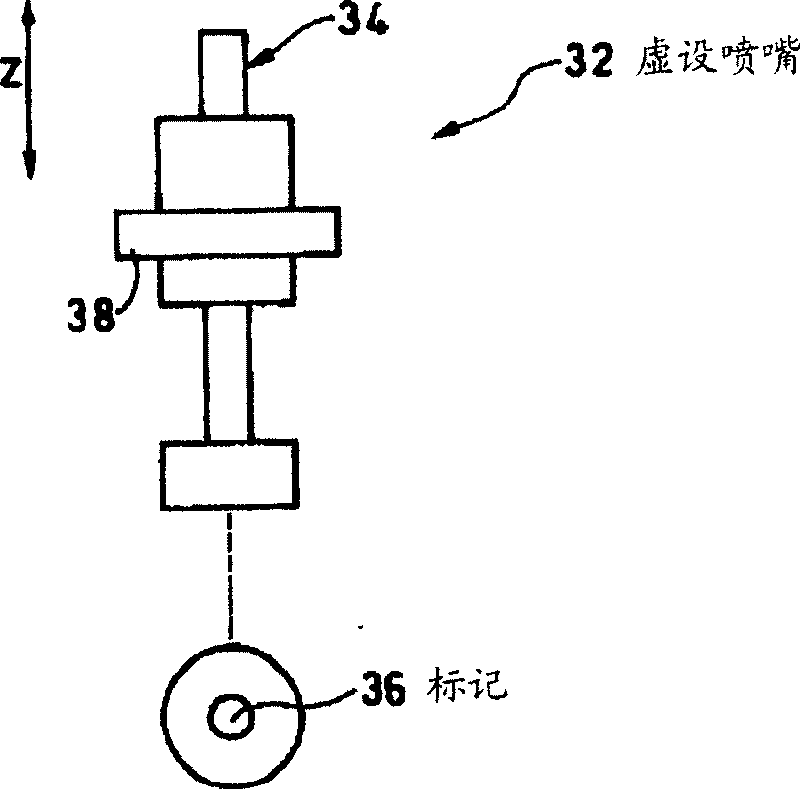

Correction method for head position of part installation device and nominal nozzle

The present invention provides a head position correction method and a dummy nozzle of a component mounting device, which can accurately identify the actual offset between the board recognition camera and the head position in simple steps, and perform appropriate correction. Install the dummy nozzle (32) on the head (14n), and use the OCC camera (second camera) (26) equipped on the holder (12) with the head (14n) to identify the VCS on the side of the base (10) The position of the camera (first camera) (20), according to the offset (On) of the design of the OCC camera (26) and the head (14n), move the head (14n) to the identified VCS camera (20) position, use the VCS camera (20) to photograph the mark (36) of the virtual nozzle (32) of the moved position, thereby the deviation (OnR) of the head (14n) after the move from the center of the VCS camera (20) Obtained as an offset correction amount.

Owner:JUKI CORP

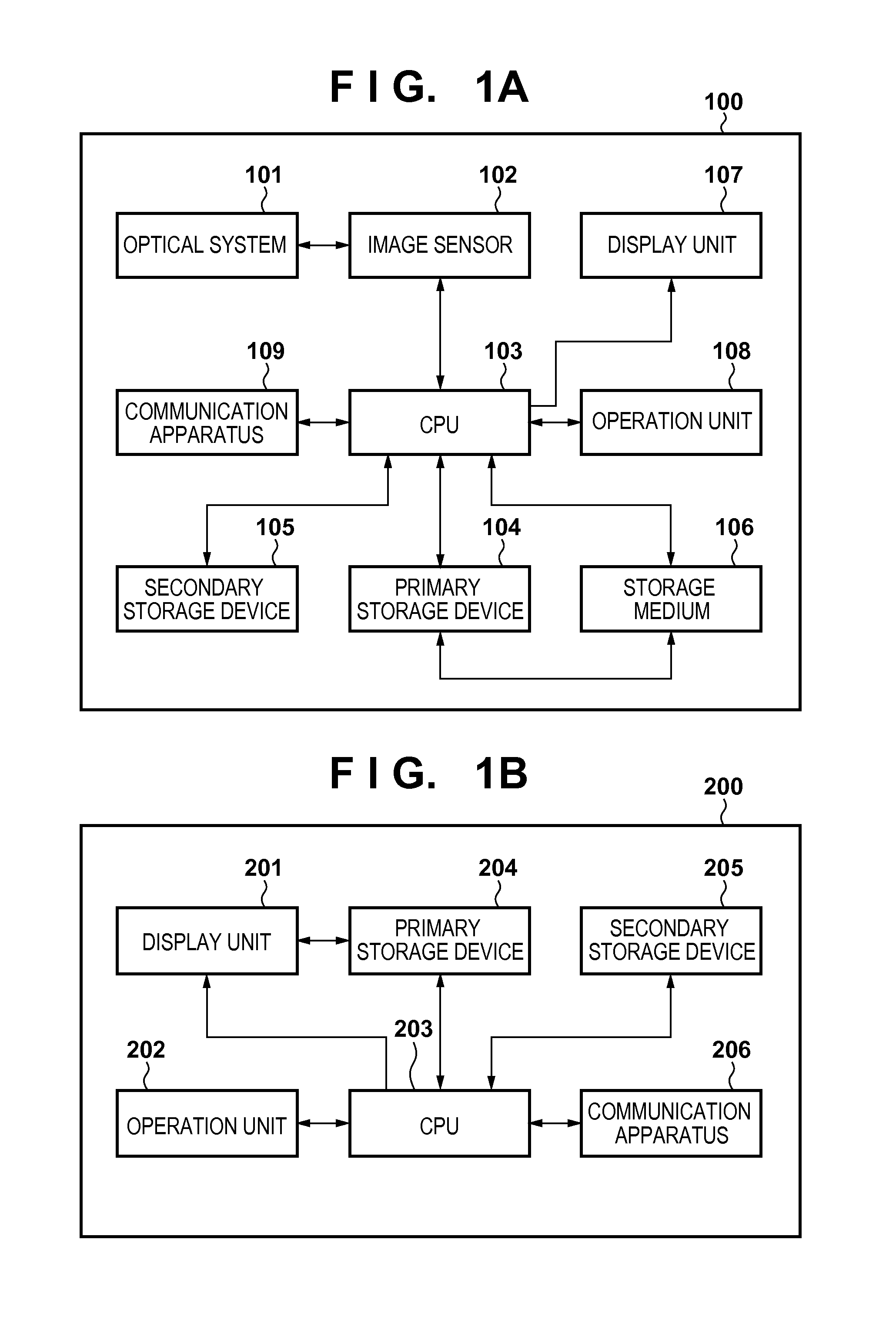

Image processing apparatus and method for controlling image processing apparatus

ActiveUS20150244953A1Appropriate correctionTelevision system detailsColor signal processing circuitsImaging processingComputer vision

Owner:CANON KK

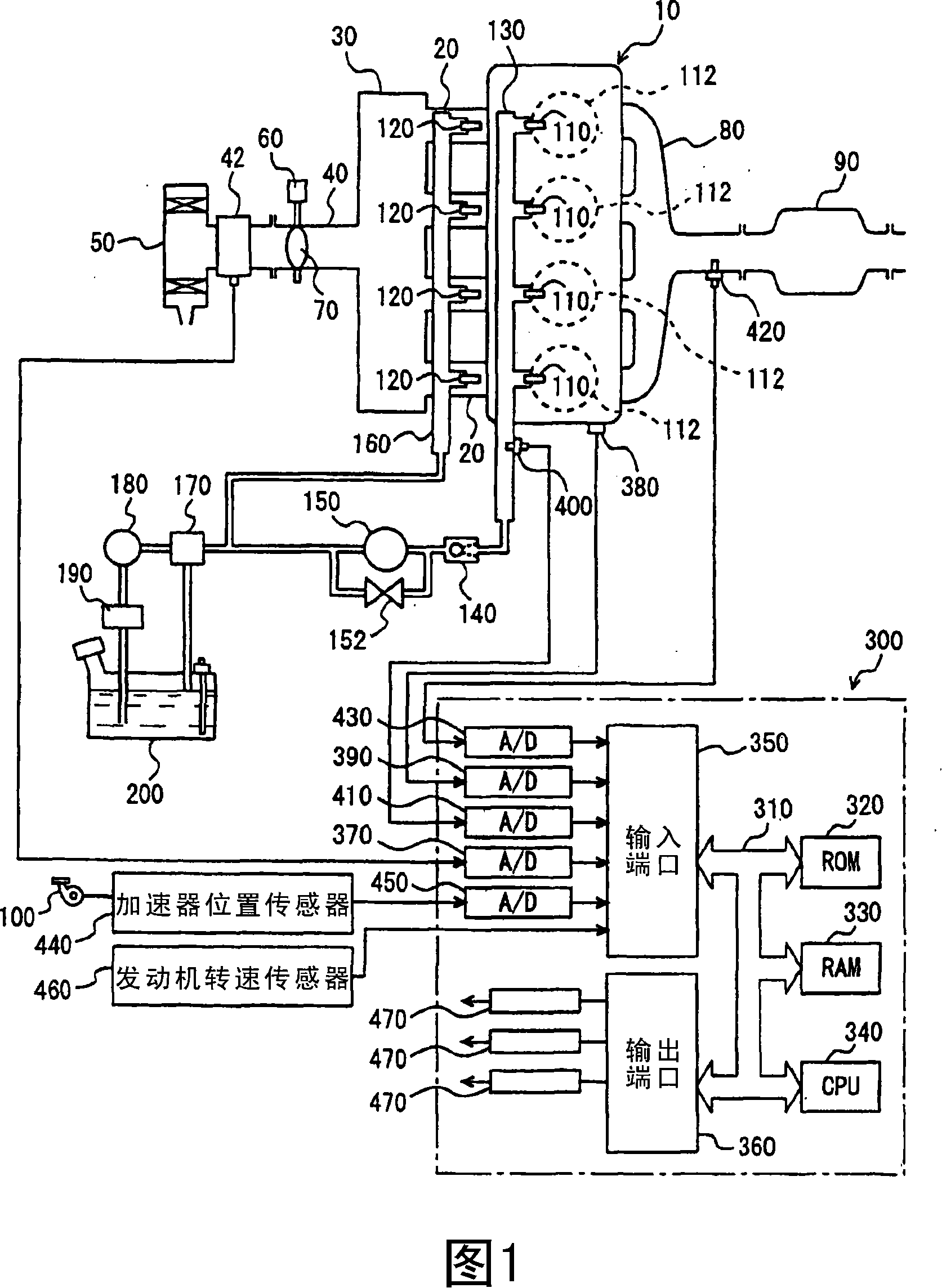

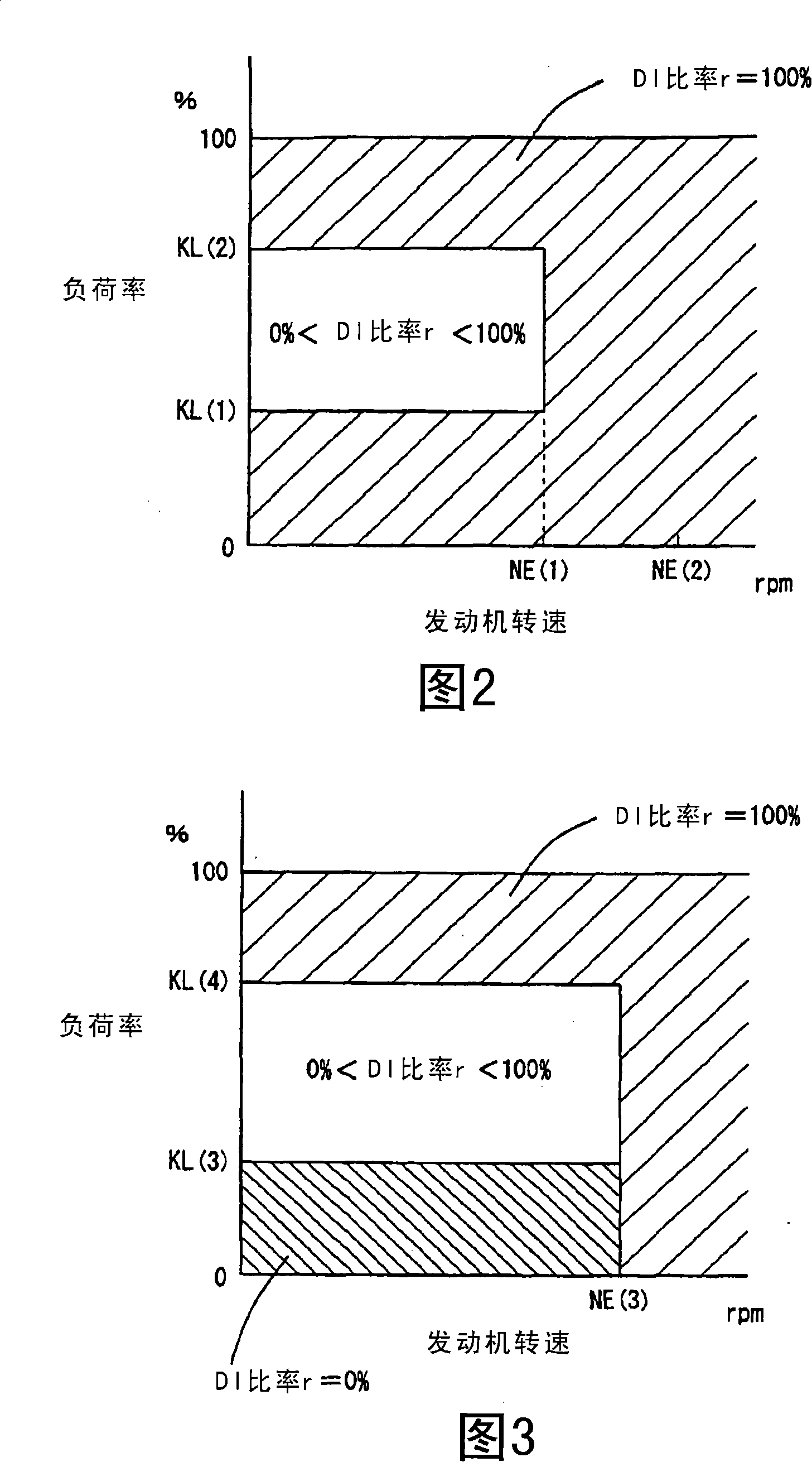

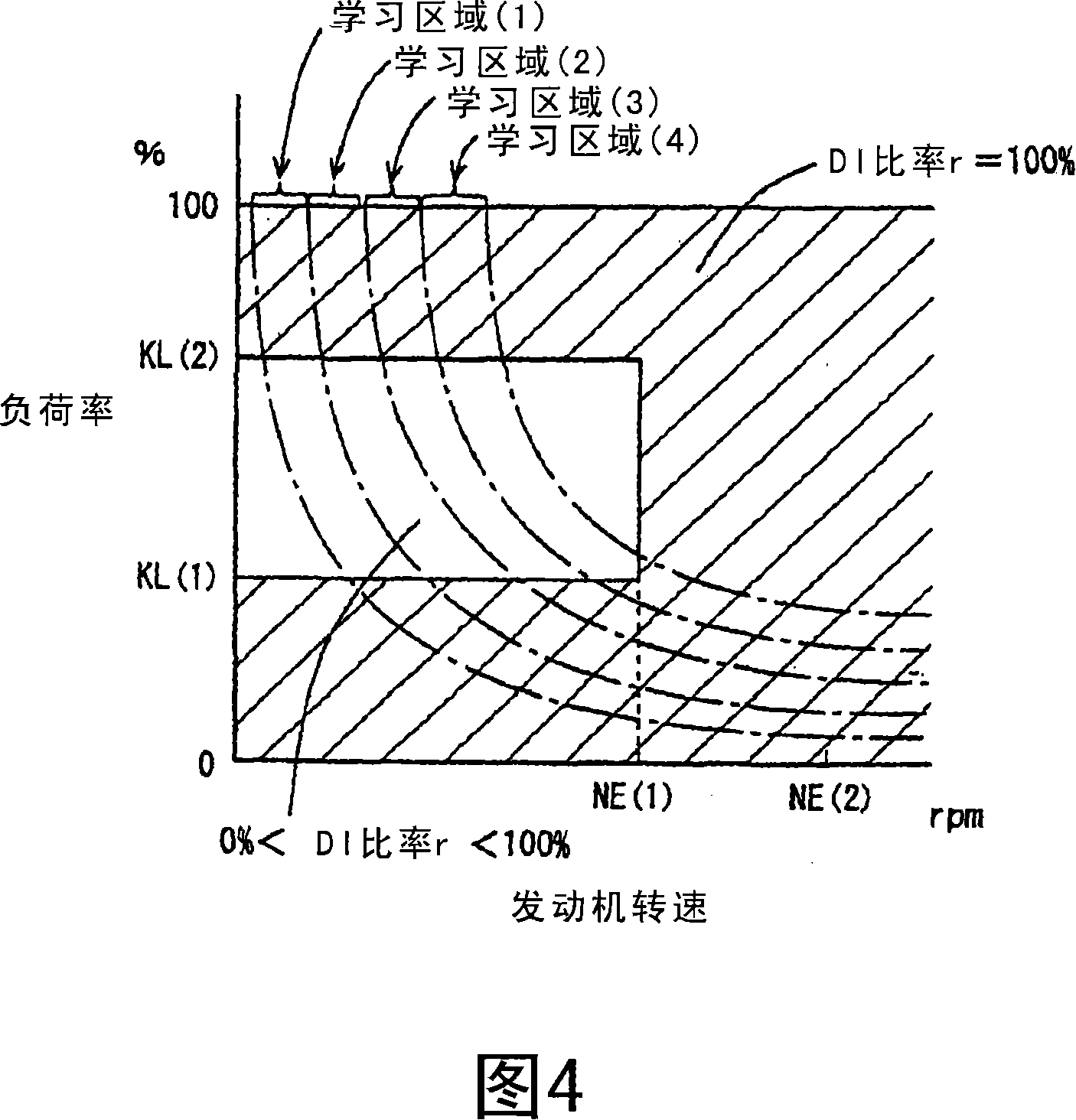

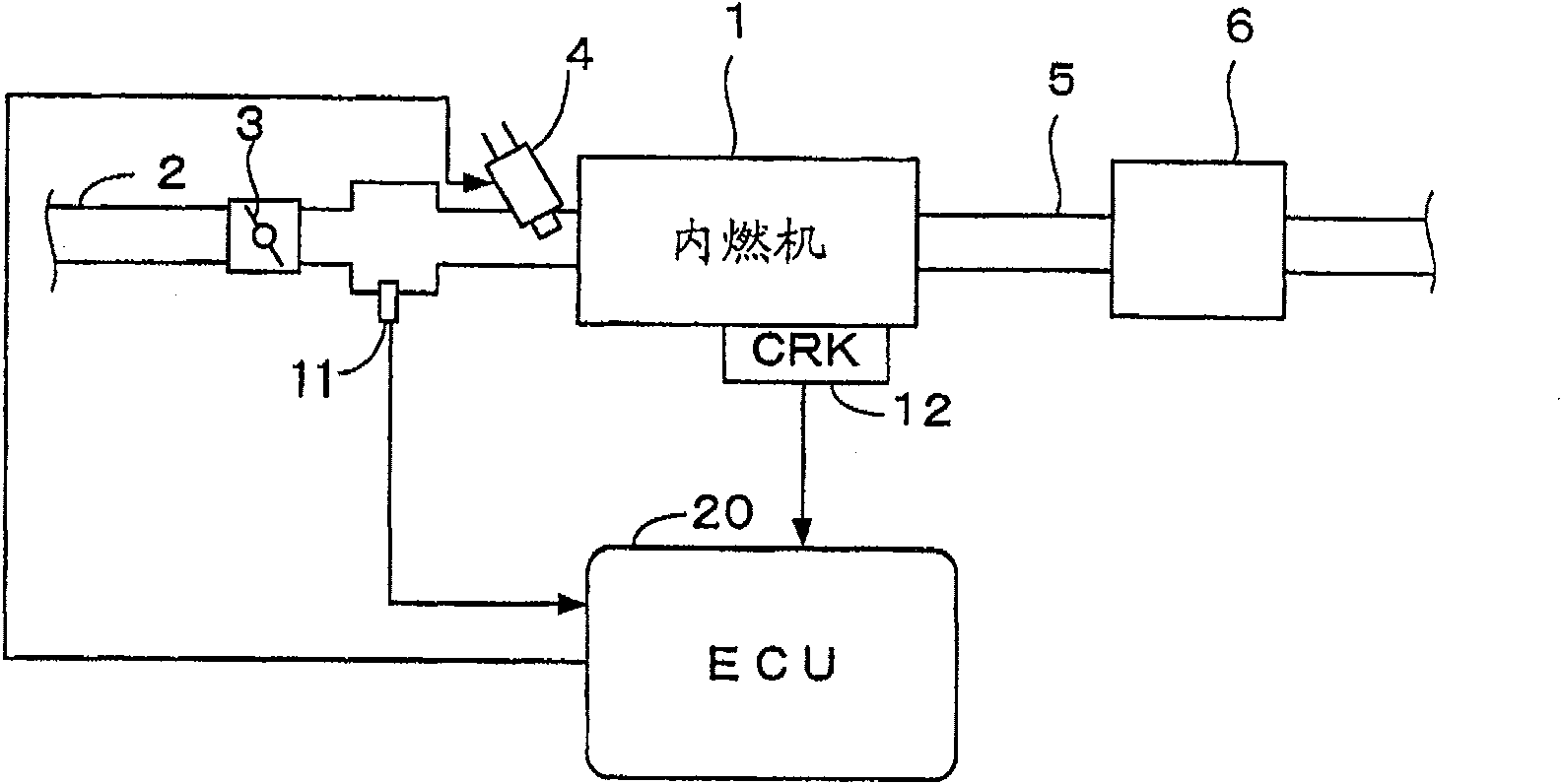

Control device for internal combustion engine

InactiveCN101142394AAppropriate correctionElectrical controlMachines/enginesEngineeringControl equipment

An engine ECU executes a program including the steps of: detecting an air-fuel ratio; calculating a learn value of a feedback correction amount for total fuel injection amount calculated based on the air-fuel ratio, for a plurality of learning regions obtained as a result of division corresponding to an intake air amount; interpolating the learn value at an intake air amount different from the intake air amount detected at the time of calculation of the learn value, based on the calculated learn value; and correcting an amount of fuel injection based on the obtained learn value.

