Correctable tension steering pinch roll for auxiliary coiling of steel strip and method of use thereof

A technology of steering pinch rolls and auxiliary coils, applied in the field of metal rolling, can solve the problems of small deviation correction and inability to bend the tail of the strip, and achieve the effect of changing the running direction, improving the rolling quality and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

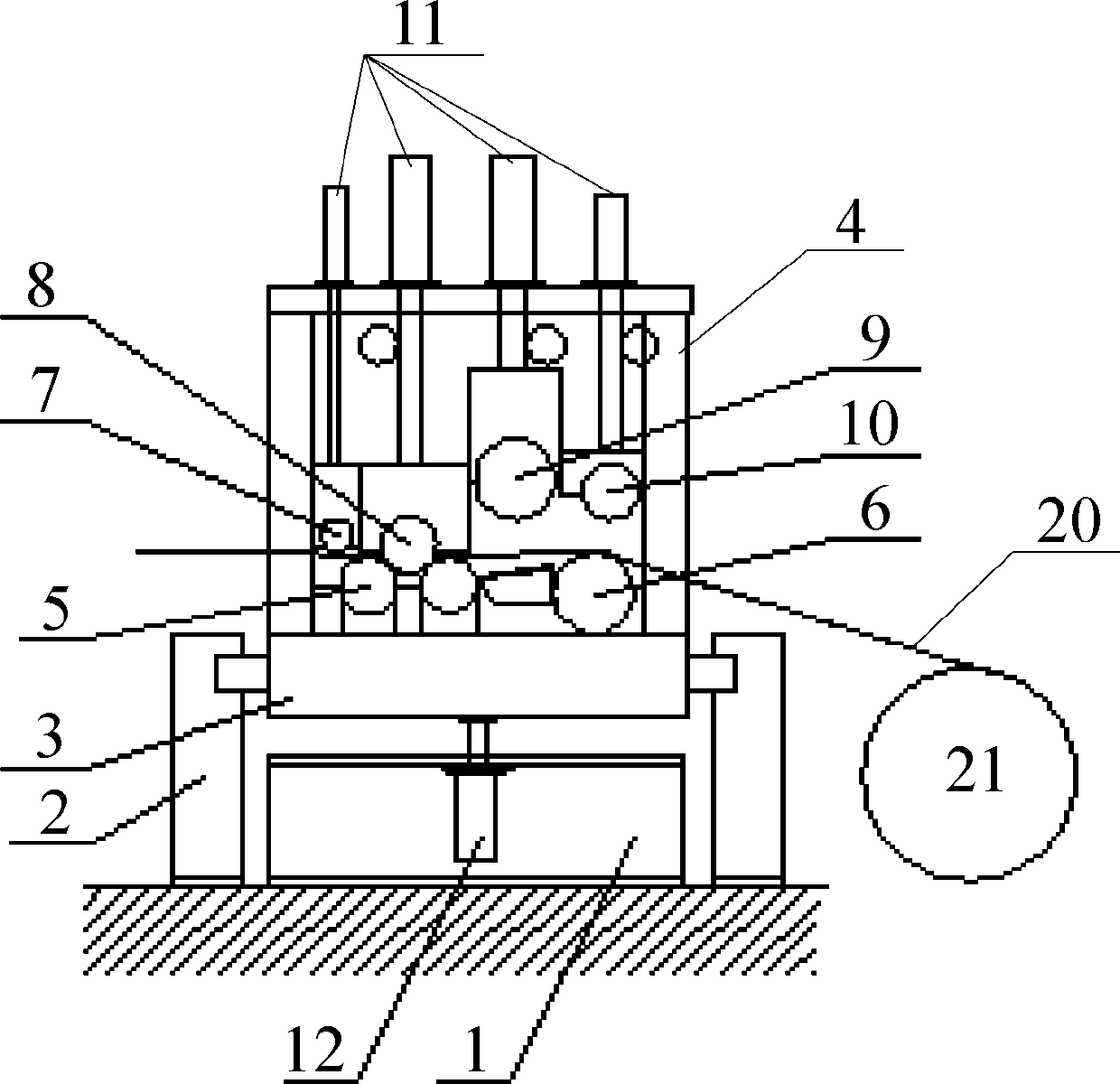

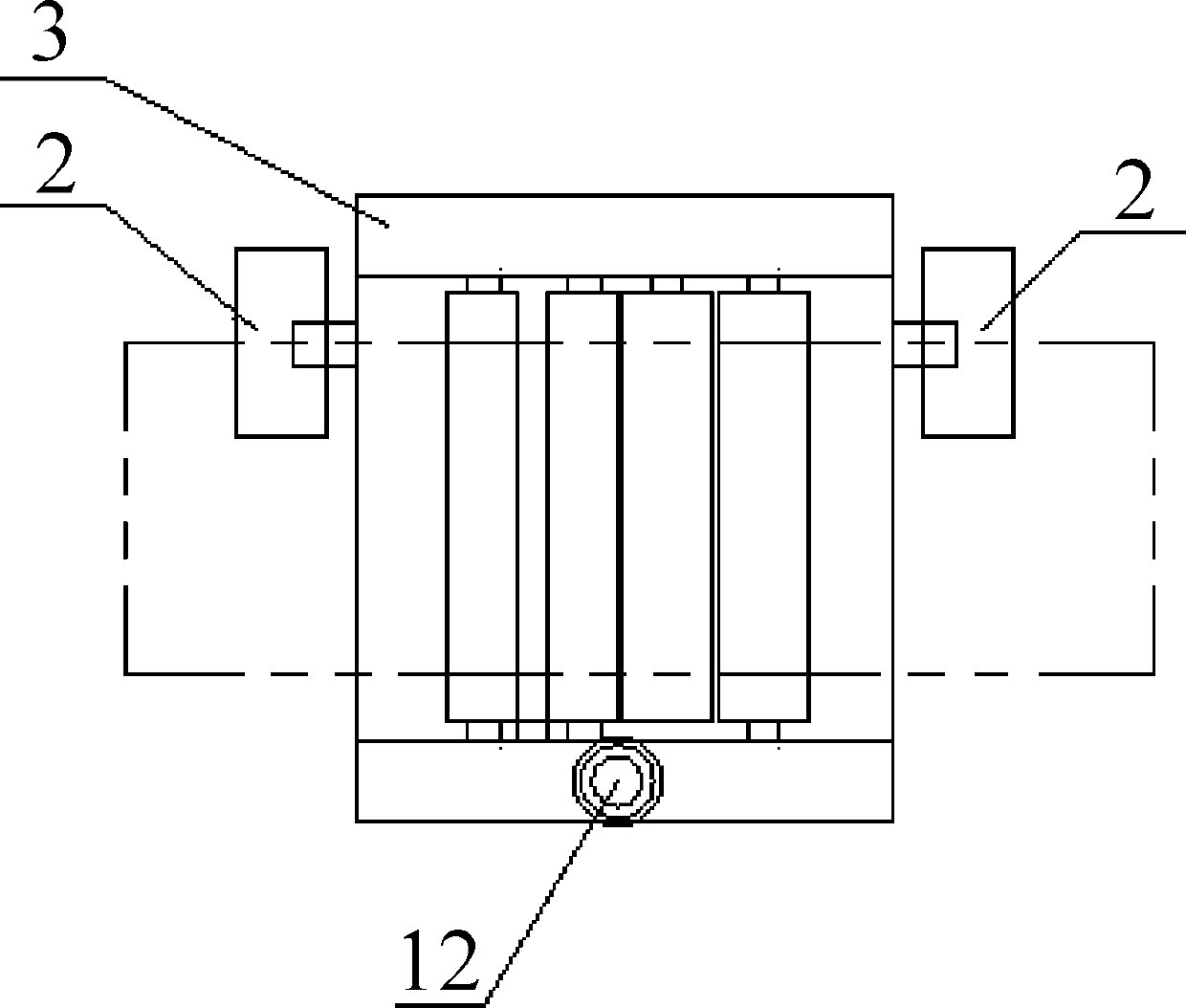

[0020] A tension-correctable tension steering pinch roller for auxiliary coiling of strip steel, including a fixed frame 1, a rotating support 2, a swing frame 3, an upper frame 4, a lower tension roller 5, a fixed steering roller 6, and an elevation Roller 7, upper tension roller 8, tail roller 9, pinch roller 10, pressing hydraulic cylinder 11 and correcting hydraulic cylinder 12, such as figure 1 with figure 2 As shown, the specific structure is:

[0021] Both the fixed frame 1 and the rotating support 2 are fixed on the ground, and the two ends of the swinging frame 3 are rotatably arranged on the rotating support 2 through bearings, and the upper frame 4 is fixed on the swinging frame 3, and the upper frame 4 is equipped with a lower tension roller 5, a fixed steering roller 6, an elevation roller 7, an upper tension roller 8, a tailing roller 9 and a pinch roller 10, wherein: the lower tension roller 5 and the fixed steering roller 6 are located below, and the elevatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com