Variable-polarization microstrip reflectarray antenna

A reflectarray antenna and reflectarray technology, applied in antennas, antenna arrays, electrical components, etc., can solve problems such as inability to realize polarization transformation, complex structure, and limited array period size, and achieve simple structure, reduced gain, and elimination of The effect of the occlusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

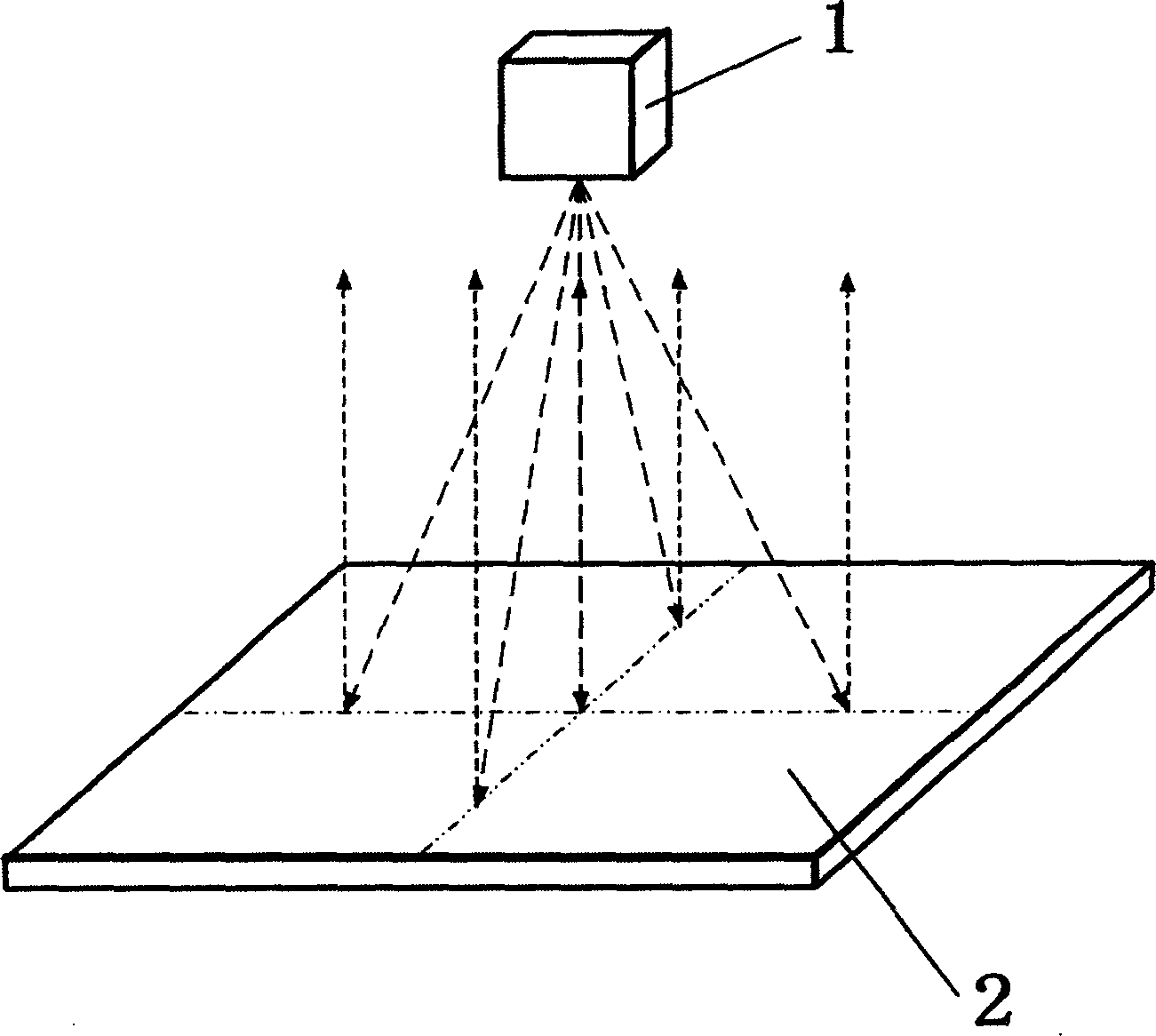

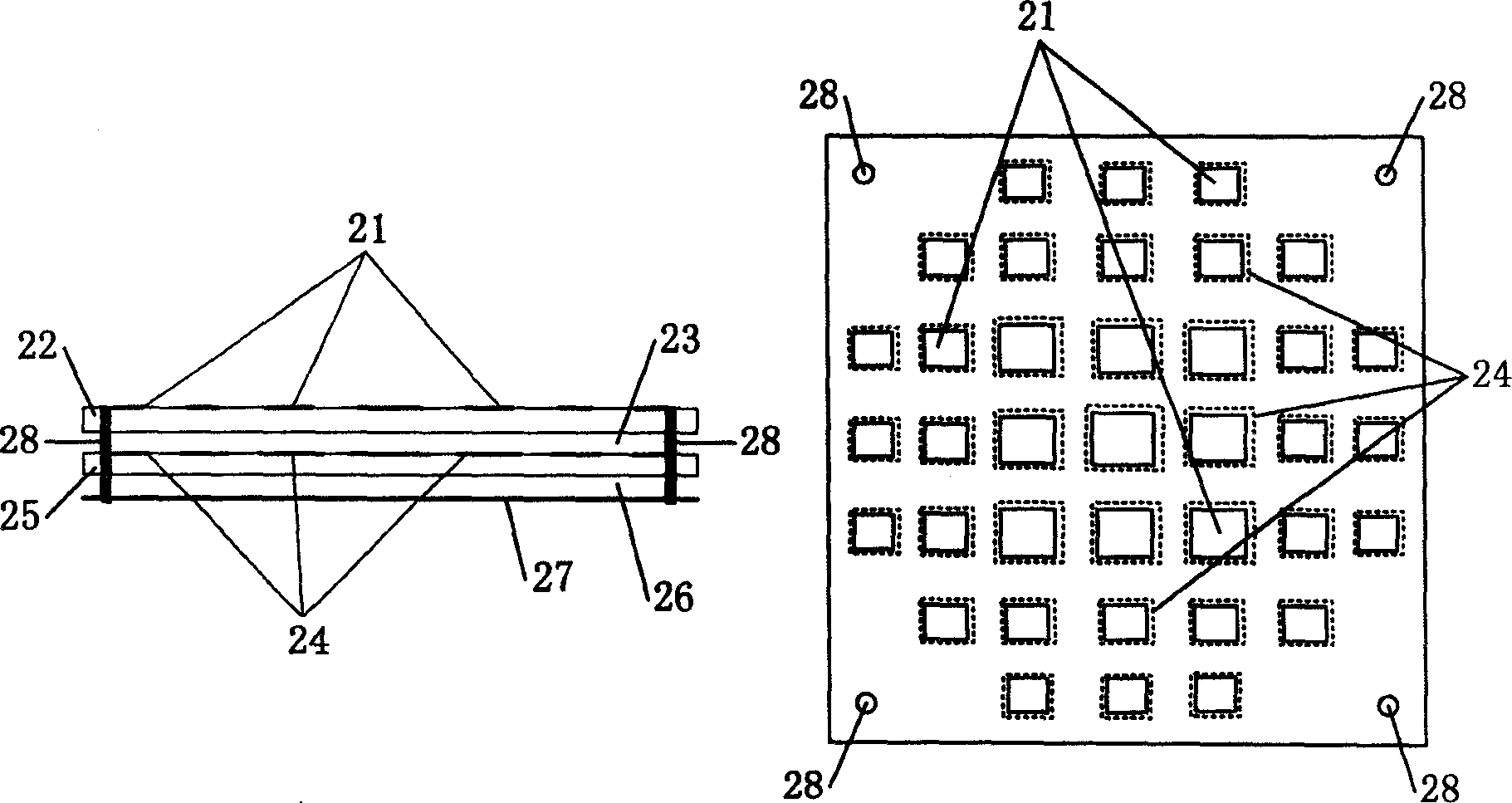

[0018] A polarization-variable microstrip reflectarray antenna capable of polarization conversion, consisting of a feed source 1 and a reflectarray 2, characterized in that the reflectarray 2 consists of an upper dielectric substrate 22, a lower dielectric substrate 25 and a grounded metal plate 27 composition, the lower dielectric substrate 25 is located between the upper dielectric substrate 22 and the grounded metal plate 27, a gap 23 is provided between the upper dielectric substrate 22 and the lower dielectric substrate 25, and the lower dielectric substrate 25 and the grounded metal plate 27 is also provided with a gap 26, an upper rectangular patch 21 is arranged on the upper dielectric substrate 22, and the upper rectangular patch 21 is located on a grid point arranged periodically, and a lower rectangular patch 24 is arranged on the lower dielectric substrate 25. , the lower rectangular patch 24 is located on the grid points arranged periodically, the grid point array ...

