Cable connector

A technology for cable connectors and docking connectors, which is applied in the direction of connection, parts of connecting devices, protective grounding/shielding devices for connecting parts, etc., and can solve the problems affecting the electrical connection between cable connectors and docking cable connectors It is difficult to cause elastic deformation and other problems, and achieve the effect of good docking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

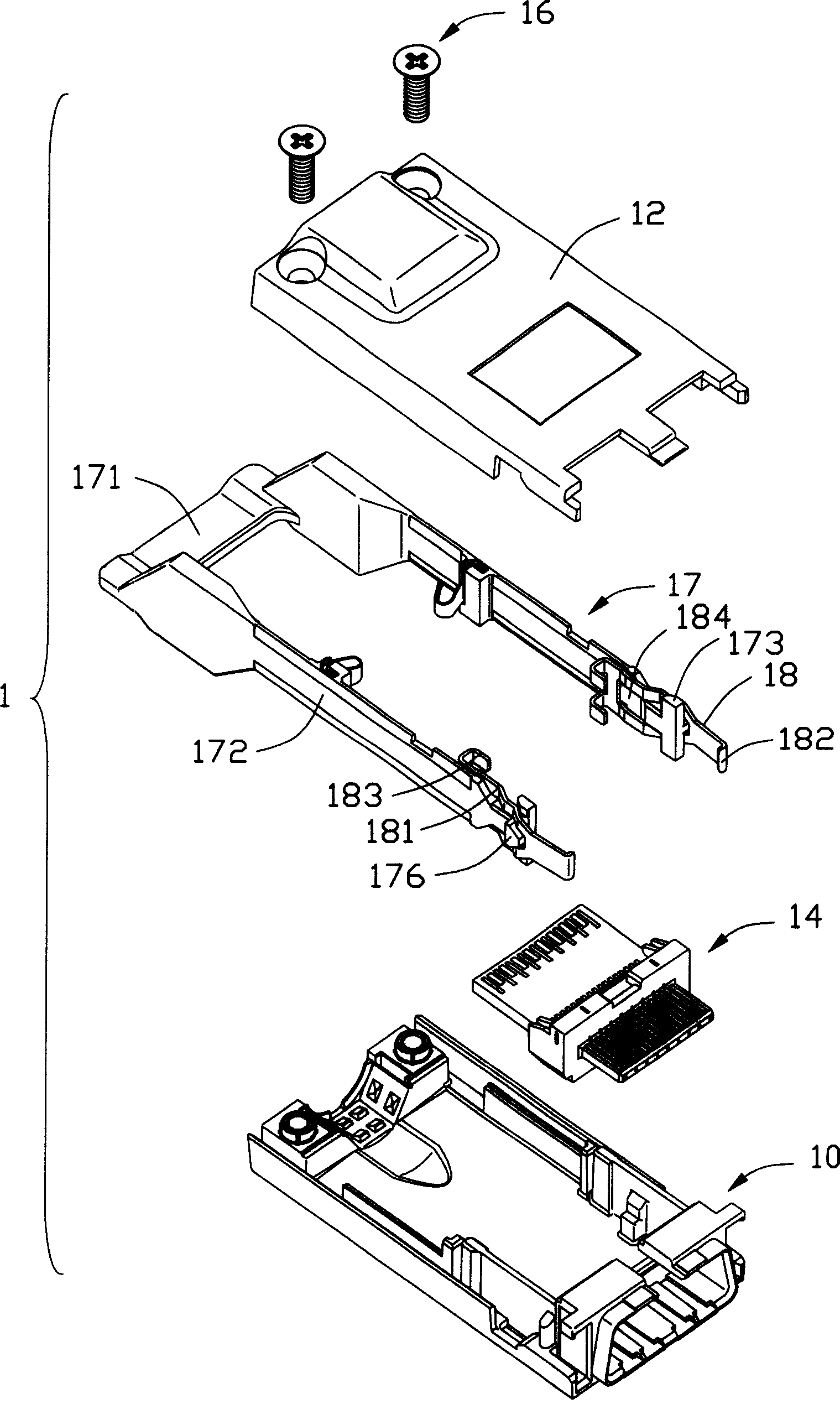

[0017] see figure 1 As shown, the cable connector 1 of the present invention includes a base 10, a cover 12 matched with the base 10, a terminal module 14 accommodated in the space formed by the base 10 and the cover 12, a pair of screws 16, A pull rod 17 and a pair of elastic locking arms 18 . Wherein, the base 10 and the cover 12 are formed by die-casting metal materials such as aluminum alloy.