Owner:TOYOTA JIDOSHA KK

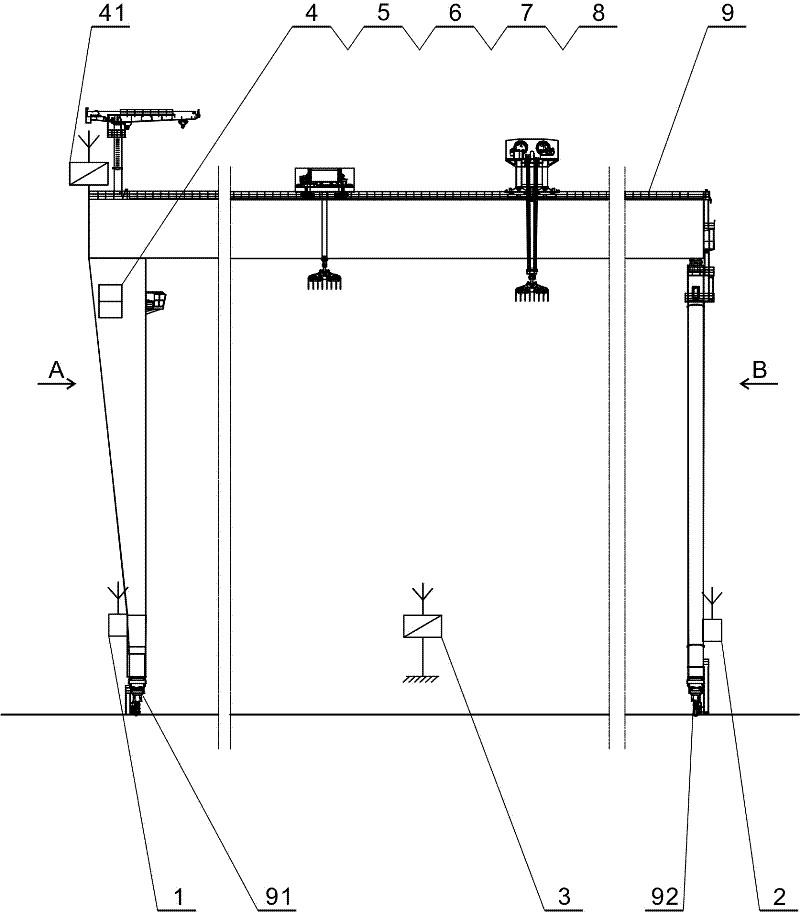

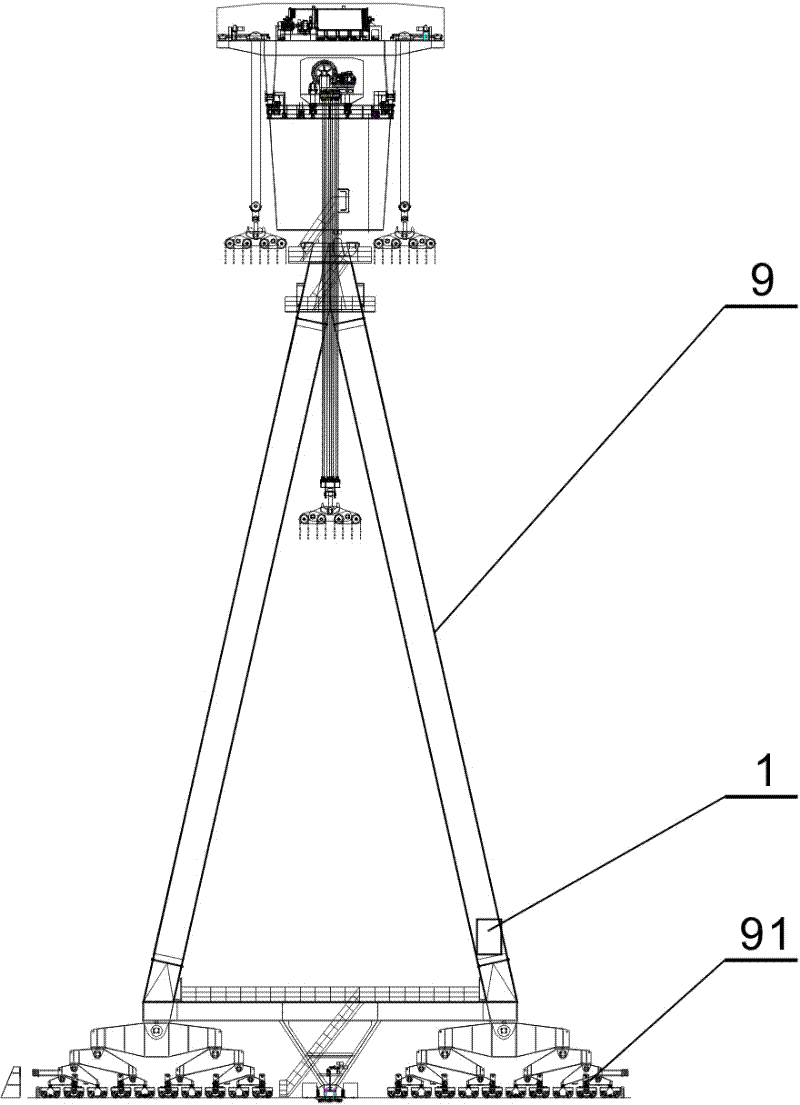

Error correcting method for large-scale gantry crane walking

ActiveCN102491175AEliminate cumulative errorsOvercoming Mechanical PrecisionSafety gearReference testWireless transmission

The invention discloses an error correcting method for large-scale gantry crane walking, which comprises a control system and an arrangement of a crane on a system, the control system comprises a first test point, a second work station, a reference test point, a wireless signal receiver, a data processing center, a driving control computer, a monitor terminal and a driving frequency converter, the first test point and the second test point are arrange on two side door legs of the gantry crane, a reference work station is provided on the ground, other devices are arranged in a control chamber of the crane. The coordinate position between the position indicator detection moving point and static point can be used, by wireless transmission and computer processing information, the error correcting method enforced by the drive unit of the crane can be controlled, the detection of the displacement by the method is accurate, the accumulative error can be eliminated, the influence of machinery precision and machinery jitter can be overcome, so that the error correcting method has the advantages of proper error correction, stable operation, safety and reliability.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

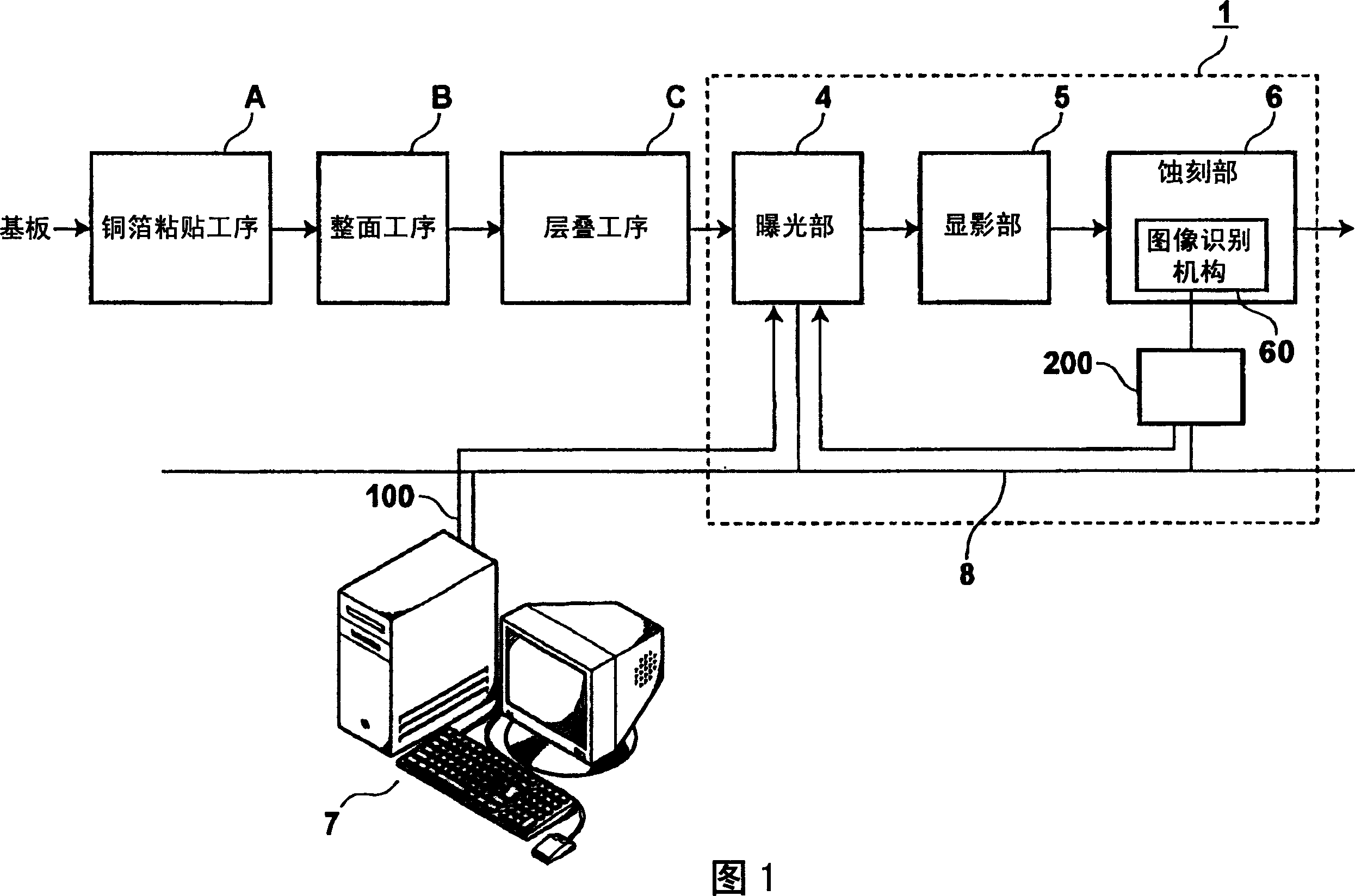

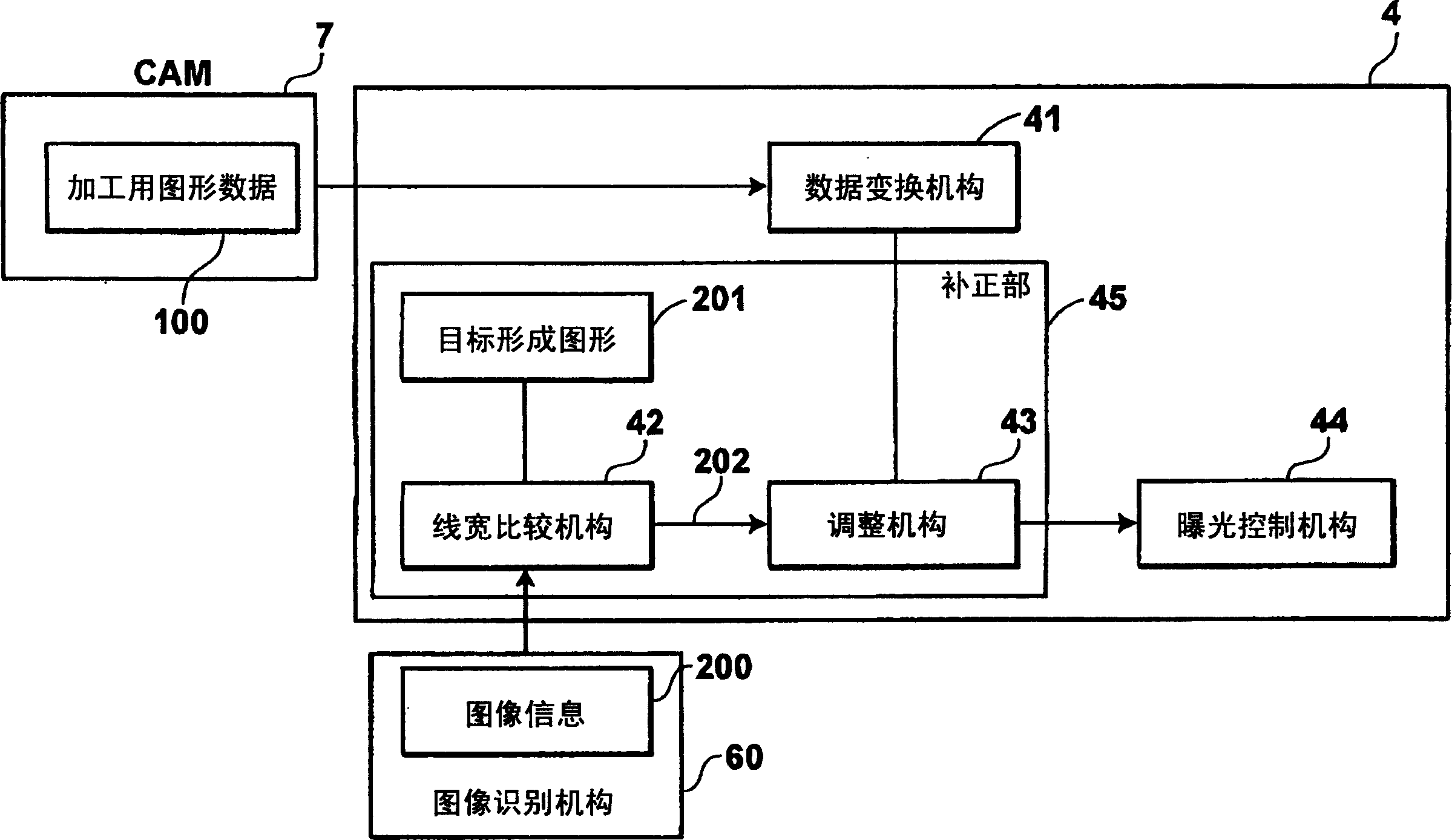

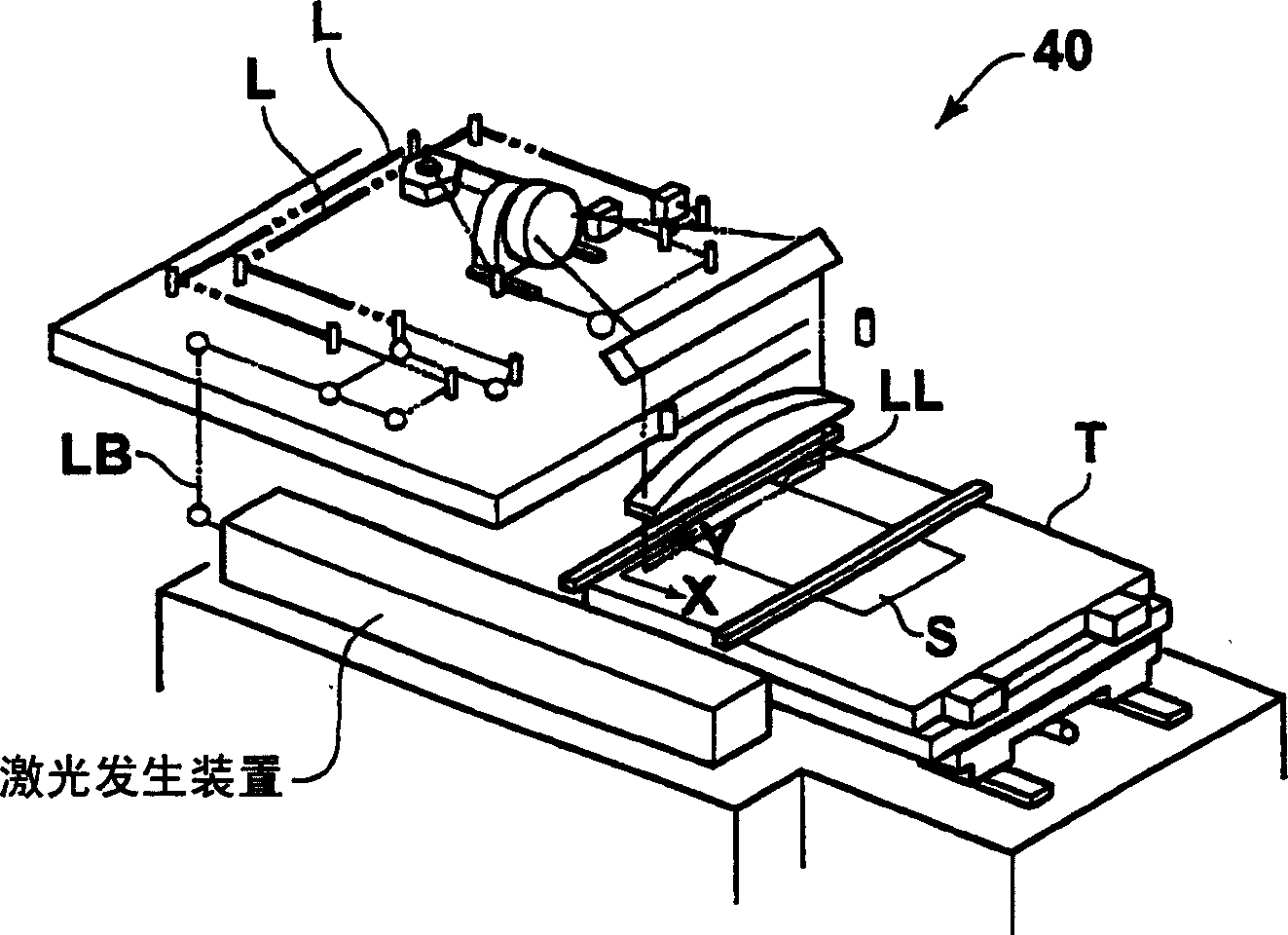

Pattern production system, exposure system, and exposure method

InactiveCN1580950AEliminate finished product deviationBias adjustmentLiquid processingSemiconductor/solid-state device manufacturingResistLine width

