Production for soft packed frozen paste food and products therefrom

A production method and flexible packaging technology, applied in the direction of packaging, packaging sterilization, multiple packages, etc., can solve the problems of hindering the opening of the packaging bag from tearing, difficulty in tearing, dirty hands, clothes and the environment, and achieve food hygiene Safe, easy to tear, and the effect of improving hygiene conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

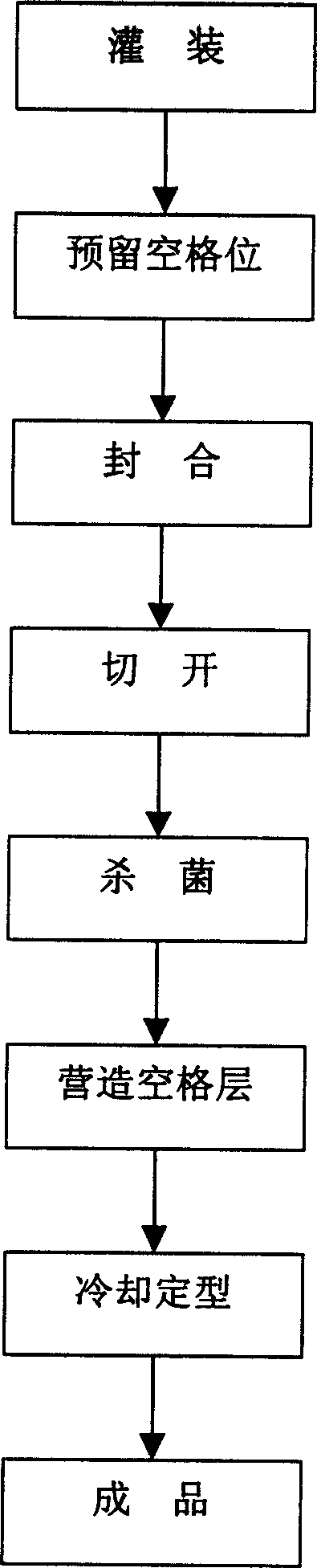

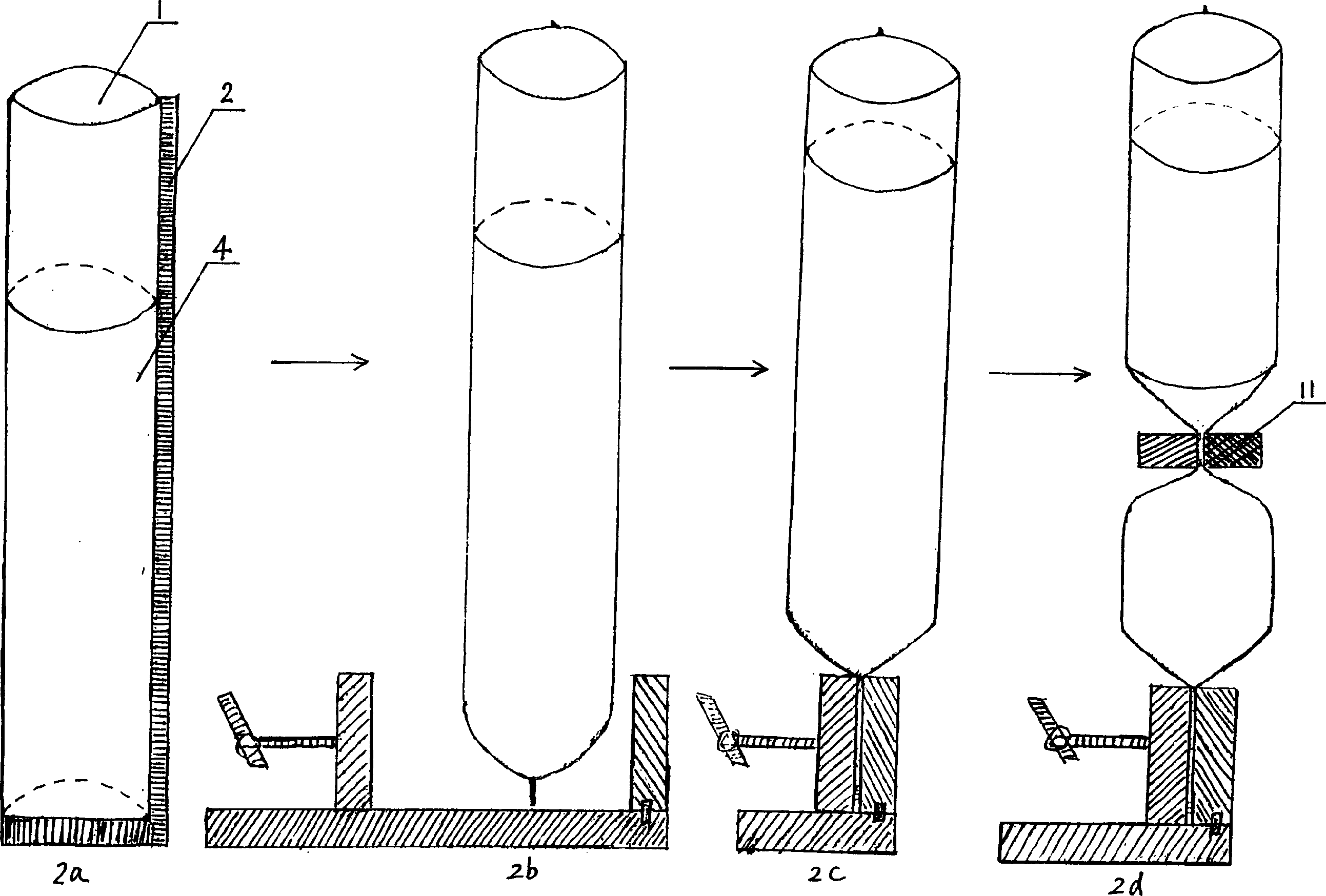

[0042] like Figure 1~3As shown, the production process of the present invention comprises the following steps: (1) filling; (2) reserving a space; (3) sealing; (4) cutting; (5) sterilization; (6) creating a space layer; (7) Cooling and shaping; (8) Setting the tooth gap; (9) Finished product. When producing, earlier the jelly paste hot solution is filled into a long side and the bottom end all has in the transparent plastic composite film flexible packaging bag 1 that protrudes sealing edge 2, then the bottom end of this packaging bag 1 is put into The clamping operation is carried out in the clamping device, so that the jelly paste hot solution 4 and the air are squeezed out of the clamped area at the same time, so that this area becomes a vacuum space layer 3 without content, and then the heat sealer 11 is used in the frozen area. Hot-melt sealing is carried out on the appropriate position of the packaging bag 1 under the liquid level of the paste hot solution 4, so that t...

Embodiment 2

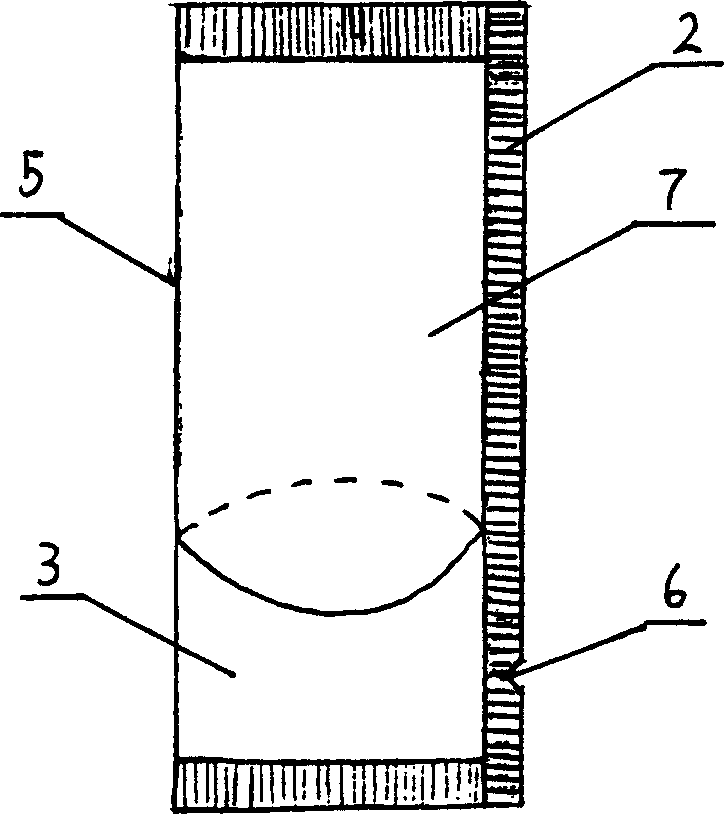