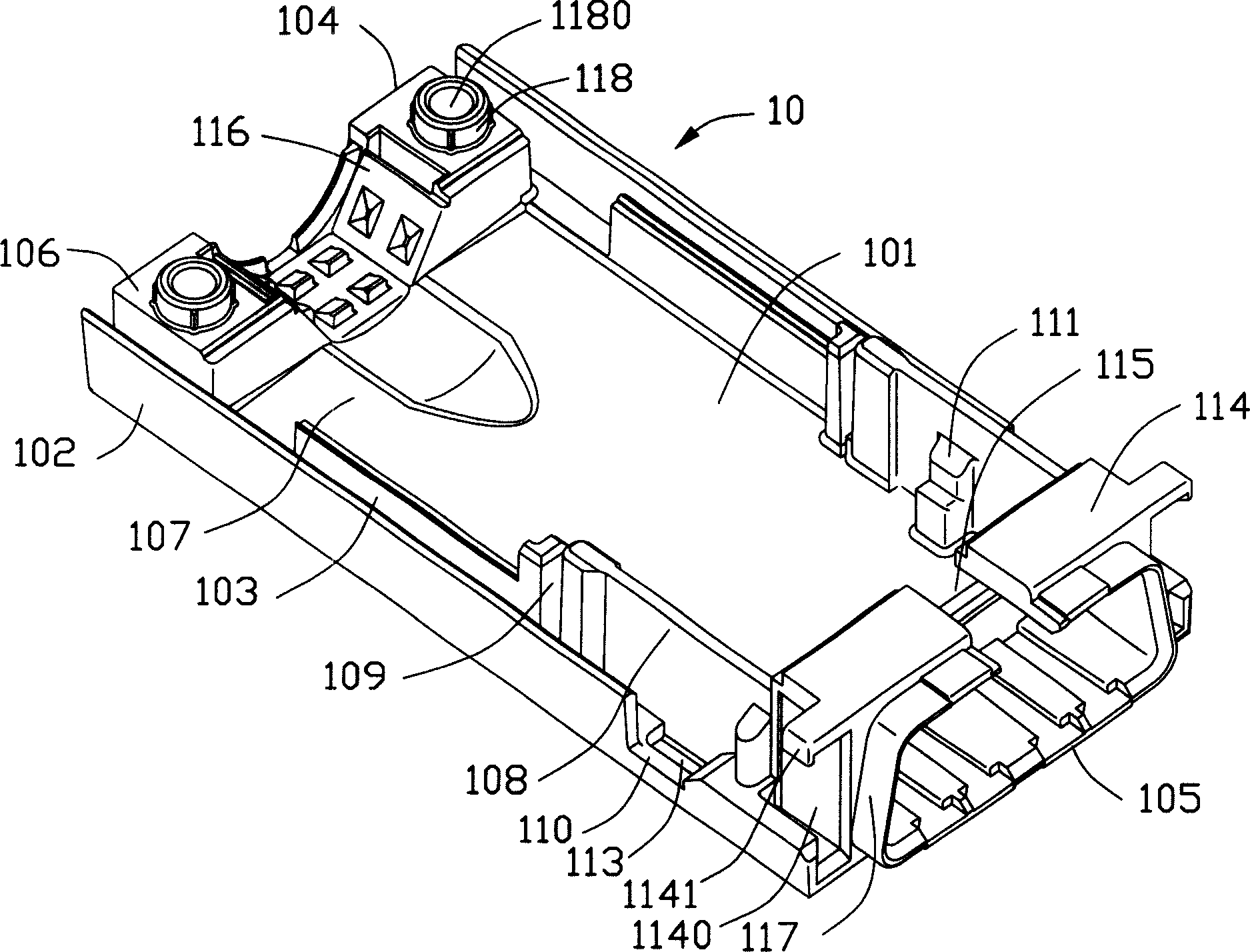

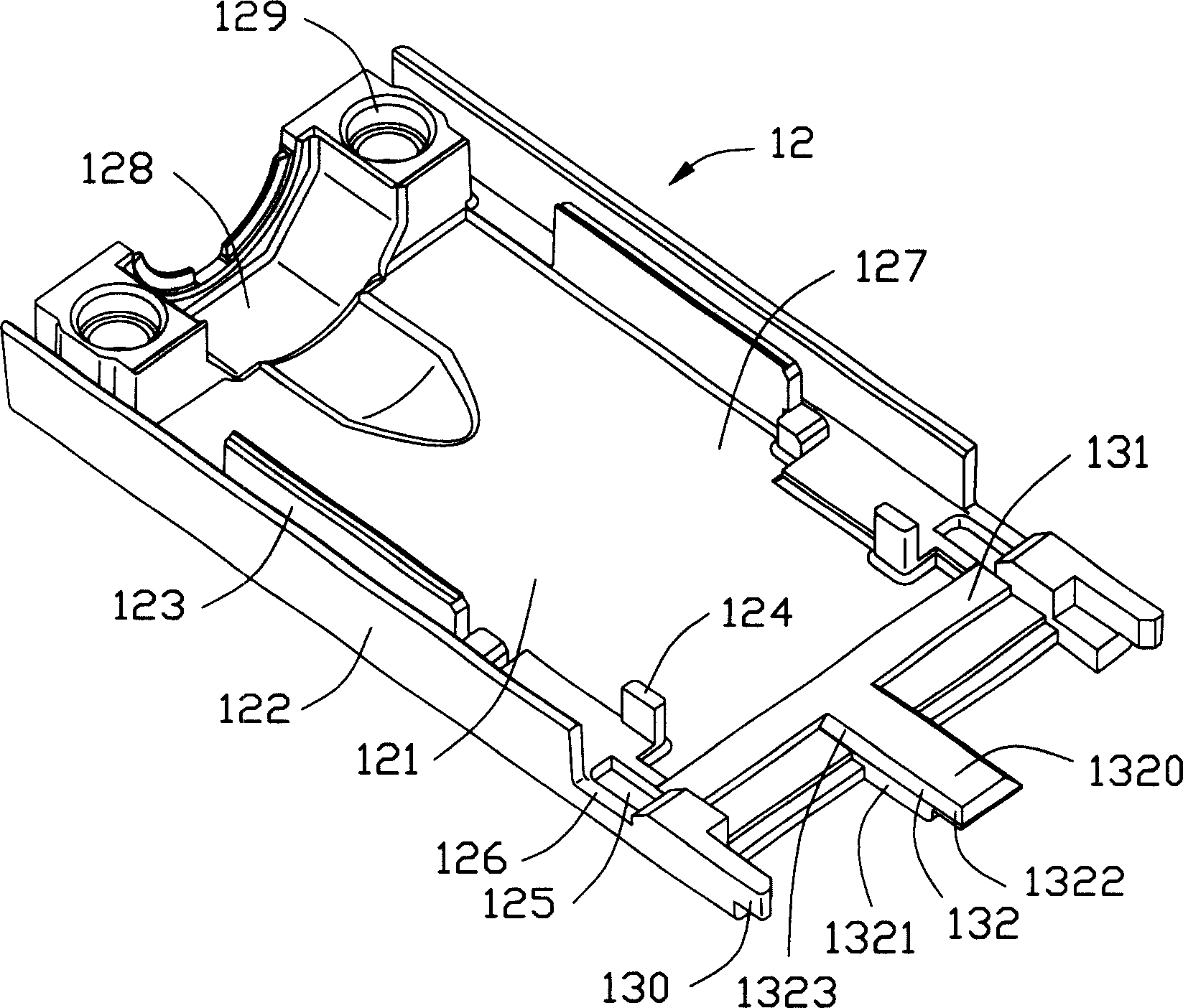

[0018] see figure 2 and image 3 As shown, the base 10 includes a substrate 101 , first sidewalls 102 extending upward from opposite sides of the substrate 101 , and a first receiving cavity 107 formed by the substrate 101 and the first sidewalls 102 . Each first sidewall 102 defines a first slot 103 , and the first slot 103 extends from the rear end 104 to the front end 105 of the base 10 and penetrates through the mating surface 106 at the top of the base 10 . Each first side wall 102 has a shoulder 108 and a first notch 110 adjacent to its front end 105 , and the shoulder 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap