Self-propelled road milling machine

A road roller, self-propelled technology, applied in the direction of roads, roads, road repairs, etc., can solve problems such as increasing the risk of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

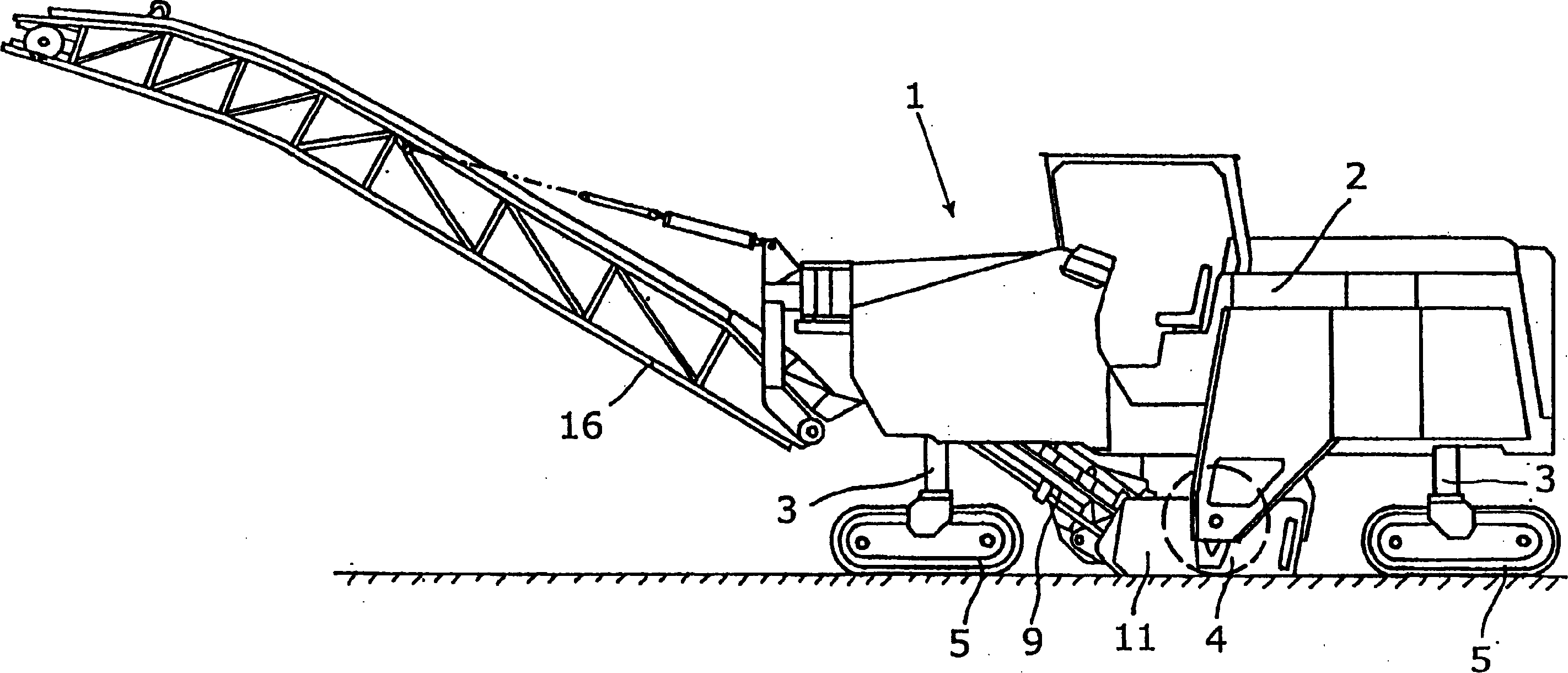

[0037] exist figure 1Shown is a road roller 1 which can employ the quick change roller tube system described below. In general, a road roller comprises a road roller frame 2 on which an internal combustion engine and a driving platform are mounted. The self-propelled road roller comprises a height-adjustable lifting column 3 mounted on a frame 2, on which support wheels or chain drive gears 5 are mounted.