Owner:FUJIFILM CORP

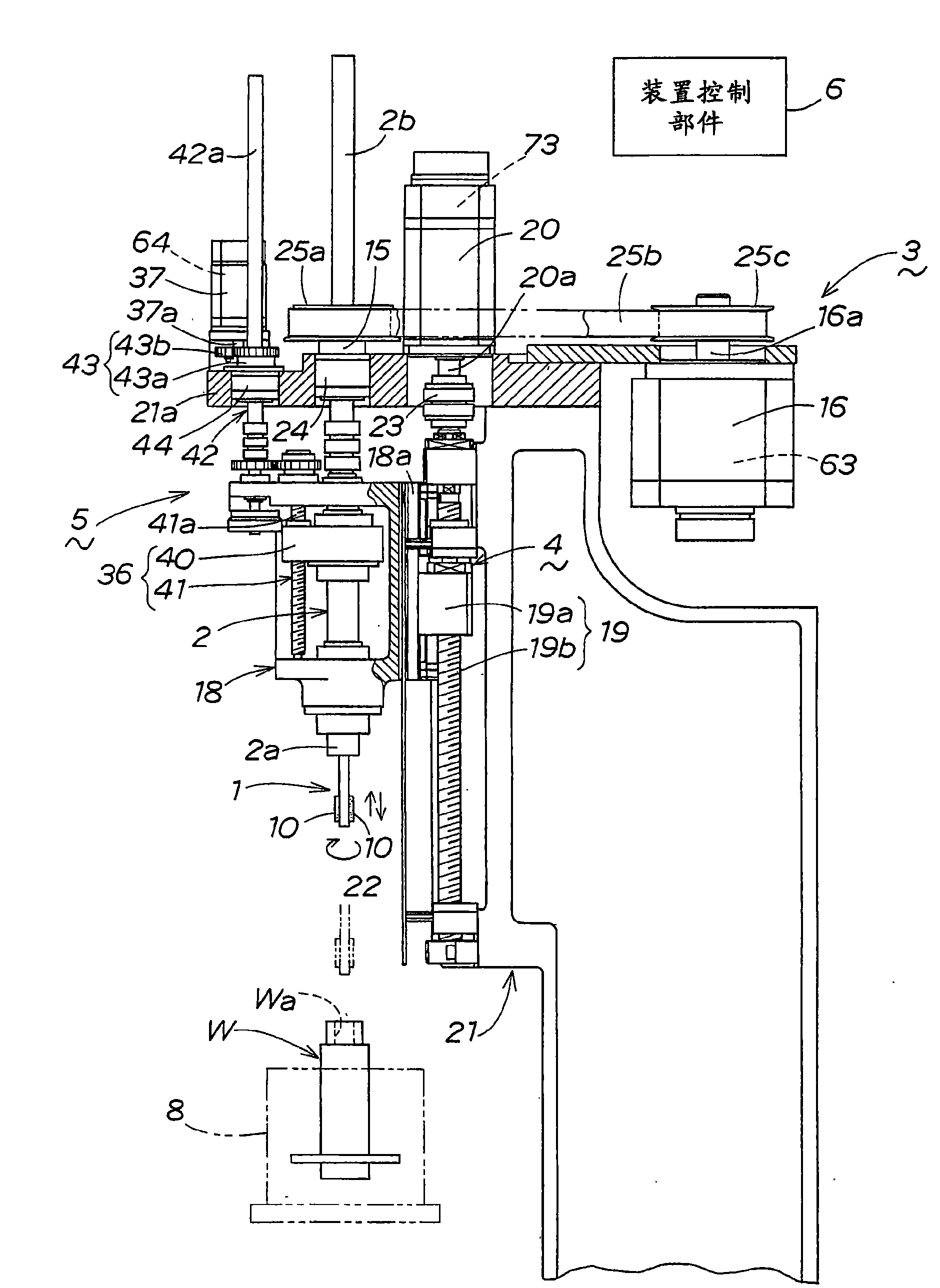

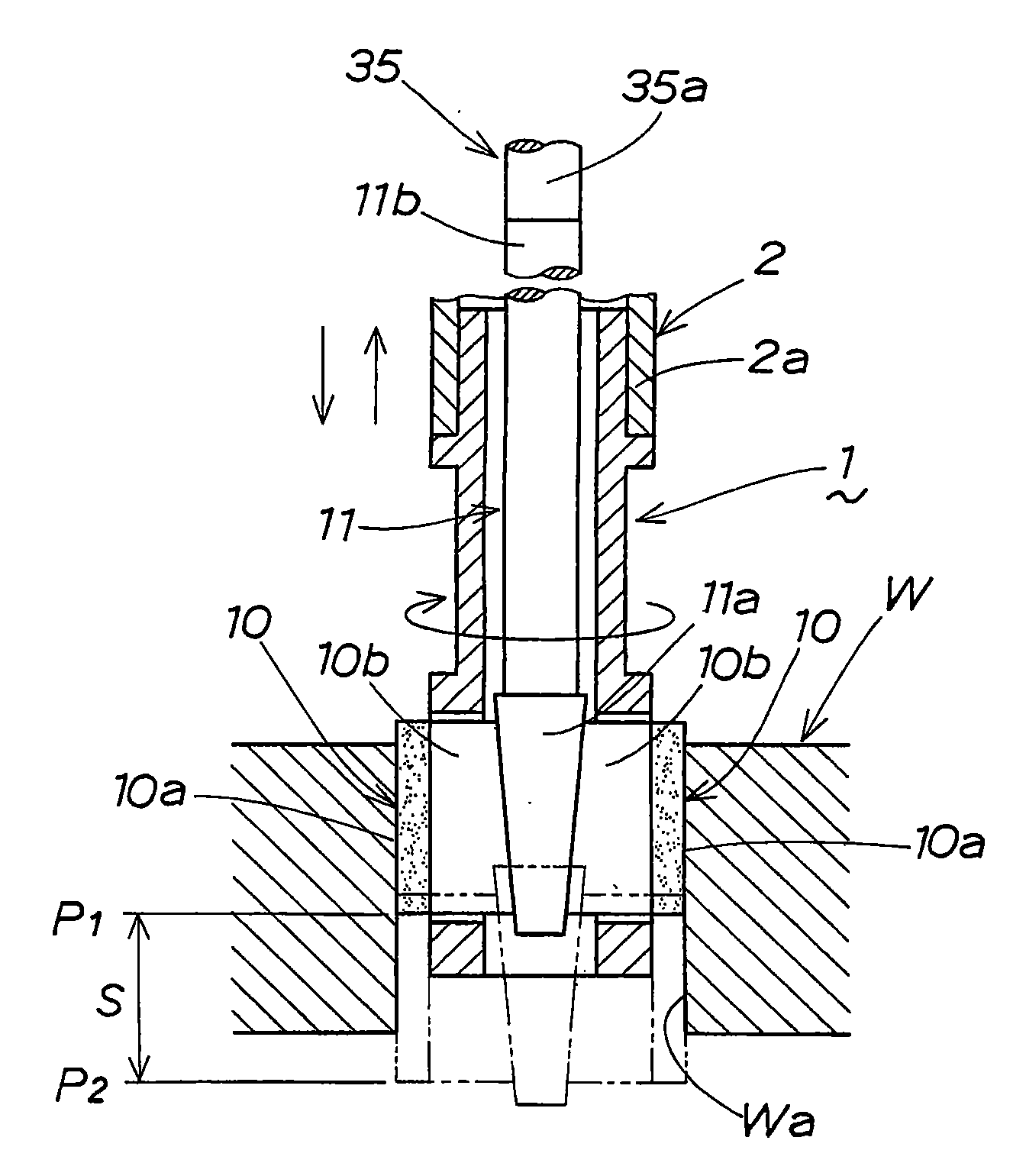

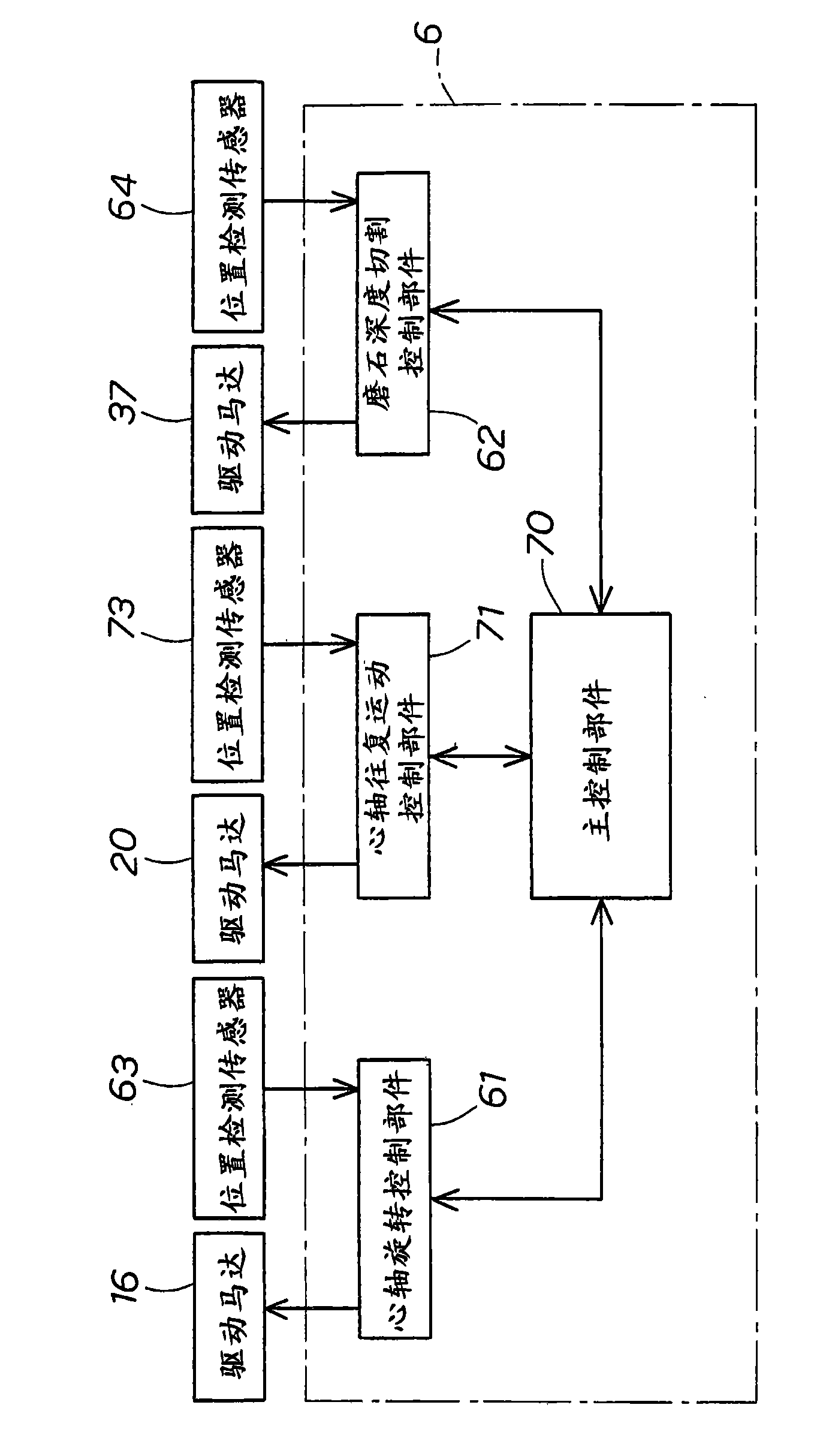

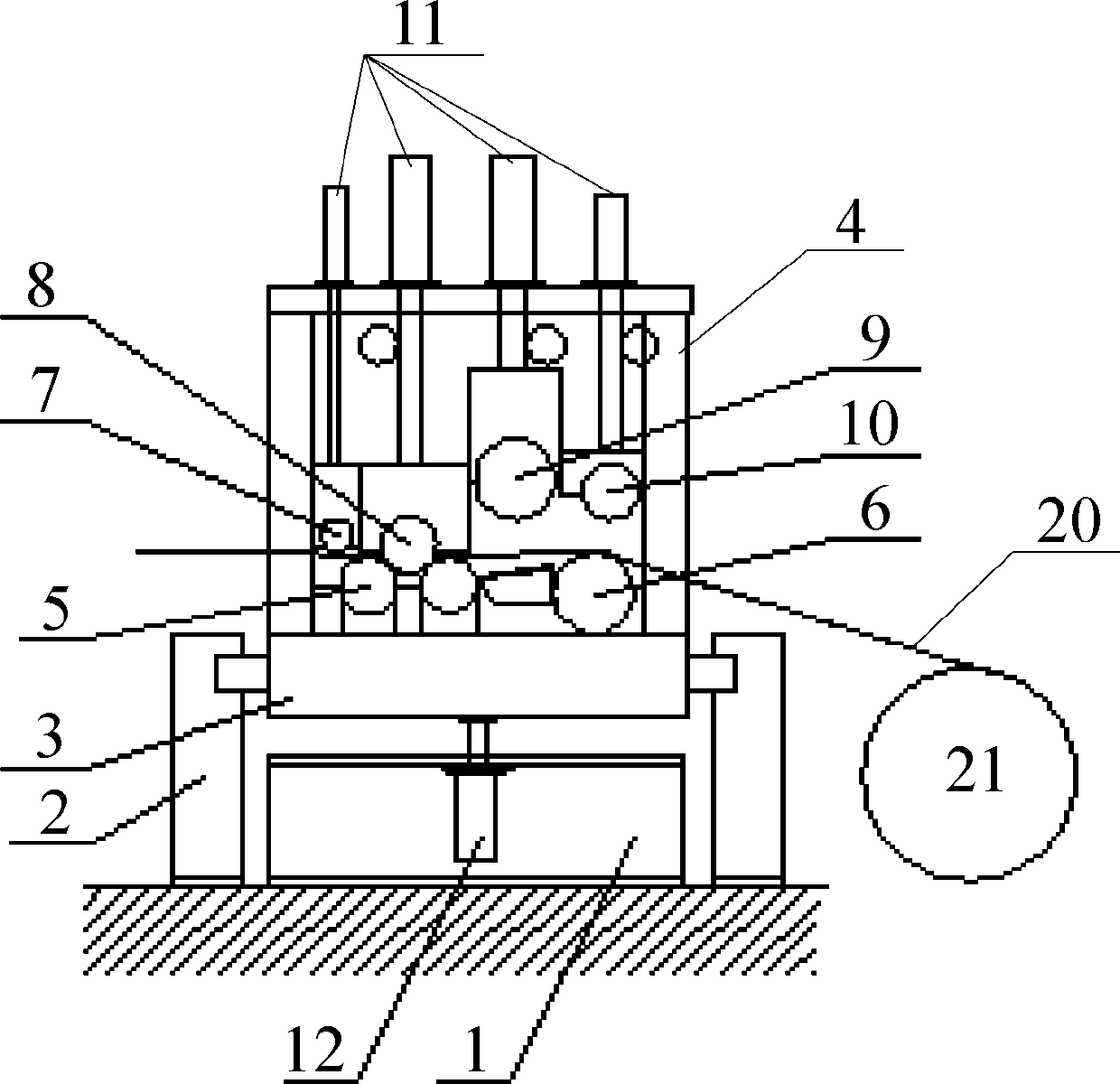

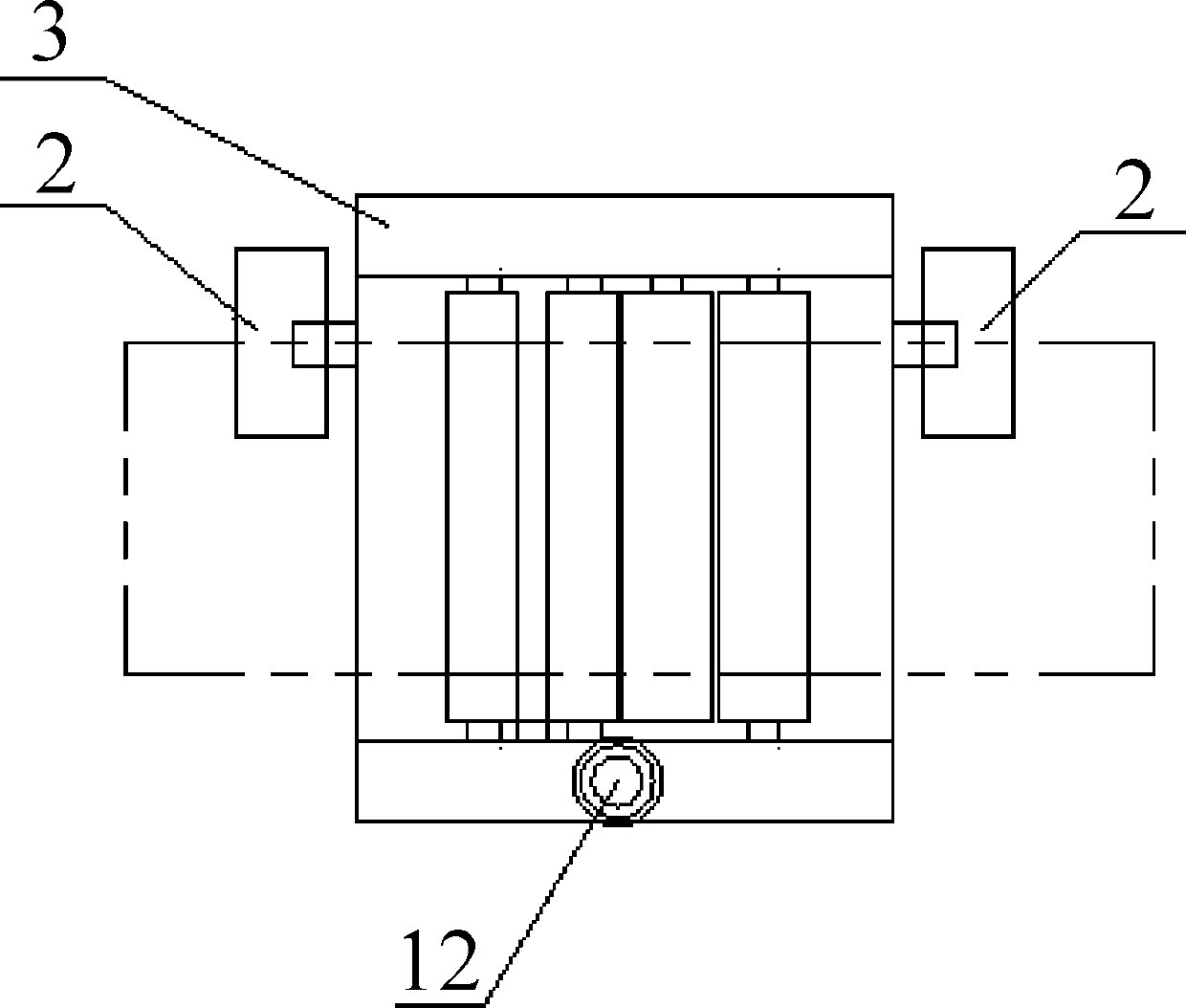

Honing method and honing machine

ActiveCN101670551ALower position waveformPrecise machining loadHoning toolsHoning machinesReciprocating motionServomotor

A honing processing technology for making uniform the load applied to honing grindstones by cooperating the reciprocal motion of the honing grindstones with the feeding and expanding motion at high precision by a specified relation. Servo motors are used as drive sources respectively for spindle reciprocal drive part and grindstone depth cutting part, and these two servo motors are mutually cooperated, and the feeding and expanding motion of the honing grindstones is controlled to be synchronized and tuned with the ascending and descending (reciprocal) motion of the honing tool so that the processing load applied to the honing grindstones may be averaged. Hence, without modifying the basis existing mechanical elements, the load applied to the honing grindstones may be averaged, and the honing process may be stabilized in precision and enhanced in precision.

Owner:NISSIN MFG CO LTD

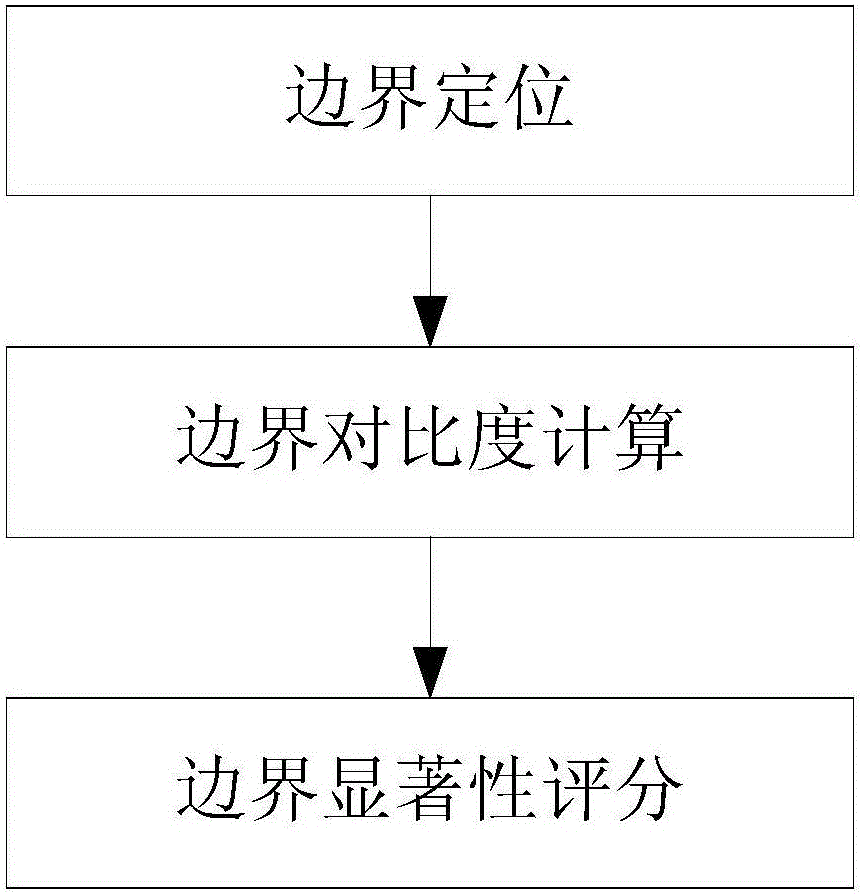

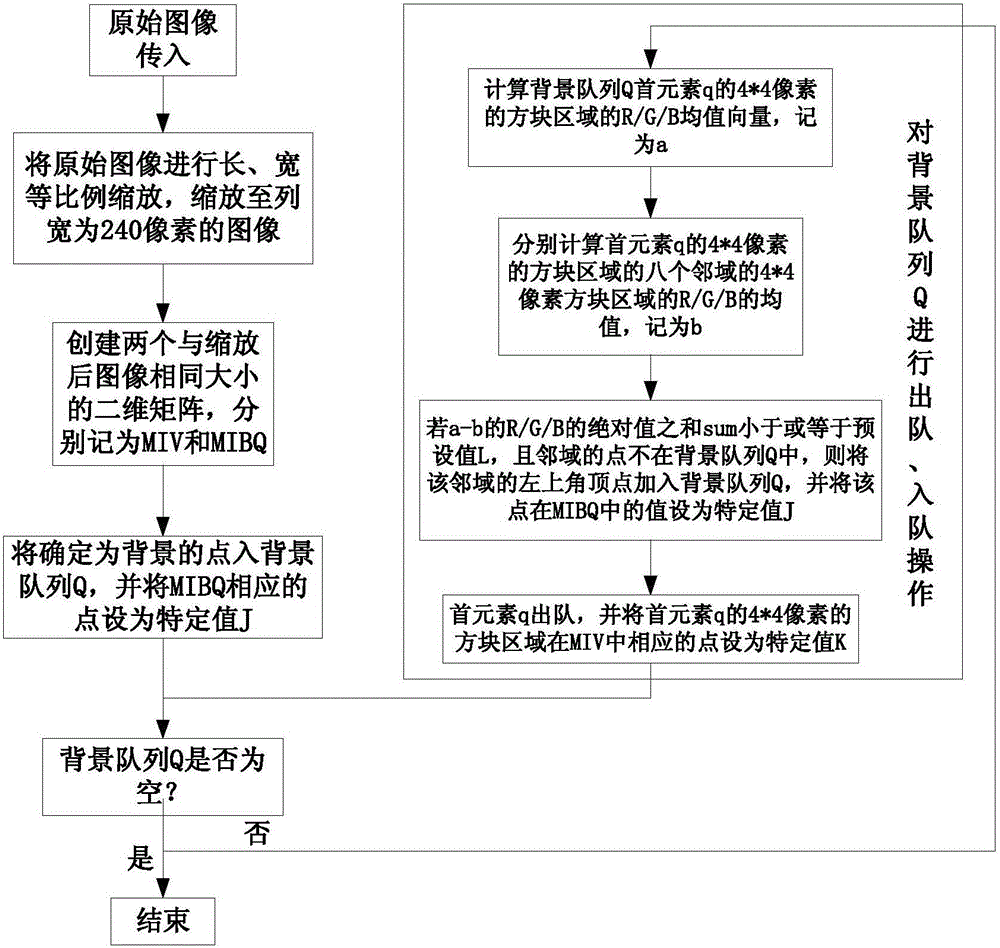

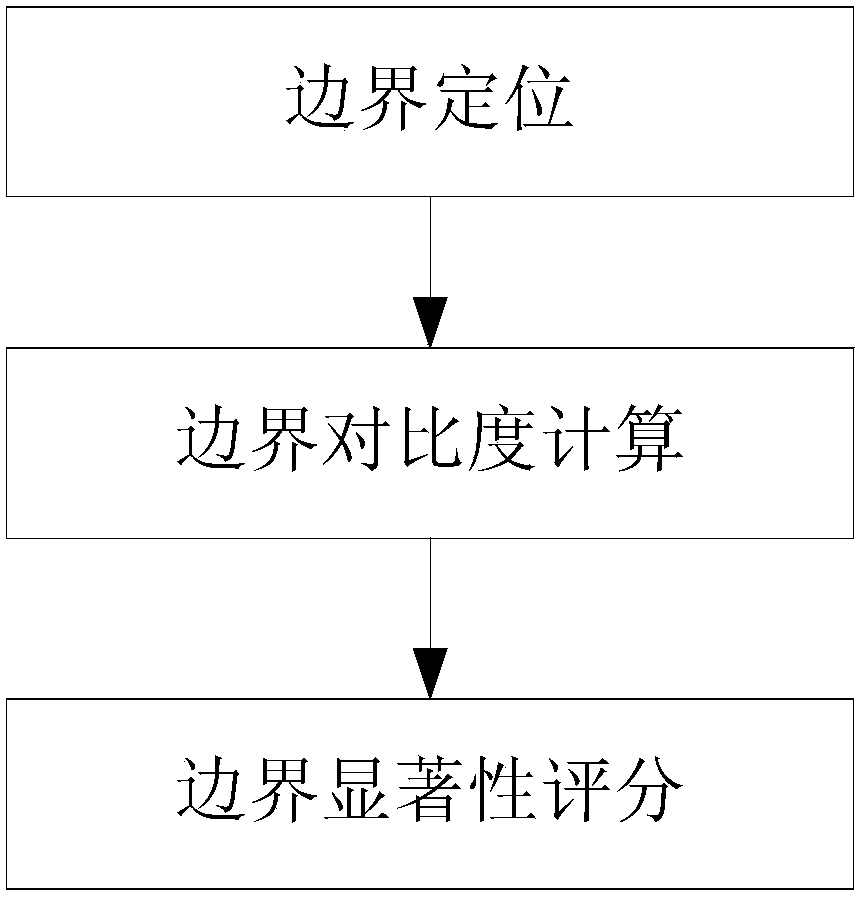

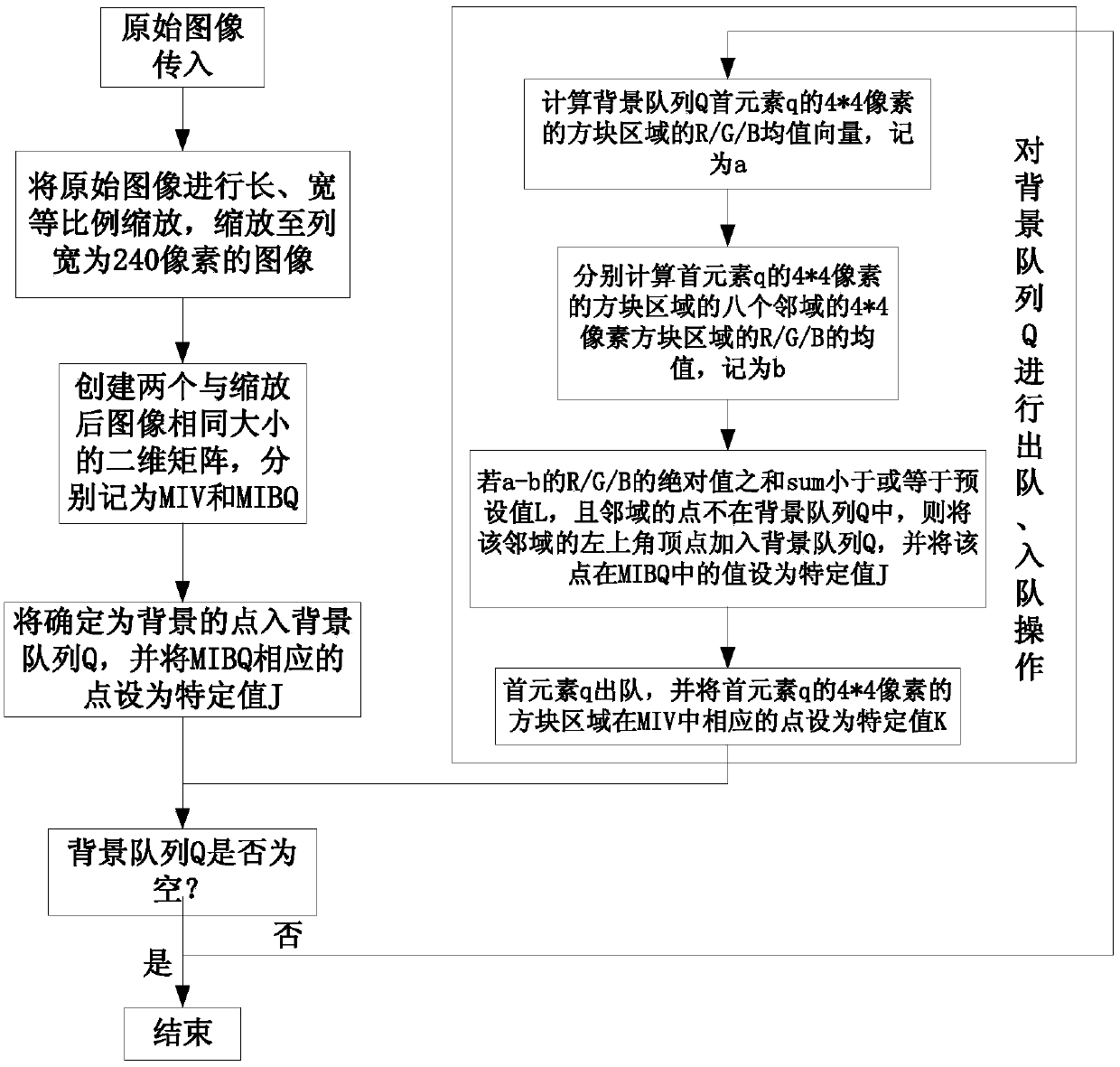

Method and system for evaluating significance of image foreground and background boundaries

