Air make-up hole position determination method for vortex compressor with air make-up loop

A scroll compressor, a technology for determining the method, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problem that the auxiliary intake hole area is not pointed out, the theoretical and experimental test results cannot be unified, and the auxiliary intake port is not pointed out. Problems such as the influence of the performance of the stomatal system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

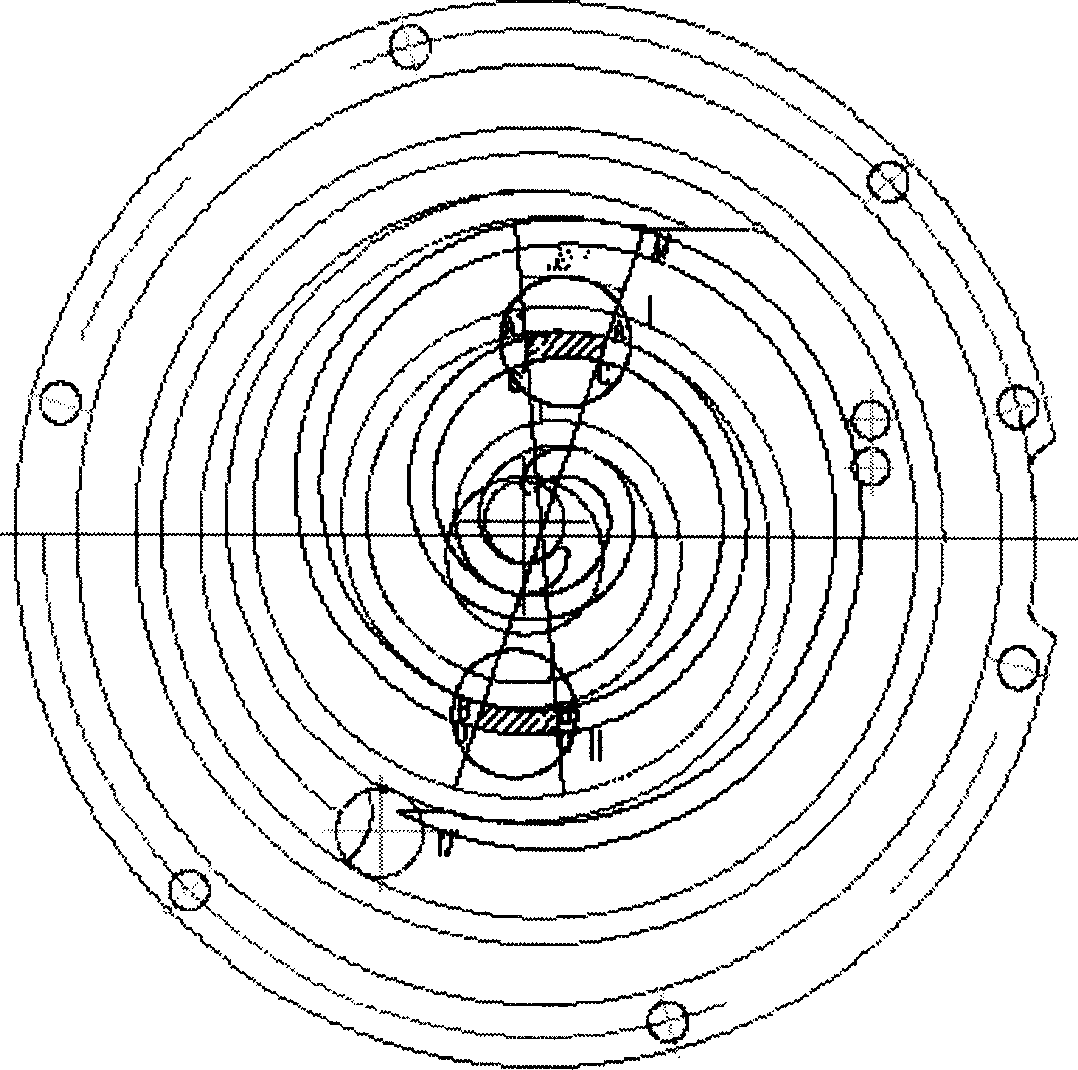

