Servo motor controller, control method and computer-readable medium

A servo motor and control device technology, applied in the direction of single motor speed/torque control, AC motor acceleration/deceleration control, computer control, etc., can solve the problem of large error in the radial direction and achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, an example of the embodiment of the present invention will be described.

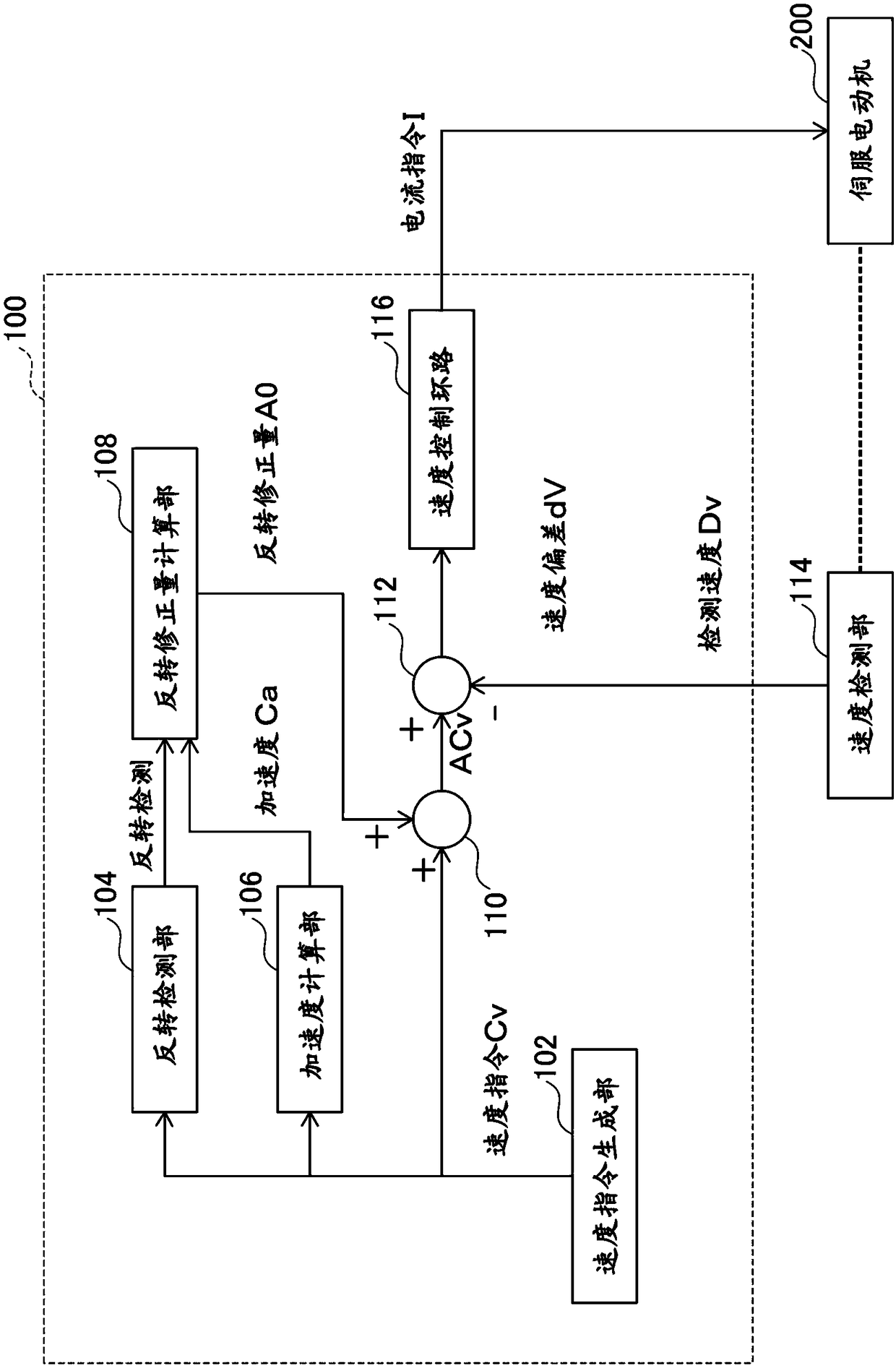

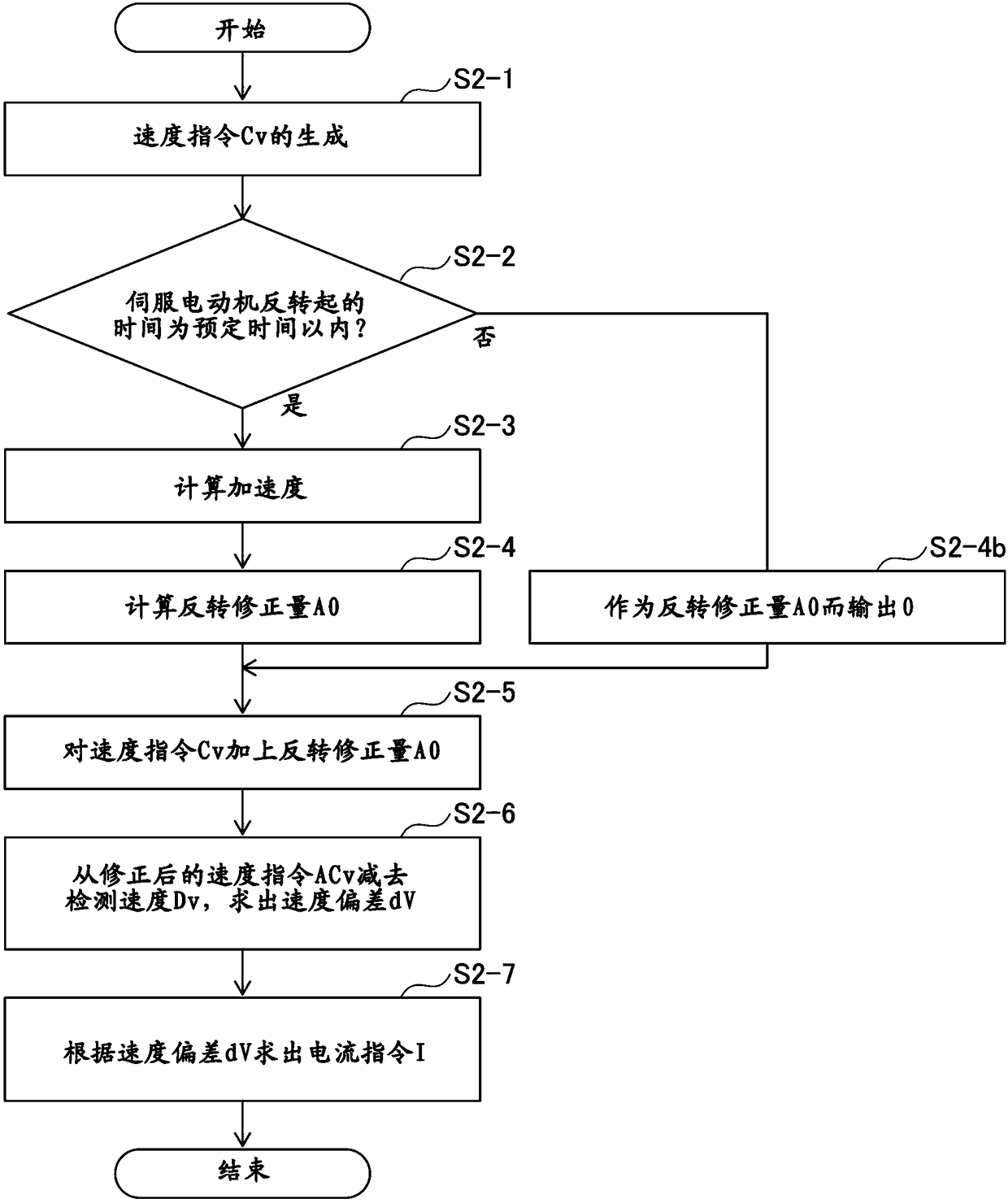

[0033] In this embodiment, a servo motor control device 100 for a machine tool will be described. figure 1 A block diagram of the configuration of the servo motor control device 100 is shown. Like a conventional servo motor control device for a machine tool, the servo motor control device 100 generates a speed command Cv to the servo motor 200 and drives the servo motor 200 based on the speed command Cv.

[0034] Therefore, the servo motor control device used in a conventional machine tool can be easily replaced with the servo motor control device 100 of this embodiment. In other words, the characteristic configuration in this embodiment is the servo motor control device 100 , and other configurations are the same as those of conventional machine tools.

[0035] Such as figure 1 As shown, the servo motor control device 100 includes: a speed command generation unit 102, a reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com