Sample warping machine with yarn recovery mechanism

A recycling mechanism and warping machine technology, which is applied in warping machines, textiles, papermaking, and thin material processing, etc., can solve the problems of meaninglessness, unsmooth switching between winding and winding, and achieve good efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below with reference to the drawings. The illustrated example is merely an example, and various modifications other than the illustrated example are possible unless the technical idea of the present invention is deviated from.

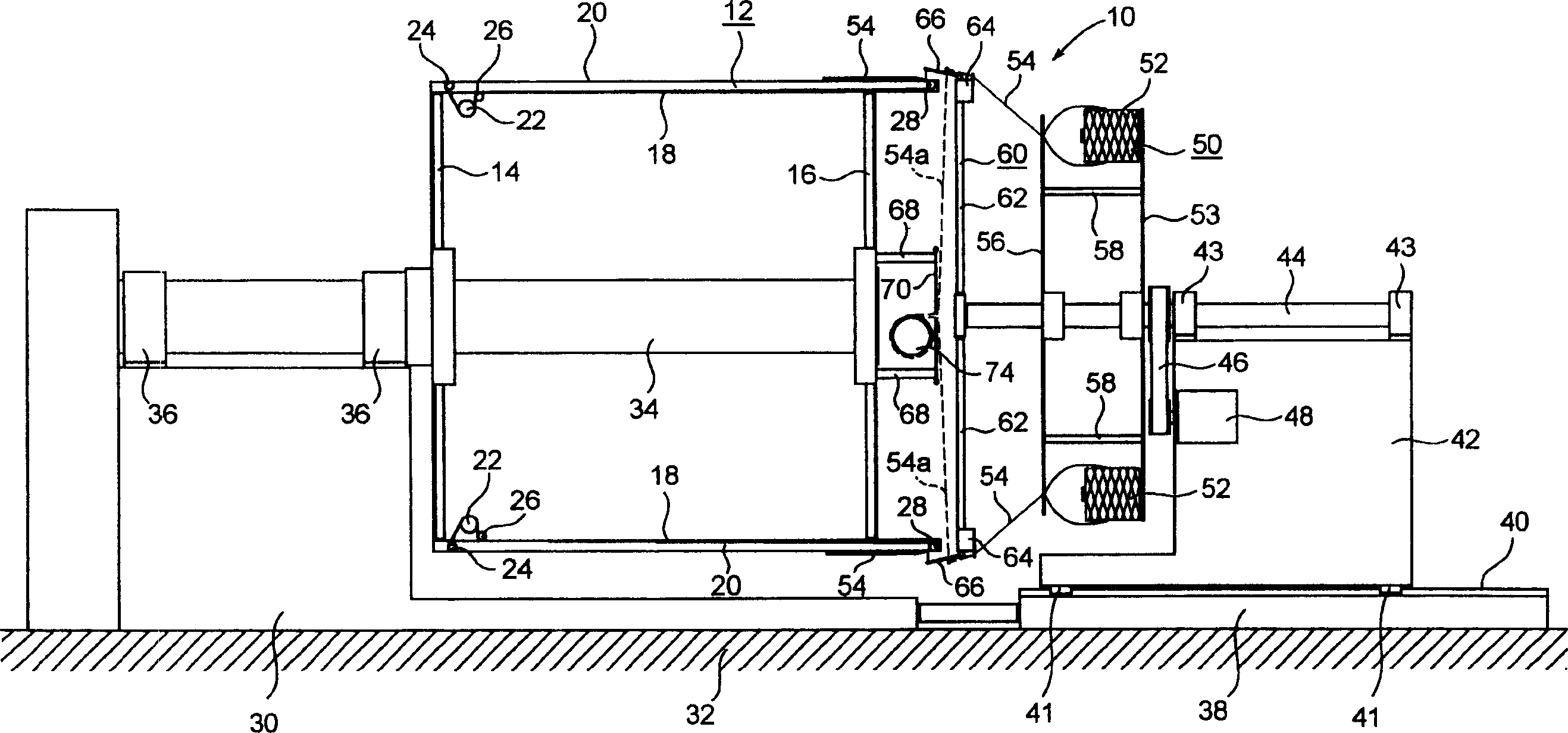

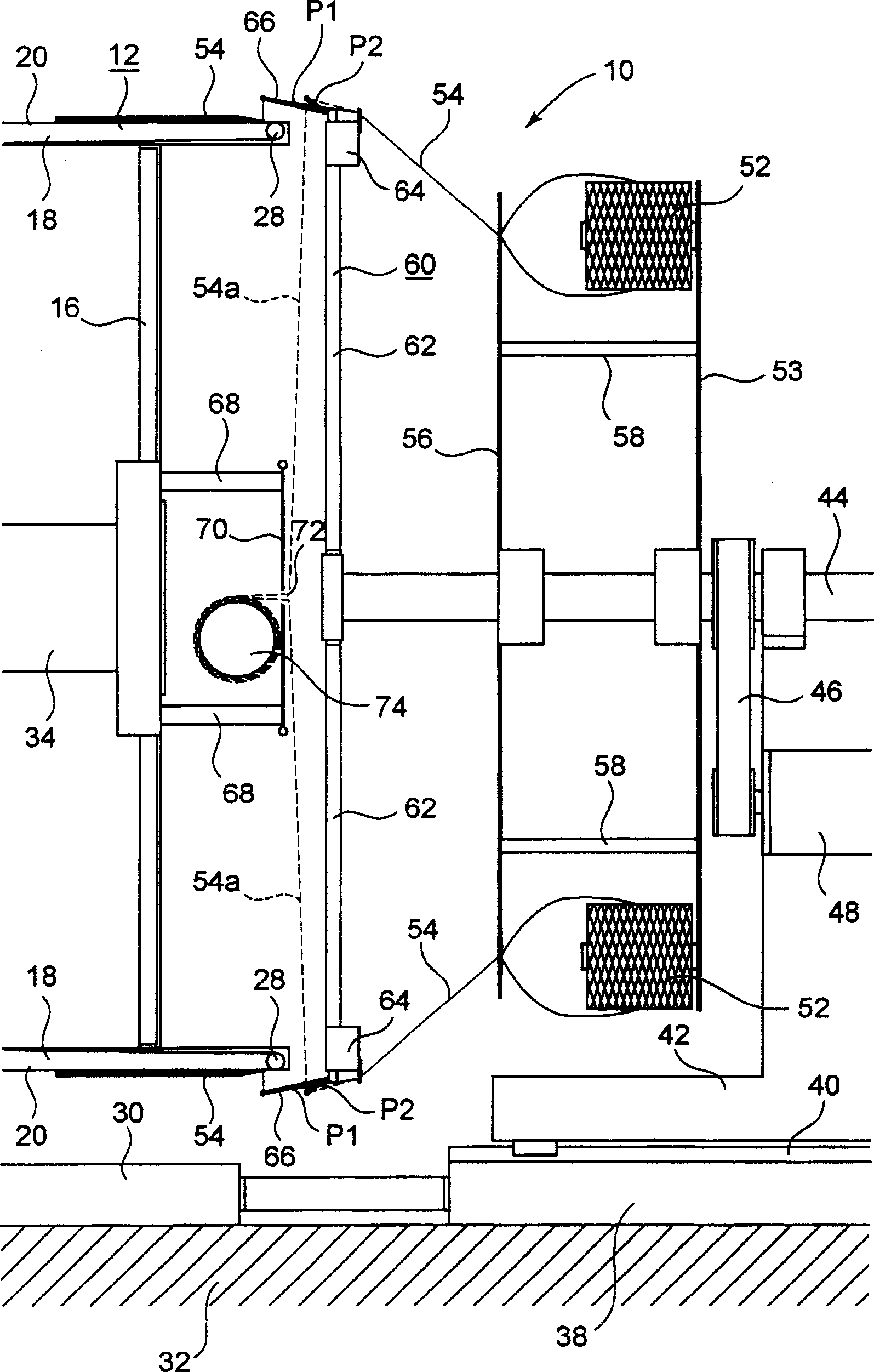

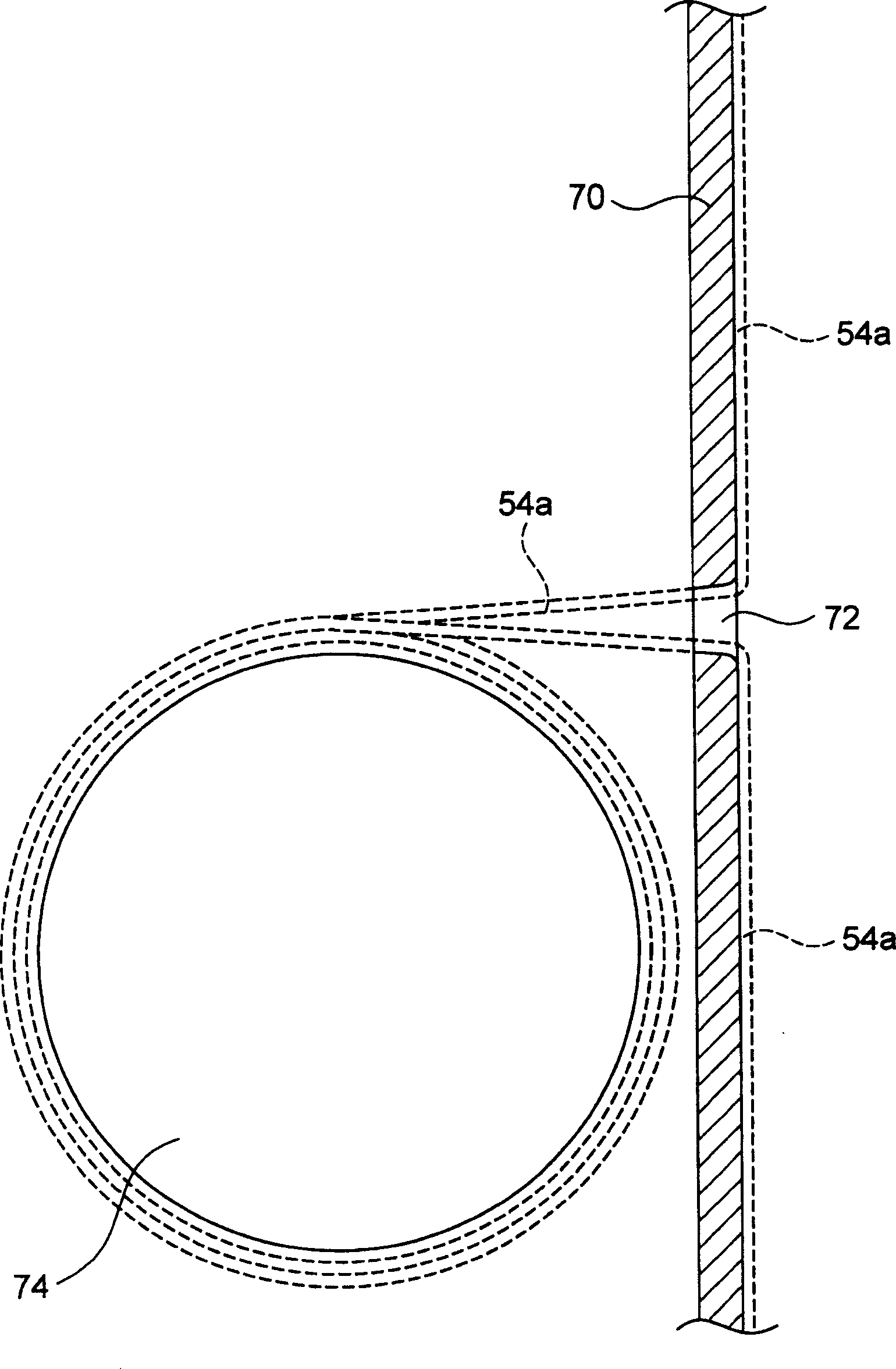

[0038] figure 1 It is a cross-sectional schematic explanatory view showing an embodiment of the sample warper of the present invention. figure 2 for figure 1 Enlarged view of the main part. image 3 It is an enlarged cross-sectional explanatory view showing the yarn recovery mechanism. Figure 4 Enlarged front view for part of warping cylinder and yarn guide. Figure 5 Enlarged front view showing part of yarn guide and rotating warp creel. Image 6 This is an enlarged front view showing the movement of the front end member of the yarn guide.

[0039] exist figure 1 Among them, figure number 10 is a sample warping machine with a warping cylinder 12. The warping cylinder 12 consists...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com