Carbonated beverage

A technology of carbonated beverages and raw materials, applied in food ingredients as antifoaming agents, food preparation, food science, etc., can solve the problems of undiscovered effect persistence, weak effect, poor safety of silicon-based defoamers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: defoaming test (premix method)

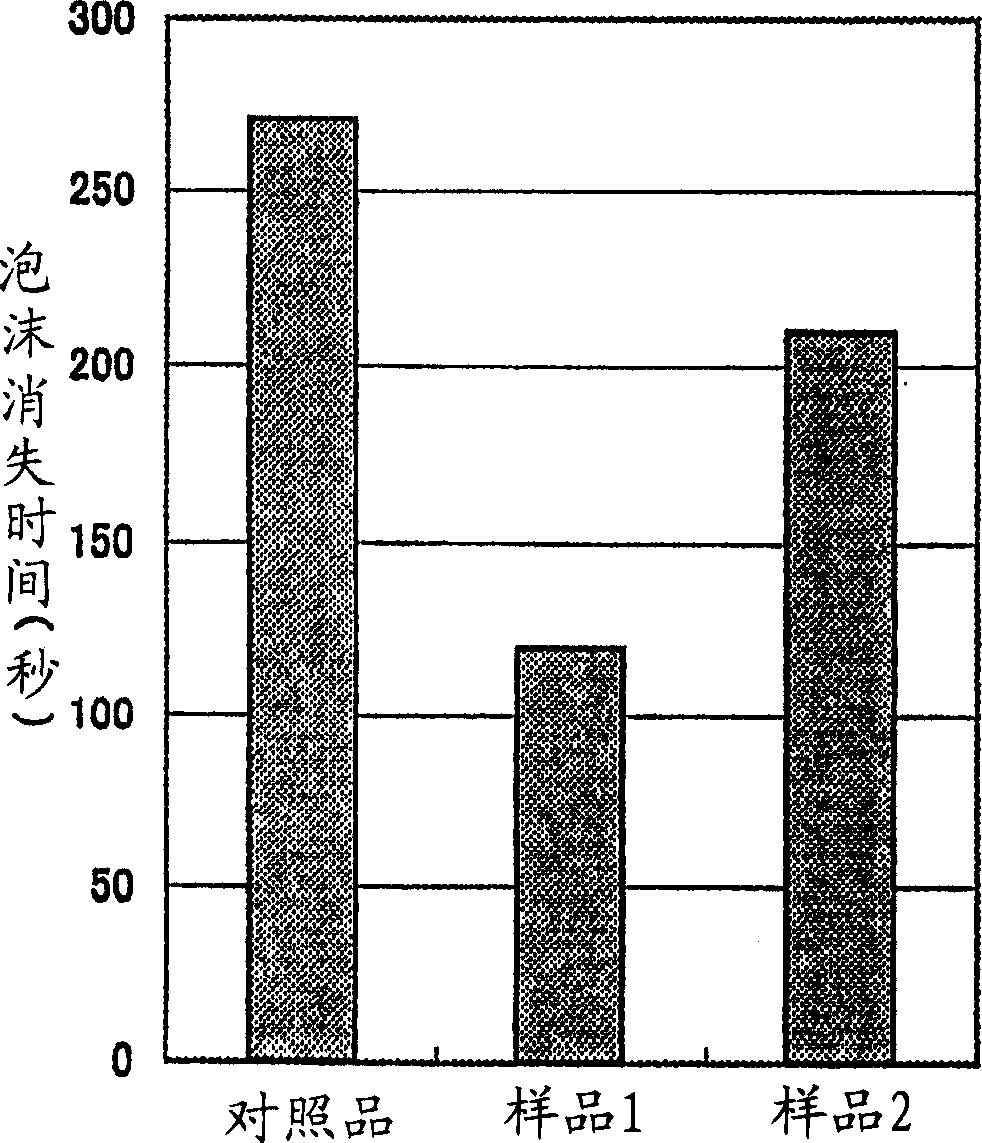

[0032] According to the ratio composition shown in Table 1 below, the raw material liquids (3 types) of cola drinks were made, and carbon dioxide was injected into them using a soda siphon to make cola drink samples. This cola drink was directly sprayed into a 1-liter graduated cylinder for 4 seconds, and the time required for the generated foam to disappear was measured.

