Self-supporting framework modular structure

A frame structure, self-supporting technology, applied in the connection of rods, connecting components, building structures, etc., can solve problems such as retention of connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

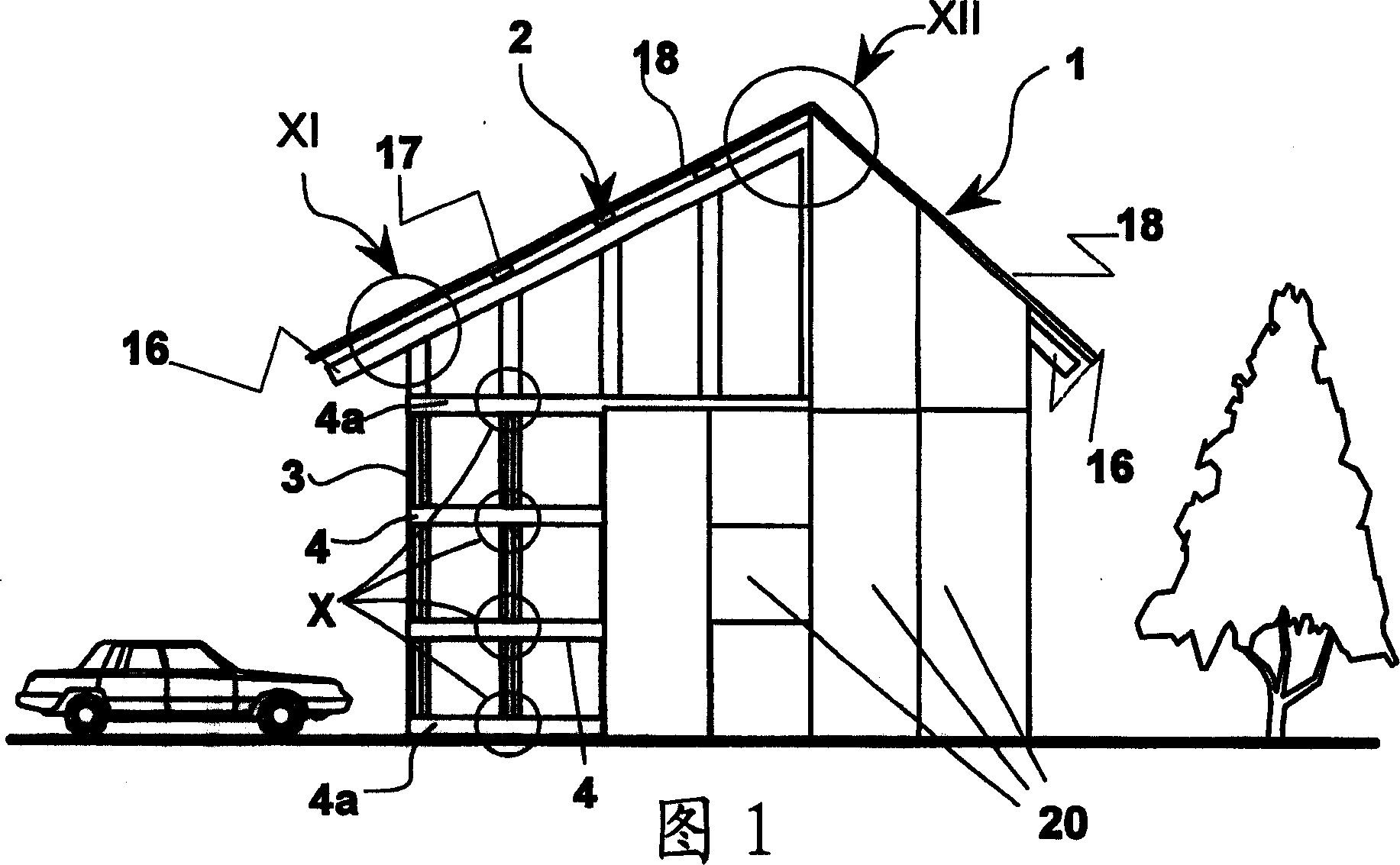

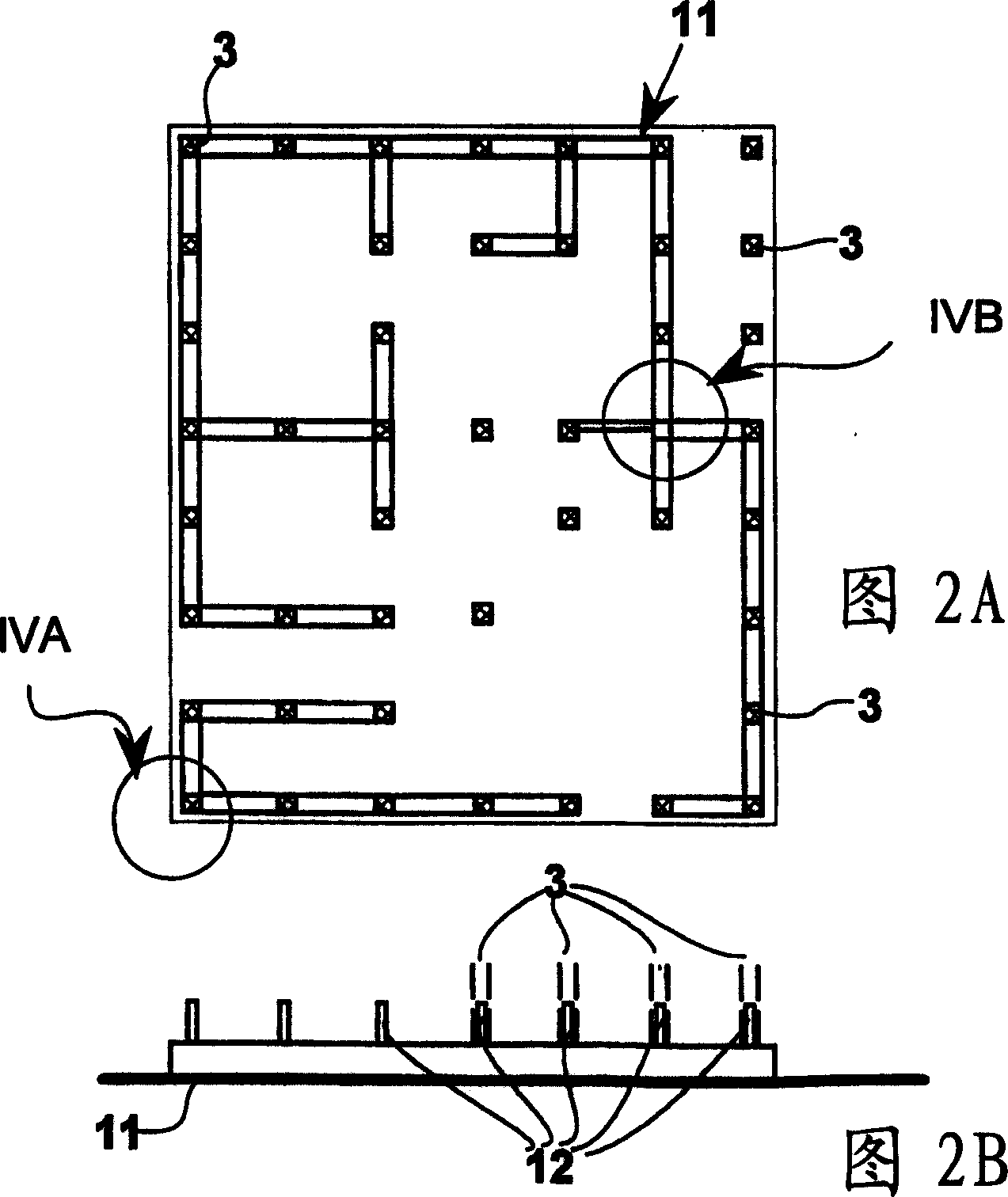

[0048] Referring to FIG. 1 , in order to manufacture a self-supporting frame structure, such as a supporting frame 2 for the structure of a prefabricated building 1 for a residence, main columns 3 ( Figure 3A ) and girders 4 and 4a ( Figure 3B or 3C).

