Bulk material pump feeder

A technology for loose materials and feed pumps, applied in the direction of conveying bulk materials, pumps, pump components, etc., can solve the problems of affecting accuracy and feeding performance, reducing and slowing down equipment operation speed, material jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

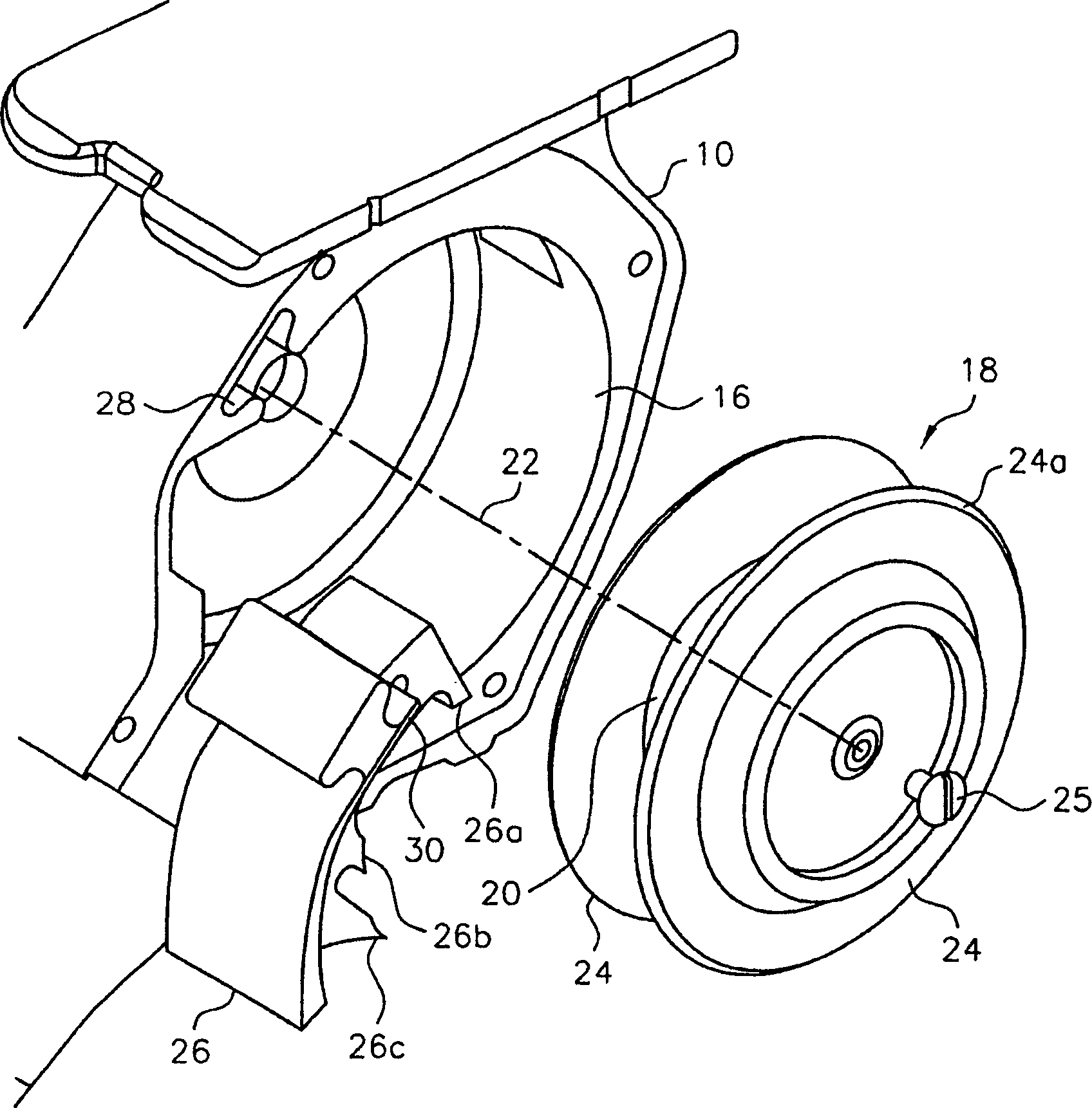

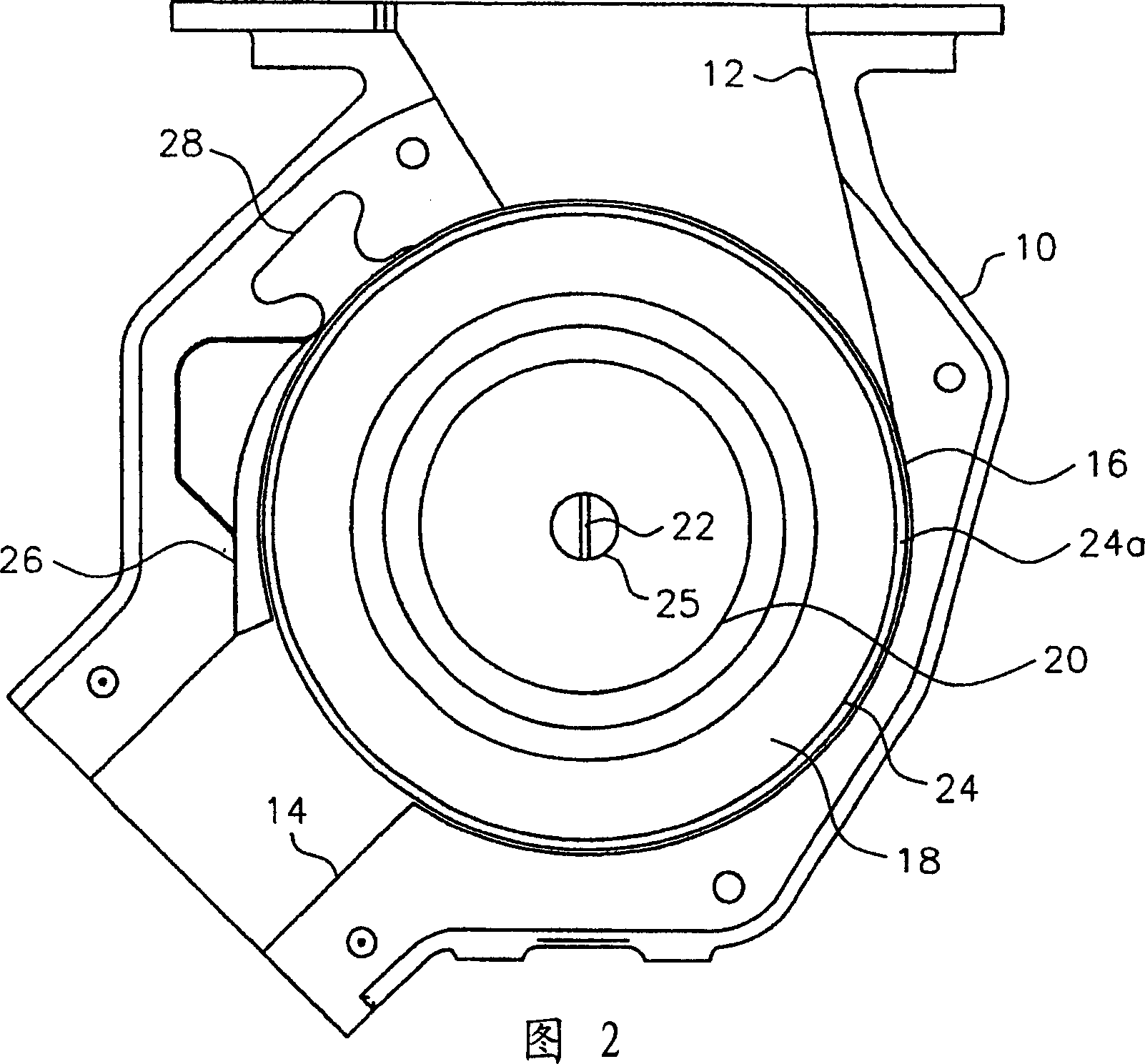

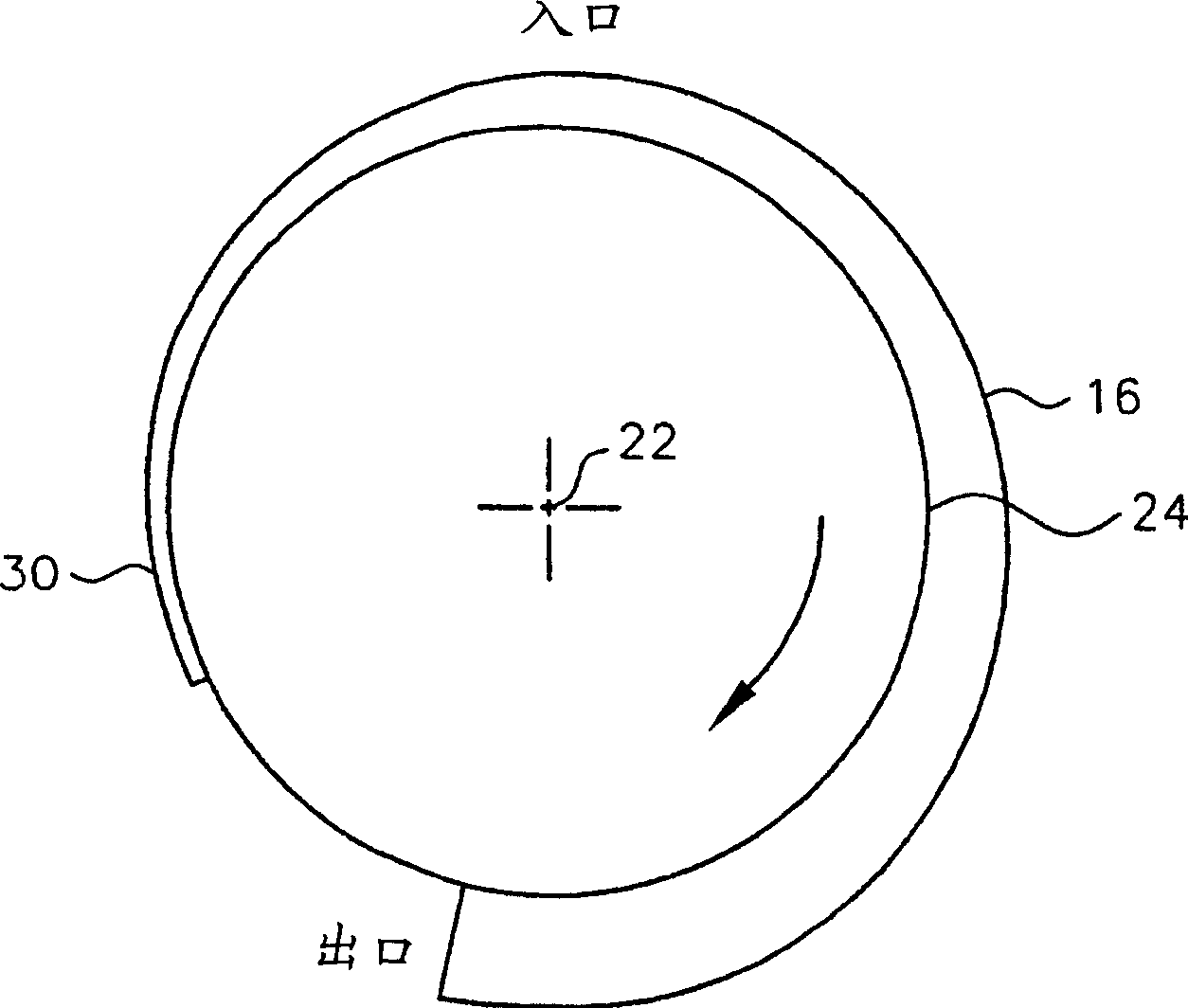

[0013] refer to figure 1 and 2, a bulk material feed pump constructed in accordance with the present invention includes a housing 10 having an inlet 12 , an outlet 14 and an inner wall 16 extending from the inlet 12 to the outlet 14 . A bulk material feed pump constructed in accordance with the present invention is substantially similar in construction and operation to the devices described and illustrated in US Patent Nos. 5,051,041 and 5,355,993, the entire contents of which are incorporated herein by reference.

[0014] figure 1 The bulk material feed pump shown in and 2 also has a drive rotor 18 having a hub 20 rotatable about an axis of rotation 22 and a pair of drive discs 24 which are directed away from the hub towards the housing 10 inner wall extension. For the embodiment of the invention being described, the hub 20 and drive disc 24 are formed as one unit. To facilitate delivery of bulk material from the inlet 12 of the housing 10 to the outlet 14 of the housing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com