ActiveCN106127744AReduce computing timeWidth normalizationImage analysisAssessment methodsComputer vision

The invention discloses a method and system for evaluating the saliency of image foreground and background boundaries. The method includes boundary positioning, boundary contrast calculation and boundary saliency scoring, and the corresponding system includes a boundary positioning module, a boundary contrast calculation module and boundary saliency scoring module. For an image with a pure background, the method and system of the present invention can automatically locate the front and background boundaries, calculate the boundary contrast, and evaluate whether the front and background boundaries of the given picture are significant , and then effectively evaluate whether the background is well distinguished from the foreground, so as to predict the image segmentation quality in advance, and can be widely used in the field of image segmentation technology, such as the matting of ID photos taken by mobile terminals.

Owner:GUANGZHOU XINGFU NETWORK TECH

Display apparatus

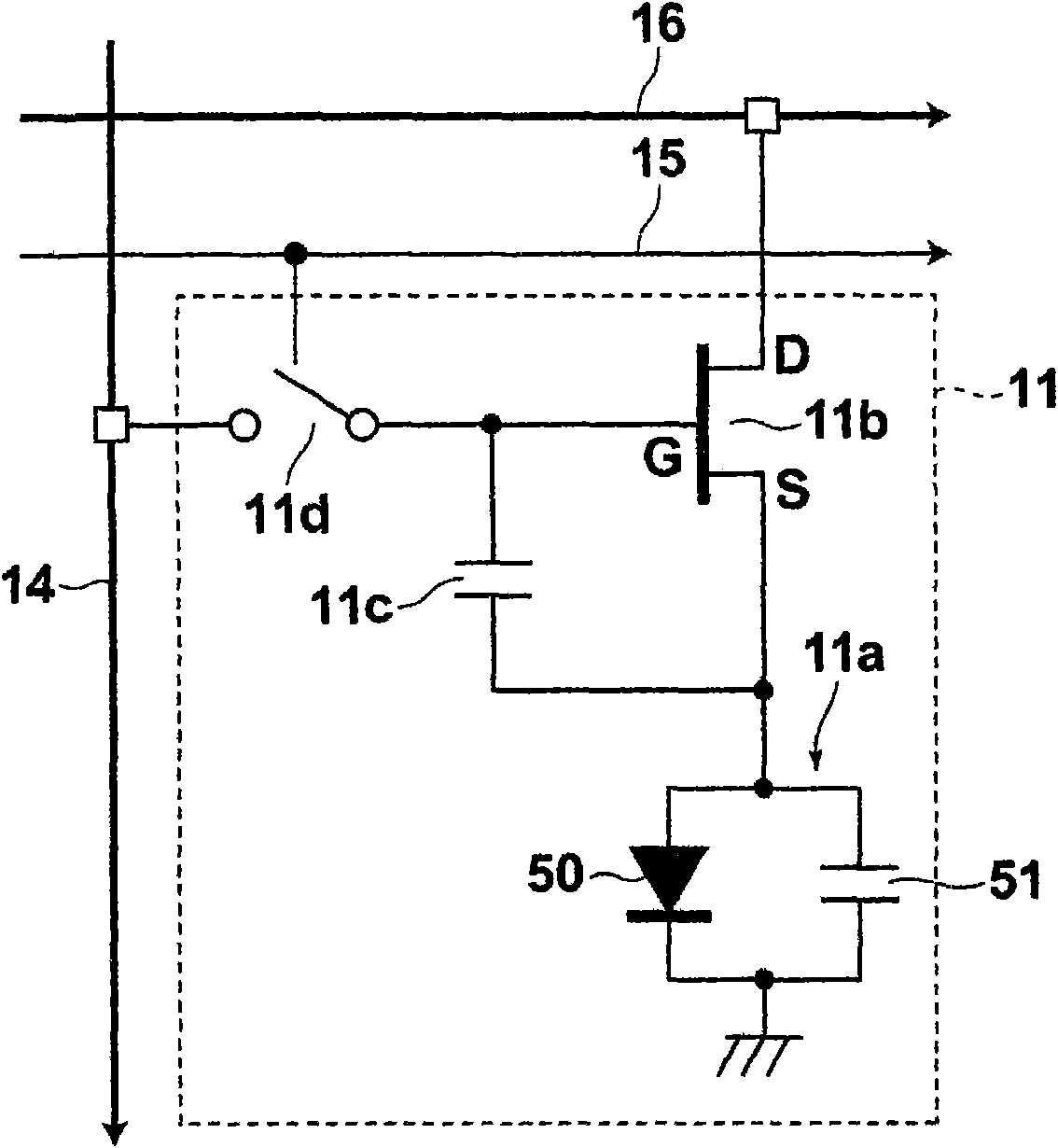

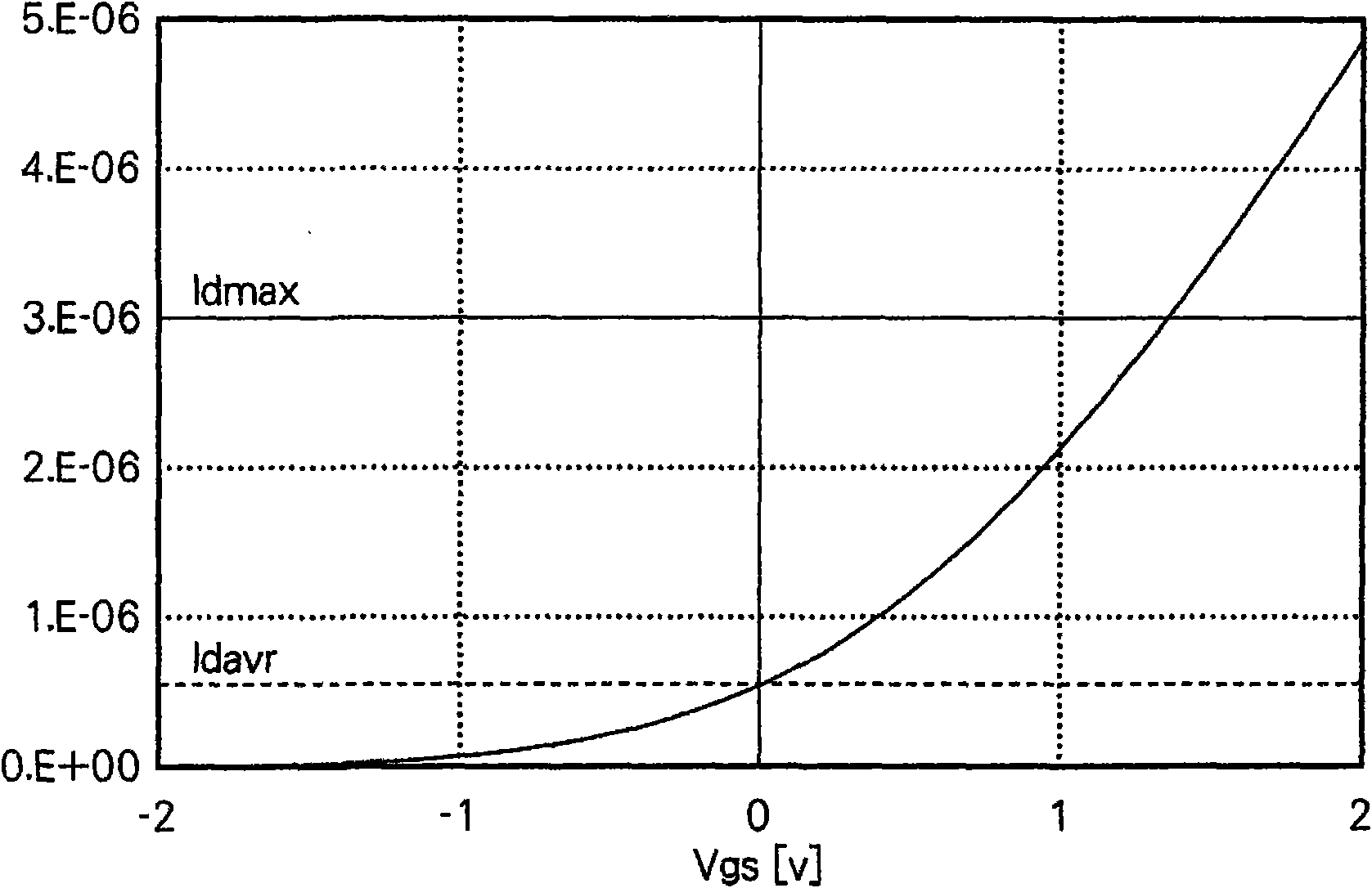

InactiveCN101673509AInhibition of threshold voltage shiftAppropriate correctionStatic indicating devicesSolid-state devicesDriving currentActive matrix

A display apparatus, prevented in threshold voltage shift in drive transistors and capable of stably correcting threshold voltage variations in the drive transistors over a long time, including an active matrix substrate with an array of multiple pixel circuits, each having a light emitting element, a drive transistor connected to the light emitting element to apply a drive current to the light emitting element, a capacitor element connected between a gate terminal and the source terminal of the drive transistor, and a selection transistor connected between the gate terminal of the drive transistor and a data line through which a predetermined data signal flows, in which the drive transistor is an n-type thin film transistor having a current characteristic in which a drive current at a gate-source voltage Vgs = 0V corresponds to an average drive current Idavr.

Owner:FUJIFILM CORP

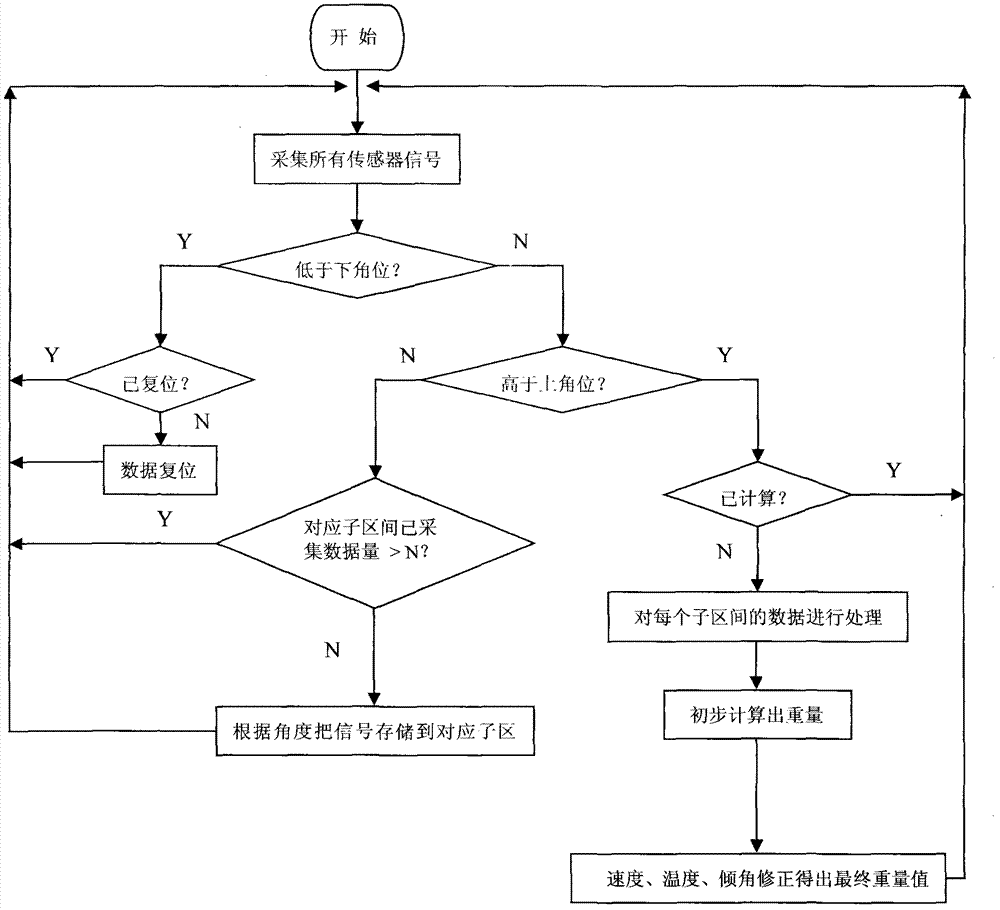

Electronic scale of loading machine

InactiveCN102788628AHigh precisionEasy to operateWeighing apparatus using fluid action balancingData acquisitionEngineering

The invention discloses an electronic scale of a loading machine. The electronic scale of the loading machine comprises (1) an oil pressure sensor installed at the position of a big arm oil inlet tube of the loading machine, (2) an angle sensor installed on a big arm, (3) a temperature sensor for measuring oil temperature, (4) a horizontal dip angle sensor for measuring a vehicle body and (5) a data processing and displaying module. A weighing region can be conveniently modified through an interface, and a problem that a weighing area and a weighing region are changeless due to the fact that a proximity switch is used is solved. An algorithm can determine to conduct data acquisition or not according to angle variation or not, and a problem that the big arm needs to pass through the weighing region at constant speed is solved. In addition, the dip angle sensor and the temperature sensor can timely monitor and modify the vehicle body and the oil temperature, and influences on weighing accuracy caused by uneven areas and oil temperature variation are removed. A large quantity of site using cases prove that the device is high in dynamic weighing accuracy, convenient to debug and capable of applying to complex working conditions and enables operation of a driver to be at will.

Owner:SHENZHEN CELIJIA CONTROL TECH

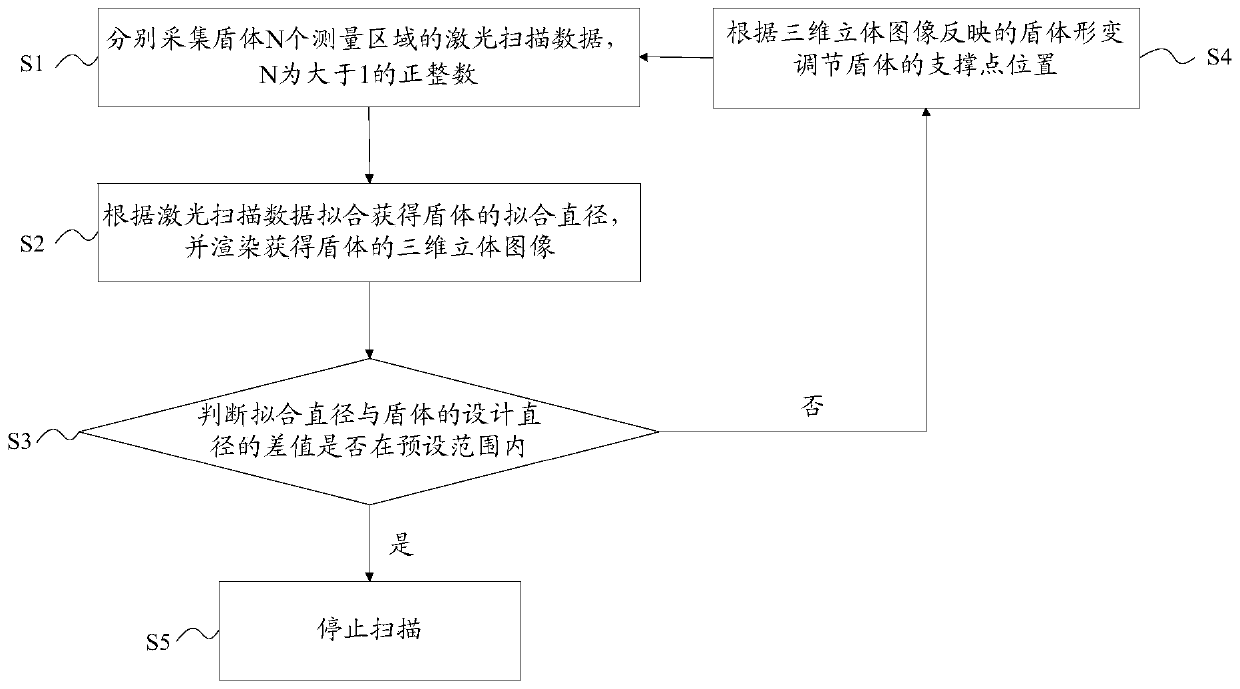

Shield tunneling machine upper shield deformation detection and online correction method

The invention discloses a shield tunneling machine upper shield deformation detection and online correction method. The method includes the steps that laser scanning data of N measuring areas of a shield are collected respectively, the fitting diameter of the shield is obtained according to the laser scanning data, and a three-dimensional image of the shield is obtained through rendering; whetherthe difference value of the fitting diameter and the design diameter of the shield is in the preset range or not is judged, and if the difference value of the fitting diameter and the design diameterof the shield is in the preset range, scanning is stopped; and if the difference value of the fitting diameter and the design diameter of the shield is not in the preset range, the position of a supporting point of the shield is adjusted according to the shield deformation reflected by the three-dimensional image, laser scanning data of all the measuring areas are collected again, subsequent stepsare executed, and scanning is stopped till the difference value of the fitting diameter and the design diameter of the shield is in the preset range. By means of the method, deformation of a workpiece can be accurately obtained, errors between the deformation of the workpiece and the theoretical mathematical model are obtained, and therefore proper correction can be conducted conveniently. In addition, the method is not limited by to-be-machined sizes, the measuring and detection size range is enlarged, an existing cumbersome measuring mode is changed, and the measuring efficiency and the measuring quality are improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