Embodiment 2

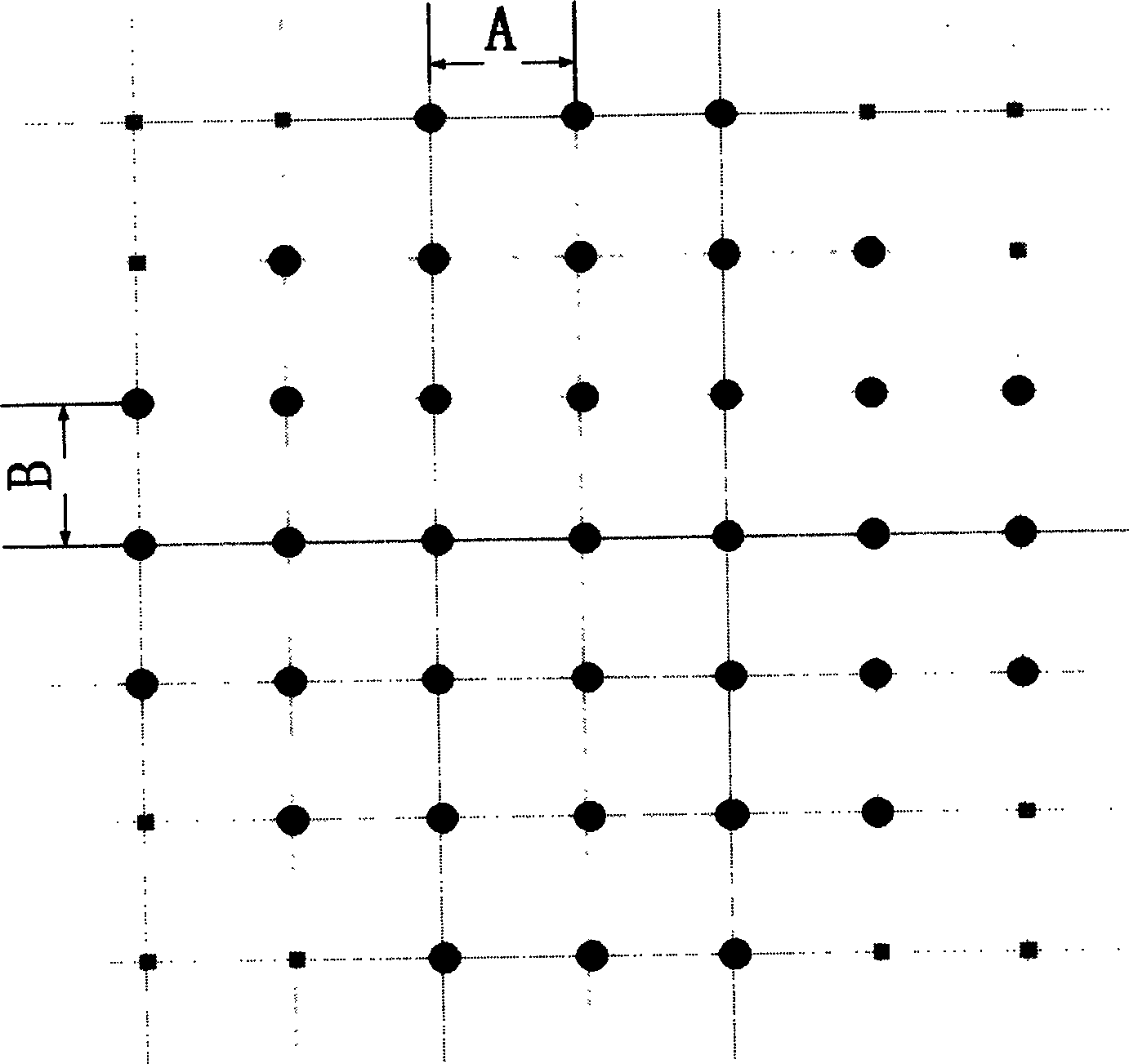

[0023] Use a medium with a thickness of 0.5mm (ε r =2.2) The substrate and the 37-element patch array with 2mm air gap, the two-dimensional period of the grid lattice is 18mm, and the similarity ratio of the size of the upper and lower patch of the same grid point is 0.7. According to the order of the distance between the center of the patch and the center of the array from small to large, the width-to-length ratio of the rectangular patch is {0.91, 0.915, 0.92, 0.90, 0.90, 0.90, 0.87, 0.86}, and the length of the lower rectangular patch (mm) are {14, 13.6, 13.3, 12.7, 12.4, 11.5, 11.1, 10.8} in turn. The design frequency is 10GHz and the working frequency band is 14%. The printed radiator with gradient groove line is used as the linear polarization feed source to realize the transformation from linear polarization to left-handed circular polarization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com