Injection molding machine

A technology of injection molding machine and injection device, which is applied in the field of injection molding machines, can solve the problems that there is no rib plate and it is difficult to prevent the fixed pressure plate from toppling over, and achieve the effect of preventing toppling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

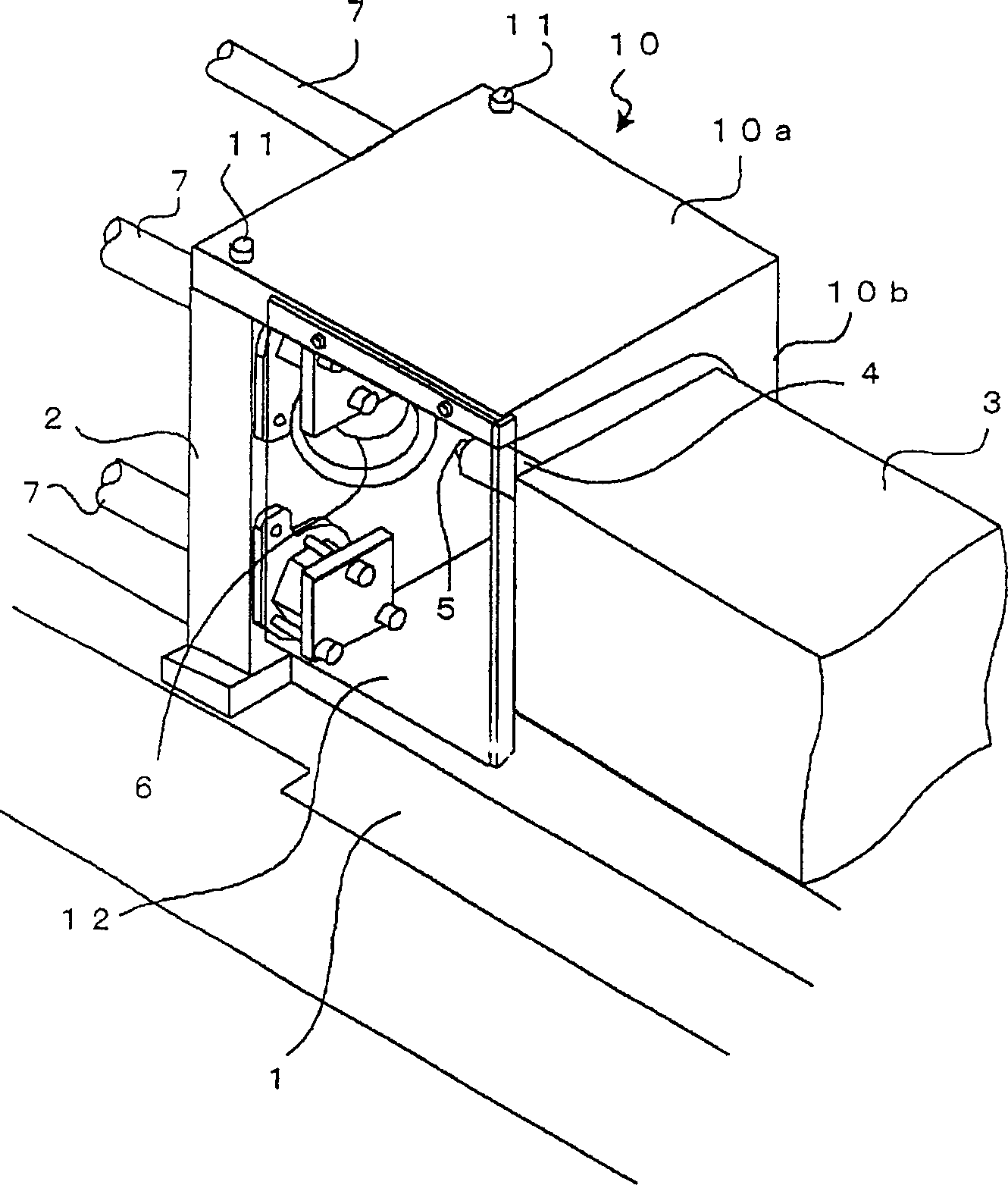

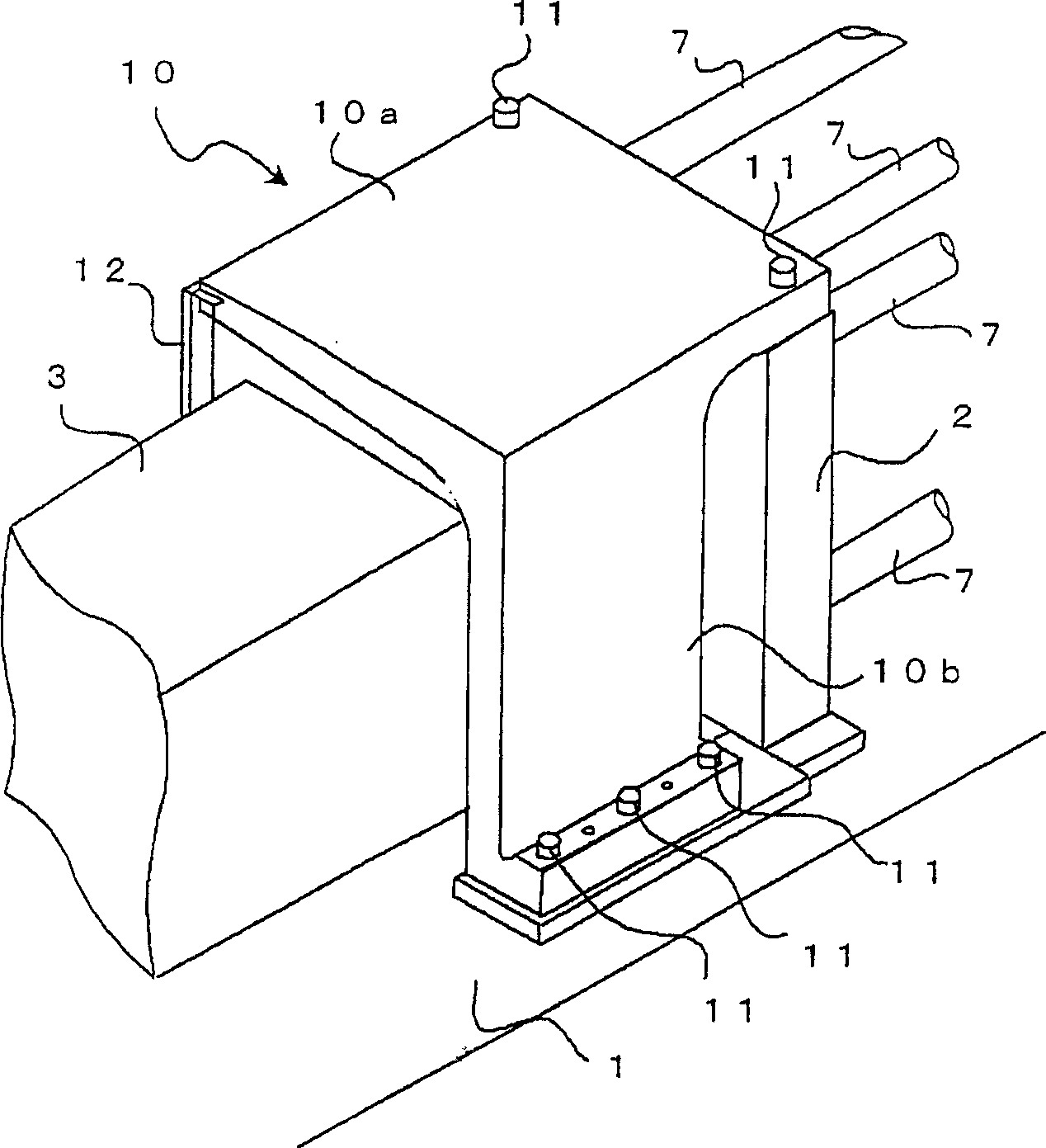

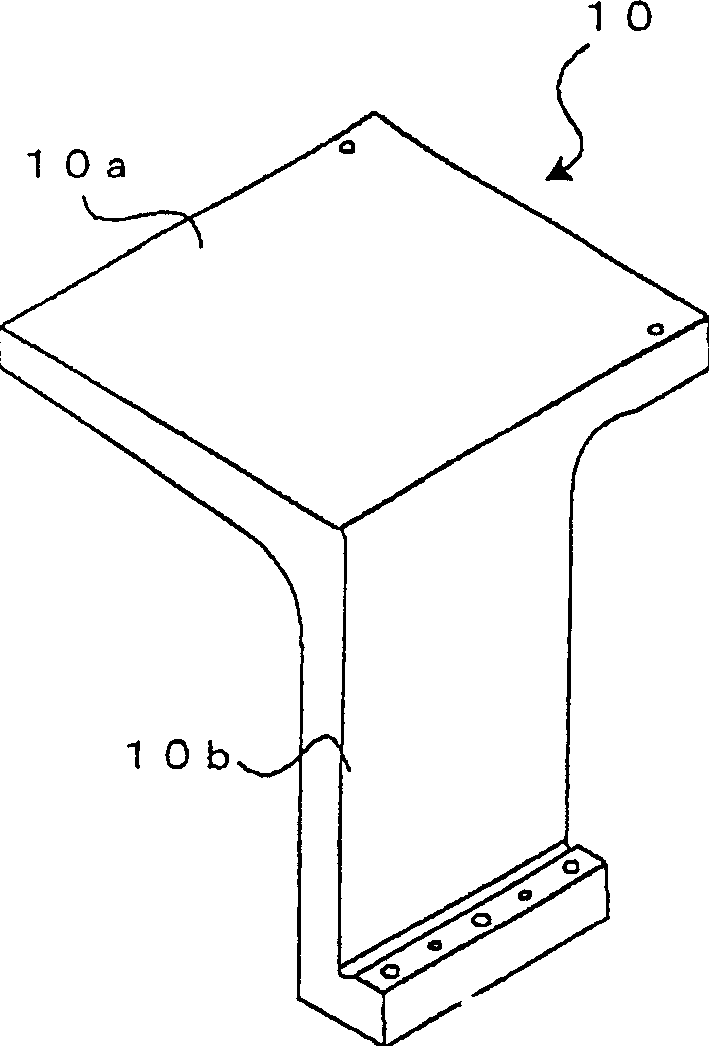

[0025] First, use Figure 1-Figure 3 , to describe the first implementation side of the injection molding machine of the present invention

[0026] The fixed platen 2 is fixed on the base frame 1 of the injection molding machine. The fixed platen 2 is connected to the rear platen (not shown) through a plurality of tie rods 7 . A fixed-side metal mold (not shown) is fixed to the fixed platen 2 . In addition, a movable side metal mold is attached to a movable platen (not shown) movable along the tie rod 7 . The mold is closed and closed by the movement of the movable platen.

[0027] In addition, on the base frame 1, the injection device 3 is installed so as to be able to advance and retreat in the direction of the fixed platen 2, and is installed so as to be rotatable around a vertical axis through a rotary joint. The nozzle 5 is arranged on the front end of the heating cylinder 4 installed on the injection device 3, and when the injection device 3 advances, the nozzle 5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com