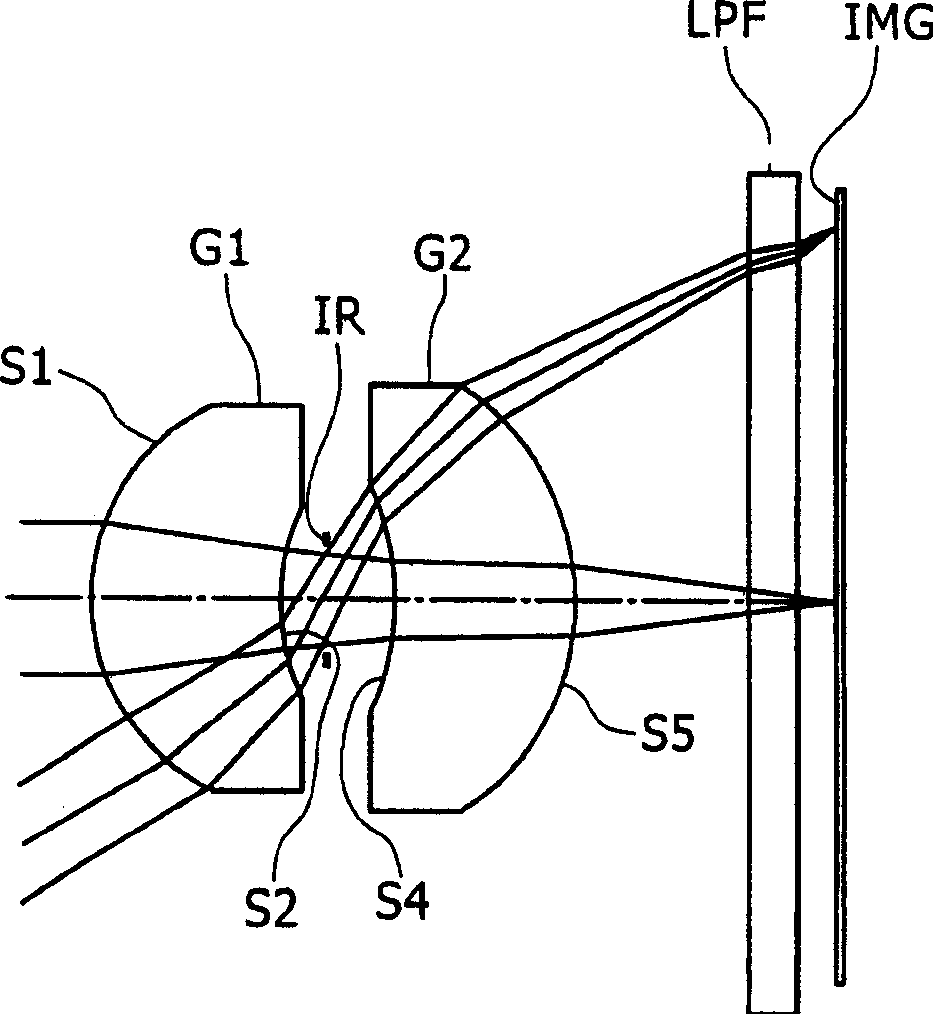

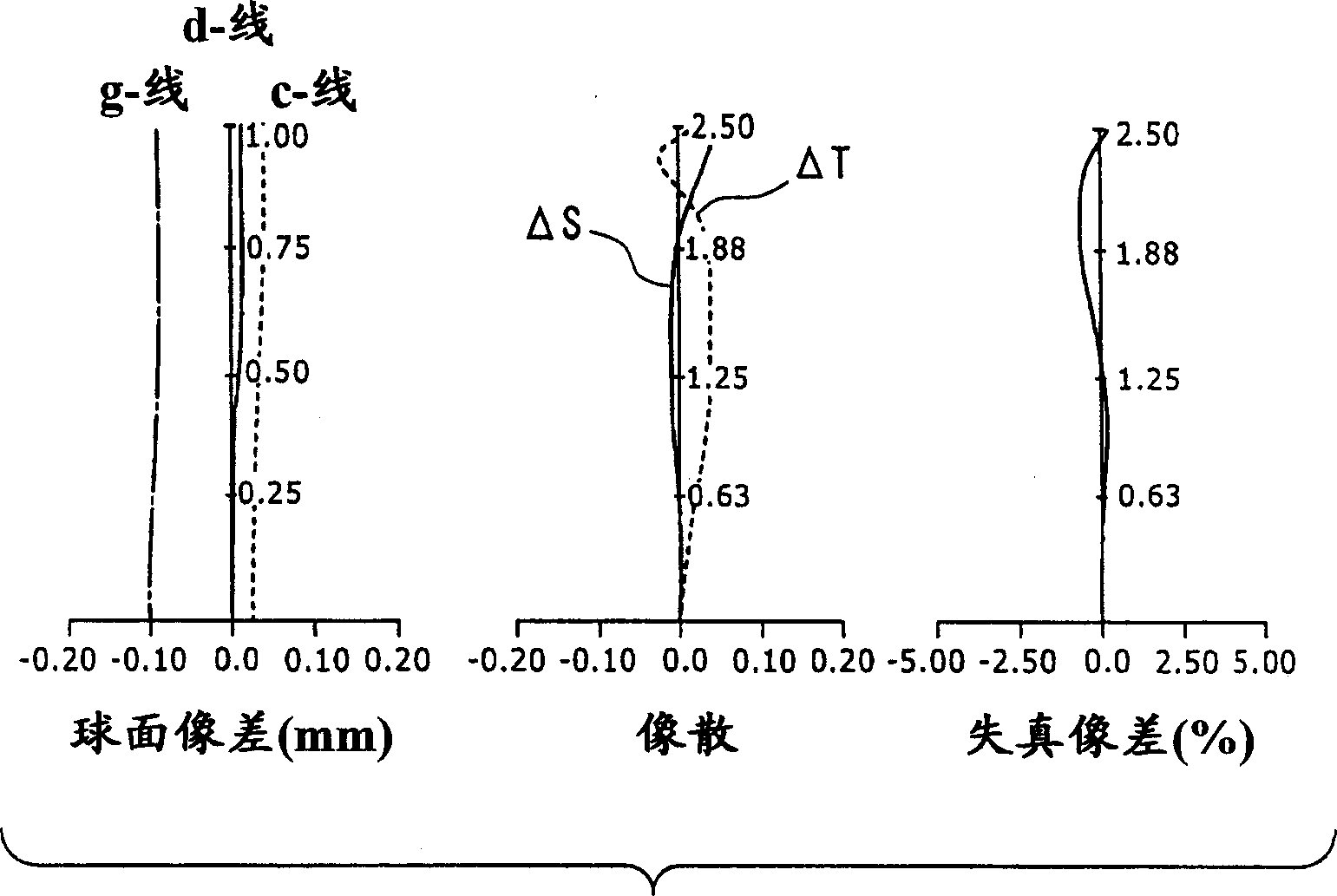

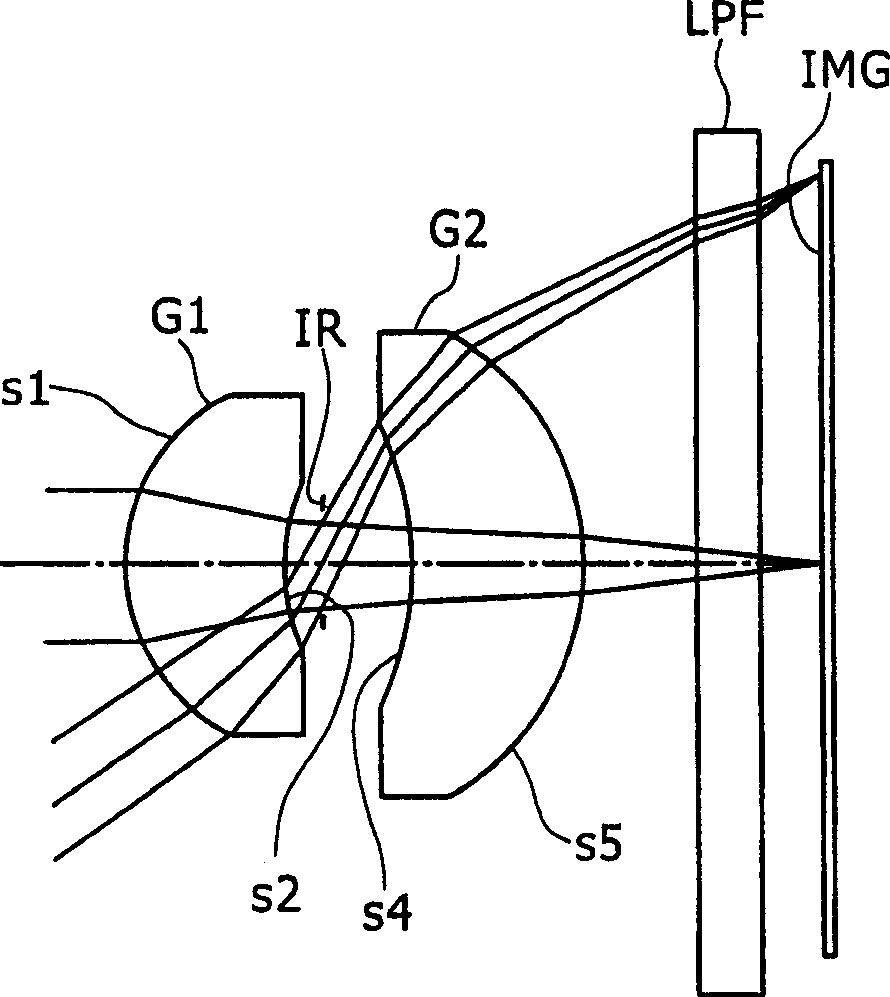

Imaging lens and imaging apparatus

To provide an extremely small imaging lens having a satisfactory optical performance capable of coping with high pixel imaging element even though the lens is composed of fewer lenses (two lenses), and to provide an imaging apparatus using the imaging lens. The imaging lens includes in order from the object side: a first lens G1 having a positive refracting power, which has a meniscus shape whose convex face is in the direction of the object; an aperture diaphragm IR; and a second lens G2 having a positive refracting power, which has a meniscus shape whose convex face is in the direction of an image. The imaging lens satisfies the following conditional formulas (1), (2) and (3): (1) 0.21.7, wherein f denotes the focal distance of the entire lens system, f1 denotes the focal distance of the first lens, and L denotes a distance from the image side face of the first lens and an image plane (a back insertion glass is calculated using thickness acquired by air conversion), and n(ave) is the average value of refractive indexes on the d-line of the two lenses composing the lens system.

Owner:SONY GRP CORP

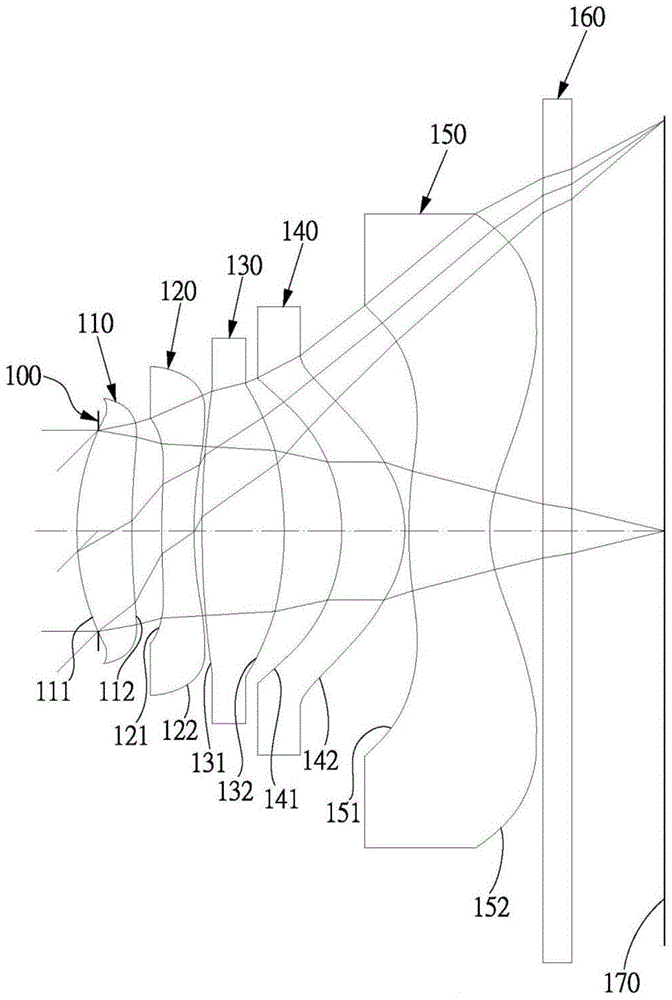

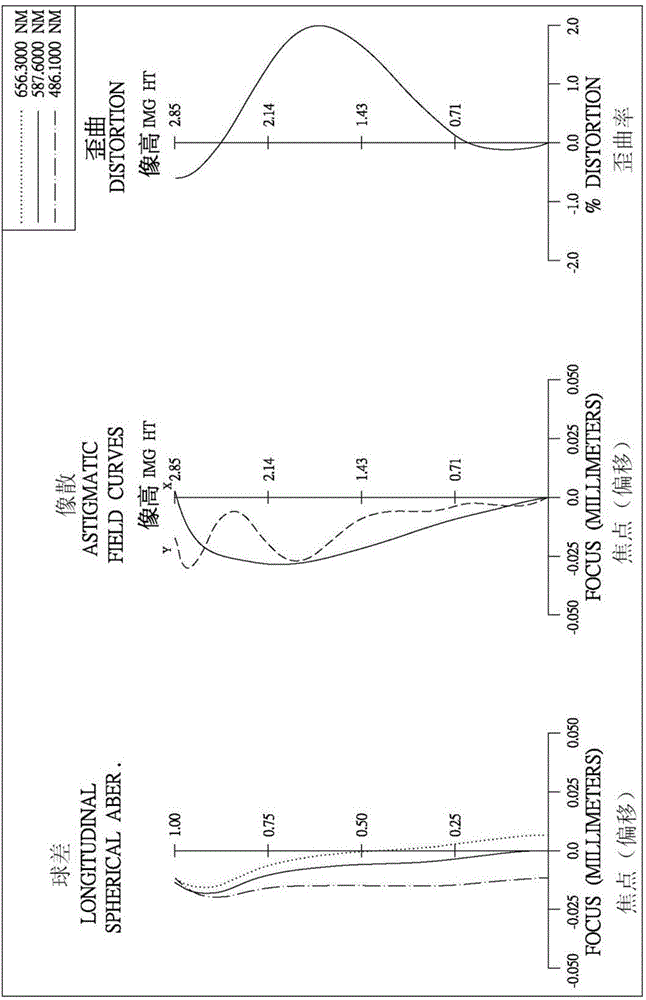

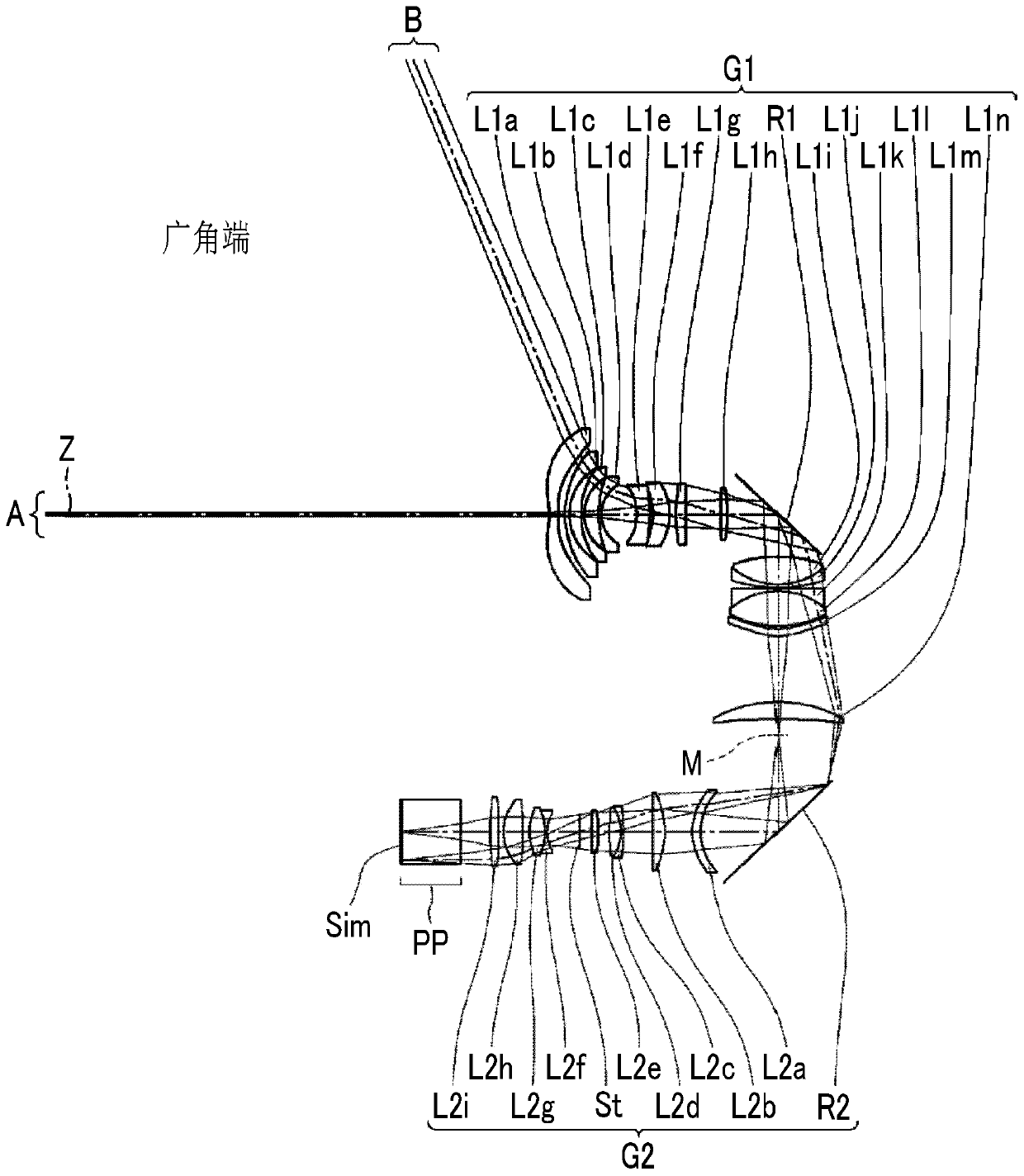

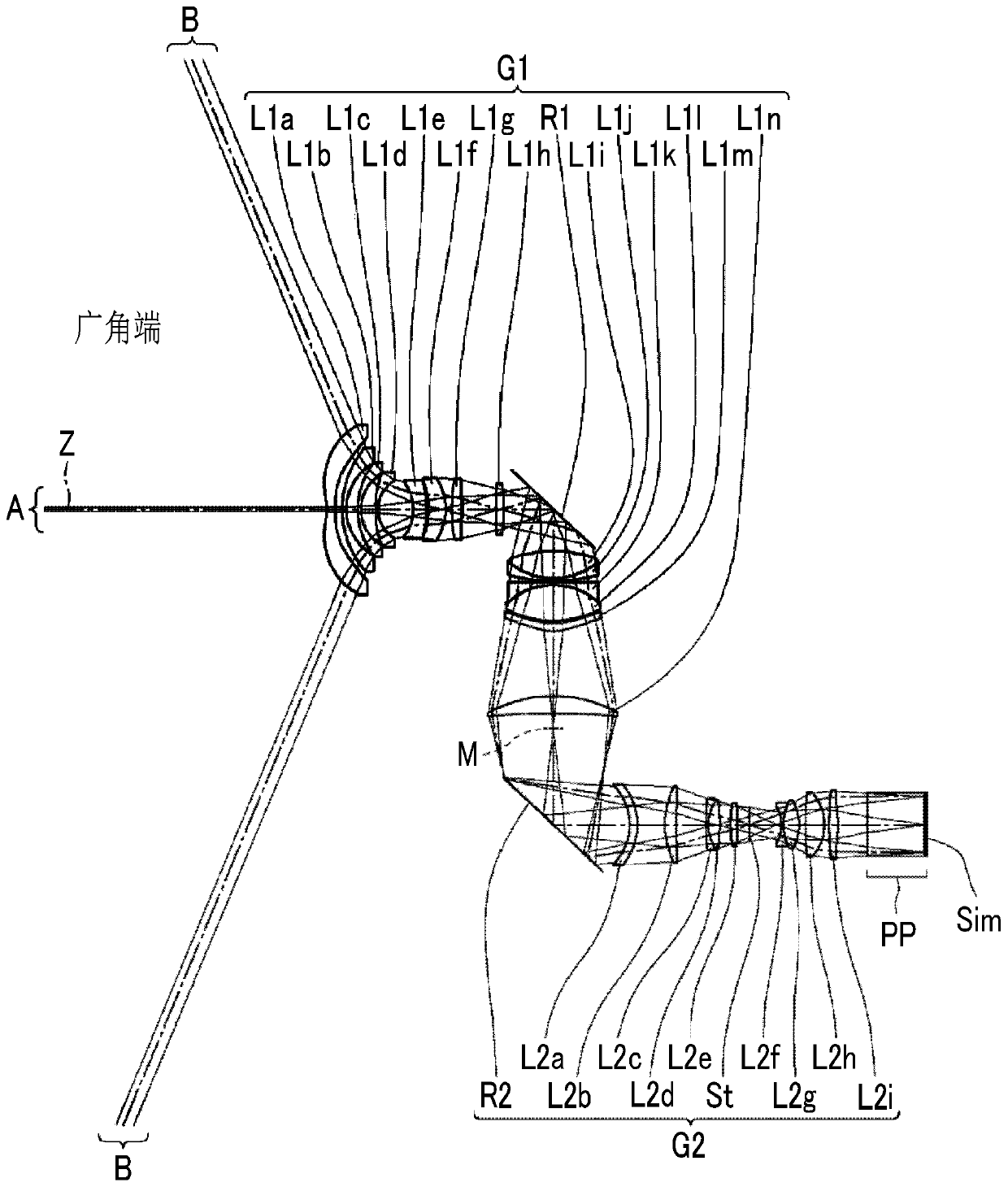

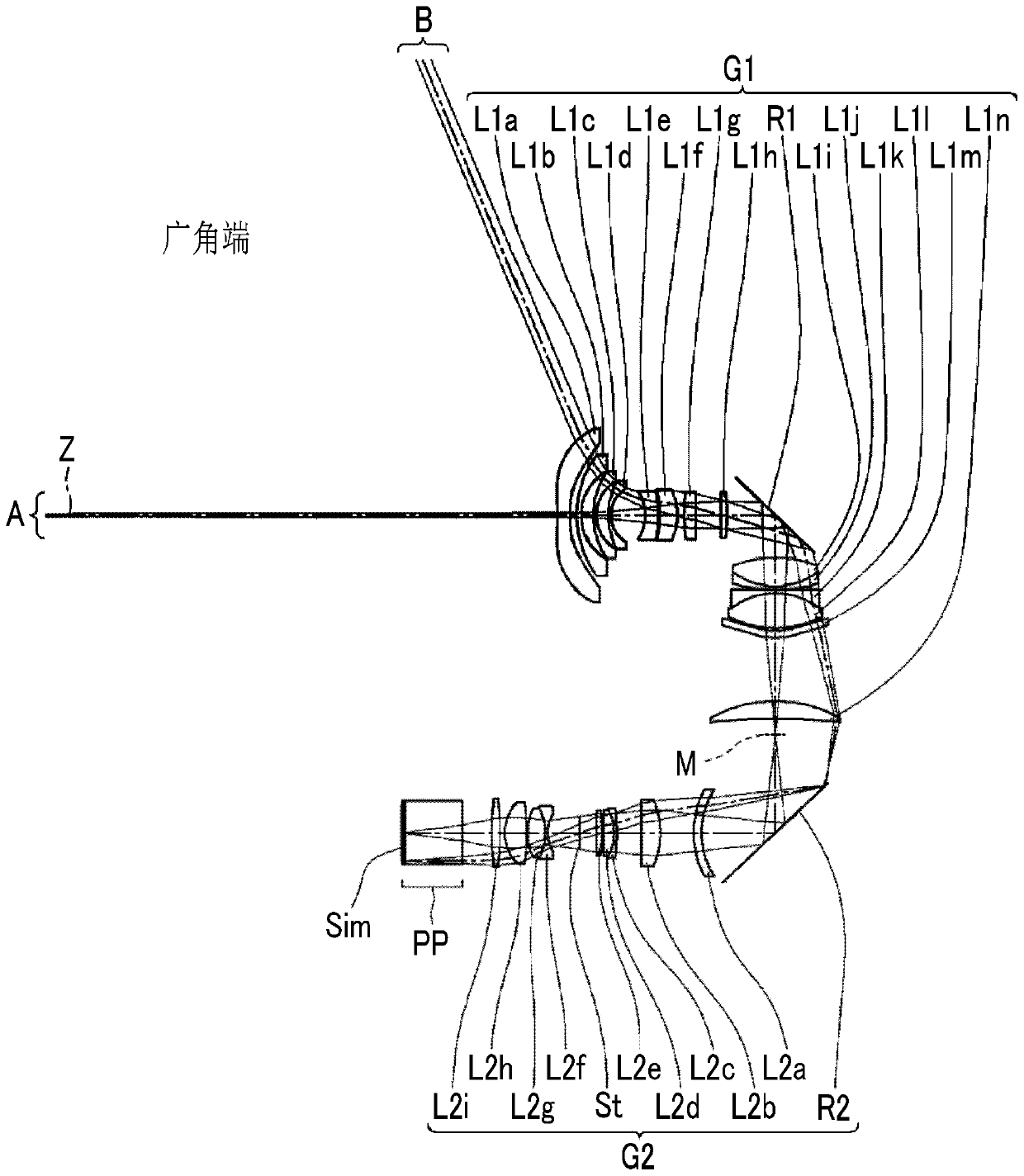

Imaging optical system, projection display device, and imaging apparatus

ActiveCN110944162AAppropriate correctionGood optical performanceProjectorsPicture reproducers using projection devicesIntermediate imageOphthalmology

The invention provides an imaging optical system which is small in size, has a wide viewing angle, has properly corrected aberrations, and has high optical performance, a projection display device provided with the imaging optical system, and an imaging device provided with the imaging optical system. The imaging optical system includes, in order from an amplification side along an optical axis, afirst lens group and a second lens group. An imaging optical system in which an intermediate image is formed between a first lens group and a second lens group on an optical axis, at least one of thefirst lens group and the second lens group is provided with a reflection member that bends the optical axis, the second lens group is provided with a moving lens group that moves during zooming, andthe imaging optical system satisfies a prescribed conditional expression.