[0038] The lamination rolls 4 are located in a lamination roll box 11 below the frame 2 , the sides of which are limited by side plates 12 , 13 . In a known manner, the material processed by the calender rollers 4 falls on a first conveyor belt 9 and is transported to a second height-adjustable and rotatable conveyor belt 16 .

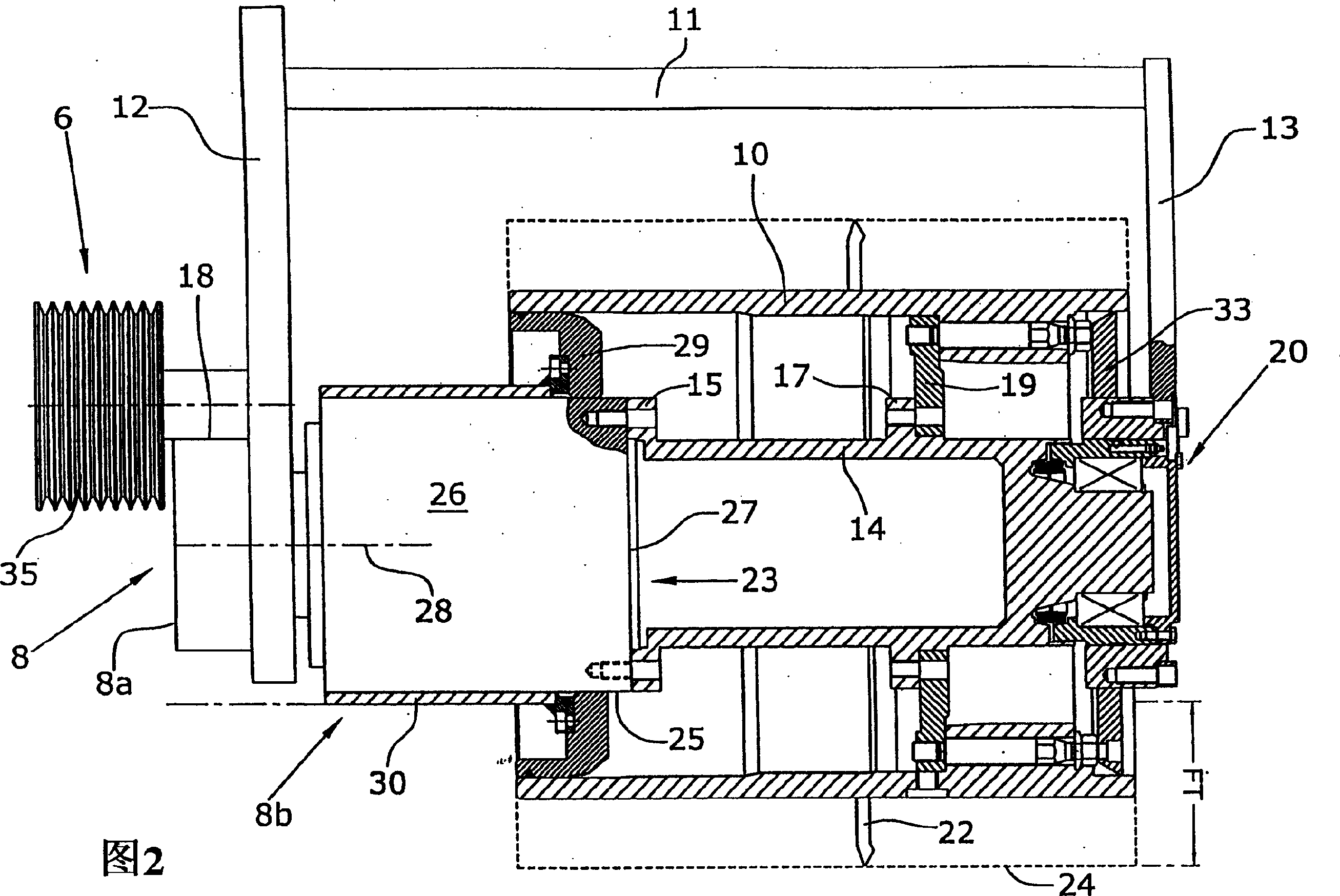

