Screw module with rivet function matched with nut and slope back stop jump ring and using method

A nut slope and nut technology, applied to nuts, threaded fasteners, screws, etc., can solve problems such as lack of use methods, and achieve the effect of simplifying the difficulty of riveting engineering, reducing the cost of riveting engineering, and reducing the amount of riveting engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

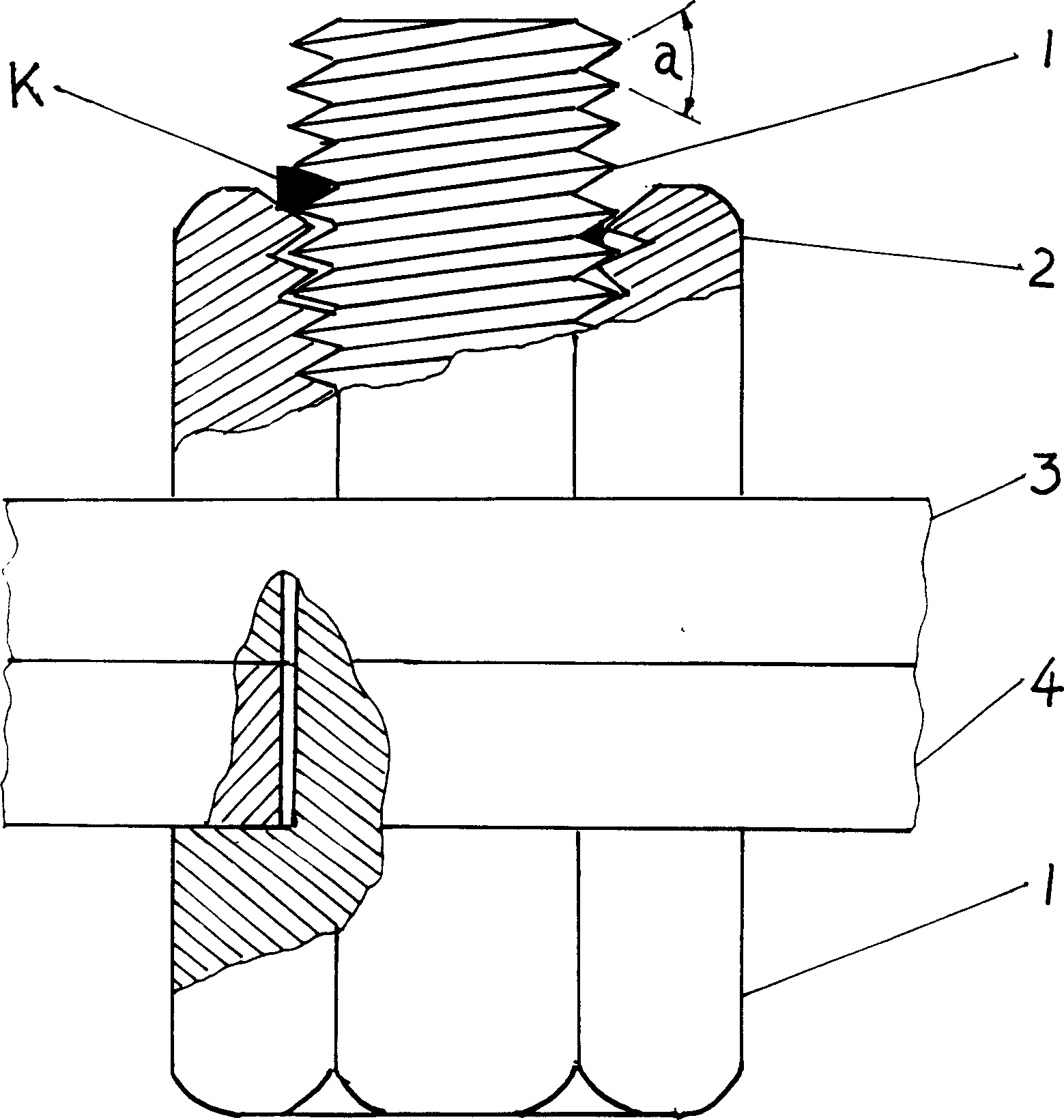

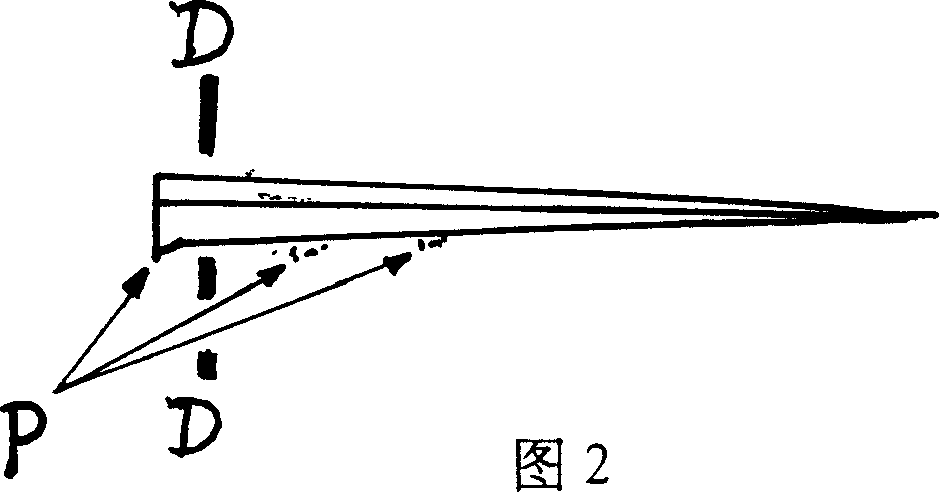

[0024] Position the bolt (1) on the engineering part A (3) and the engineering part B (4), tighten the nut (2) on the bolt (1) as usual, and then place the semi-circular bar shape with a slight slope Screw in the anti-retraction retaining ring (K) from the threaded tapered gap between the bolt (1) and the nut (2). Finally, borrow the special tool screwed in with the bolt (1) to screw the anti-retraction retaining spring ( K) Rotate and press inward. Alternatively, it is also feasible to use nails and hammers to tighten the stop jumper (K) inwardly. This is another simpler but more cumbersome operation scheme for tightening the nut (2). After that, turn the nut (2) slightly in the direction of unscrewing (objectively, it is impossible to increase the anti-rotation range), so that the anti-slip sharp corner ( P) Dig slightly into the thread groove of the bolt (1).

[0025] It is not difficult to find out from all accompanying drawings, after this, it is impossible to unscrew t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com