Owner:FUJIFILM CORP

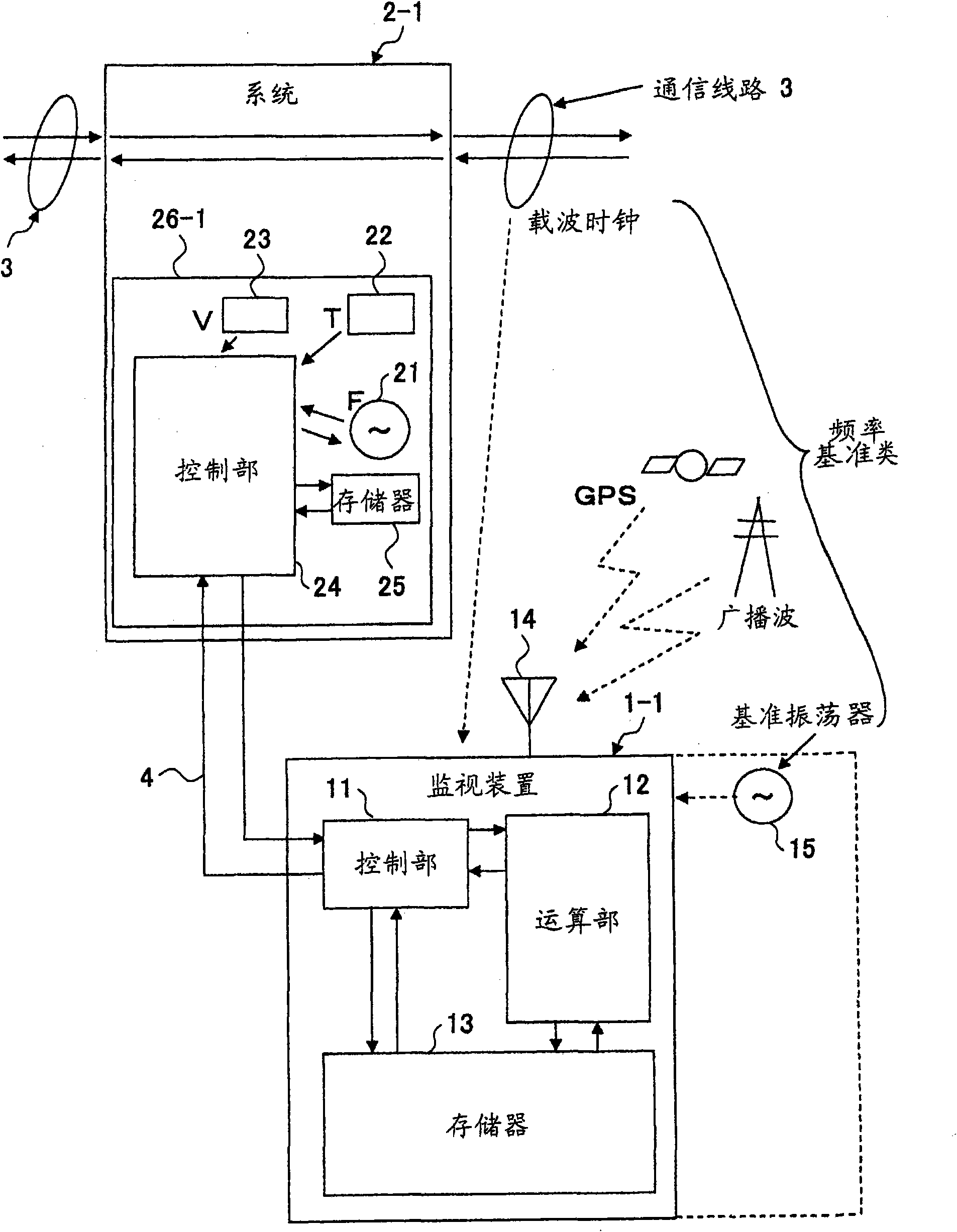

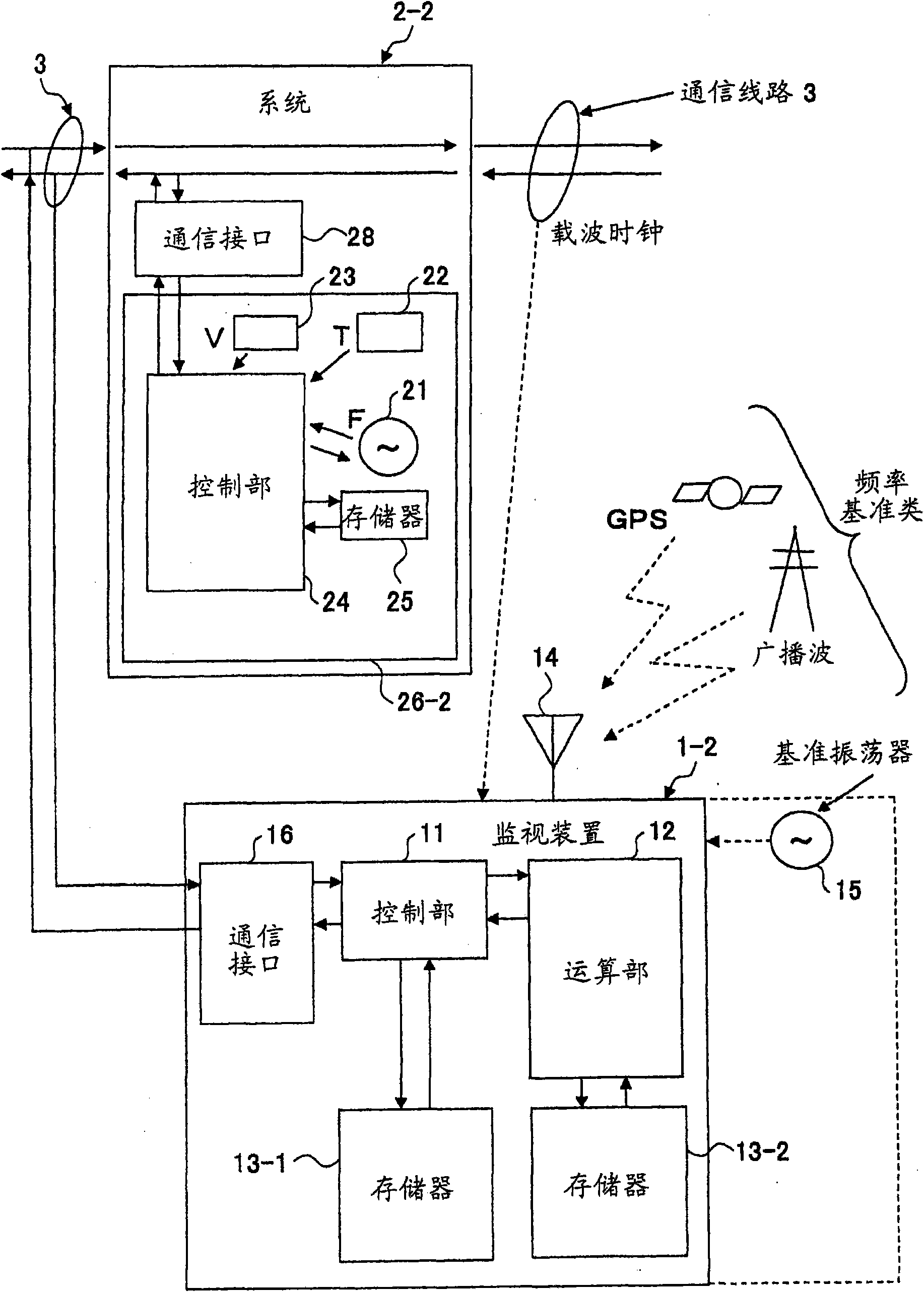

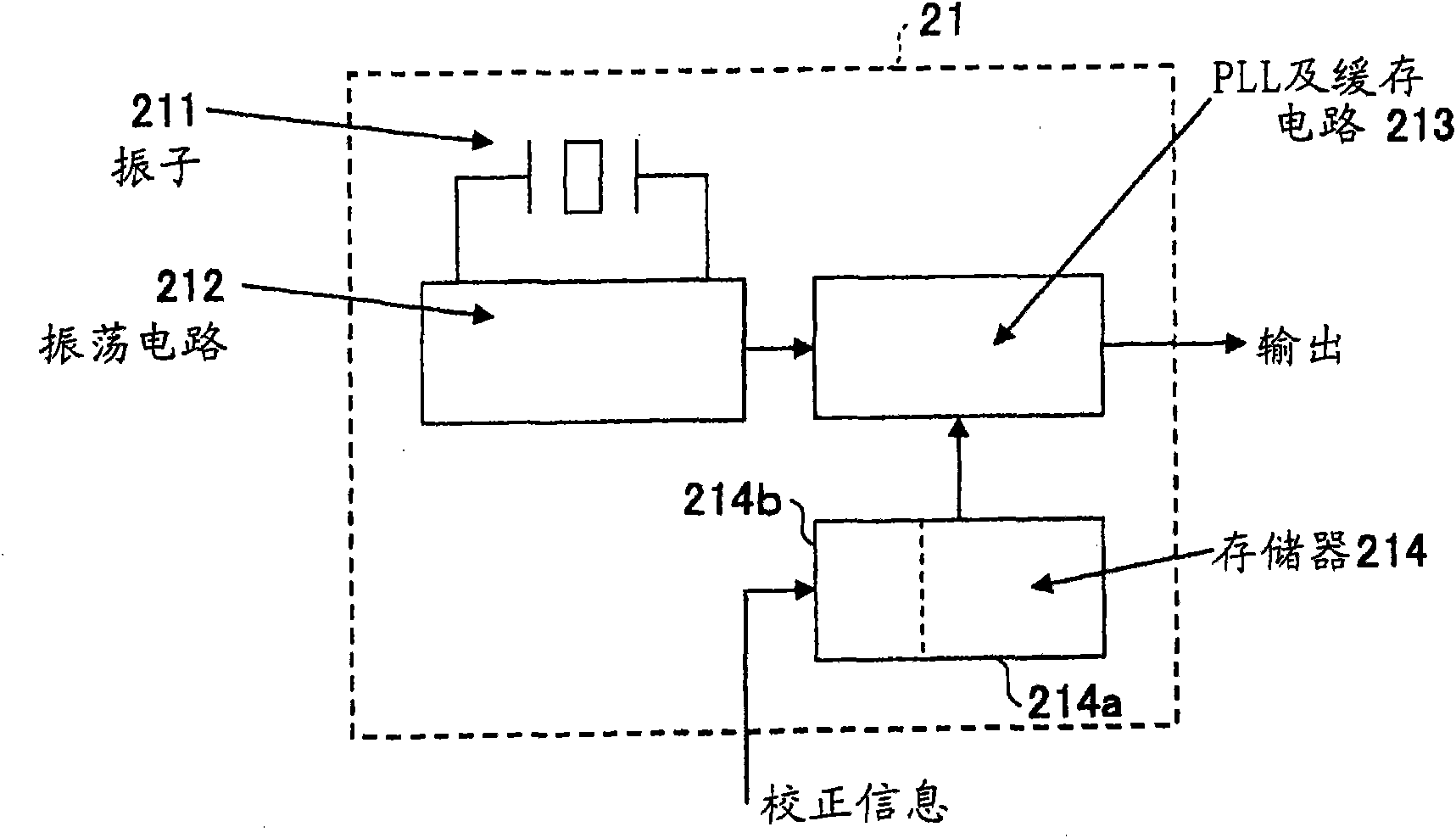

Monitoring apparatus and program

InactiveCN101809858BAppropriate correctionGenerator stabilizationAutomatic frequency control detailsControl unitReal-time computing

A monitoring apparatus monitors a system including an oscillator with a variable oscillation frequency. The monitoring apparatus has a transmitting unit to transmit an information collecting instruction for collecting state information of the system to the system at an arbitrary monitoring timing, and a control unit to perform a control operation that includes transmitting to the system control information for controlling the oscillation frequency to become a reference value or less if the oscillation frequency exceeds the reference value, and computing a changing amount of the oscillation frequency at least due to aging and a next monitoring timing.

Owner:FUJITSU LTD

Correctable tension steering pinch roll for auxiliary coiling of steel strip and method of use thereof

Owner:BAOSTEEL ENG & TECH GRP

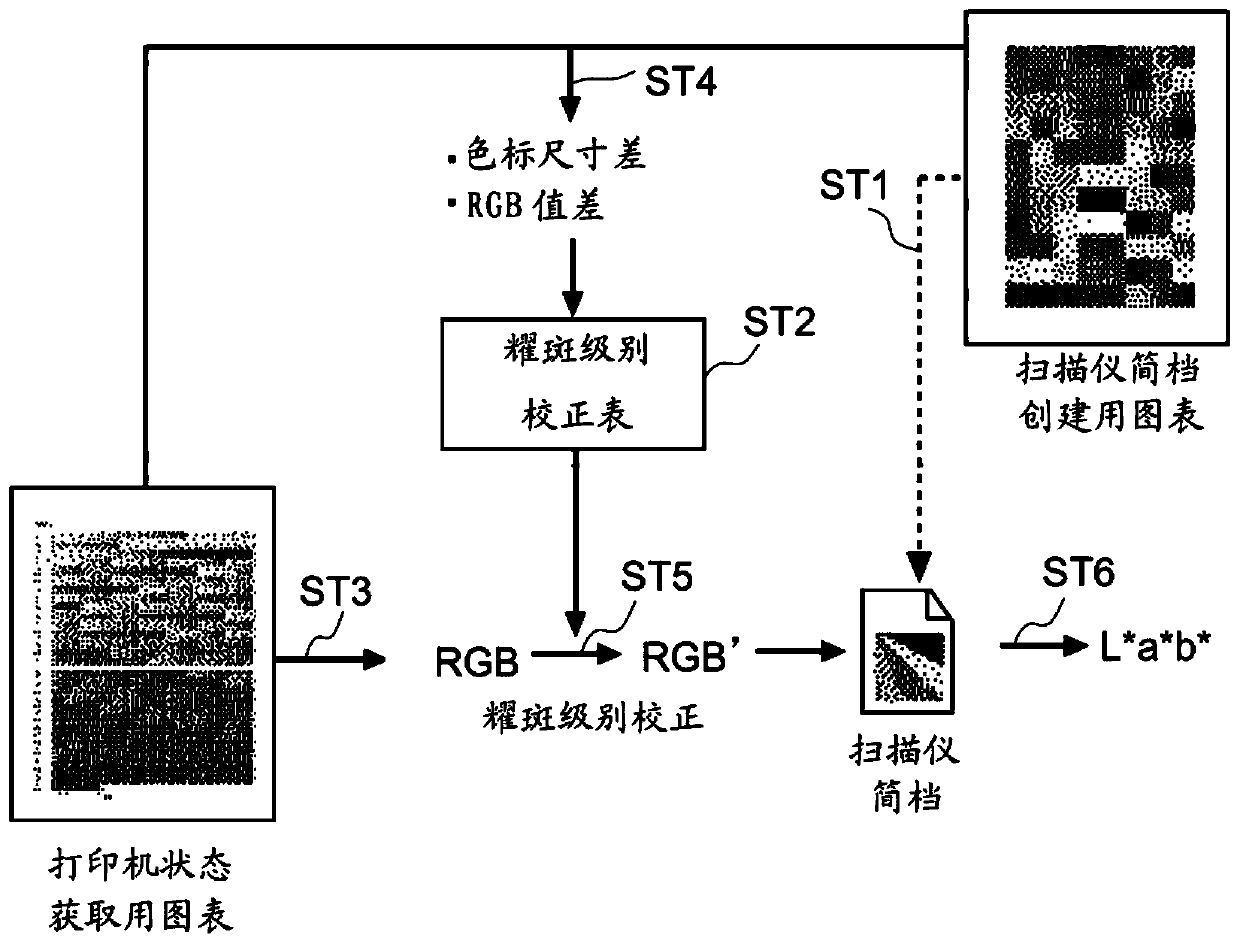

Color changing device and color changing method

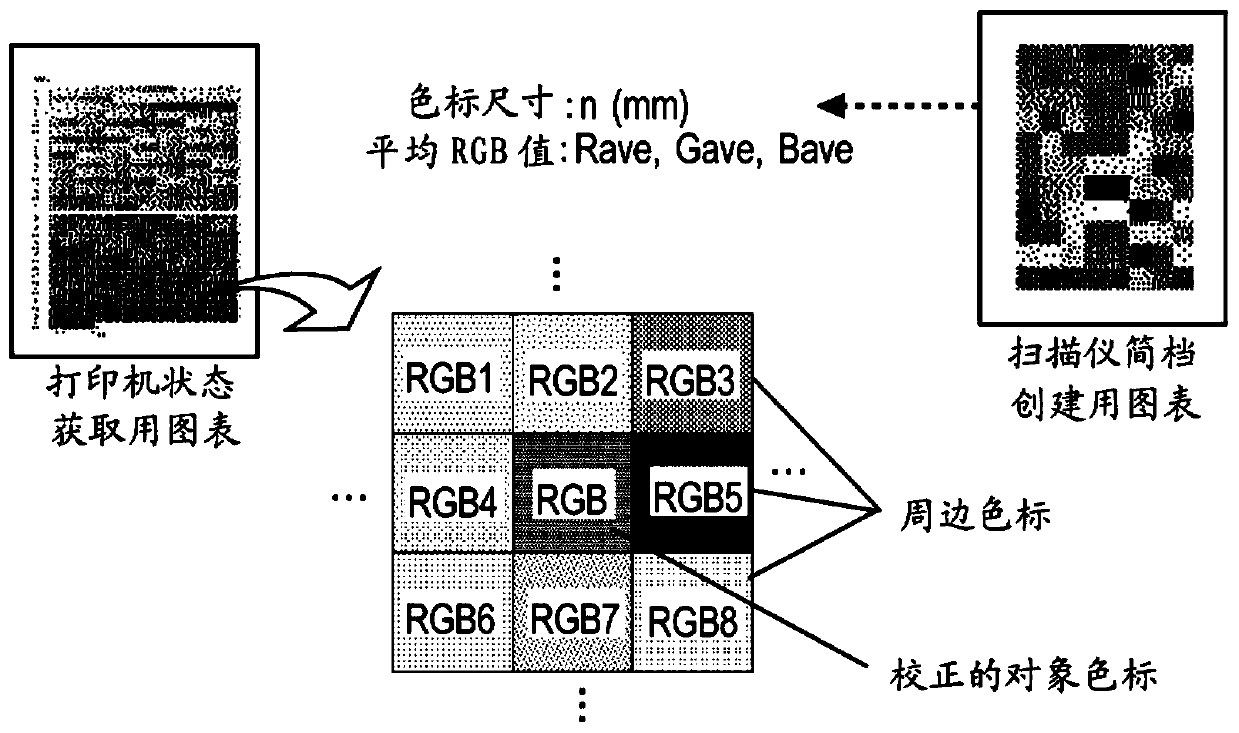

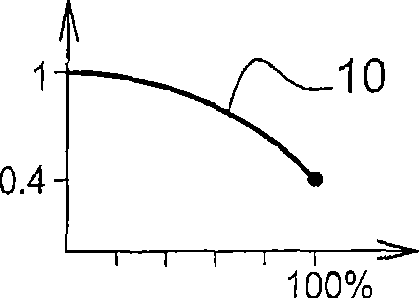

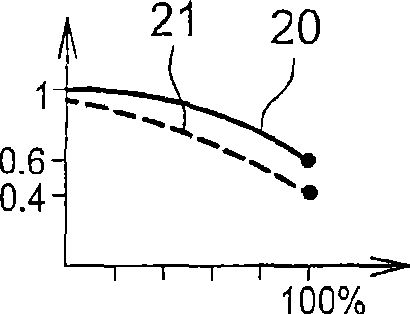

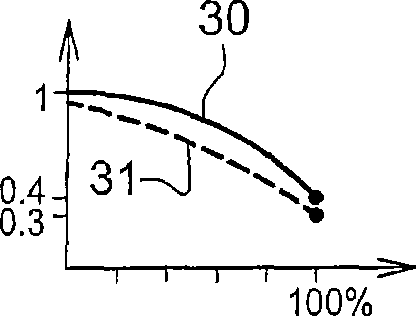

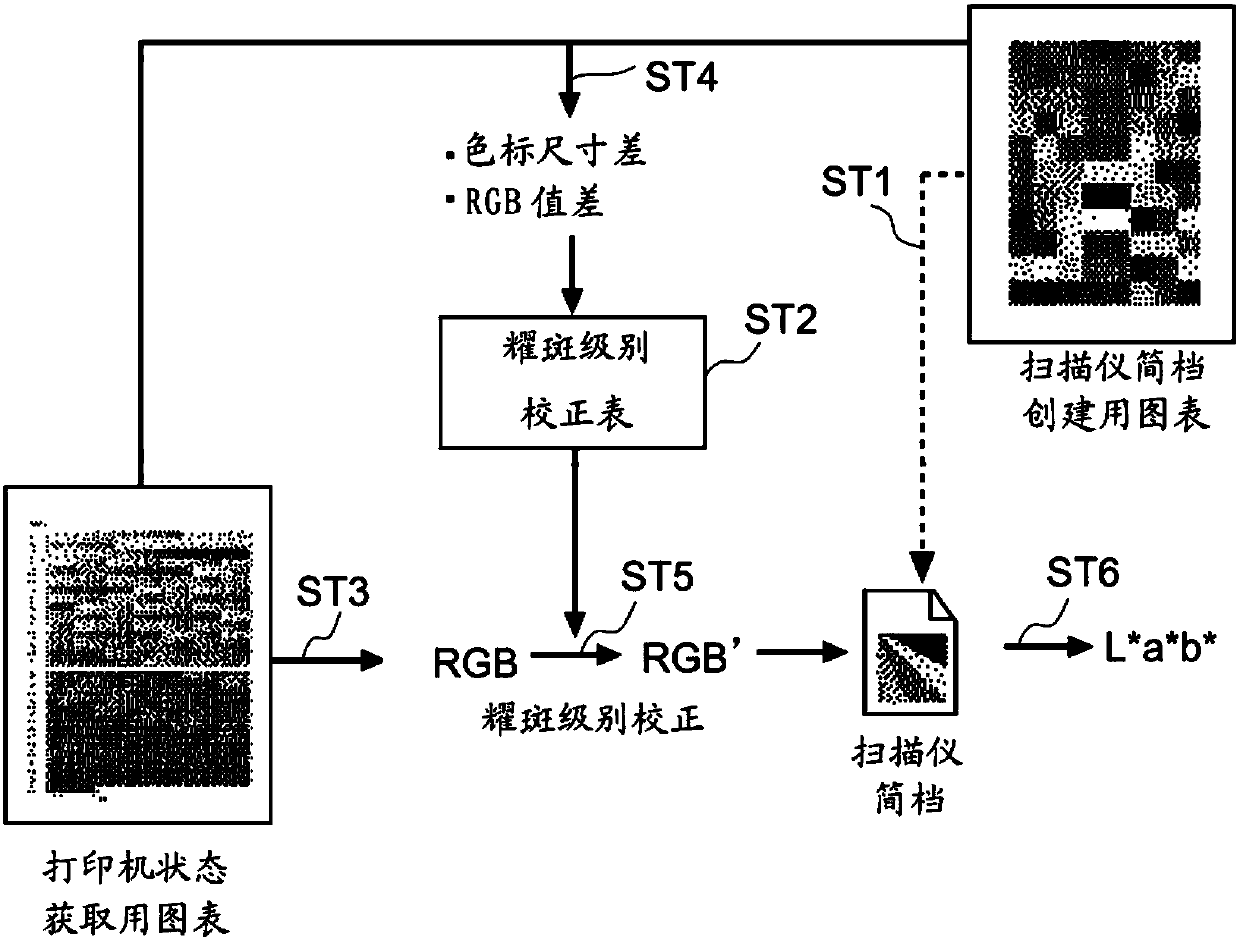

ActiveCN107613158BHigh precisionAppropriate correctionImage enhancementImage analysisPattern recognitionSize difference