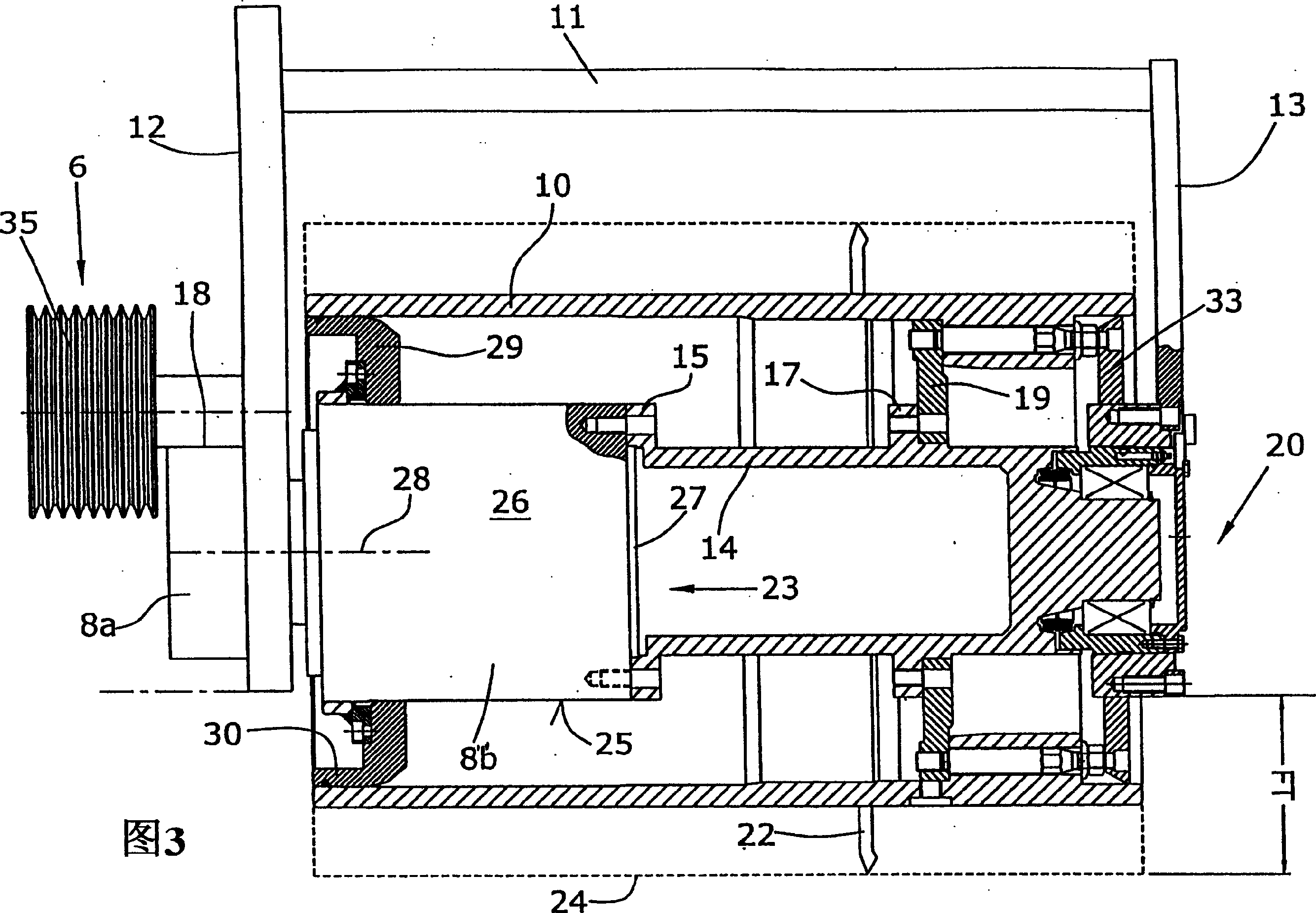

[0039] The lamination roller 4 is rotatably supported between the side plates 12, 13 of the lamination roll box 11, which extend perpendicularly to the axis of the lamination roll and are supported on the input side side plate 12 by the drive devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com