Electronic scale of loading machine

A loader and load capacity technology, which is applied in the direction of measuring devices, instruments, weighing, etc., can solve the problems of weighing result error, weighing result deviation, affecting the use effect, etc., and achieve a wide range, simple operation, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, the technical solution will be described in more detail.

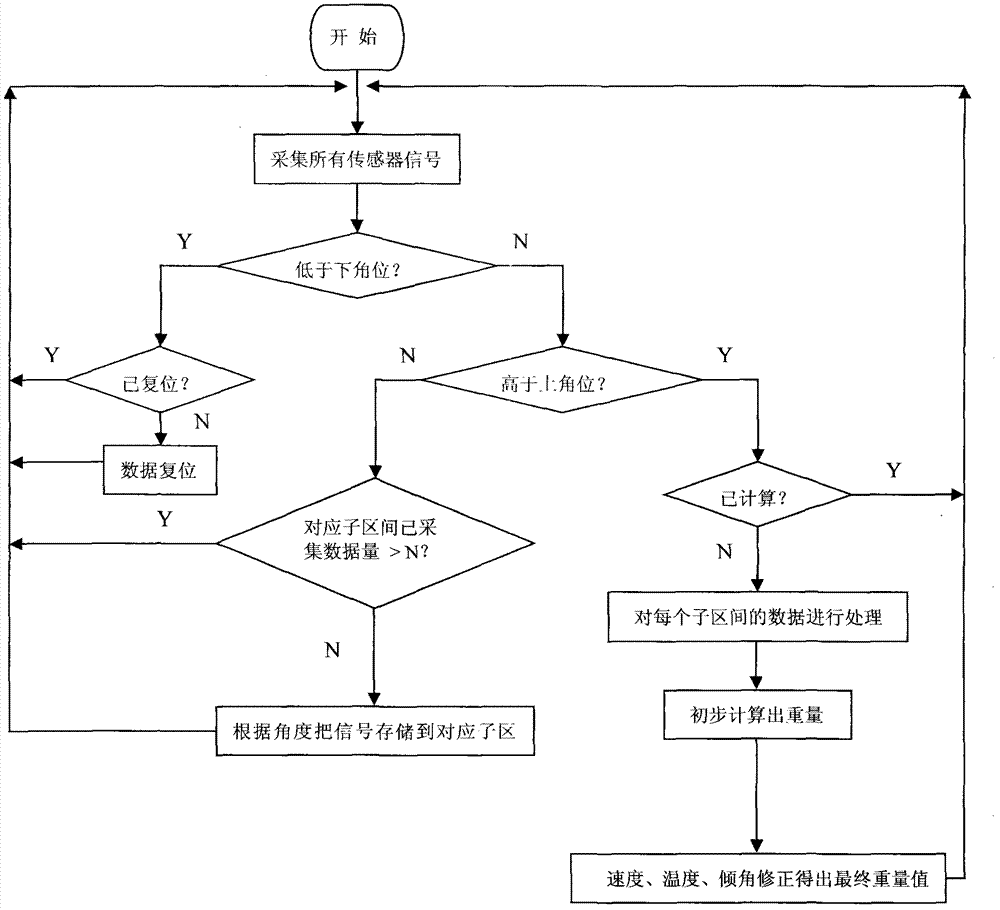

[0016] Fig. 1 is an algorithm flow chart of the technical solution. The signal acquisition part adopts the DSP interrupt method to ensure that the acquisition intervals are completely equal, and a preliminary filter is performed when the signal is acquired; then the program judges whether the position of the boom is lower than the lower angle, if the position of the boom is very low, Data reset; if the boom is in the weighing range, it is necessary to judge the sub-range. If the signal data collected in the corresponding sub-range has reached the maximum value, the collected signal will be discarded, otherwise it will be regarded as valid data. ;When the position of the boom is higher than the upper angle, it is ready to be calculated. The process is as follows: first analyze the data of each sub-interval separately, if the data volume of some intervals is abnormal, start special case processing, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com