Straight pipe fitting and bent pipe fitting welding device

A welding device and pipe bending technology, which is applied to auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult placement of elbow fittings, inconvenient connection between elbow fittings and straight pipe fittings, etc. Good effect and convenient docking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

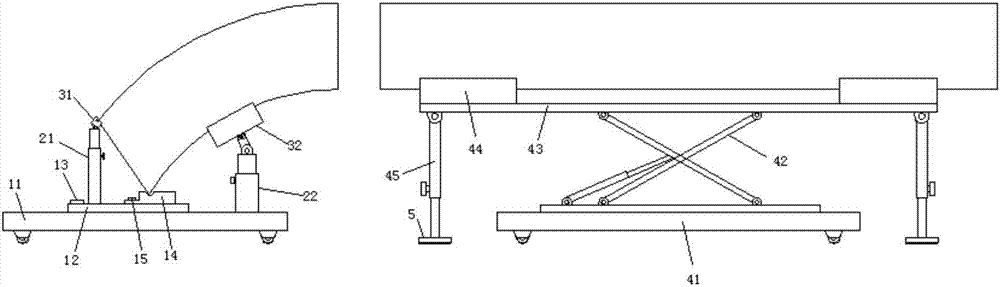

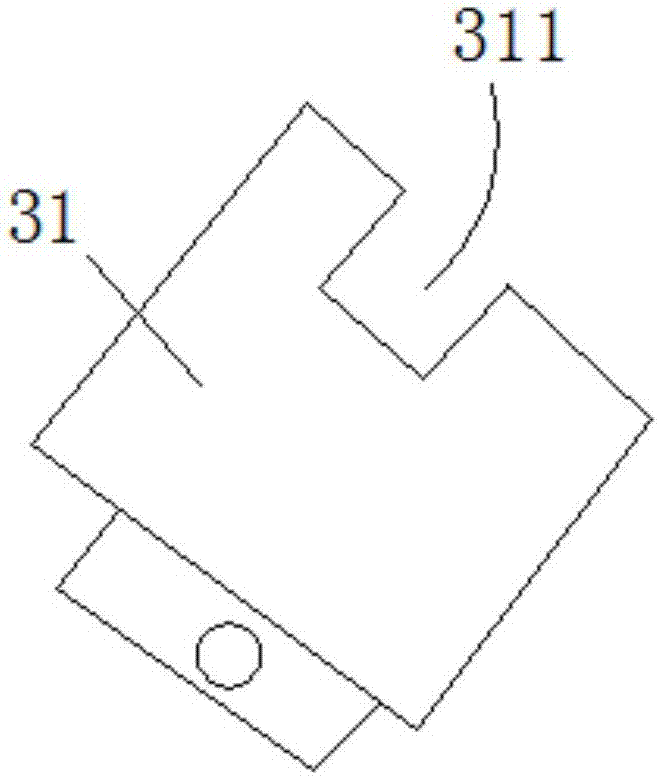

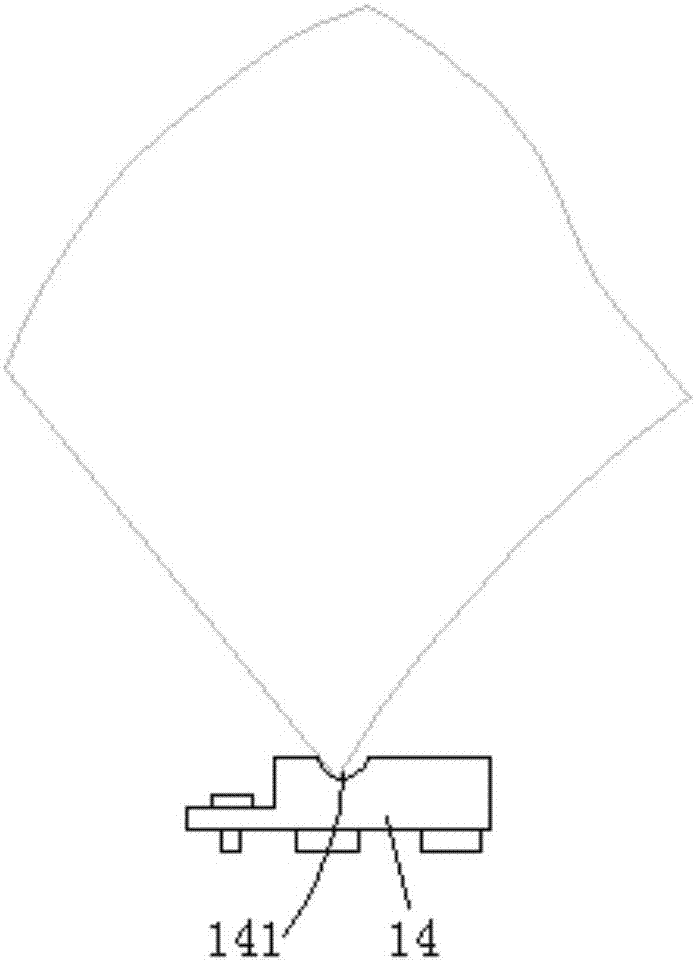

[0021] Such as Figure 1 to Figure 4 As shown, the present invention discloses a welding device for straight pipe fittings and curved pipe fittings, which includes a first base 11, a first sliding plate 12, a first fixing screw 13, a second sliding plate 14, a second fastening screw 15, and a first support column 21. The second support column 22, the nozzle positioning block 31, the first support block 32, the second base 41, the scissor lift 42, the support plate 43, the second support block 44 and the third support column 45, the first slide plate 12 Slidingly connected on the first base 11, the first fixing screw 13 is threaded on the first sliding plate 12, and the first fixing screw 13 passes through the first sliding plate 12 and abuts on the first base 11, and the second sliding plate 14 slides Connected to the first slide plate 12 , the second fastening screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com