[0033] Reference substance

[0034] The result is attached figure 1 shown. It can be seen from this figure that the defoaming time of the emulsifier-added (sample 1 and sample 2) is significantly shorter than that of the control, taking the emulsifier-free (reference product) as a control. In terms of sensory properties, it was evaluated that there were few peculiar smells and special flavors compared with common antifoaming agents (for example, sugar esters).

Embodiment 2

[0035] Embodiment 2: defoaming test (post-mixing method)

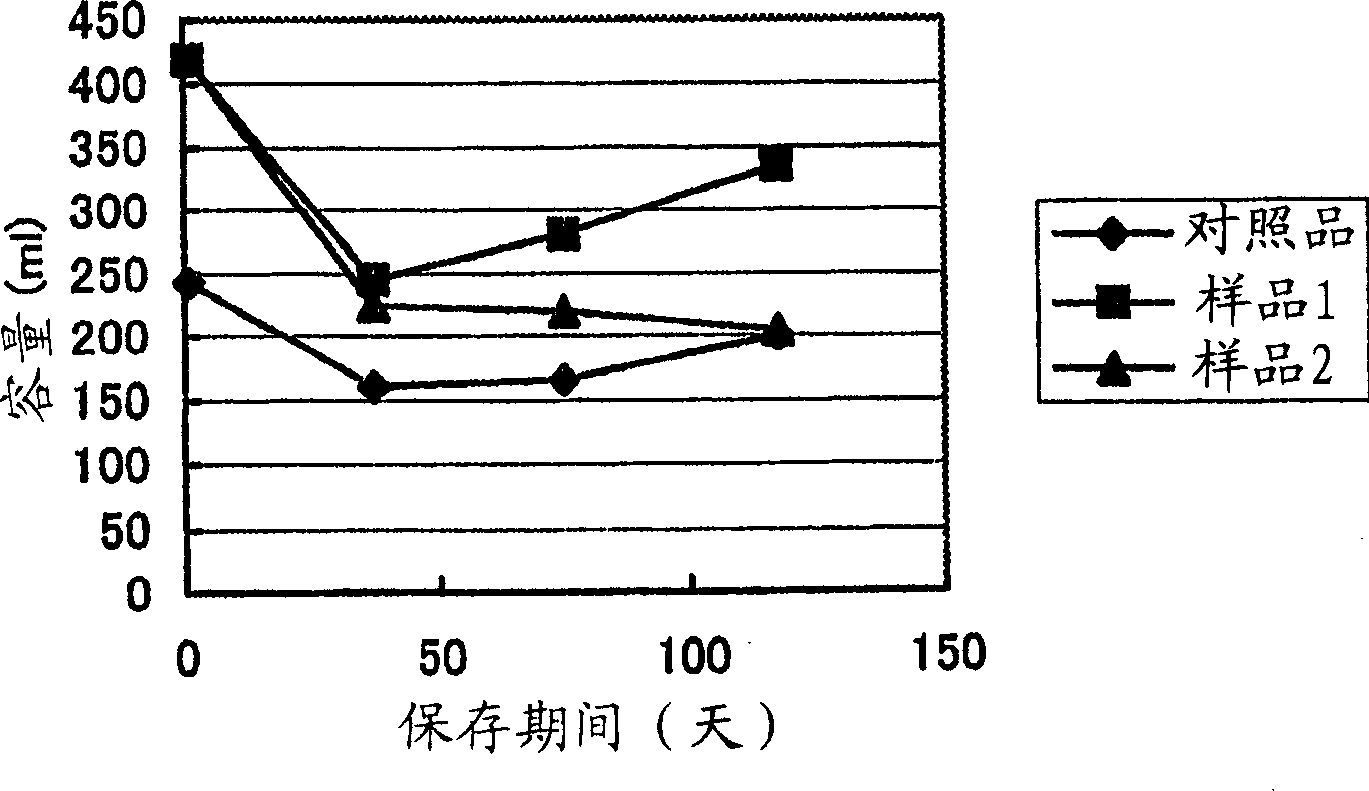

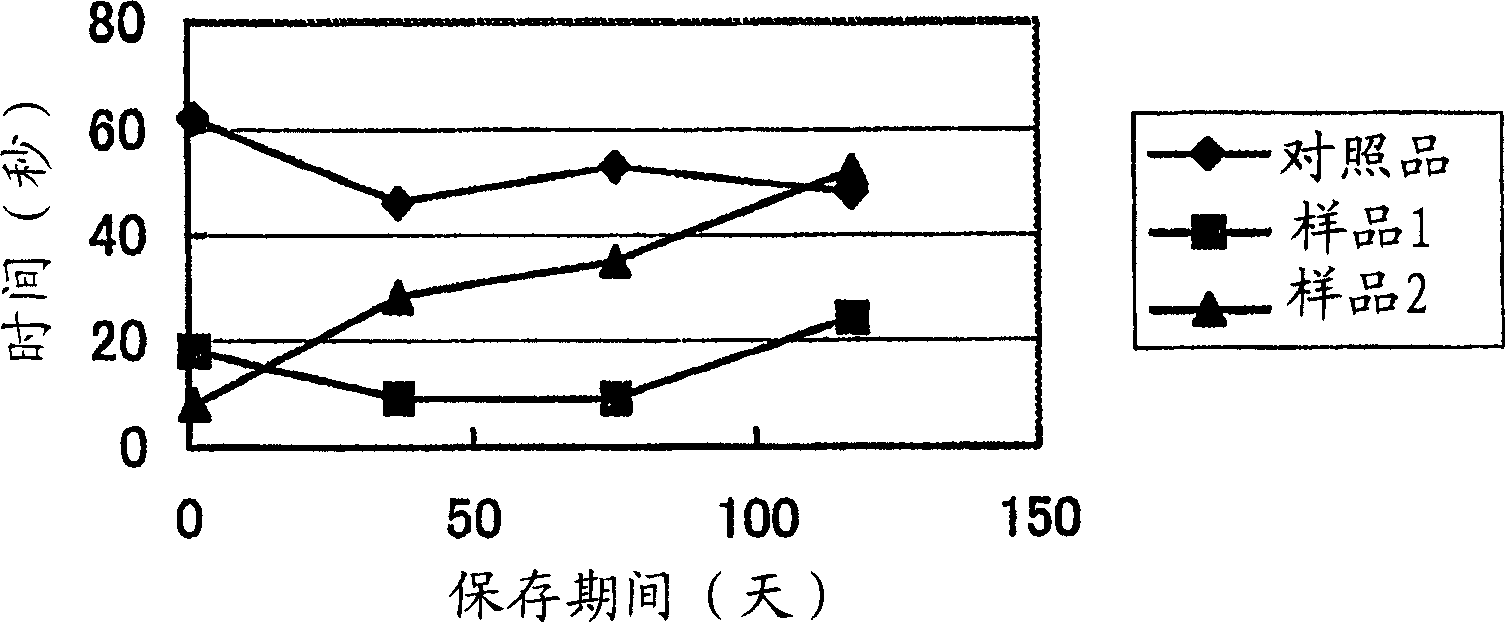

[0036] According to the ratio shown in the following table 2, the raw material concentrated liquids (3 kinds) of cola drinks are made, and they are respectively diluted according to (concentrated liquid): (carbonated water)=1: 5.4, and are extracted in the cup by the dispenser. When the cup is filled with liquid and foam, measure the liquid capacity in the cup. In addition, the cola drink was poured into the cup for 5 seconds, and the time required for the generated foam to disappear was measured. Finally, the number of times the dispenser button was pressed to fill the cup with Coke was measured. The above measurements were carried out on the 0th day, 37th day, 75th day and 117th day after storage of the syrup (raw material concentrated liquid), respectively.

[0037] Reference substance

sample 1

sample 2

citric acid

2.88

2.88

2.88

Sodium citrate

1.14

1.14

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com