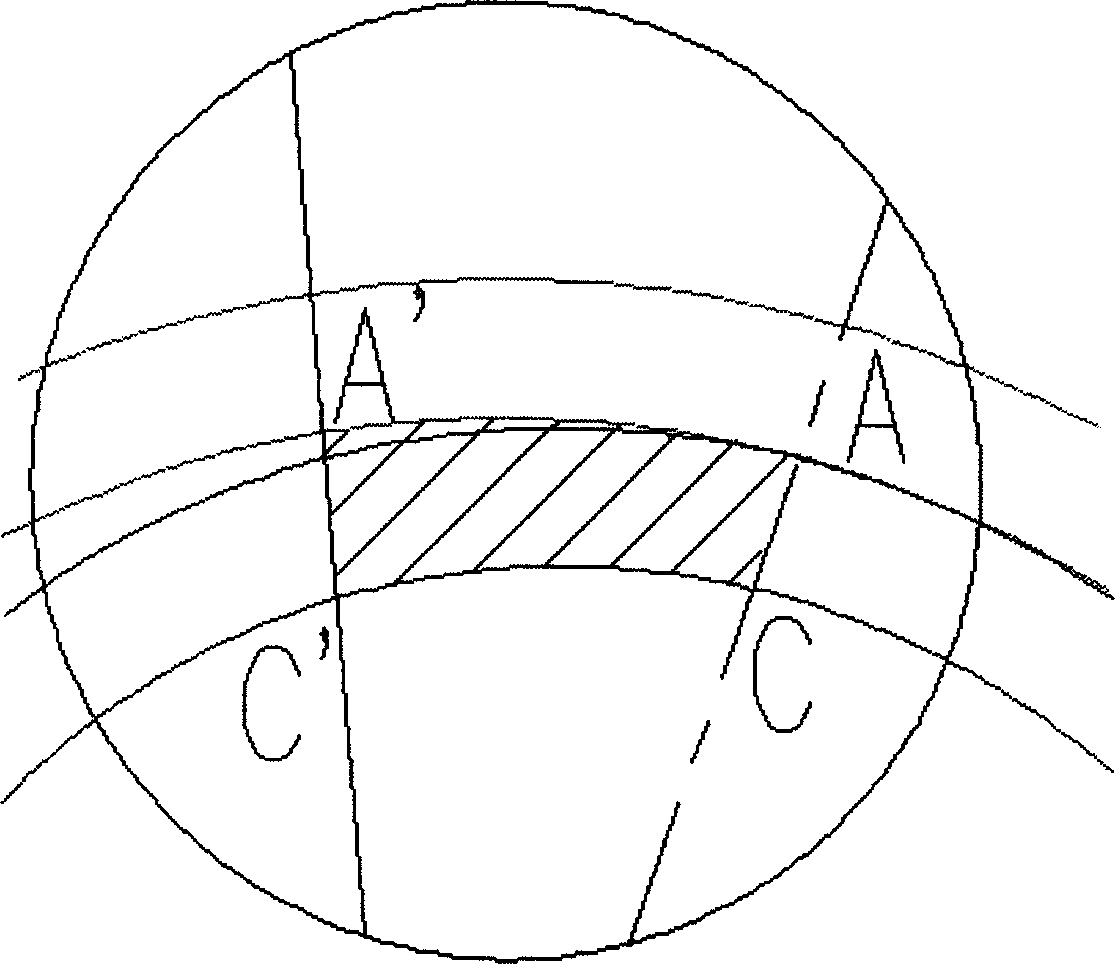

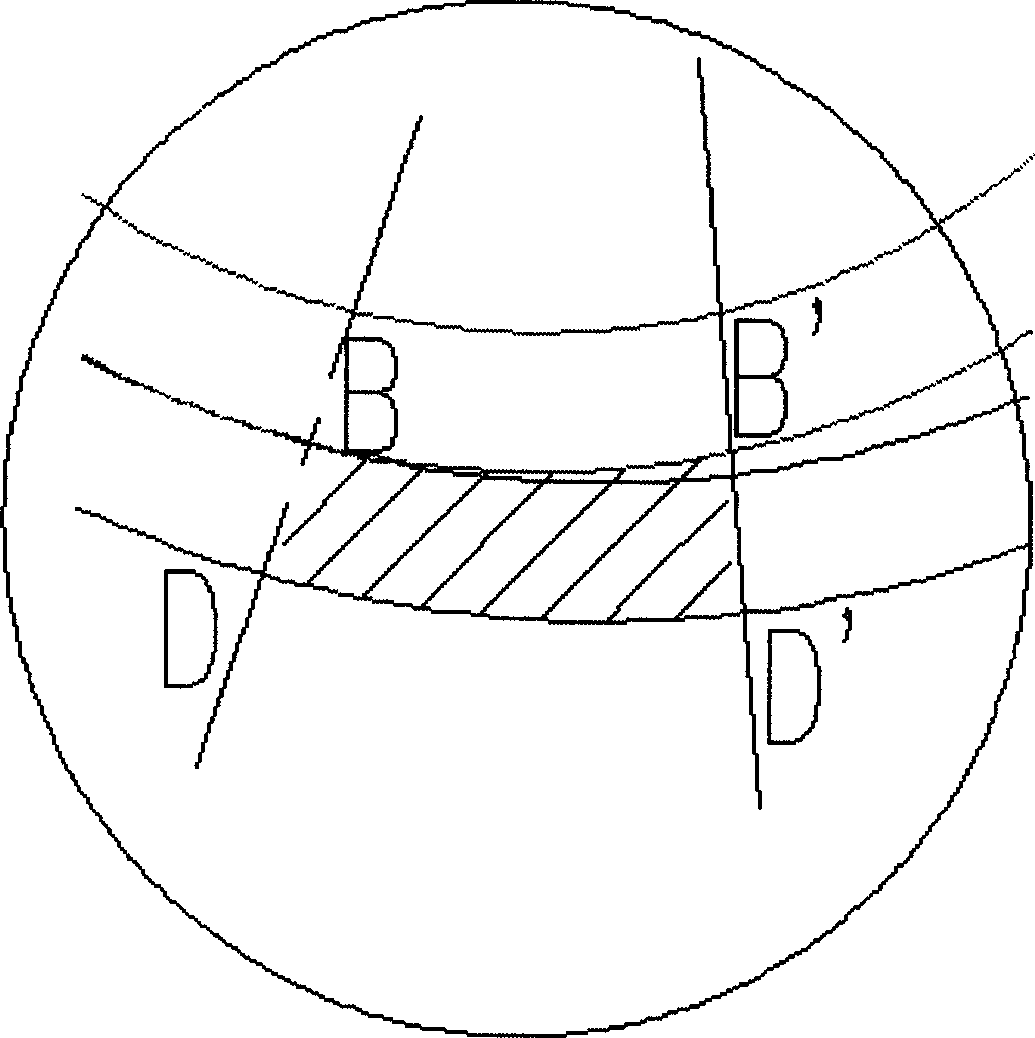

[0028] see figure 1 , a method for determining the position of the air supply hole of a scroll compressor with an air supply circuit, mainly comprising the following steps: 1) the farthest end of the scroll profile on the fixed scroll of the scroll compressor on the side of the center of the circle Point M moves 360° to the center of the circle to obtain point A on the fixed scroll; 2) Make a straight line through point O and point A at the center of the fixed scroll to intersect the scroll line on the fixed scroll to obtain B 3) Rotate the straight line AB between point A and point B counterclockwise by 30° to obtain straight line A'B', which intersects the molded line on the scroll at point A' and point B'; 4) When the profile line of the movable scroll of the scroll compressor is in a position symmetrical to the center of the profile line of the fixed scroll, the line AB intersects with the profile line of the movable scroll or the profile line of the sealing ring to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com