Segmented ball/roller guide for a linear motion bearing

A technology of linear motion and bearing balls, which is applied in the direction of linear motion bearings, bearings, ball bearings, etc., and can solve problems such as balls easily detached from ball tracks, bearing failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. In the following description, obvious functions or constructions are not described in detail to avoid obscuring the invention in unnecessary detail. Throughout the drawings, like elements are provided to be equivalent in structure and function.

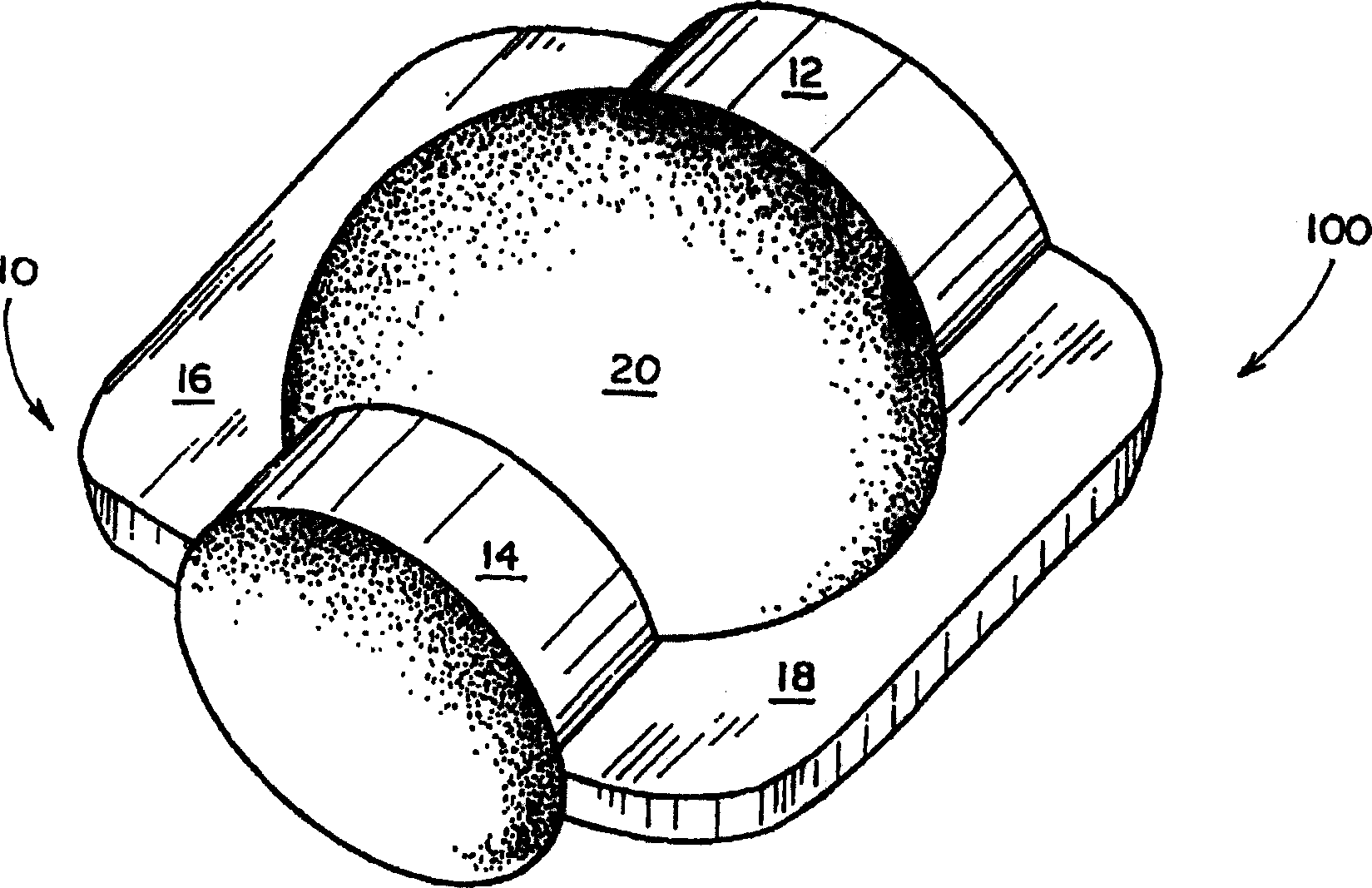

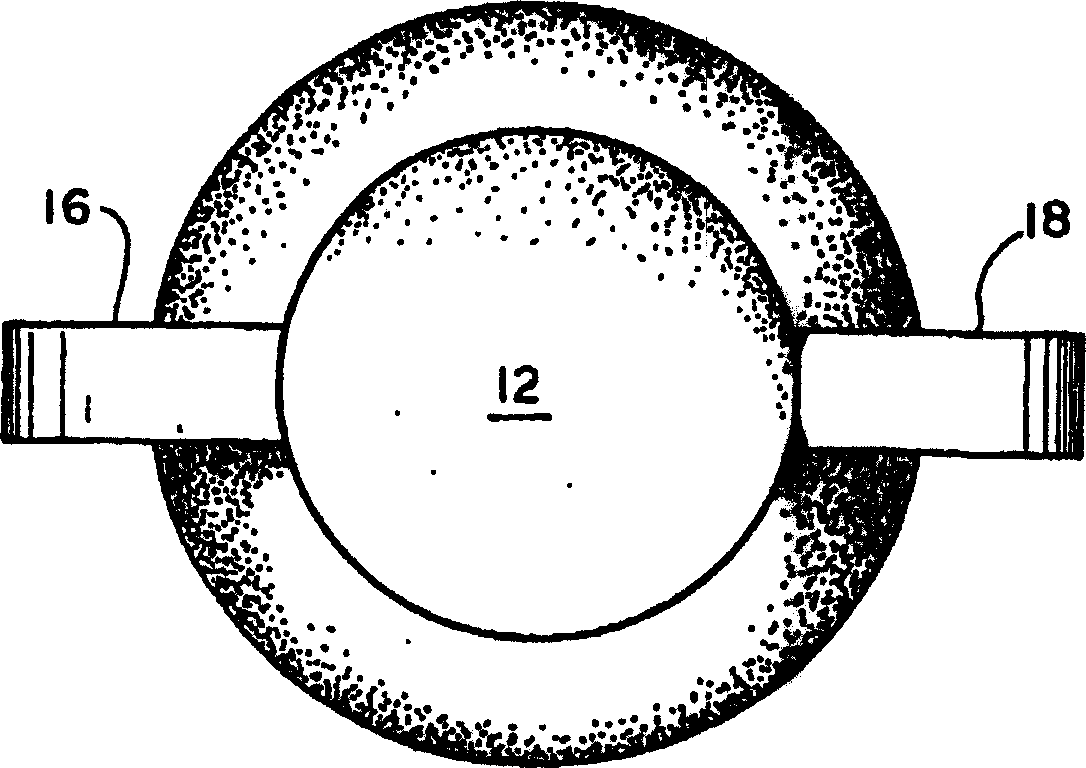

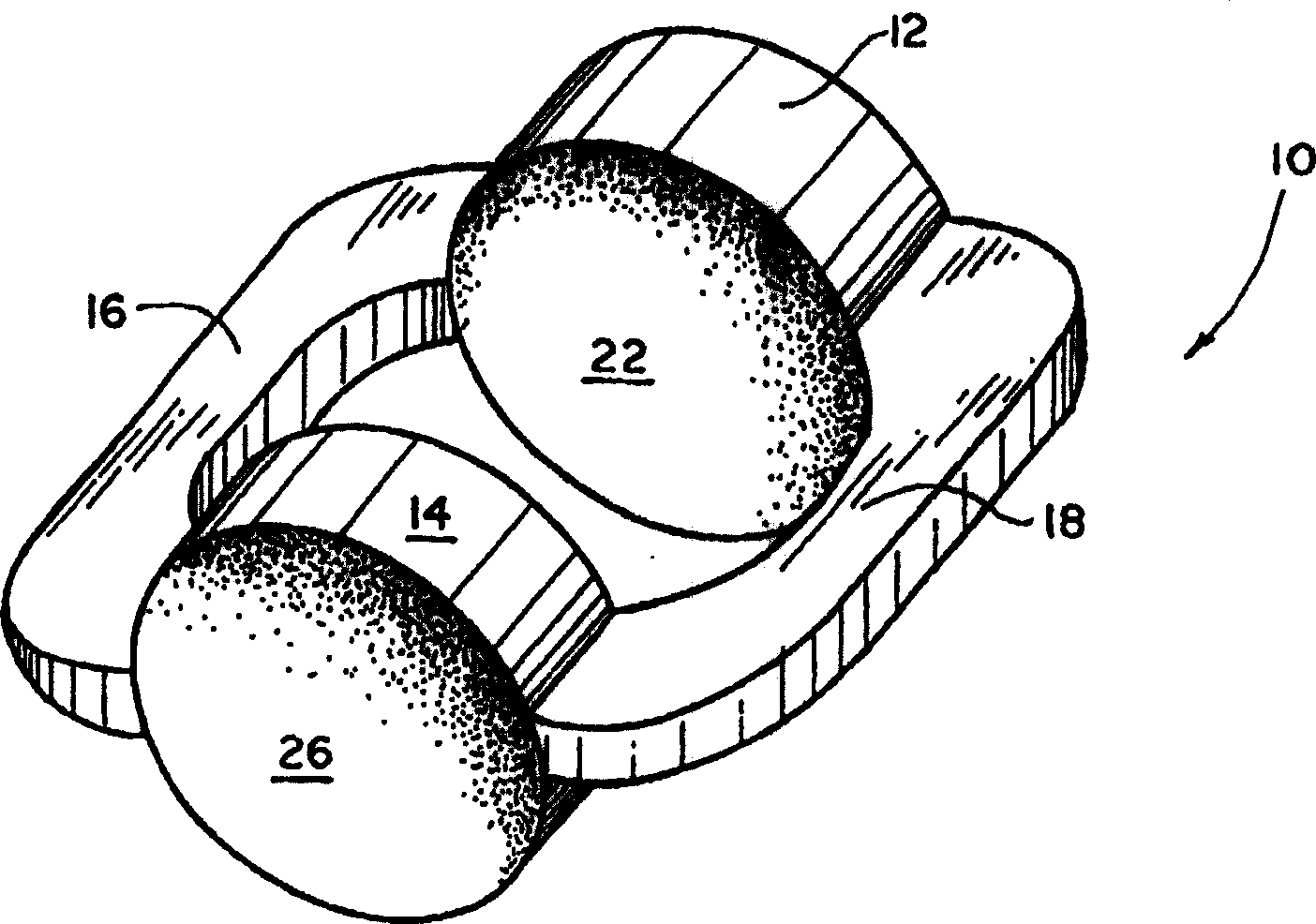

[0035] refer to Figure 1-8 , the segmented ball / roller guide according to the invention is generally identified by the reference numeral 10 .

[0036] Figure 1-5Illustrated is a segmented ball / roller guide assembly 100 housing a ball bearing therein. The segmented ball / roller guide 10 of the present invention includes at least one first spacer assembly 12 . Many inventive modifications of the support / guide 10 also include a second spacer 14, although the first spacer assembly 12 can wholly or partially surround rolling elements, such as ball bearings 20, as will be described below. Spacers 12 and 14 are spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com