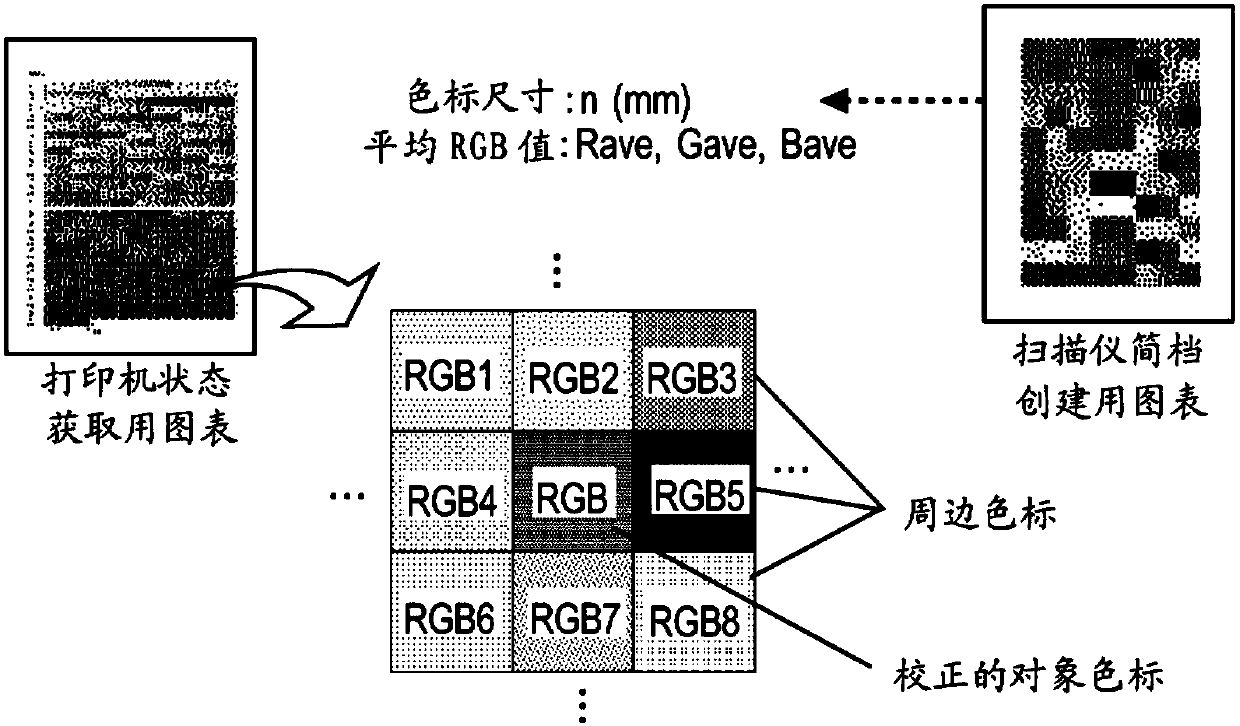

To provide a color conversion device and a color conversion method capable of appropriately correcting the flare level and improving the accuracy of color conversion even when measuring a chart having a different configuration from the scanner profile creation chart. The color conversion device acquires a scanner profile that correlates the RGB values obtained by measuring the color scales of the first color chart printed by the printer with the colorimetric values, based on the RGB values of the respective color scales of the first color chart and the first color chart. The RGB value of each color patch in the predetermined chart created by changing the RGB value of a part of the color patch or the color patch size is created, and a table is created that correlates the RGB value difference and the color patch size difference with the correction amount of the RGB value corresponding to the flare level, Referring to the created table, correct the RGB values obtained by measuring each color patch of the second color chart whose RGB value or color patch size is different from that of the first color chart, and refer to the scanner profile to convert the corrected RGB values to Convert to colorimetric values.

Owner:KONICA MINOLTA INC

Method of processing a relative illumination phenomenon on a digital image and associated processing system

ActiveCN101444083BAppropriate correctionImage enhancementTelevision system detailsIlluminanceComputer vision

The present invention relates to a method and to an associated system for processing digital images which intervenes at the level of any relative illumination phenomenon, including that of coloured relative illumination. Accordingly, the invention proposes that an illuminant of a photographed scene be taken into consideration so as to make appropriate modifications to any digital image to be processed.

Owner:LENS CORRECTION TECH CORP

Method of processing a relative illumination phenomenon on a digital image and associated processing system

ActiveCN101444083AAppropriate correctionImage enhancementTelevision system detailsIlluminanceComputer vision

The present invention relates to a method and to an associated system for processing digital images which intervenes at the level of any relative illumination phenomenon, including that of coloured relative illumination. Accordingly, the invention proposes that an illuminant of a photographed scene be taken into consideration so as to make appropriate modifications to any digital image to be processed.

Owner:LENS CORRECTION TECH CORP

Color conversion apparatus and color conversion method

ActiveCN107613158AHigh precisionAppropriate correctionImage enhancementImage analysisFlareColor chart

Provided are a color conversion apparatus and a color conversion method to properly correct the level of flare occurring in measurement of a chart and thereby improves the accuracy of color conversion, even if the chart is different in composition from the chart for creating a scanner profile. The color conversion apparatus obtains a scanner profile in which measured RGB values and corresponding measured colorimetric values both given by measurement of patches in a first color chart printed by the printer are associated with each other, creates a table on a basis of RGB values of patches in the first color chart and RGB values of patches in a specific chart created by using a part of the patches in the first color chart with an RGB value or patch size being changed, wherein the table includes correction amounts of RGB values, each according to a level of flare estimated for a patch and each associated with an RGB-value difference and a patch-size difference, further corrects, by usingthe table, measured RGB values given by measurement of patches in a second color chart which is different from the first color chart in RGB values or patch size of at least a part of patches, to obtain corrected RGB values; and converts the corrected RGB values into colorimetric values by using the scanner profile.

Owner:KONICA MINOLTA INC

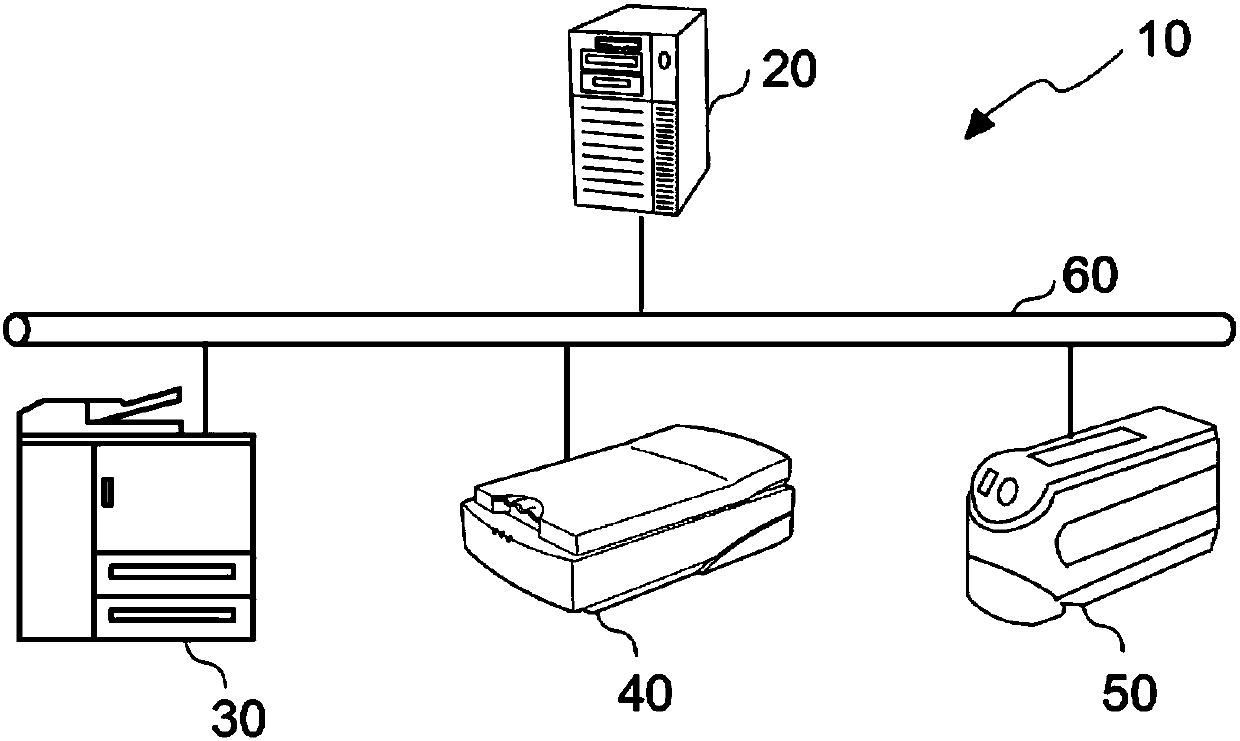

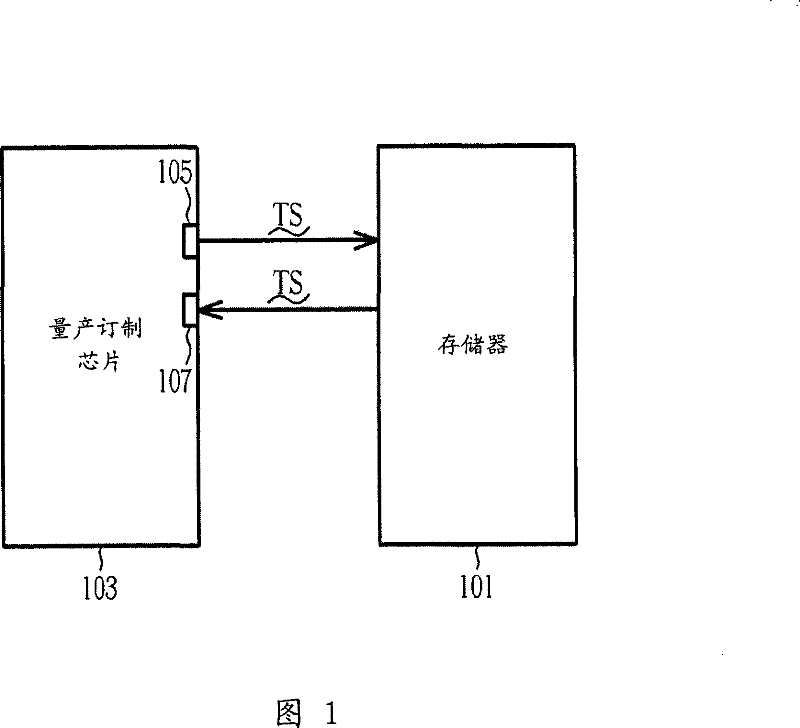

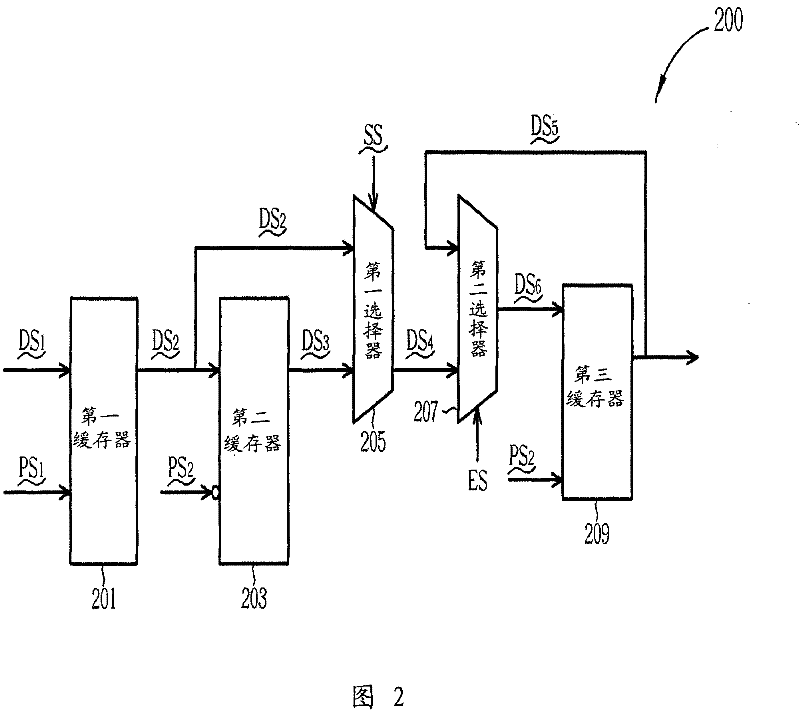

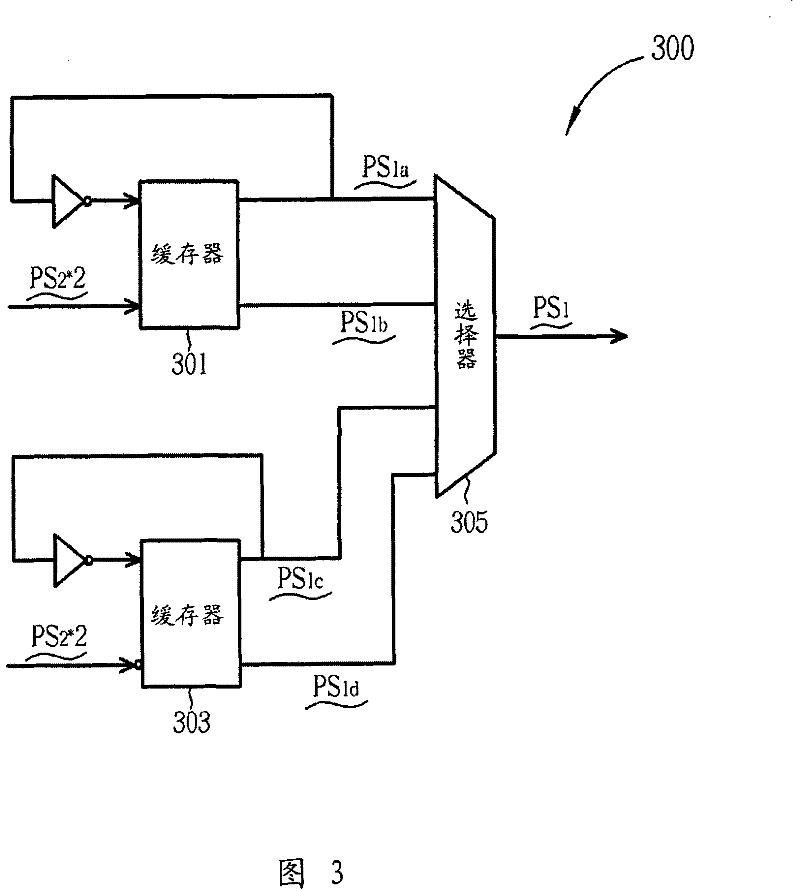

Data reading circuit and method

The present invention provides a data reading circuit and a data reading method. The data reading circuit comprises a first buffer, a second buffer, a first selector, a second selector and a third buffer, wherein the first buffer is used for receiving a first data signal and sampling the first data signal according to a first edge of a first prearranged signal to generate a second data signal; the second buffer is used for sampling the second data signal according to a second edge of a second prearranged signal to generate a third data signal; the first selector is used for selecting and outputting the second data signal or the third data signal according to the phase difference between the first prearranged signal and the second prearranged signal so as to generate a fourth data signal; the second selector is used for selecting and outputting the fourth data signal or a fifth data signal according to a selecting signal to generate a sixth data signal; and the third buffer is used for sampling the sixth data signal according to the first edge of the second prearranged signal so as to generate the fifth data signal.

Owner:REALTEK SEMICON CORP

Image foreground and background boundary saliency assessment method and system

ActiveCN106127744BReduce computing timeWidth normalizationImage analysisImage segmentationComputer vision

The invention discloses a method and system for evaluating significance of image foreground and background boundaries. The method comprises boundary positioning, boundary contrast calculation and boundary significance scoring. The corresponding system comprises a boundary positioning module, a boundary contrast calculation module and a boundary significance scoring module. According to the method and system disclosed by the invention, for an image with a pure background, in the case that a plurality of background points are given, foreground and background boundaries can be automatically positioned, a boundary contrast is calculated, and whether the foreground and background boundaries of the given image are significant are evaluated to effectively evaluate whether the background is well distinguished from the foreground, so as to evaluate image division quality in advance. The method and system can be widely used in the technical field of image division, for example, sectional drawing of identification pictures shot by mobile terminals.

Owner:GUANGZHOU XINGFU NETWORK TECH

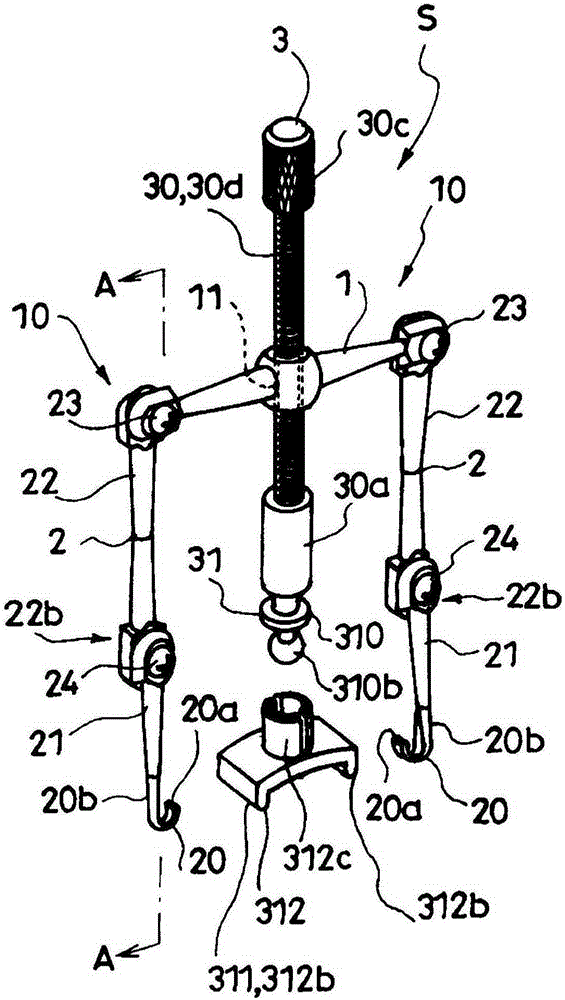

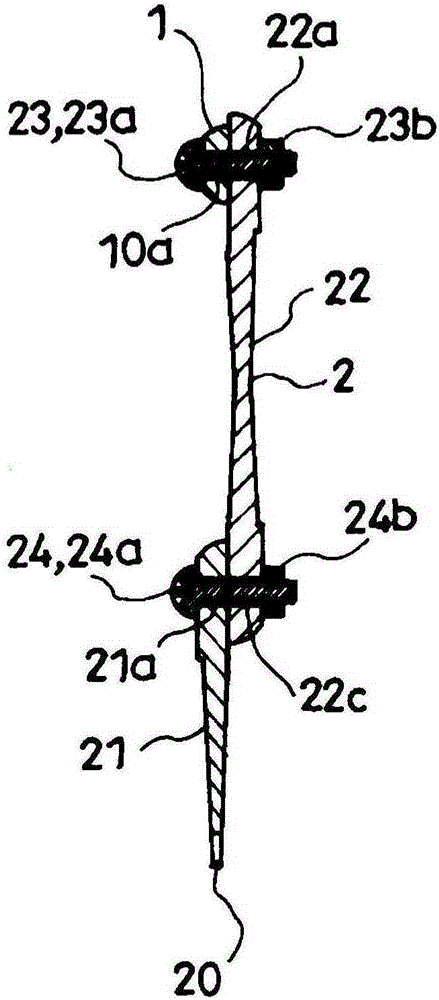

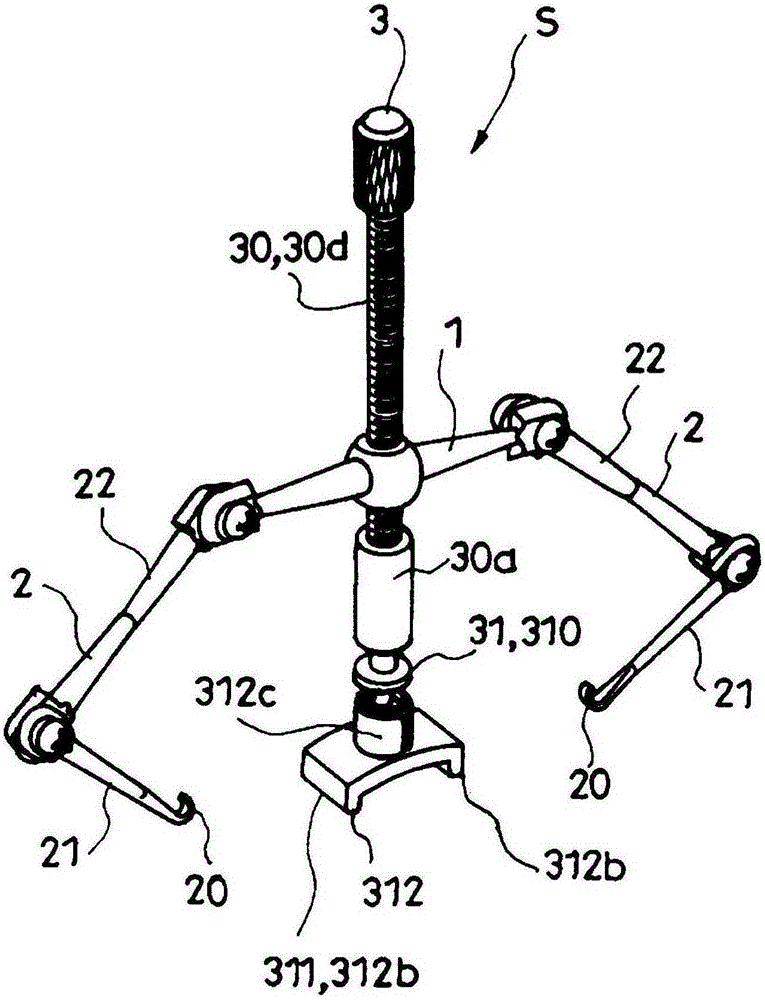

Pincer nail correction instrument

An objective of the present invention is to provide a correction instrument which is mountable without imparting excess force to a nail, and which is appropriately usable for respective correction of nails with different measurements. Provided is a pincer nail correction instrument, comprising: a left-side arm and a right-side arm, further comprising hook parts upon free ends thereof onto the lateral edge parts of a nail; and a fulcrum member between the left-side arm and the right-side arm with lower end parts as contact parts with respect to the nail. The fulcrum member further comprises: an axle which is combined to be vertically threadably extendable and retractable with respect to a base; a movable body which is vertically movably combined with the axle and which disposes the contact parts below the axle; and an impelling member which is interposed between the movable body and the axle with respect to the movable body. The contact member extends to the left and right, and further comprises protrusion parts respectively on the left end and the right end. The contact member makes contact with the nail via the protrusion parts, and does not make contact with the nail between the left and right protrusion parts.

