Hot pressing device for plate splicing for furniture production

A hot-pressing device and board technology, which is applied to household components, veneer presses, plywood presses, etc., can solve the problems of difficult clamping, wide heat-receiving range of splicing, difficult hot-press splicing, etc., and can improve the speed of heat transfer , Improve the effect of docking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

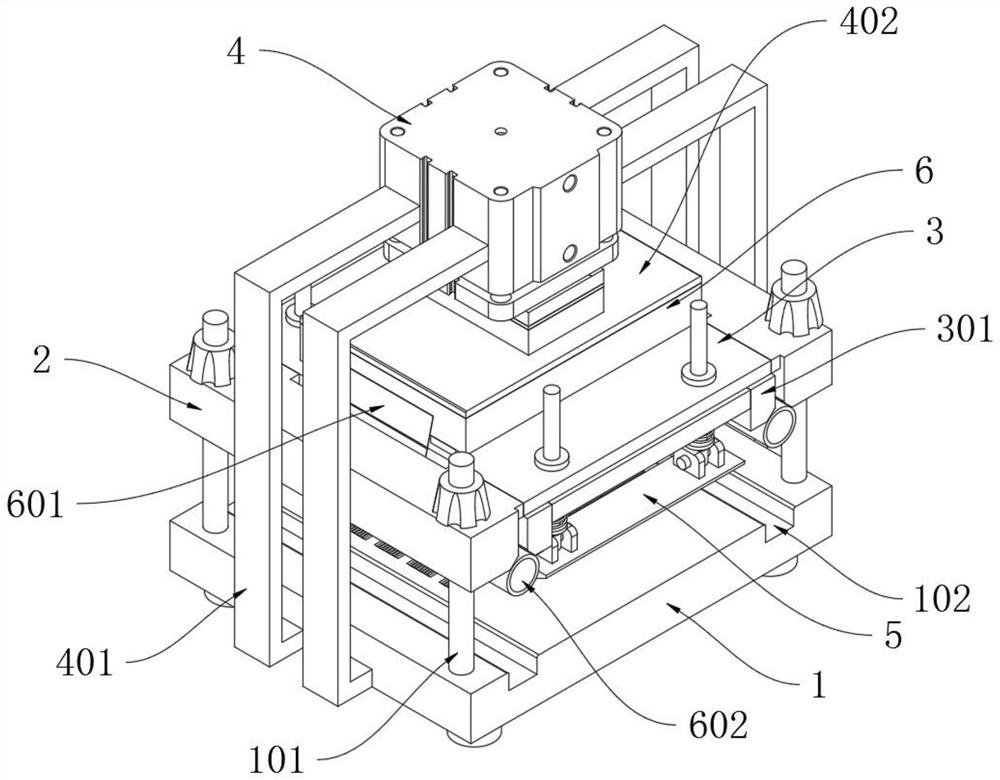

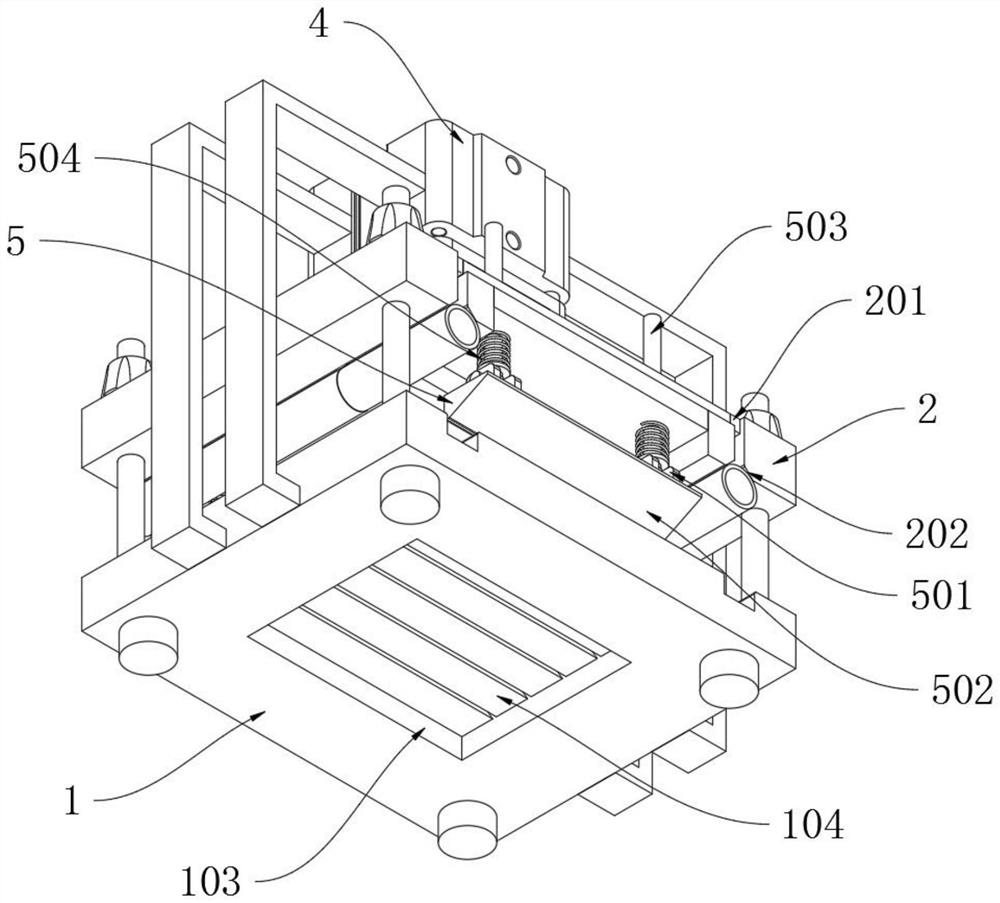

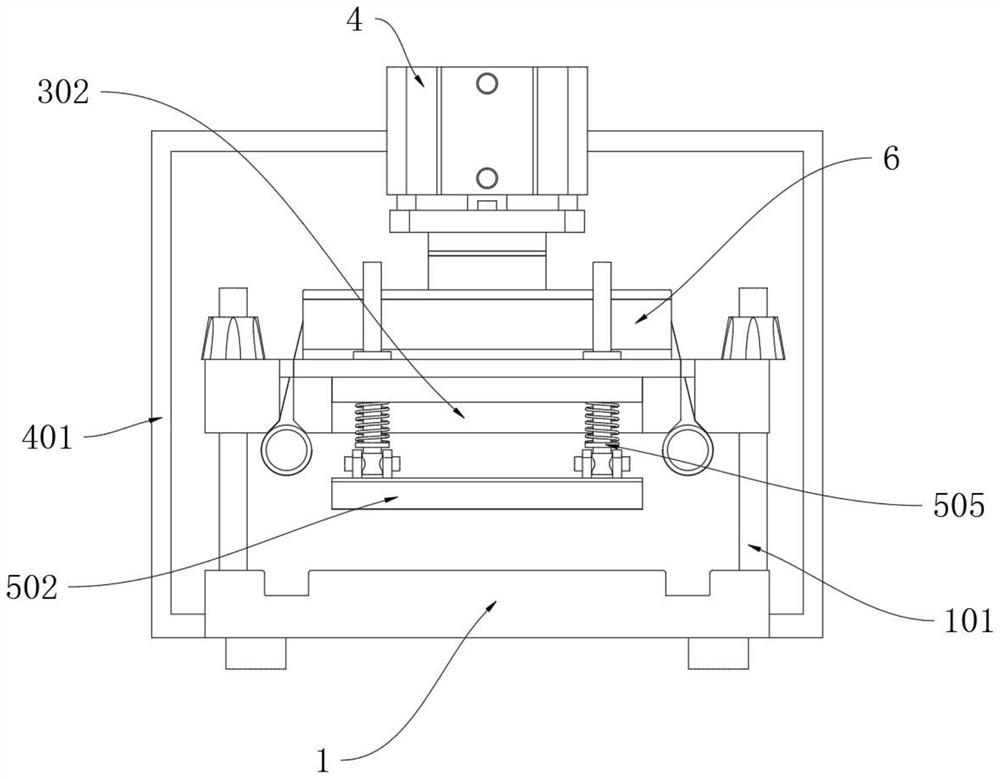

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a hot-pressing device for splicing boards for furniture production, which includes a hot-pressing table 1; an end-sealing mechanism 2 is installed vertically upwardly at the left edge and right edge of the top plane of the hot-pressing table 1; The table 1 includes guide support columns 101, and the four corners of the top plane of the hot pressing table 1 are respectively vertically fixed and upwardly installed with guide support columns 101, and the left and right guide support columns 101 are respectively slidably installed with an end sealing mechanism 2 , the guide support column 101 above the end seal mechanism 2 is screwed with a screw plug, and a buffer spring can be installed on the guide support column 101 below the end seal mechanism 2; a hot press is fixed between the left and right end seal mechanisms 2 Mechanism 3; the left side wall and the right side wall of the hot pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com