[0049] Any struts 3 shown in Figure 2 having the function of a column are hereinafter denoted main struts, and any horizontal beams 4 and 4a connecting the main struts to each other are hereinafter denoted main girders.

[0050]Furthermore, the oblique beams 16 and cross beams 17 and panels 18 shown in FIG. 1 are used to manufacture a roof, wherein the coating of the roof rests on the horizontal beams 17 and panels 18 . Furthermore, a bearing plate 20 is shown, which is connected to both the main struts and the main girder.

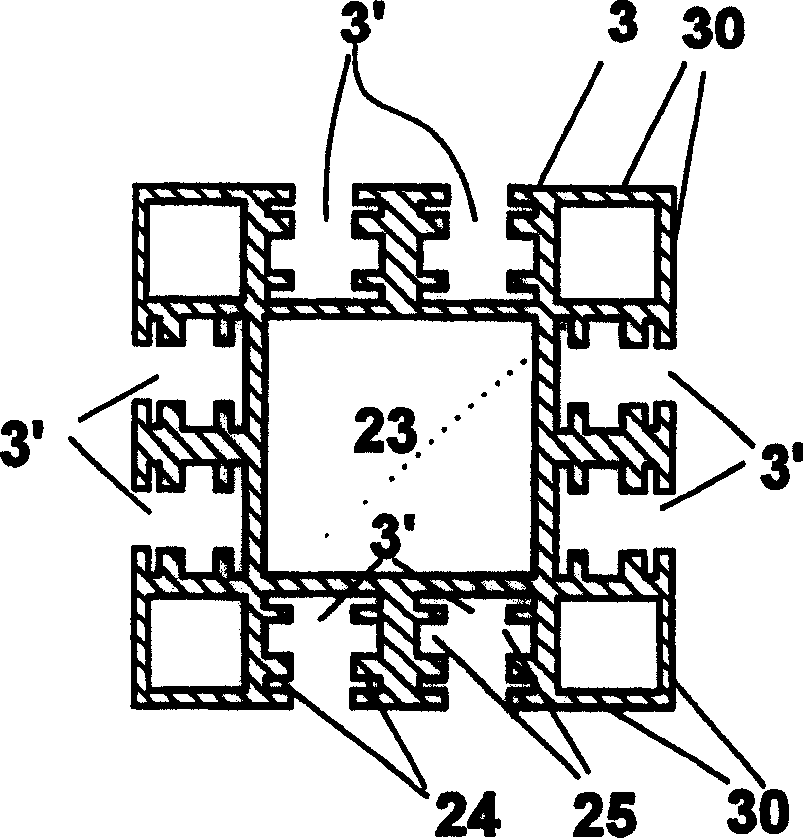

[0051] Such as Figure 3A and 3B As shown, the main struts 3 and the main beams 4 are obtainable by extrusion and they have the characteristic cross-section of a shaped part with a plurality of longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com