[0044] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that after the production process step (7), the barrier positioning step taken to prevent the jelly paste 7 in the packaging bag 5 from being placed in the space layer 3 is added, That is, a barrier structure is set at the position adjacent to the space layer 3 and the jelly paste 7, the space layer 3 of the packaging bag 5 is folded on the boundary line between it and the jelly paste 7, and an adhesive strip 8 is used to make it and the jelly paste 7. The packaging bag can be glued and fixed. When storing and transporting, the jelly paste 7 and the space layer 3 will not be interlaced with each other due to the force, ensuring that the space layer 3 is located at one end of the packaging bag 5 to play its effective role.

Embodiment 3

[0046] like Figure 5 The structure shown is embodiment 3 of the present utility model, and it differs from embodiment 2 in that: a hygienic envelope 9 and an adhesive strip 10 are added on the packaging bag 5, while the space layer 3 and the frozen layer are omitted. The adhesive strip that the packaging bag where the ointment 7 is in is bonded, and the hygienic envelope 9 is positioned at the space layer end of the packaging bag 5, and the space layer 3 and the folded part of the packaging bag 5 are sealed, and the adhesive strip 10 will The hygienic envelope 9 is bonded together with the packaging bag 5 where the jelly paste 7 is located. Such a structure can keep the opening end of the packaging bag 5 in a good hygienic condition, and can also achieve the purpose of barrier positioning in embodiment 2. During edible, only need to tear the viscose strip 10 on the hygienic envelope 9, the hygienic envelope 9 is taken off from the space layer end of the flexible packaging bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com