Owner:SHIKAHAMA

Imaging lens group

The invention discloses an imaging lens group, which comprises an aperture and an optical group, wherein the optical group comprises a first lens with positive refractive power, a second lens with negative refractive power, a third lens with positive refractive power, a fourth lens with positive refractive power and a fifth lens with negative refractive power sequentially from an object side to an image side; and the aperture is arranged between the image side surface of the first lens and a photographed object. The imaging lens group has the advantages of large view angle, high pixel, high resolution ability, short lens length, low material cost and low assembly tolerance sensitivity.

Owner:GLORY SCI

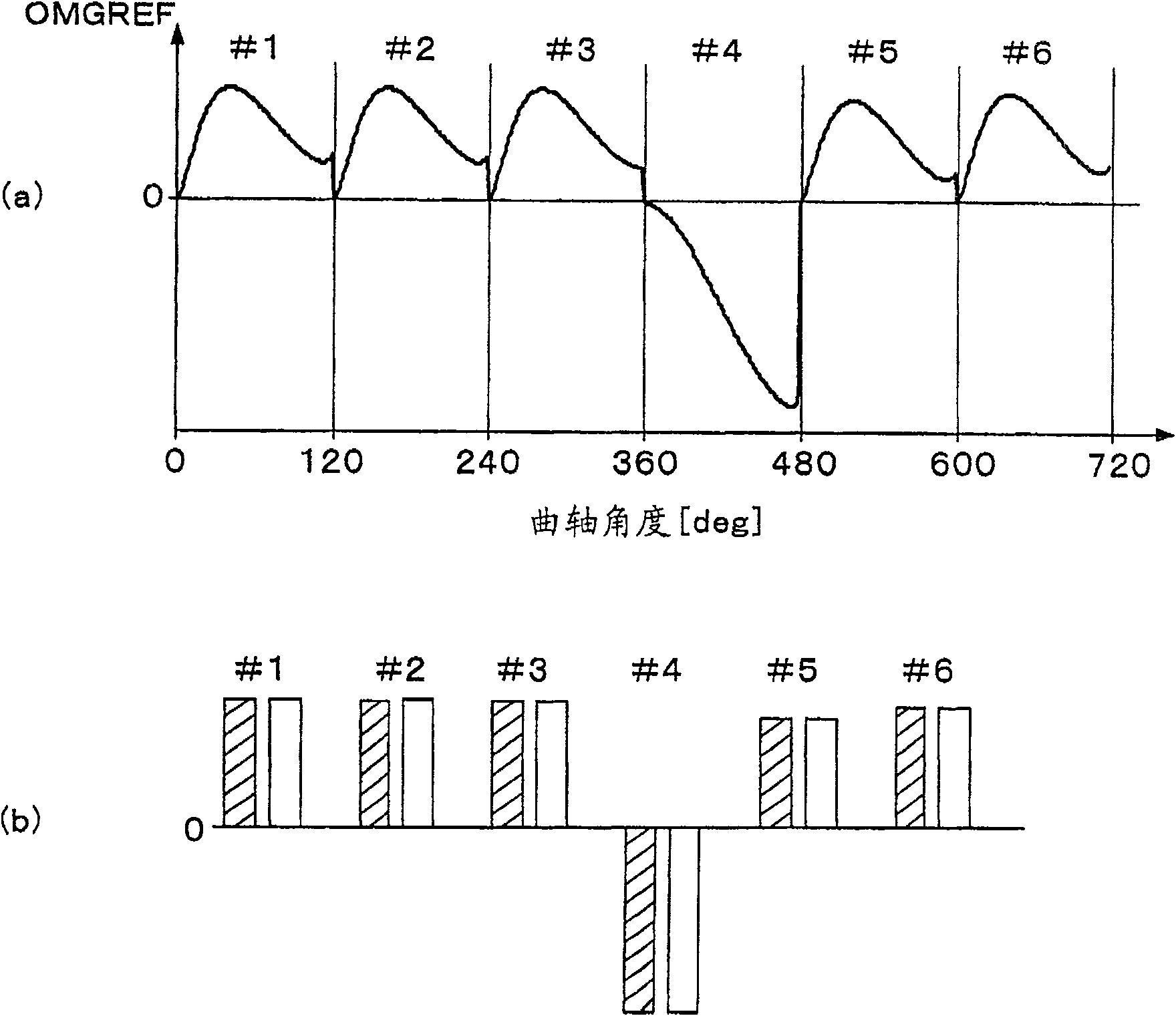

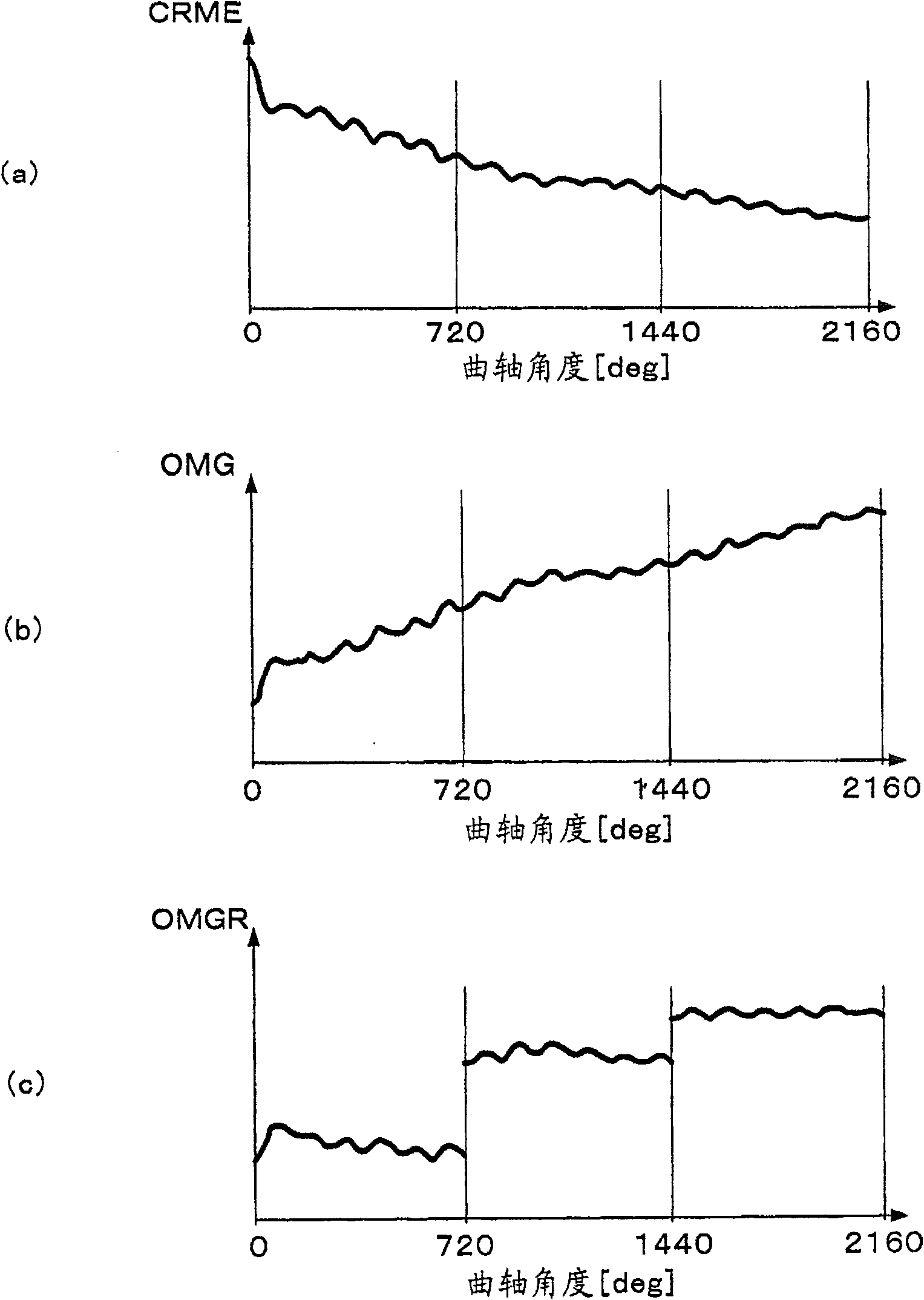

Misfire detecting device of internal combustion engine

InactiveCN100580241CSure easyMisfire judgment is accurateElectrical controlMachines/enginesTop dead centerReciprocating motion

Owner:HONDA MOTOR CO LTD

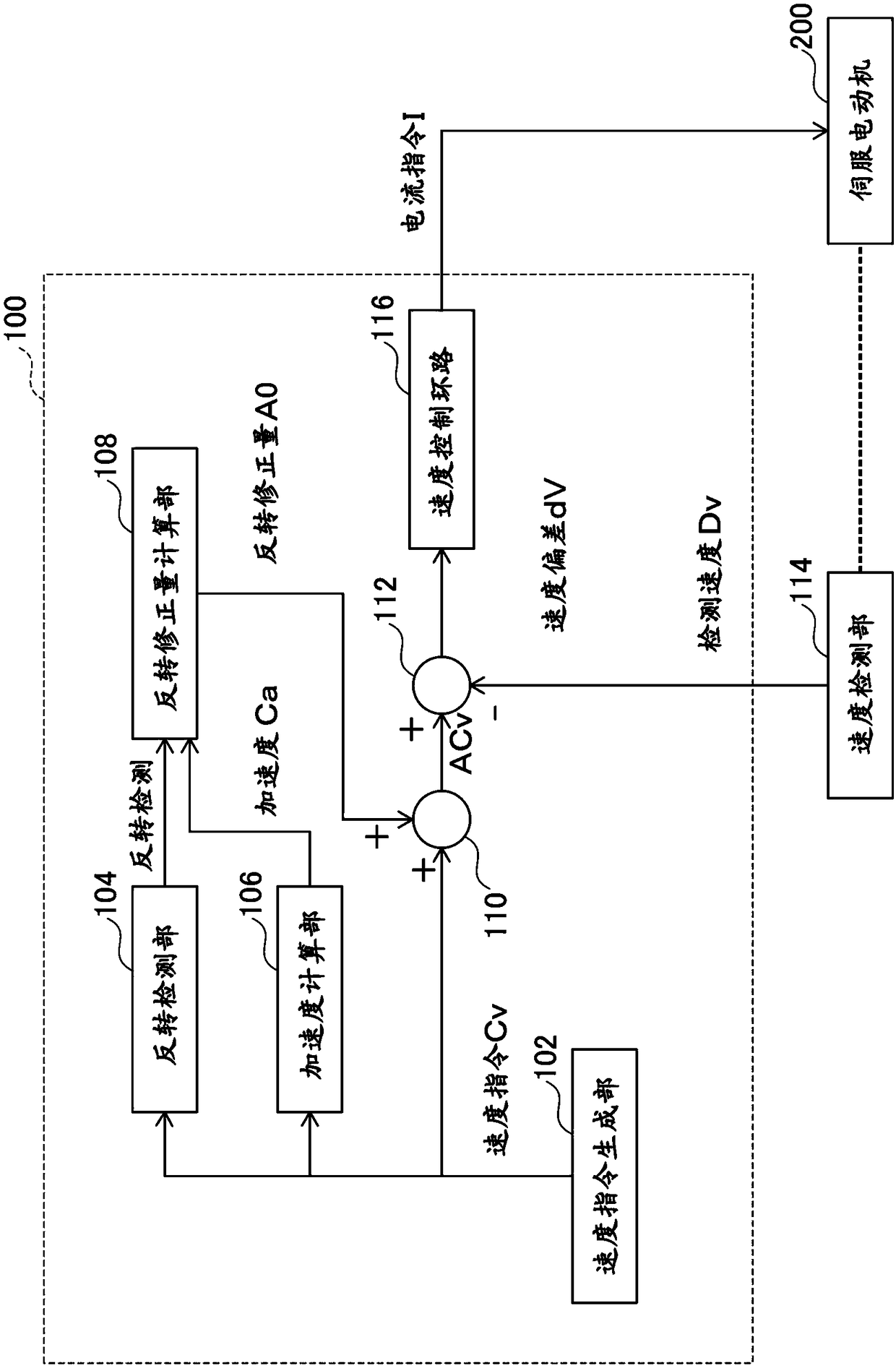

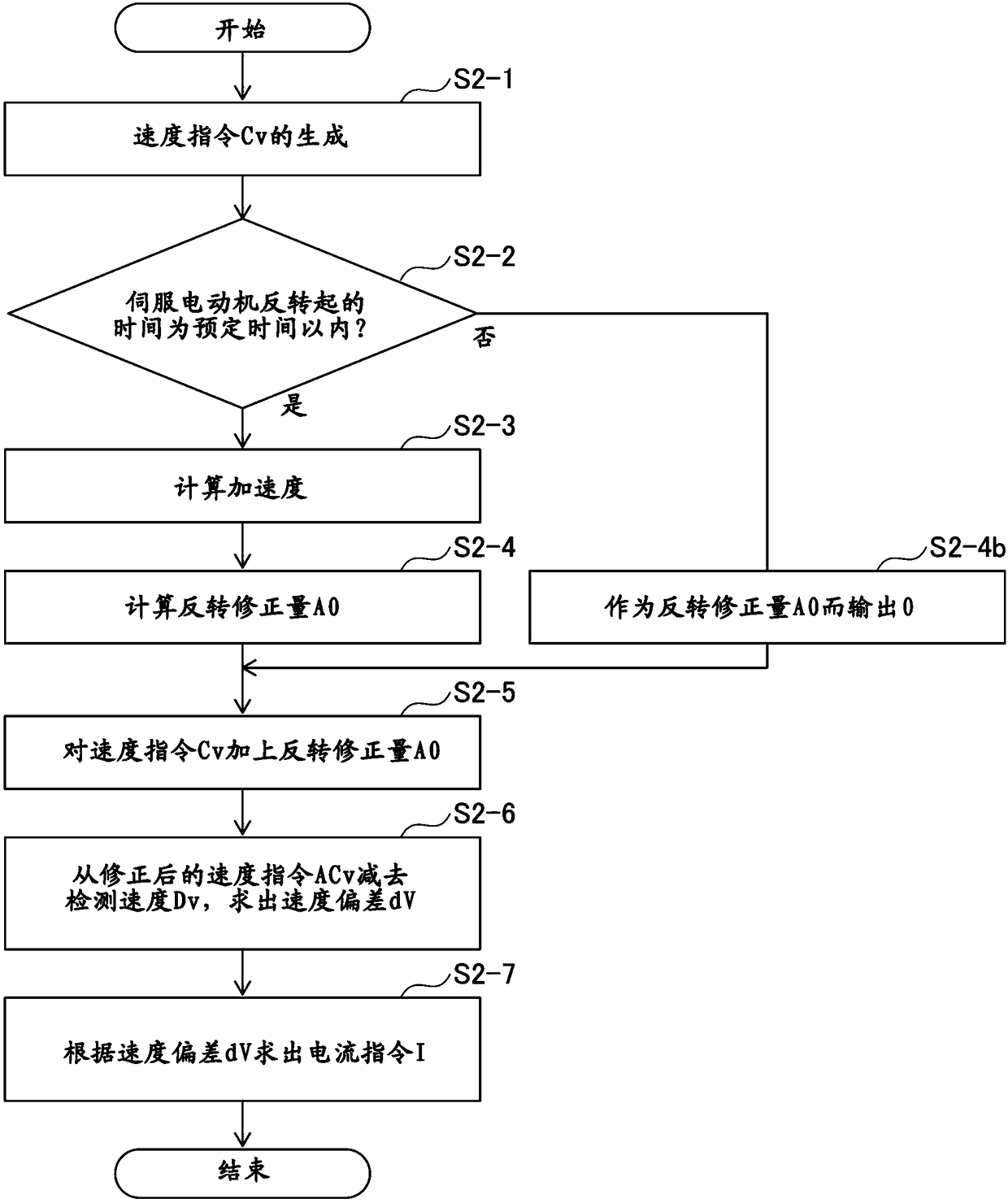

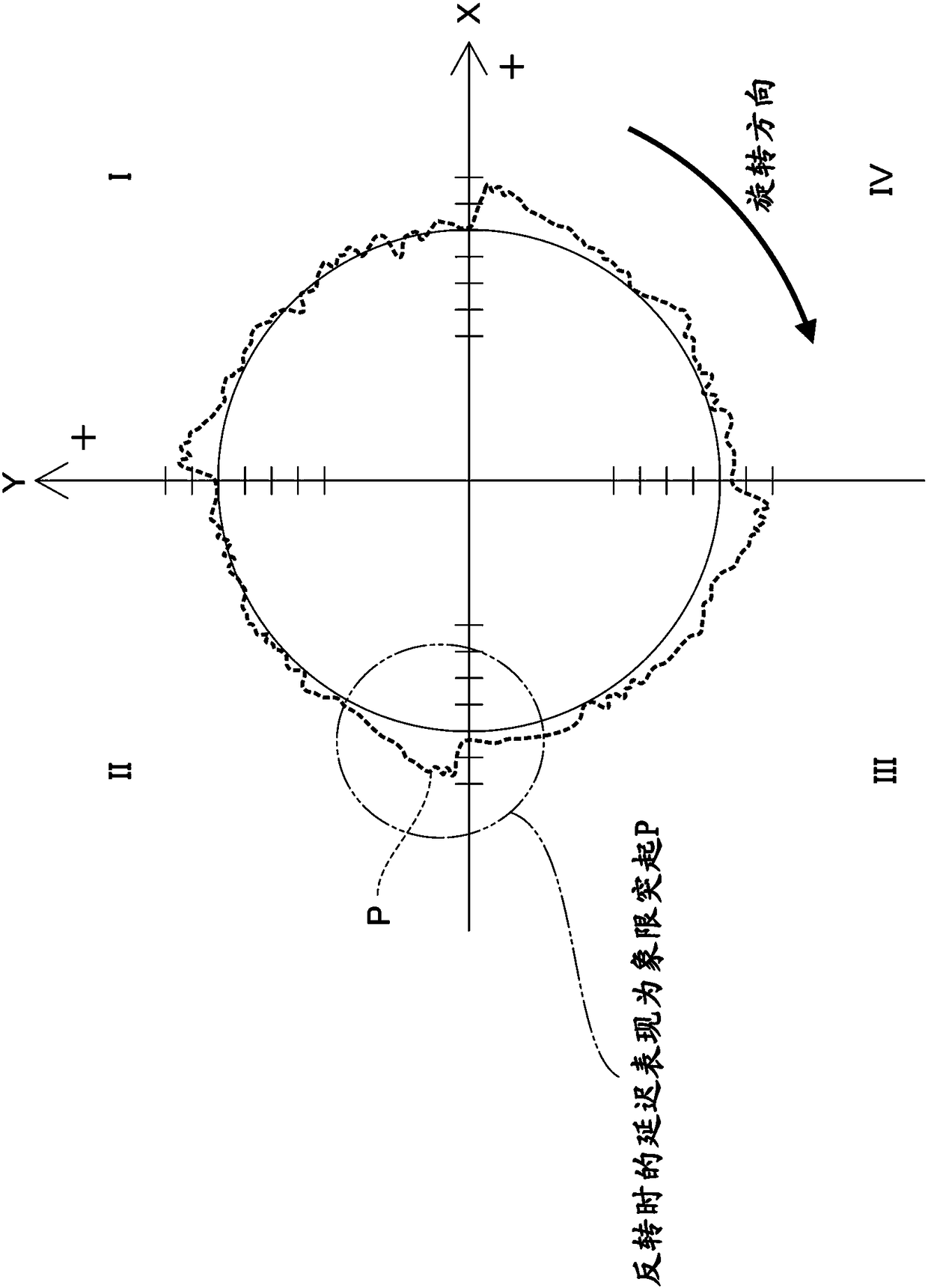

Servo motor controller, control method and computer-readable medium

InactiveCN108153236AEasy to controlAppropriate correctionComputer controlSimulator controlMotor controllerControl theory

The invention provides a servo motor controller, a control method and a computer-readable medium. The servo motor controller comprises a command generating part for generating a position / speed commandof a servo motor at every scheduled period; a determining part for determining that the servo motor is performing reversal or movement from stop at every scheduled period; an acceleration calculationpart for obtaining the acceleration of the servo motor based on the determination result; and a compensation amount calculation part for calculating a compensation amount for compensation of delay ofthe servo motor. The acceleration calculation part obtains the acceleration even after the servo motor performs reversal or movement from stop. The compensation amount calculation part calculates thecompensation amount according to the obtained acceleration, even after the servo motor performs reversal or movement from stop.

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com