Misfire detecting device of internal combustion engine

A detection device and internal combustion engine technology, applied in the direction of mechanical equipment, engine control, machine/engine, etc., can solve problems such as many man-hours, inability to accurately determine cylinder misfire, and complicated misfire determination processing, etc., to achieve accurate misfire determination and versatility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

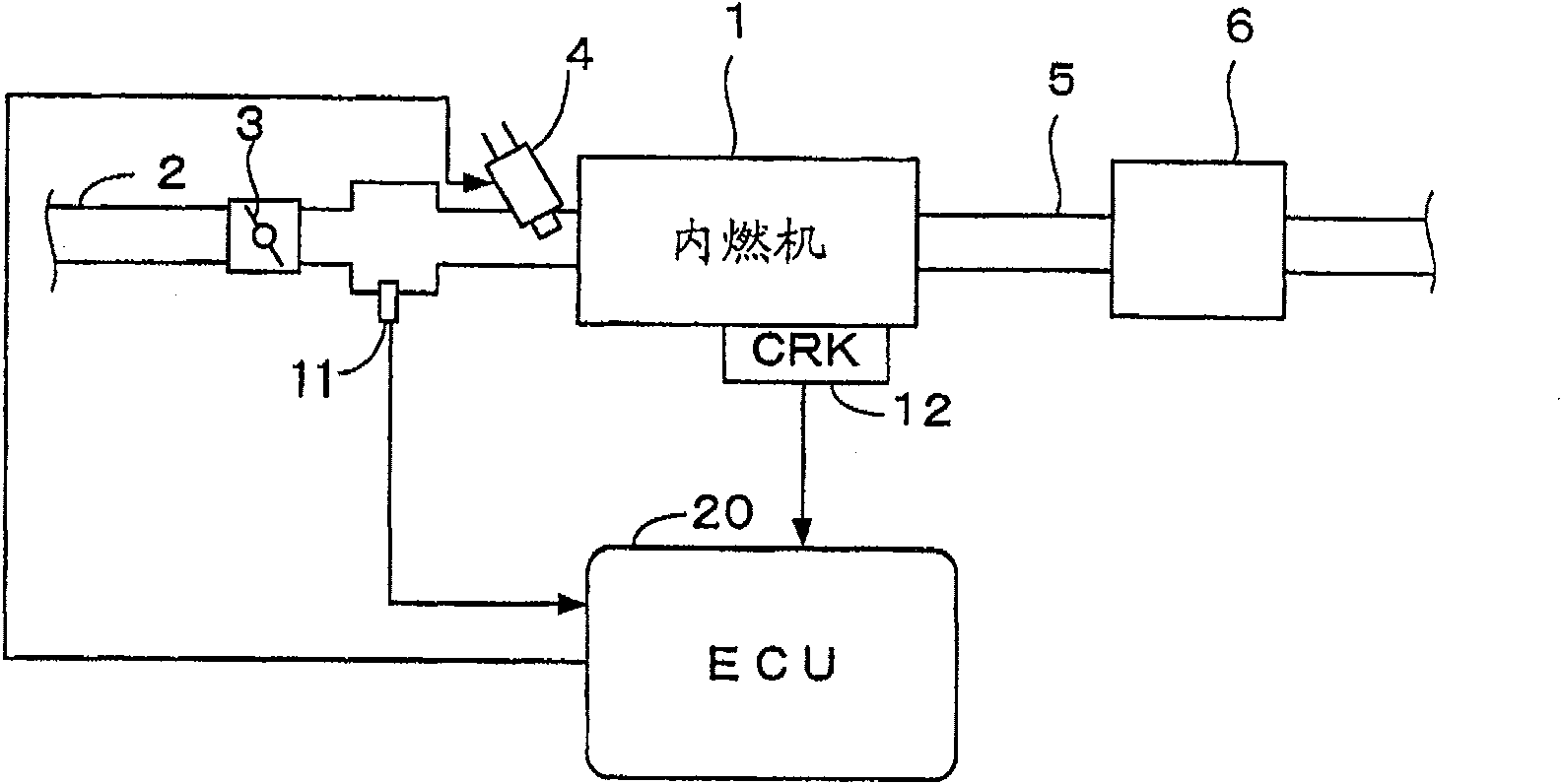

[0045] figure 1 It is a diagram showing the configuration of an internal combustion engine and its control device according to an embodiment of the present invention. An internal combustion engine (hereinafter referred to as “engine”) 1 has, for example, six cylinders, and includes an intake pipe 2 and an exhaust pipe 5 . A throttle valve 3 is provided in the intake manifold 2 . Also, a catalytic converter 6 for purifying exhaust gas is provided in the exhaust pipe 5 .

[0046] Each cylinder is provided with a fuel injection valve 4, which is arranged between the engine 1 and the throttle valve 3 and is located on the slightly upstream side of the intake valve not shown in the intake pipe 2. The pump is connected and electrically connected to an electronic control unit (hereinafter referred to as “ECU”) 20 , and the opening timing of fuel injection valve 4 is controlled by a control signal from ECU 20 .

