High performance composite shock absorber

A shock absorber, high-performance technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of restricting the application of the damper, the hysteresis curve is not smooth, easy to leak, etc. Self-limiting ability, the effect of solving the problem of insufficient filling and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

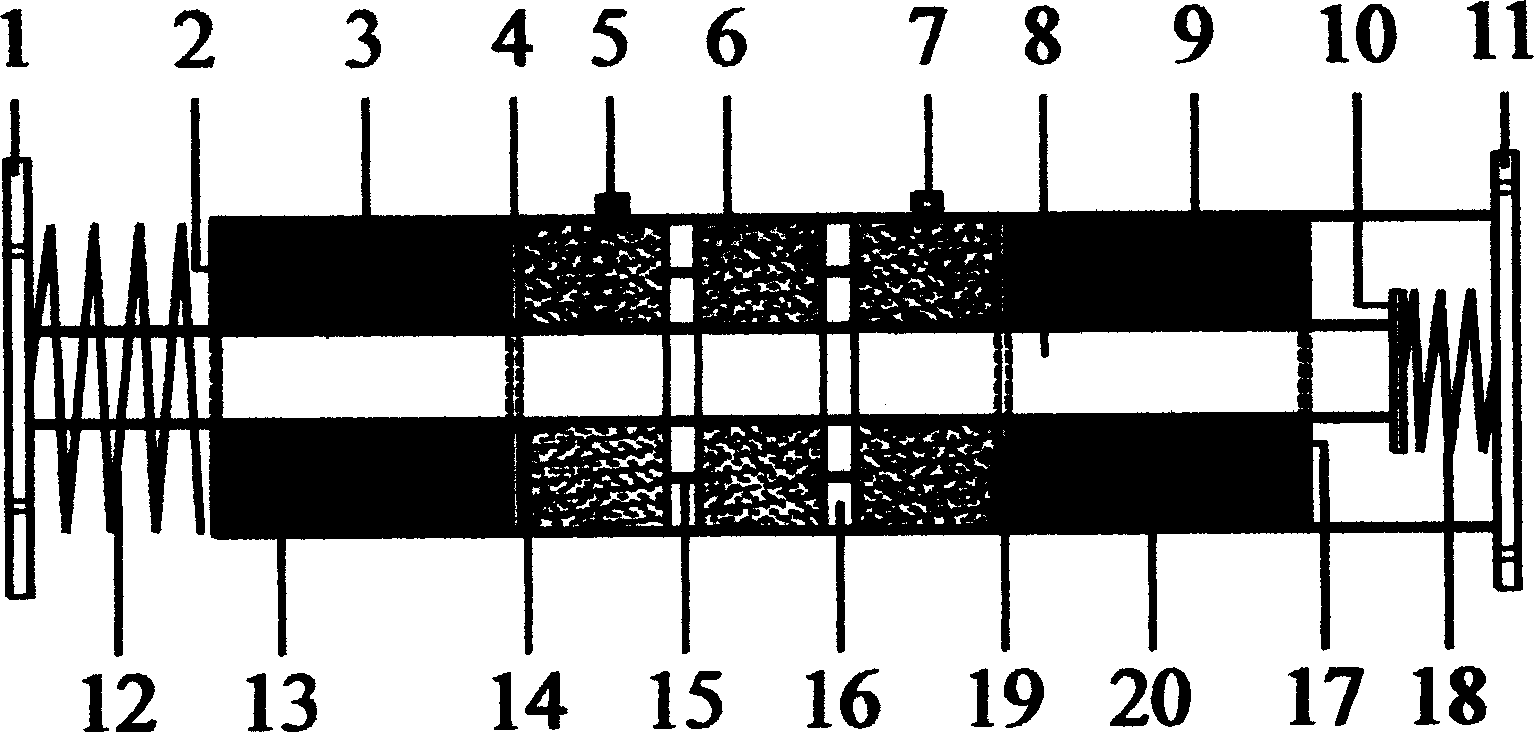

[0009] In the high-performance composite shock absorber of the present invention, the inner steel pipe 8 is located in the outer steel pipe 9, the left end of the inner steel pipe 8 extends out of the outer steel pipe 9, the left end of the inner steel pipe 8 is fixed with a left connecting steel plate 1, and the left end of the outer steel pipe 9 is fixed with a Outer steel pipe end plate 2, a left spring 12 is arranged between the outer steel pipe end plate 2 and the left connecting steel plate 1; A right spring 18 is provided between the limiting plate 10 and the right connecting steel plate 11; an inner sealing plate 17 is provided in the inner hole at the right end of the outer steel pipe 9, and a cavity dividing plate is fixed in the outer steel tube 9; An ellipsoidal protrusion 3 is fixed on the inner steel pipe 8 between the outer steel pipe end plate 2, in the cavity surrounded by the left cavity partition plate 4, the outer steel pipe end plate 2, the outer steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com