Centrifugal fan and its frame structure

A centrifugal fan and fan frame technology, which is applied to non-variable volume pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve the problem of uneven air output, reduce the cooling efficiency of centrifugal fans, reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

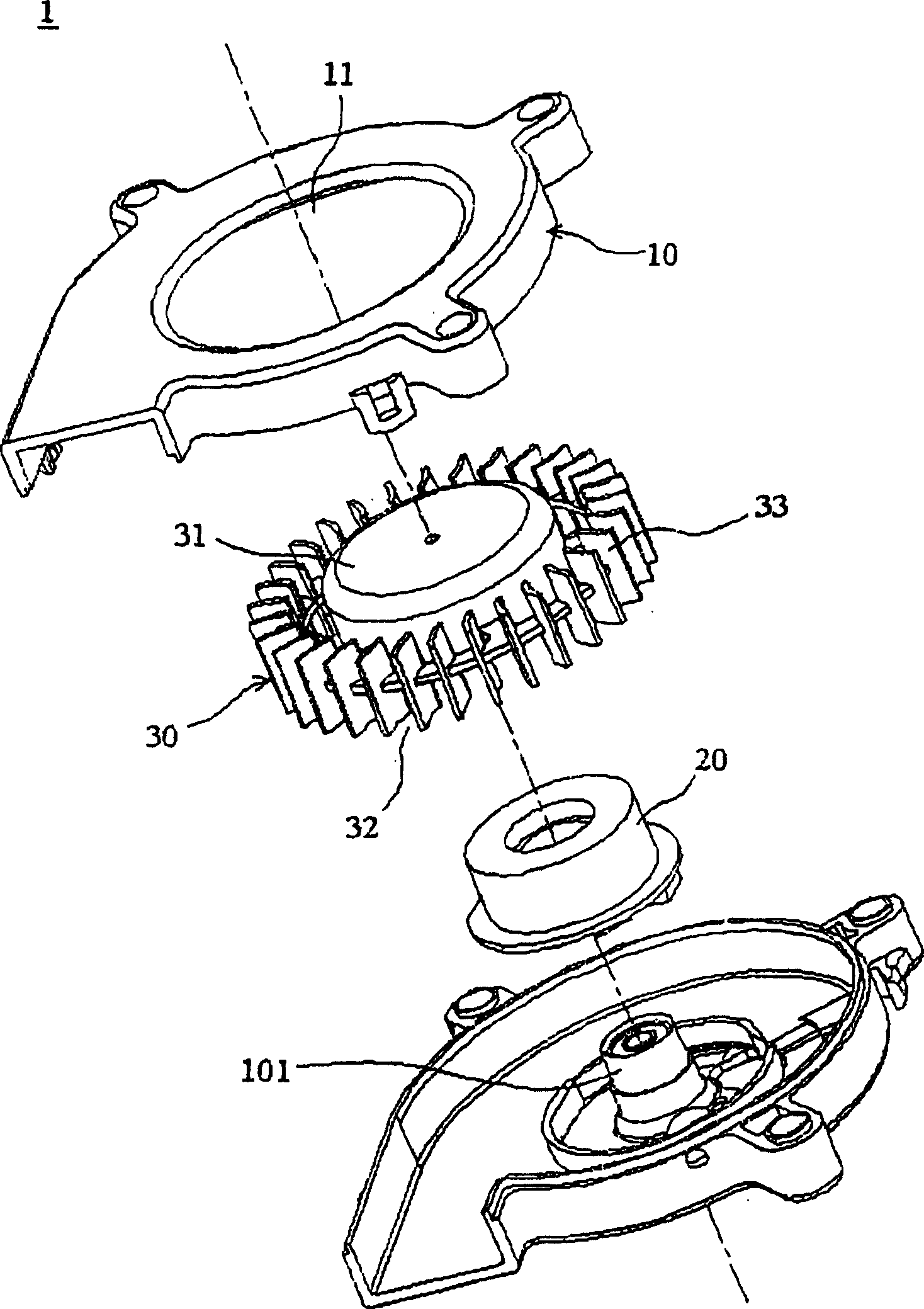

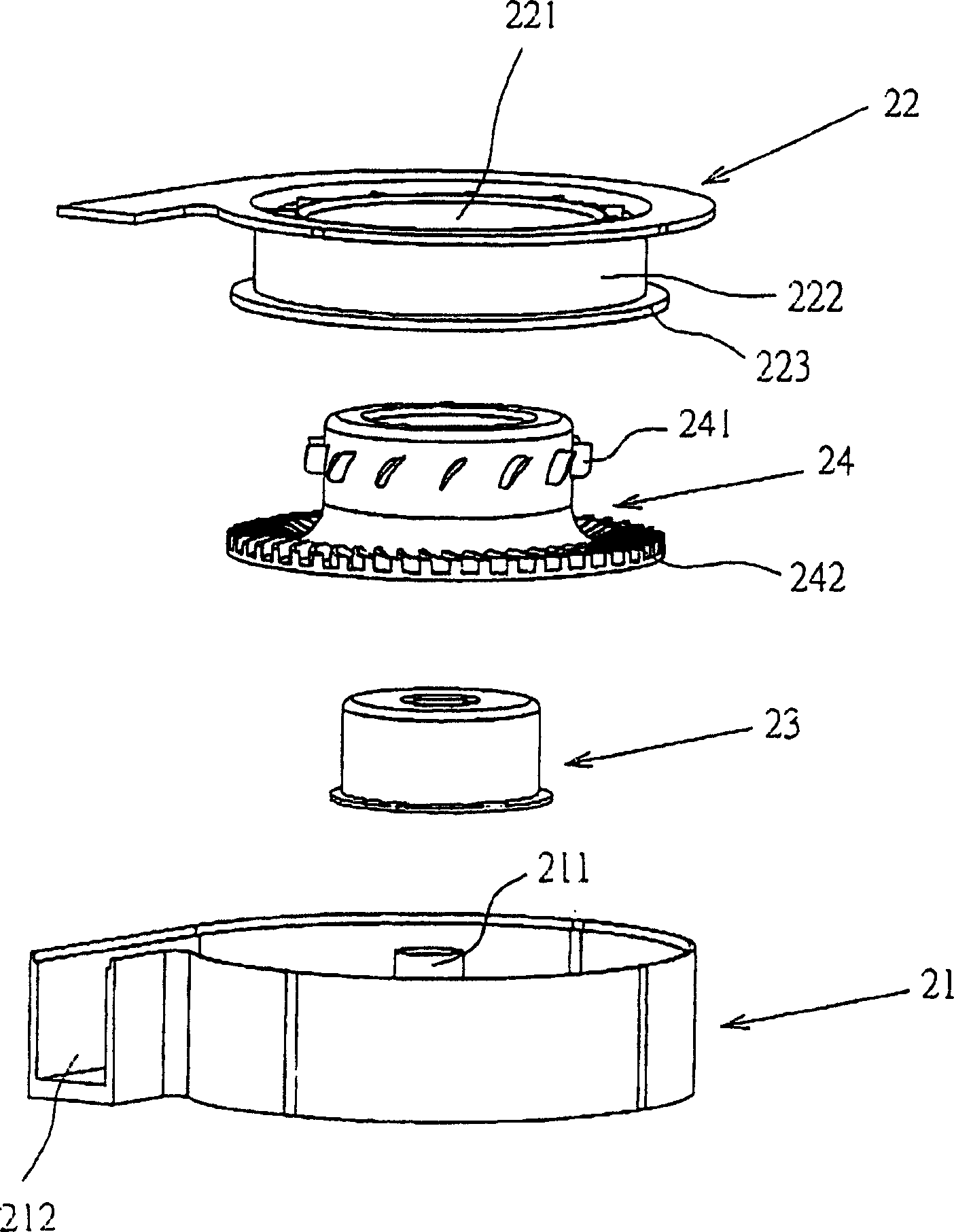

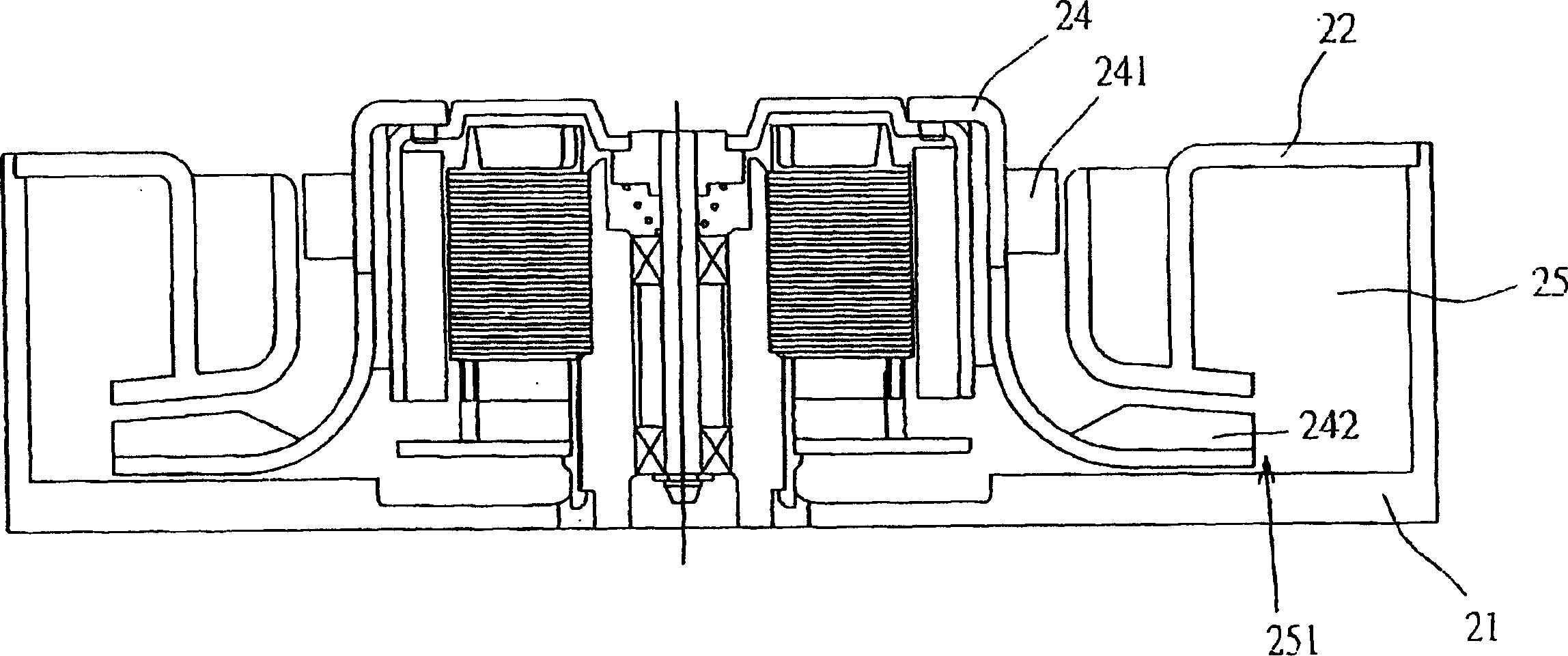

[0026] see Figure 2A and 2B , which shows the first preferred embodiment of the centrifugal fan of the present invention. The centrifugal fan is a one-way blower, which mainly includes a first frame 21 , a second frame 22 , a driving device 23 and a moving blade 24 . The first frame 21 has a sleeve seat 211, so that the driving device 23 can be placed on it, and the second frame 22 has an air inlet 221 and a wall 222 extending downward from the inner edge of the air inlet. After the second frame 22 is combined with the first frame 21, the wall surface 222 forms an air collecting channel 25 in the space formed by the combination of the second frame 22 and the first frame 21 and accommodates the moving blade. The space of the part 24 also forms an air outlet 212 at the same time. The bottom end of the wall has a radially outwardly extending flange 223 for forming an inlet 251 of the flow collecting channel. The moving blade part has a first blade group 241 and a second blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com