[0047] Immediately downstream of the throttle valve 3 is provided an ...

no. 2 Embodiment approach

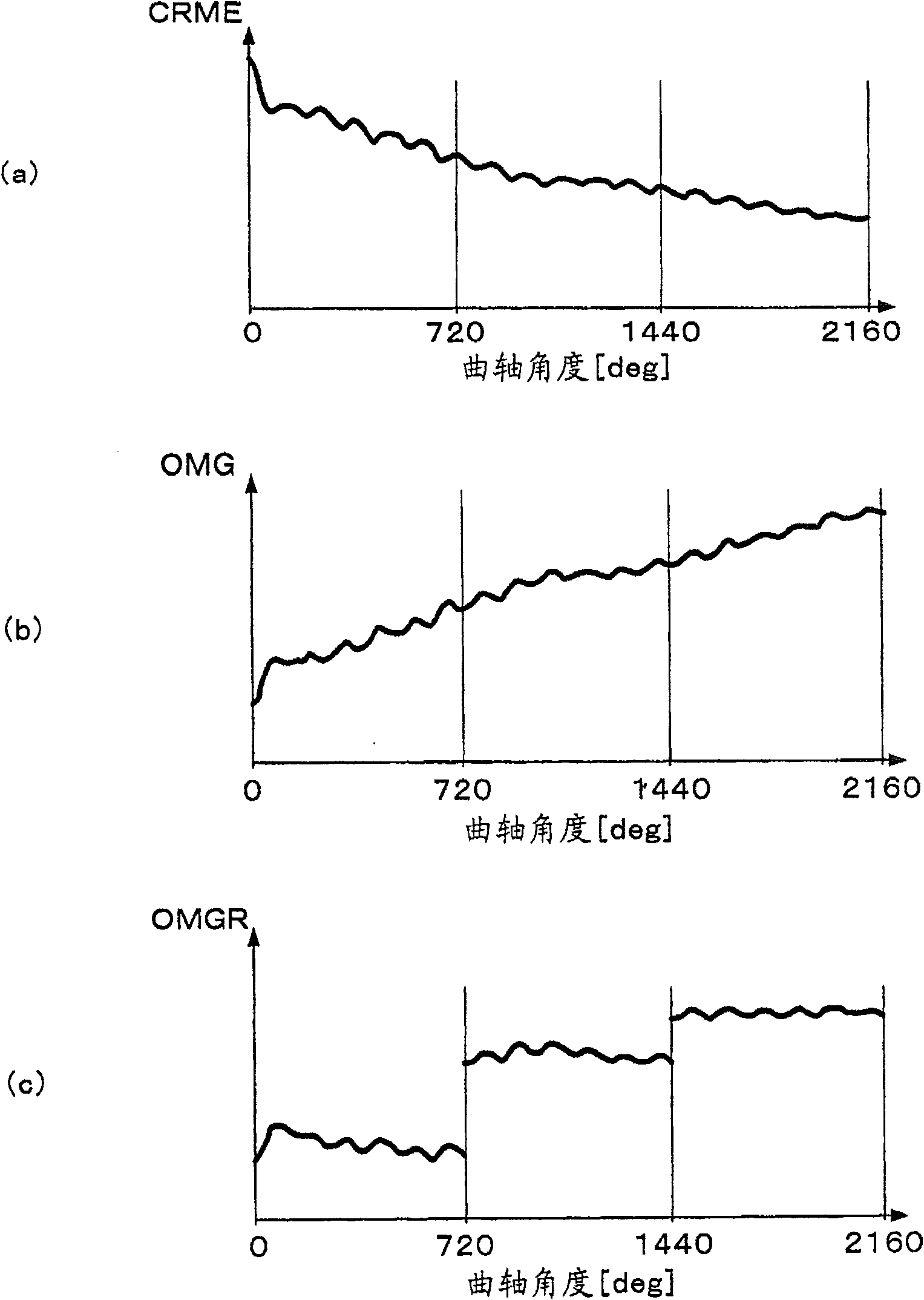

[0109]In the above-mentioned embodiment, the time parameter CRME is converted into the rotational speed OMG, and the misfire determination is performed using the rotational speed OMG as the speed parameter, but in this embodiment, the misfire determination is performed using the time parameter CRME as the speed parameter. In addition, it is the same as that of the first embodiment except for the points described below.

[0110] Figure 10 It is a flowchart of the misfire determination process using the time parameter CRME as the speed parameter.

[0111] In step S32, the 720-degree filtering process is performed by the following formula (21), and the post-filtering time parameter CRMER(i) is calculated.

[0112] CRMER(i) = CRME(i)

[0113] -(CRME(0)-CRME(ND))×Dθ×i / 4π

[0114] (twenty one)

[0115] In step S33, the relative time parameter CRMEREF(i) is calculated by the following formula (22).

[0116] CRMEREF(i)=CRMER((k-1)NTDC)-C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com